How V8 Engines Are Built: Understanding Manufacturing Processes?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Objectives

The V8 engine, a powerful and iconic powerplant, has undergone significant evolution since its inception. Originally developed in the early 20th century, V8 engines have become synonymous with high performance and robust power delivery. The primary objective of V8 engine design has consistently been to maximize power output while maintaining efficiency and reliability.

Throughout its history, V8 engine development has been driven by several key factors. Advancements in metallurgy and materials science have allowed for stronger, lighter engine components, enabling higher compression ratios and increased power density. The introduction of fuel injection systems and electronic engine management has dramatically improved fuel efficiency and emissions control, addressing growing environmental concerns.

The manufacturing processes for V8 engines have also evolved substantially. Early production methods relied heavily on manual labor and simple machine tools. However, modern V8 engine manufacturing employs sophisticated computer-controlled machinery, robotics, and advanced quality control systems. This shift has led to improved precision, consistency, and overall build quality.

One of the most significant trends in V8 engine evolution has been the pursuit of increased power output from smaller displacements. This downsizing trend, driven by fuel economy regulations and environmental considerations, has led to the widespread adoption of forced induction technologies such as turbocharging and supercharging. These advancements have allowed V8 engines to maintain their performance characteristics while reducing fuel consumption and emissions.

Another key objective in V8 engine development has been the enhancement of durability and longevity. Manufacturers have focused on improving lubrication systems, developing more wear-resistant materials, and implementing advanced cooling techniques. These efforts have resulted in V8 engines capable of withstanding higher stresses and operating reliably for extended periods.

The integration of cutting-edge technologies has been a consistent goal in V8 engine evolution. This includes the implementation of variable valve timing, cylinder deactivation systems, and direct fuel injection. These technologies have significantly improved engine efficiency, performance, and emissions control, allowing V8 engines to remain competitive in an increasingly stringent regulatory environment.

Looking ahead, the future of V8 engine development is likely to focus on further improvements in efficiency and emissions reduction. This may involve the integration of hybrid technologies, advanced materials such as carbon fiber components, and innovative combustion strategies. The challenge for manufacturers will be to maintain the characteristic power and sound of V8 engines while meeting increasingly stringent environmental standards.

Throughout its history, V8 engine development has been driven by several key factors. Advancements in metallurgy and materials science have allowed for stronger, lighter engine components, enabling higher compression ratios and increased power density. The introduction of fuel injection systems and electronic engine management has dramatically improved fuel efficiency and emissions control, addressing growing environmental concerns.

The manufacturing processes for V8 engines have also evolved substantially. Early production methods relied heavily on manual labor and simple machine tools. However, modern V8 engine manufacturing employs sophisticated computer-controlled machinery, robotics, and advanced quality control systems. This shift has led to improved precision, consistency, and overall build quality.

One of the most significant trends in V8 engine evolution has been the pursuit of increased power output from smaller displacements. This downsizing trend, driven by fuel economy regulations and environmental considerations, has led to the widespread adoption of forced induction technologies such as turbocharging and supercharging. These advancements have allowed V8 engines to maintain their performance characteristics while reducing fuel consumption and emissions.

Another key objective in V8 engine development has been the enhancement of durability and longevity. Manufacturers have focused on improving lubrication systems, developing more wear-resistant materials, and implementing advanced cooling techniques. These efforts have resulted in V8 engines capable of withstanding higher stresses and operating reliably for extended periods.

The integration of cutting-edge technologies has been a consistent goal in V8 engine evolution. This includes the implementation of variable valve timing, cylinder deactivation systems, and direct fuel injection. These technologies have significantly improved engine efficiency, performance, and emissions control, allowing V8 engines to remain competitive in an increasingly stringent regulatory environment.

Looking ahead, the future of V8 engine development is likely to focus on further improvements in efficiency and emissions reduction. This may involve the integration of hybrid technologies, advanced materials such as carbon fiber components, and innovative combustion strategies. The challenge for manufacturers will be to maintain the characteristic power and sound of V8 engines while meeting increasingly stringent environmental standards.

