How V8 Engines Enable Efficient High-Altitude Operations?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The evolution of V8 engines for high-altitude operations has been a remarkable journey of technological advancement. Initially designed for high-performance aircraft, these engines have undergone significant transformations to meet the unique challenges posed by thin air and extreme conditions at high altitudes.

In the early stages of development, V8 engines faced numerous obstacles when operating at high altitudes. The primary issue was the reduced air density, which led to decreased oxygen intake and compromised engine performance. Engineers tackled this problem by implementing turbocharging and supercharging systems, which compress the incoming air to increase its density and oxygen content.

As the demand for more efficient high-altitude operations grew, manufacturers focused on optimizing fuel injection systems. Advanced electronic fuel injection replaced carburetors, allowing for precise fuel metering and better combustion control across varying altitudes. This innovation significantly improved fuel efficiency and engine responsiveness in thin air conditions.

The next major leap in V8 engine evolution came with the integration of variable valve timing (VVT) technology. VVT systems allowed engines to adjust valve opening and closing times based on altitude and engine load, optimizing performance and fuel economy across a wide range of operating conditions. This adaptability proved crucial for maintaining engine efficiency at high altitudes.

Material science played a pivotal role in enhancing V8 engine capabilities for high-altitude operations. The introduction of lightweight, heat-resistant alloys enabled the construction of more durable engine components that could withstand the extreme temperature fluctuations encountered at high altitudes. These advancements led to improved reliability and extended engine life in challenging environments.

The advent of advanced engine management systems marked another significant milestone in V8 engine evolution. These sophisticated electronic control units (ECUs) continuously monitor and adjust various engine parameters in real-time, compensating for changes in air pressure and temperature as altitude increases. This dynamic adaptation ensures optimal performance and efficiency regardless of the operating altitude.

Recent developments in V8 engine technology have focused on enhancing thermal management. Improved cooling systems and heat dissipation techniques have been implemented to address the unique thermal challenges posed by high-altitude operations. These innovations have resulted in more stable engine temperatures and reduced the risk of overheating in thin air conditions.

The ongoing evolution of V8 engines for high-altitude operations continues to push the boundaries of engineering. Current research is exploring the potential of hybrid technologies and alternative fuels to further improve efficiency and reduce environmental impact. As these engines become more sophisticated, they are enabling aircraft to operate at higher altitudes with greater efficiency and reliability than ever before.

In the early stages of development, V8 engines faced numerous obstacles when operating at high altitudes. The primary issue was the reduced air density, which led to decreased oxygen intake and compromised engine performance. Engineers tackled this problem by implementing turbocharging and supercharging systems, which compress the incoming air to increase its density and oxygen content.

As the demand for more efficient high-altitude operations grew, manufacturers focused on optimizing fuel injection systems. Advanced electronic fuel injection replaced carburetors, allowing for precise fuel metering and better combustion control across varying altitudes. This innovation significantly improved fuel efficiency and engine responsiveness in thin air conditions.

The next major leap in V8 engine evolution came with the integration of variable valve timing (VVT) technology. VVT systems allowed engines to adjust valve opening and closing times based on altitude and engine load, optimizing performance and fuel economy across a wide range of operating conditions. This adaptability proved crucial for maintaining engine efficiency at high altitudes.

Material science played a pivotal role in enhancing V8 engine capabilities for high-altitude operations. The introduction of lightweight, heat-resistant alloys enabled the construction of more durable engine components that could withstand the extreme temperature fluctuations encountered at high altitudes. These advancements led to improved reliability and extended engine life in challenging environments.

The advent of advanced engine management systems marked another significant milestone in V8 engine evolution. These sophisticated electronic control units (ECUs) continuously monitor and adjust various engine parameters in real-time, compensating for changes in air pressure and temperature as altitude increases. This dynamic adaptation ensures optimal performance and efficiency regardless of the operating altitude.