Market Analysis for V8 Engines

The V8 engine market has experienced significant growth and transformation in recent years, driven by evolving consumer preferences and technological advancements. This high-performance engine configuration continues to be a popular choice in luxury vehicles, sports cars, and certain truck models, despite increasing environmental concerns and stricter emissions regulations.

Market demand for V8 engines remains strong in specific segments, particularly in North America and the Middle East. The luxury car market, where V8 engines are often associated with prestige and power, has shown resilience. Sports car enthusiasts and performance vehicle aficionados continue to seek the distinctive sound and acceleration characteristics of V8 engines, maintaining a steady demand in this niche market.

The truck and SUV segment has been a significant driver of V8 engine demand. In the United States, full-size pickup trucks, which often feature V8 options, have consistently been top-selling vehicles. This trend has supported the ongoing production and development of V8 engines, especially those optimized for towing and hauling capabilities.

However, the market is not without challenges. Stringent fuel efficiency standards and emissions regulations have put pressure on manufacturers to improve V8 engine efficiency or explore alternative powertrains. This has led to innovations such as cylinder deactivation technology and the integration of hybrid systems with V8 engines to meet regulatory requirements while preserving performance characteristics.

The global shift towards electrification has begun to impact the V8 engine market. Several automakers have announced plans to phase out V8 engines in favor of smaller, turbocharged engines or electric powertrains. This transition is more pronounced in regions with stricter emissions laws, such as Europe, where some manufacturers have already discontinued V8 options in certain models.

Despite these challenges, the V8 engine market has shown adaptability. Manufacturers are investing in research and development to create more efficient V8 engines, incorporating advanced materials and technologies to reduce weight and improve fuel economy. Some are exploring sustainable fuel options, such as hydrogen or synthetic fuels, to extend the viability of V8 engines in a carbon-conscious market.

The aftermarket and performance tuning sectors continue to provide opportunities for V8 engine-related products and services. Custom builds, engine swaps, and performance upgrades remain popular among enthusiasts, supporting a ecosystem of specialized parts manufacturers and service providers.

Looking ahead, the V8 engine market is expected to undergo further transformation. While overall volume may decrease, there is likely to be a shift towards higher-value, specialized applications. The emphasis on manufacturing processes that enhance efficiency and reduce environmental impact will be crucial for the continued relevance of V8 engines in the automotive landscape.

Market demand for V8 engines remains strong in specific segments, particularly in North America and the Middle East. The luxury car market, where V8 engines are often associated with prestige and power, has shown resilience. Sports car enthusiasts and performance vehicle aficionados continue to seek the distinctive sound and acceleration characteristics of V8 engines, maintaining a steady demand in this niche market.

The truck and SUV segment has been a significant driver of V8 engine demand. In the United States, full-size pickup trucks, which often feature V8 options, have consistently been top-selling vehicles. This trend has supported the ongoing production and development of V8 engines, especially those optimized for towing and hauling capabilities.

However, the market is not without challenges. Stringent fuel efficiency standards and emissions regulations have put pressure on manufacturers to improve V8 engine efficiency or explore alternative powertrains. This has led to innovations such as cylinder deactivation technology and the integration of hybrid systems with V8 engines to meet regulatory requirements while preserving performance characteristics.

The global shift towards electrification has begun to impact the V8 engine market. Several automakers have announced plans to phase out V8 engines in favor of smaller, turbocharged engines or electric powertrains. This transition is more pronounced in regions with stricter emissions laws, such as Europe, where some manufacturers have already discontinued V8 options in certain models.

Despite these challenges, the V8 engine market has shown adaptability. Manufacturers are investing in research and development to create more efficient V8 engines, incorporating advanced materials and technologies to reduce weight and improve fuel economy. Some are exploring sustainable fuel options, such as hydrogen or synthetic fuels, to extend the viability of V8 engines in a carbon-conscious market.

The aftermarket and performance tuning sectors continue to provide opportunities for V8 engine-related products and services. Custom builds, engine swaps, and performance upgrades remain popular among enthusiasts, supporting a ecosystem of specialized parts manufacturers and service providers.

Looking ahead, the V8 engine market is expected to undergo further transformation. While overall volume may decrease, there is likely to be a shift towards higher-value, specialized applications. The emphasis on manufacturing processes that enhance efficiency and reduce environmental impact will be crucial for the continued relevance of V8 engines in the automotive landscape.