Recent developments in V8 engine technology have focused on enhancing thermal management. Improved cooling systems and heat dissipation techniques have been implemented to address the unique thermal challenges posed by high-altitude operations. These innovations have resulted in more stable engine temperatures and reduced the risk of overheating in thin air conditions.

The ongoing evolution of V8 engines for high-altitude operations continues to push the boundaries of engineering. Current research is exploring the potential of hybrid technologies and alternative fuels to further improve efficiency and reduce environmental impact. As these engines become more sophisticated, they are enabling aircraft to operate at higher altitudes with greater efficiency and reliability than ever before.

High-Altitude Market

The high-altitude market for V8 engines has experienced significant growth in recent years, driven by increasing demand for efficient and powerful propulsion systems in various applications. This market segment primarily encompasses aircraft, helicopters, and unmanned aerial vehicles (UAVs) designed to operate at altitudes above 10,000 feet, where traditional engines often struggle to maintain optimal performance.

The aviation industry has been a key driver of this market, with commercial airlines and military organizations seeking more fuel-efficient and reliable engines for high-altitude operations. The demand for V8 engines in this sector is particularly strong for medium-sized aircraft and business jets, where the balance between power output and fuel efficiency is crucial.

Another growing segment within the high-altitude market is the UAV sector. As unmanned systems become more sophisticated and are deployed for a wider range of missions, including surveillance, reconnaissance, and scientific research at high altitudes, the need for efficient V8 engines has increased substantially. These engines offer the power-to-weight ratio and reliability required for extended high-altitude operations.

The market for high-altitude V8 engines also extends to specialized applications such as high-altitude research platforms and stratospheric balloons. These niche sectors, while smaller in volume, contribute to the overall market growth and drive innovation in engine design and performance optimization for extreme conditions.

Geographically, North America and Europe lead the high-altitude V8 engine market, owing to their advanced aerospace industries and significant investments in research and development. However, emerging markets in Asia-Pacific, particularly China and India, are showing rapid growth as these countries expand their aviation capabilities and invest in high-altitude technologies.

The market size for high-altitude V8 engines is substantial, with steady growth projected over the next decade. This growth is fueled by increasing air traffic, expanding military and civilian UAV applications, and the push for more efficient and environmentally friendly propulsion systems. Additionally, the ongoing development of supersonic and hypersonic aircraft is expected to create new opportunities for advanced high-altitude engine technologies.

Challenges in this market include stringent regulatory requirements, the need for continuous innovation to improve fuel efficiency and reduce emissions, and competition from alternative engine technologies. However, the unique capabilities of V8 engines in high-altitude operations, combined with ongoing advancements in materials science and engine design, position this market segment for continued expansion and technological progress.

The aviation industry has been a key driver of this market, with commercial airlines and military organizations seeking more fuel-efficient and reliable engines for high-altitude operations. The demand for V8 engines in this sector is particularly strong for medium-sized aircraft and business jets, where the balance between power output and fuel efficiency is crucial.

Another growing segment within the high-altitude market is the UAV sector. As unmanned systems become more sophisticated and are deployed for a wider range of missions, including surveillance, reconnaissance, and scientific research at high altitudes, the need for efficient V8 engines has increased substantially. These engines offer the power-to-weight ratio and reliability required for extended high-altitude operations.

The market for high-altitude V8 engines also extends to specialized applications such as high-altitude research platforms and stratospheric balloons. These niche sectors, while smaller in volume, contribute to the overall market growth and drive innovation in engine design and performance optimization for extreme conditions.

Geographically, North America and Europe lead the high-altitude V8 engine market, owing to their advanced aerospace industries and significant investments in research and development. However, emerging markets in Asia-Pacific, particularly China and India, are showing rapid growth as these countries expand their aviation capabilities and invest in high-altitude technologies.

The market size for high-altitude V8 engines is substantial, with steady growth projected over the next decade. This growth is fueled by increasing air traffic, expanding military and civilian UAV applications, and the push for more efficient and environmentally friendly propulsion systems. Additionally, the ongoing development of supersonic and hypersonic aircraft is expected to create new opportunities for advanced high-altitude engine technologies.