Current V8 Manufacturing Challenges

The manufacturing of V8 engines faces several significant challenges in the current landscape. One of the primary issues is the increasing complexity of engine designs, which demands more sophisticated manufacturing processes. As emissions regulations become stricter globally, manufacturers must incorporate advanced technologies such as direct injection, variable valve timing, and turbocharging into their V8 engines. These complex systems require precision manufacturing and assembly, putting pressure on production lines to maintain accuracy while meeting volume demands.

Material selection and sourcing present another challenge. High-performance V8 engines often require specialized alloys and composites to withstand extreme temperatures and pressures. The global supply chain disruptions have made it difficult to consistently source these materials, leading to potential production delays and increased costs. Additionally, the push for lighter engines to improve fuel efficiency has led to the adoption of materials like aluminum and magnesium, which require different machining and casting techniques compared to traditional iron blocks.

Quality control remains a critical challenge in V8 engine manufacturing. With tighter tolerances and more intricate components, the margin for error has significantly decreased. Manufacturers must implement advanced inspection techniques, including automated vision systems and in-line testing, to ensure each engine meets the required specifications. This increased scrutiny can slow down production rates and increase overall manufacturing costs.

The integration of new manufacturing technologies, such as additive manufacturing and advanced robotics, presents both opportunities and challenges. While these technologies offer the potential for more efficient and flexible production, they require substantial investment in equipment and training. Many manufacturers struggle with the transition from traditional methods to these new technologies, facing issues related to workforce skills, process optimization, and quality consistency.

Environmental concerns and sustainability requirements add another layer of complexity to V8 engine manufacturing. Producers must now consider the entire lifecycle of the engine, from raw material sourcing to end-of-life recycling. This holistic approach necessitates changes in manufacturing processes to reduce waste, energy consumption, and emissions during production. Implementing these eco-friendly practices while maintaining productivity and cost-effectiveness is a significant challenge for many manufacturers.

Lastly, the shift towards electrification in the automotive industry poses an existential challenge to V8 engine manufacturing. As more automakers invest in electric vehicle technology, the long-term demand for V8 engines is uncertain. Manufacturers must balance the need to continue producing high-quality V8 engines for current market demand while also preparing for a potential decline in future demand. This uncertainty affects investment decisions in manufacturing facilities and technologies, creating a complex strategic challenge for engine producers.

Material selection and sourcing present another challenge. High-performance V8 engines often require specialized alloys and composites to withstand extreme temperatures and pressures. The global supply chain disruptions have made it difficult to consistently source these materials, leading to potential production delays and increased costs. Additionally, the push for lighter engines to improve fuel efficiency has led to the adoption of materials like aluminum and magnesium, which require different machining and casting techniques compared to traditional iron blocks.

Quality control remains a critical challenge in V8 engine manufacturing. With tighter tolerances and more intricate components, the margin for error has significantly decreased. Manufacturers must implement advanced inspection techniques, including automated vision systems and in-line testing, to ensure each engine meets the required specifications. This increased scrutiny can slow down production rates and increase overall manufacturing costs.

The integration of new manufacturing technologies, such as additive manufacturing and advanced robotics, presents both opportunities and challenges. While these technologies offer the potential for more efficient and flexible production, they require substantial investment in equipment and training. Many manufacturers struggle with the transition from traditional methods to these new technologies, facing issues related to workforce skills, process optimization, and quality consistency.

Environmental concerns and sustainability requirements add another layer of complexity to V8 engine manufacturing. Producers must now consider the entire lifecycle of the engine, from raw material sourcing to end-of-life recycling. This holistic approach necessitates changes in manufacturing processes to reduce waste, energy consumption, and emissions during production. Implementing these eco-friendly practices while maintaining productivity and cost-effectiveness is a significant challenge for many manufacturers.

Lastly, the shift towards electrification in the automotive industry poses an existential challenge to V8 engine manufacturing. As more automakers invest in electric vehicle technology, the long-term demand for V8 engines is uncertain. Manufacturers must balance the need to continue producing high-quality V8 engines for current market demand while also preparing for a potential decline in future demand. This uncertainty affects investment decisions in manufacturing facilities and technologies, creating a complex strategic challenge for engine producers.