Challenges in this market include stringent regulatory requirements, the need for continuous innovation to improve fuel efficiency and reduce emissions, and competition from alternative engine technologies. However, the unique capabilities of V8 engines in high-altitude operations, combined with ongoing advancements in materials science and engine design, position this market segment for continued expansion and technological progress.

Altitude Challenges

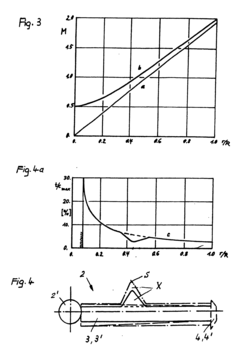

Operating aircraft at high altitudes presents significant challenges for engine performance and efficiency. As air density decreases with altitude, engines struggle to maintain power output and combustion efficiency. This phenomenon, known as altitude derating, can result in a substantial loss of engine power, sometimes up to 3% per 1,000 feet of elevation gain.

The reduced air density at high altitudes affects various aspects of engine operation. Firstly, it impacts the air-fuel mixture, leading to potential combustion instability and reduced power output. The lower oxygen concentration can cause incomplete fuel burning, resulting in increased fuel consumption and emissions. Additionally, the thinner air reduces the cooling capacity of the engine, potentially leading to overheating issues and increased wear on engine components.

Another critical challenge is the lower atmospheric pressure at high altitudes, which affects the engine's intake and exhaust processes. The reduced pressure differential between the intake and exhaust manifolds can lead to decreased volumetric efficiency, further compromising engine performance. This issue is particularly pronounced in naturally aspirated engines, which rely solely on atmospheric pressure for air intake.

Turbocharging systems, commonly used to mitigate altitude-related performance losses, face their own set of challenges at high altitudes. As the ambient air pressure decreases, turbochargers must work harder to compress the thinner air to maintain boost pressure. This increased workload can lead to higher turbocharger speeds and temperatures, potentially reducing component lifespan and reliability.

The extreme temperature variations encountered at high altitudes pose additional challenges for engine operation. Cold temperatures can affect fuel viscosity and vaporization, potentially leading to starting difficulties and poor initial performance. Conversely, the reduced air density can result in inadequate cooling, causing engines to run hotter and increasing the risk of thermal stress on components.

Furthermore, the harsh environmental conditions often associated with high-altitude operations, such as dust, sand, and ice, can accelerate wear on engine components and affect overall reliability. These factors necessitate more frequent maintenance and specialized design considerations to ensure optimal engine performance and longevity in high-altitude environments.

Addressing these altitude-related challenges requires innovative engineering solutions and advanced technologies. Engine manufacturers must develop strategies to optimize air-fuel mixtures, enhance combustion efficiency, and improve cooling systems for high-altitude operations. Additionally, the integration of advanced materials and coatings can help mitigate the effects of extreme temperatures and environmental factors on engine components.

The reduced air density at high altitudes affects various aspects of engine operation. Firstly, it impacts the air-fuel mixture, leading to potential combustion instability and reduced power output. The lower oxygen concentration can cause incomplete fuel burning, resulting in increased fuel consumption and emissions. Additionally, the thinner air reduces the cooling capacity of the engine, potentially leading to overheating issues and increased wear on engine components.

Another critical challenge is the lower atmospheric pressure at high altitudes, which affects the engine's intake and exhaust processes. The reduced pressure differential between the intake and exhaust manifolds can lead to decreased volumetric efficiency, further compromising engine performance. This issue is particularly pronounced in naturally aspirated engines, which rely solely on atmospheric pressure for air intake.

Turbocharging systems, commonly used to mitigate altitude-related performance losses, face their own set of challenges at high altitudes. As the ambient air pressure decreases, turbochargers must work harder to compress the thinner air to maintain boost pressure. This increased workload can lead to higher turbocharger speeds and temperatures, potentially reducing component lifespan and reliability.

The extreme temperature variations encountered at high altitudes pose additional challenges for engine operation. Cold temperatures can affect fuel viscosity and vaporization, potentially leading to starting difficulties and poor initial performance. Conversely, the reduced air density can result in inadequate cooling, causing engines to run hotter and increasing the risk of thermal stress on components.

Furthermore, the harsh environmental conditions often associated with high-altitude operations, such as dust, sand, and ice, can accelerate wear on engine components and affect overall reliability. These factors necessitate more frequent maintenance and specialized design considerations to ensure optimal engine performance and longevity in high-altitude environments.

Addressing these altitude-related challenges requires innovative engineering solutions and advanced technologies. Engine manufacturers must develop strategies to optimize air-fuel mixtures, enhance combustion efficiency, and improve cooling systems for high-altitude operations. Additionally, the integration of advanced materials and coatings can help mitigate the effects of extreme temperatures and environmental factors on engine components.

Current V8 Solutions

01 Improved combustion efficiency

V8 engines can be optimized for better combustion efficiency through various methods such as advanced fuel injection systems, improved cylinder design, and optimized valve timing. These enhancements lead to more complete fuel burning, reduced emissions, and increased power output.- Improved combustion efficiency: V8 engines can be optimized for better combustion efficiency through various methods such as advanced fuel injection systems, improved cylinder design, and optimized valve timing. These enhancements lead to more complete fuel burning, reduced emissions, and increased overall engine efficiency.

- Variable displacement technology: Implementing variable displacement technology in V8 engines allows for selective deactivation of cylinders during low-load conditions. This reduces fuel consumption and improves efficiency by operating the engine with fewer cylinders when full power is not required.

- Advanced materials and manufacturing techniques: Utilizing lightweight materials and advanced manufacturing techniques in V8 engine components can reduce overall engine weight and friction, leading to improved efficiency. This includes the use of materials such as aluminum alloys and carbon fiber composites for engine blocks and other components.

- Turbocharging and supercharging: Implementing forced induction systems such as turbochargers or superchargers in V8 engines can significantly increase power output and efficiency. These systems compress the intake air, allowing for more fuel to be burned and resulting in improved performance and fuel economy.

- Engine management systems and electronic control: Advanced engine management systems and electronic control units can optimize V8 engine performance in real-time. These systems can adjust various parameters such as fuel injection timing, ignition timing, and valve timing to maximize efficiency across different operating conditions.

02 Variable displacement technology

Implementing variable displacement technology in V8 engines allows for selective deactivation of cylinders during low-load conditions. This feature significantly improves fuel efficiency by reducing unnecessary fuel consumption when full engine power is not required.Expand Specific Solutions03 Advanced thermal management

Enhancing thermal management systems in V8 engines can lead to improved efficiency. This includes optimizing coolant flow, implementing advanced heat recovery systems, and using thermal barrier coatings to reduce heat loss and improve overall engine performance.Expand Specific Solutions04 Friction reduction techniques

Implementing various friction reduction techniques in V8 engines can significantly improve efficiency. This includes using low-friction coatings on engine components, optimizing piston ring designs, and employing advanced lubricants to minimize energy loss due to friction.Expand Specific Solutions05 Integration of hybrid technology

Incorporating hybrid technology into V8 engine systems can greatly enhance overall efficiency. This involves integrating electric motors and advanced energy recovery systems to supplement the V8 engine's power output and reduce fuel consumption during various driving conditions.Expand Specific Solutions

Key V8 Manufacturers

The V8 engine technology for high-altitude operations is in a mature stage, with established players like Honda, Yamaha, and Pratt & Whitney leading the market. The industry is characterized by ongoing innovation to improve efficiency and performance at high altitudes. The market size is substantial, driven by applications in aviation, automotive, and specialized vehicles. Companies like AeroVironment and Airbus Defence & Space are pushing boundaries in unmanned aerial systems, while traditional manufacturers focus on refining V8 technology for diverse high-altitude applications. The competitive landscape is diverse, with both legacy manufacturers and new entrants contributing to technological advancements in this field.