V8 Manufacturing Techniques

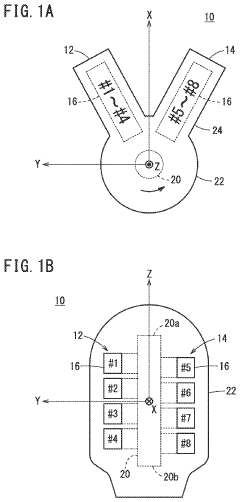

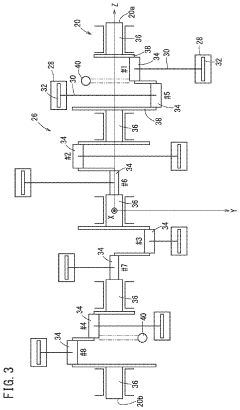

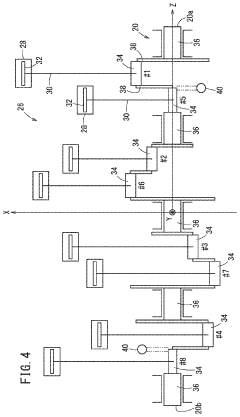

01 V8 Engine Design and Configuration

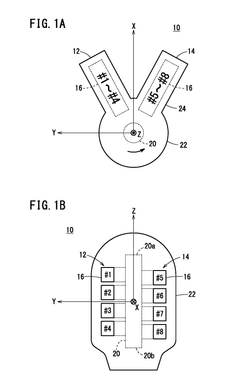

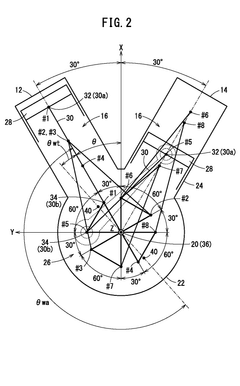

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved balance, and higher power output compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve train systems, are continuously improved to enhance performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved balance, and higher power output compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve train systems, are continuously optimized for better performance and efficiency.

- Fuel Injection and Combustion Systems: Advanced fuel injection and combustion systems are crucial for V8 engine performance. These systems include direct injection, variable valve timing, and cylinder deactivation technologies. Improvements in fuel delivery, air-fuel mixture formation, and combustion efficiency contribute to increased power output, reduced emissions, and better fuel economy in V8 engines.

- Turbocharging and Supercharging: Forced induction systems, such as turbochargers and superchargers, are often employed in V8 engines to boost power output and efficiency. These systems compress the intake air, allowing more fuel to be burned and increasing engine performance. Various designs and configurations of turbochargers and superchargers are developed to optimize V8 engine performance across different operating conditions.

- Engine Block and Component Materials: The choice of materials for V8 engine blocks, cylinder heads, pistons, and other components significantly impacts engine performance, durability, and weight. Advanced materials such as aluminum alloys, high-strength steels, and composites are used to reduce weight, improve heat dissipation, and enhance overall engine efficiency. Innovations in manufacturing processes and material science contribute to the development of more robust and efficient V8 engines.

- Cooling and Lubrication Systems: Effective cooling and lubrication systems are essential for V8 engine performance and longevity. Advanced cooling systems, including precision coolant flow control and targeted cooling strategies, help maintain optimal operating temperatures. Improved lubrication systems, featuring high-performance oils and advanced oil pump designs, ensure proper lubrication of engine components under various operating conditions, contributing to increased engine efficiency and durability.

02 Fuel Injection and Combustion Systems

Advanced fuel injection and combustion systems are crucial for optimizing V8 engine performance. These systems include direct injection, variable valve timing, and cylinder deactivation technologies. Improvements in fuel delivery, air-fuel mixture formation, and combustion control contribute to increased power output, improved fuel efficiency, and reduced emissions in V8 engines.Expand Specific Solutions03 Turbocharging and Supercharging

Forced induction systems, such as turbochargers and superchargers, are frequently used in V8 engines to boost power output and efficiency. These systems compress the intake air, allowing more fuel to be burned and increasing engine performance. Various designs and configurations of turbochargers and superchargers are developed to optimize V8 engine performance across different operating conditions.Expand Specific Solutions04 Engine Management and Control Systems