GM Global Technology Operations LLC

Technical Solution: GM has adapted its V8 engine technology for high-altitude applications, particularly in the automotive sector. Their approach includes the use of variable geometry turbochargers that adjust boost pressure based on altitude, maintaining consistent power output across a wide range of elevations[7]. GM's V8 engines for high-altitude operations also feature advanced fuel injection systems with altitude compensation, ensuring optimal fuel-air mixture at different atmospheric pressures. The company has implemented cylinder deactivation technology, which can selectively shut down cylinders when full power is not required, improving fuel efficiency at high altitudes where engines typically run richer[8]. Additionally, GM has developed specialized engine oil formulations that maintain proper viscosity and lubrication properties in low-pressure, high-altitude environments[9].

Strengths: Extensive experience in mass-production of engines, adaptable technologies for various vehicle types, and strong focus on fuel efficiency. Weaknesses: Primary focus on automotive applications may limit optimization for other high-altitude scenarios.

The Boeing Co.

Technical Solution: Boeing has developed a proprietary V8 engine design optimized for high-altitude aircraft operations. Their approach focuses on a lean-burn combustion system that maintains efficiency at varying altitudes. The engine incorporates variable valve timing and lift, allowing for dynamic adjustment of the combustion process as altitude changes[4]. Boeing's V8 engines also feature an advanced cooling system that utilizes a combination of air and liquid cooling to manage engine temperatures effectively at high altitudes where air density is lower[5]. The company has implemented a sophisticated electronic control unit (ECU) that continuously monitors and adjusts engine parameters based on altitude, temperature, and air pressure, ensuring optimal performance and fuel efficiency throughout the flight envelope[6].

Strengths: Extensive aerospace engineering expertise, integrated systems approach, and advanced electronic control systems. Weaknesses: High development costs, potential over-engineering for some applications.

Core V8 Innovations

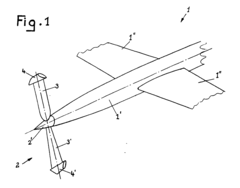

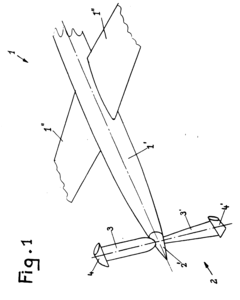

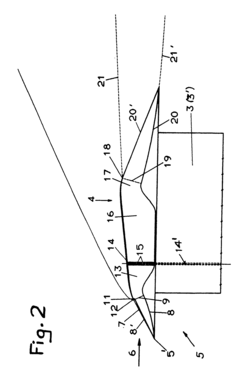

Propulsion unit for aircrafts flying at very high altitude

PatentInactiveEP0398109A2

Innovation

- A propeller-driven aircraft engine design featuring ramjet engines at the blade tips, operating at high supersonic speeds, with adjustable propeller blade pitch for power control, a multi-impact diffuser air intake for external compression, and a convergent/divergent nozzle for efficient combustion, utilizing liquid hydrogen fuel and direct cooling from the airflow, allowing for efficient operation at high altitudes and low speeds.

Powerplant and related control system and method

PatentInactiveEP2328772A1

Innovation

- A hydrogen powerplant with a combustion engine, generator, and control system that maintains constant engine speed during steady-state operations and varies speed during transient conditions, utilizing a turbocharger and afterburner to optimize efficiency and recover energy from unburned hydrogen in the exhaust, without the need for a wastegate, allowing for rapid power changes and engine restarts.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development and operation of V8 engines in high-altitude environments. These regulations are designed to mitigate the environmental impact of aircraft emissions, particularly at higher altitudes where the atmosphere is more sensitive to pollutants.

The International Civil Aviation Organization (ICAO) has established stringent standards for aircraft engine emissions, including those for V8 engines used in high-altitude operations. These standards focus on reducing nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (UHC), and particulate matter (PM) emissions. As aircraft operate at higher altitudes, the combustion efficiency of engines becomes increasingly important to meet these regulatory requirements.