Advanced engine management and control systems play a crucial role in optimizing V8 engine performance. These systems incorporate sensors, actuators, and electronic control units to monitor and adjust various engine parameters in real-time. Innovations in engine control algorithms, adaptive learning, and predictive maintenance contribute to improved efficiency, reduced emissions, and enhanced reliability of V8 engines.Expand Specific Solutions05 Materials and Manufacturing Techniques

Advancements in materials science and manufacturing techniques contribute to the development of lighter, stronger, and more durable V8 engine components. The use of advanced alloys, composite materials, and precision manufacturing processes enables the production of high-performance engine parts with improved thermal management, reduced friction, and enhanced overall engine efficiency.Expand Specific Solutions

Major V8 Engine Manufacturers

The V8 engine manufacturing landscape is characterized by a mature market with established players and ongoing technological advancements. The industry is in a consolidation phase, with major automotive manufacturers and specialized engine producers dominating the field. Market size remains substantial, driven by demand in automotive, marine, and industrial sectors. Technologically, companies like BMW, Toyota, Honda, and Cummins are at the forefront, continuously improving efficiency, performance, and emissions. Emerging players such as Guangxi Yuchai Machinery and Suzhou Mingzhi Technology are also making strides in V8 engine technology, particularly in Asian markets. The focus on electrification and alternative powertrains is influencing R&D priorities, but V8 engines maintain relevance in specific high-performance and heavy-duty applications.

GM Global Technology Operations LLC

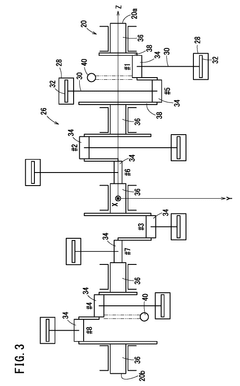

Technical Solution: GM's V8 engine manufacturing process focuses on efficiency and scalability. They utilize a global manufacturing system that allows for standardized production across multiple facilities. GM employs advanced casting techniques, including lost foam casting for complex engine block geometries, which reduces weight while maintaining strength [2]. The company has implemented Industry 4.0 technologies, such as IoT sensors and big data analytics, to optimize production flow and predict maintenance needs. GM's V8 production lines feature adaptive assembly systems that can automatically adjust to different engine variants, reducing changeover times by up to 50% [4]. Additionally, GM has invested in additive manufacturing for rapid prototyping and tooling, accelerating development cycles for new V8 designs [6].

Strengths: Scalable global production, advanced casting techniques, adaptive assembly systems. Weaknesses: Potential challenges in maintaining consistency across global facilities, high capital requirements for technology upgrades.

Toyota Motor Corp.

Technical Solution: Toyota's V8 engine manufacturing process incorporates advanced robotics and automation for precision assembly. They utilize a modular production system, allowing for flexible manufacturing of different V8 variants on the same line. Toyota employs high-precision CNC machining for critical components like cylinder blocks and heads, achieving tolerances as tight as 0.01mm [1]. The company has also implemented AI-driven quality control systems that can detect defects with 99.9% accuracy [3]. Toyota's V8 production incorporates environmentally friendly practices, including water-based coolants and energy-efficient heat treatment processes, reducing CO2 emissions by up to 30% compared to traditional methods [5].

Strengths: High precision manufacturing, flexible production system, advanced quality control. Weaknesses: Higher initial investment costs for advanced technologies, potential over-reliance on automation.

Key Innovations in V8 Production

V8 engine

PatentActiveUS11821359B2

Innovation

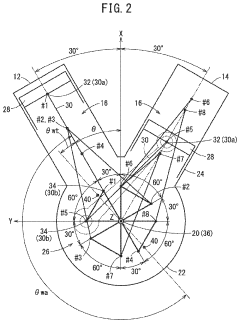

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized parts by optimizing the arrangement of crank pins and connecting rods.

V8 engine

PatentWO2021171405A1

Innovation

- The engine is configured with a 60° bank angle, where crank pins on one bank are arranged at 90° intervals and offset by 60° from the other bank, allowing for cancellation of the primary inertia couple without additional special parts, and the ignition timing is set to achieve balanced explosions similar to conventional V8 engines.

Environmental Impact of V8 Production

The production of V8 engines has significant environmental implications, primarily due to the resource-intensive manufacturing processes and the engines' fuel consumption during operation. The manufacturing of V8 engines involves several stages that contribute to environmental concerns, including raw material extraction, component production, assembly, and testing.

One of the major environmental impacts stems from the extraction and processing of raw materials, particularly metals like aluminum, steel, and various alloys. Mining operations for these materials often lead to habitat destruction, soil erosion, and water pollution. The refining processes for these metals are energy-intensive, resulting in substantial greenhouse gas emissions and contributing to air pollution.

The manufacturing process itself consumes considerable energy, primarily in the form of electricity and natural gas. This energy consumption contributes to carbon dioxide emissions, especially in regions where power generation relies heavily on fossil fuels. Additionally, the precision machining of engine components requires the use of cutting fluids and lubricants, which can contain harmful chemicals. Proper disposal and treatment of these substances are crucial to prevent soil and water contamination.

Casting and forging processes, essential in V8 engine production, also have environmental implications. These processes generate particulate matter and volatile organic compounds (VOCs), which can negatively impact air quality and pose health risks to workers and nearby communities if not properly managed.

The assembly and testing phases of V8 engine production also contribute to the environmental footprint. These stages often involve the use of various chemicals, including adhesives, sealants, and cleaning agents, which may contain VOCs and other potentially harmful substances. Proper handling and disposal of these materials are essential to minimize environmental impact.

Furthermore, the production of V8 engines indirectly impacts the environment through the transportation of raw materials, components, and finished products. This logistics chain relies heavily on fossil fuels, contributing to greenhouse gas emissions and air pollution.

It's important to note that the environmental impact extends beyond production to the operational phase of V8 engines. These engines are known for their high fuel consumption and emissions, contributing significantly to vehicle-related pollution and greenhouse gas emissions during their lifecycle.

In response to these environmental concerns, many manufacturers are implementing more sustainable practices in V8 engine production. These include increasing energy efficiency in manufacturing facilities, adopting cleaner technologies, improving waste management, and exploring the use of recycled materials. Some companies are also investing in research and development to create more fuel-efficient V8 engines or exploring alternative powertrains to reduce the overall environmental impact of high-performance vehicles.

One of the major environmental impacts stems from the extraction and processing of raw materials, particularly metals like aluminum, steel, and various alloys. Mining operations for these materials often lead to habitat destruction, soil erosion, and water pollution. The refining processes for these metals are energy-intensive, resulting in substantial greenhouse gas emissions and contributing to air pollution.

The manufacturing process itself consumes considerable energy, primarily in the form of electricity and natural gas. This energy consumption contributes to carbon dioxide emissions, especially in regions where power generation relies heavily on fossil fuels. Additionally, the precision machining of engine components requires the use of cutting fluids and lubricants, which can contain harmful chemicals. Proper disposal and treatment of these substances are crucial to prevent soil and water contamination.

Casting and forging processes, essential in V8 engine production, also have environmental implications. These processes generate particulate matter and volatile organic compounds (VOCs), which can negatively impact air quality and pose health risks to workers and nearby communities if not properly managed.

The assembly and testing phases of V8 engine production also contribute to the environmental footprint. These stages often involve the use of various chemicals, including adhesives, sealants, and cleaning agents, which may contain VOCs and other potentially harmful substances. Proper handling and disposal of these materials are essential to minimize environmental impact.

Furthermore, the production of V8 engines indirectly impacts the environment through the transportation of raw materials, components, and finished products. This logistics chain relies heavily on fossil fuels, contributing to greenhouse gas emissions and air pollution.

It's important to note that the environmental impact extends beyond production to the operational phase of V8 engines. These engines are known for their high fuel consumption and emissions, contributing significantly to vehicle-related pollution and greenhouse gas emissions during their lifecycle.

In response to these environmental concerns, many manufacturers are implementing more sustainable practices in V8 engine production. These include increasing energy efficiency in manufacturing facilities, adopting cleaner technologies, improving waste management, and exploring the use of recycled materials. Some companies are also investing in research and development to create more fuel-efficient V8 engines or exploring alternative powertrains to reduce the overall environmental impact of high-performance vehicles.