V8 engine manufacturers have implemented various technologies to comply with emissions regulations while maintaining performance at high altitudes. Advanced fuel injection systems and combustion chamber designs have been developed to optimize fuel-air mixture and combustion efficiency. These improvements help reduce emissions across a wide range of operating conditions, including the lower air densities encountered at high altitudes.

Exhaust gas recirculation (EGR) systems have also been adapted for use in high-altitude V8 engines. By recirculating a portion of the exhaust gases back into the combustion chamber, EGR helps lower combustion temperatures and reduce NOx formation. This technology has been fine-tuned to maintain its effectiveness even in the challenging conditions of high-altitude flight.

The use of advanced materials and coatings in V8 engines has further contributed to emissions reduction. High-temperature resistant materials allow for more efficient combustion and reduced heat loss, while specialized coatings can catalyze the breakdown of pollutants in the exhaust stream. These innovations are particularly beneficial at high altitudes where engine temperatures and pressures can be more extreme.

Emissions monitoring and control systems have become increasingly sophisticated to ensure compliance with regulations during high-altitude operations. Real-time sensors and adaptive engine management systems allow for continuous optimization of engine performance and emissions control. This dynamic approach is essential for maintaining regulatory compliance across the diverse operating conditions encountered during high-altitude flight.

As emissions regulations continue to evolve, V8 engine manufacturers are investing in research and development to further improve high-altitude performance while reducing environmental impact. Emerging technologies such as hybrid-electric propulsion systems and sustainable aviation fuels are being explored as potential solutions to meet future regulatory challenges and enhance the efficiency of high-altitude operations.

The International Civil Aviation Organization (ICAO) has established stringent standards for aircraft engine emissions, including those for V8 engines used in high-altitude operations. These standards focus on reducing nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (UHC), and particulate matter (PM) emissions. As aircraft operate at higher altitudes, the combustion efficiency of engines becomes increasingly important to meet these regulatory requirements.

V8 engine manufacturers have implemented various technologies to comply with emissions regulations while maintaining performance at high altitudes. Advanced fuel injection systems and combustion chamber designs have been developed to optimize fuel-air mixture and combustion efficiency. These improvements help reduce emissions across a wide range of operating conditions, including the lower air densities encountered at high altitudes.

Exhaust gas recirculation (EGR) systems have also been adapted for use in high-altitude V8 engines. By recirculating a portion of the exhaust gases back into the combustion chamber, EGR helps lower combustion temperatures and reduce NOx formation. This technology has been fine-tuned to maintain its effectiveness even in the challenging conditions of high-altitude flight.

The use of advanced materials and coatings in V8 engines has further contributed to emissions reduction. High-temperature resistant materials allow for more efficient combustion and reduced heat loss, while specialized coatings can catalyze the breakdown of pollutants in the exhaust stream. These innovations are particularly beneficial at high altitudes where engine temperatures and pressures can be more extreme.

Emissions monitoring and control systems have become increasingly sophisticated to ensure compliance with regulations during high-altitude operations. Real-time sensors and adaptive engine management systems allow for continuous optimization of engine performance and emissions control. This dynamic approach is essential for maintaining regulatory compliance across the diverse operating conditions encountered during high-altitude flight.

As emissions regulations continue to evolve, V8 engine manufacturers are investing in research and development to further improve high-altitude performance while reducing environmental impact. Emerging technologies such as hybrid-electric propulsion systems and sustainable aviation fuels are being explored as potential solutions to meet future regulatory challenges and enhance the efficiency of high-altitude operations.

Fuel Efficiency

V8 engines have become increasingly popular in high-altitude operations due to their superior fuel efficiency compared to other engine types. This efficiency is particularly crucial in aviation, where fuel consumption directly impacts operational costs and environmental footprint.