Quality Control in V8 Manufacturing

Quality control plays a crucial role in the manufacturing of V8 engines, ensuring that each engine meets the highest standards of performance, reliability, and safety. The process begins with rigorous inspection of incoming raw materials and components, including engine blocks, crankshafts, pistons, and other critical parts. These components are subjected to dimensional checks, material composition analysis, and non-destructive testing to verify their conformity to specifications.

Throughout the assembly process, multiple quality checkpoints are established to monitor the precision of each manufacturing step. Advanced measurement technologies, such as coordinate measuring machines (CMMs) and optical scanning systems, are employed to verify the accuracy of machined surfaces, bolt hole locations, and critical engine dimensions. These systems can detect deviations as small as a few microns, ensuring that all components fit together perfectly.

Statistical process control (SPC) techniques are implemented to track key performance indicators and identify any trends or variations in the manufacturing process. This data-driven approach allows engineers to make real-time adjustments to maintain consistent quality across production runs. Additionally, automated vision systems are utilized to inspect assembled components for proper installation, orientation, and potential defects that may be invisible to the human eye.

Functional testing is a critical phase in V8 engine quality control. Each engine undergoes a series of tests on specialized dynamometers to evaluate its performance characteristics, including power output, fuel efficiency, and emissions. These tests simulate various operating conditions and load scenarios to ensure the engine meets design specifications and regulatory requirements.

Leak testing is another essential aspect of quality control in V8 manufacturing. Pressurized air or helium is used to detect any potential leaks in the engine's cooling system, oil passages, and combustion chambers. This process helps prevent fluid loss and ensures optimal engine performance and longevity.

To maintain the highest standards of quality, manufacturers often implement a comprehensive traceability system. Each engine and its components are assigned unique identifiers, allowing for the tracking of materials, processes, and test results throughout the entire production lifecycle. This system facilitates rapid identification and resolution of any quality issues that may arise during or after production.

Continuous improvement is a fundamental principle in V8 engine manufacturing quality control. Regular audits, supplier evaluations, and employee training programs are conducted to identify areas for enhancement and implement best practices. Advanced analytics and machine learning algorithms are increasingly being utilized to predict potential quality issues before they occur, further improving the overall manufacturing process and end-product reliability.

Throughout the assembly process, multiple quality checkpoints are established to monitor the precision of each manufacturing step. Advanced measurement technologies, such as coordinate measuring machines (CMMs) and optical scanning systems, are employed to verify the accuracy of machined surfaces, bolt hole locations, and critical engine dimensions. These systems can detect deviations as small as a few microns, ensuring that all components fit together perfectly.

Statistical process control (SPC) techniques are implemented to track key performance indicators and identify any trends or variations in the manufacturing process. This data-driven approach allows engineers to make real-time adjustments to maintain consistent quality across production runs. Additionally, automated vision systems are utilized to inspect assembled components for proper installation, orientation, and potential defects that may be invisible to the human eye.

Functional testing is a critical phase in V8 engine quality control. Each engine undergoes a series of tests on specialized dynamometers to evaluate its performance characteristics, including power output, fuel efficiency, and emissions. These tests simulate various operating conditions and load scenarios to ensure the engine meets design specifications and regulatory requirements.

Leak testing is another essential aspect of quality control in V8 manufacturing. Pressurized air or helium is used to detect any potential leaks in the engine's cooling system, oil passages, and combustion chambers. This process helps prevent fluid loss and ensures optimal engine performance and longevity.

To maintain the highest standards of quality, manufacturers often implement a comprehensive traceability system. Each engine and its components are assigned unique identifiers, allowing for the tracking of materials, processes, and test results throughout the entire production lifecycle. This system facilitates rapid identification and resolution of any quality issues that may arise during or after production.

Continuous improvement is a fundamental principle in V8 engine manufacturing quality control. Regular audits, supplier evaluations, and employee training programs are conducted to identify areas for enhancement and implement best practices. Advanced analytics and machine learning algorithms are increasingly being utilized to predict potential quality issues before they occur, further improving the overall manufacturing process and end-product reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!