The key to V8 engines' fuel efficiency at high altitudes lies in their ability to maintain optimal air-fuel mixture ratios. As altitude increases, air density decreases, which can lead to inefficient combustion in conventional engines. However, V8 engines equipped with advanced fuel injection systems and turbochargers can compensate for this reduced air density, ensuring proper fuel atomization and combustion even in thin air.

Turbocharging plays a vital role in maintaining fuel efficiency at high altitudes. By compressing the intake air, turbochargers increase its density, allowing more oxygen to enter the combustion chamber. This compensates for the naturally lower air density at high altitudes, enabling the engine to maintain its power output without consuming excessive fuel.

Variable valve timing (VVT) technology further enhances fuel efficiency in V8 engines operating at high altitudes. VVT systems can adjust the timing of valve opening and closing based on altitude and engine load, optimizing combustion efficiency across a wide range of operating conditions.

Advanced engine management systems in modern V8 engines continuously monitor and adjust various parameters to maintain optimal fuel efficiency. These systems use real-time data from multiple sensors to fine-tune fuel injection, ignition timing, and air-fuel ratios, ensuring peak performance and efficiency regardless of altitude.

The compact design of V8 engines also contributes to their fuel efficiency in high-altitude operations. With a favorable power-to-weight ratio, V8 engines can deliver substantial power output while minimizing the overall weight of the aircraft or vehicle. This reduced weight translates to lower fuel consumption, especially during climb and cruise phases at high altitudes.

Furthermore, V8 engines often incorporate lightweight materials and advanced manufacturing techniques, such as precision casting and 3D printing, to reduce internal friction and improve thermal efficiency. These enhancements contribute to better fuel economy across all operating conditions, including high-altitude flight.

In summary, the fuel efficiency of V8 engines in high-altitude operations stems from a combination of advanced technologies and design features. From turbocharging and variable valve timing to sophisticated engine management systems and lightweight construction, these engines are well-equipped to maintain optimal performance and fuel economy in the challenging conditions of high-altitude flight.

The key to V8 engines' fuel efficiency at high altitudes lies in their ability to maintain optimal air-fuel mixture ratios. As altitude increases, air density decreases, which can lead to inefficient combustion in conventional engines. However, V8 engines equipped with advanced fuel injection systems and turbochargers can compensate for this reduced air density, ensuring proper fuel atomization and combustion even in thin air.

Turbocharging plays a vital role in maintaining fuel efficiency at high altitudes. By compressing the intake air, turbochargers increase its density, allowing more oxygen to enter the combustion chamber. This compensates for the naturally lower air density at high altitudes, enabling the engine to maintain its power output without consuming excessive fuel.

Variable valve timing (VVT) technology further enhances fuel efficiency in V8 engines operating at high altitudes. VVT systems can adjust the timing of valve opening and closing based on altitude and engine load, optimizing combustion efficiency across a wide range of operating conditions.

Advanced engine management systems in modern V8 engines continuously monitor and adjust various parameters to maintain optimal fuel efficiency. These systems use real-time data from multiple sensors to fine-tune fuel injection, ignition timing, and air-fuel ratios, ensuring peak performance and efficiency regardless of altitude.

The compact design of V8 engines also contributes to their fuel efficiency in high-altitude operations. With a favorable power-to-weight ratio, V8 engines can deliver substantial power output while minimizing the overall weight of the aircraft or vehicle. This reduced weight translates to lower fuel consumption, especially during climb and cruise phases at high altitudes.

Furthermore, V8 engines often incorporate lightweight materials and advanced manufacturing techniques, such as precision casting and 3D printing, to reduce internal friction and improve thermal efficiency. These enhancements contribute to better fuel economy across all operating conditions, including high-altitude flight.

In summary, the fuel efficiency of V8 engines in high-altitude operations stems from a combination of advanced technologies and design features. From turbocharging and variable valve timing to sophisticated engine management systems and lightweight construction, these engines are well-equipped to maintain optimal performance and fuel economy in the challenging conditions of high-altitude flight.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!