How V8 Engines Leverage Digital Frameworks for Quality Control?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine QC Evolution

The evolution of quality control (QC) in V8 engine manufacturing has undergone significant transformations over the years, driven by advancements in digital technologies and the increasing complexity of engine designs. In the early stages, QC primarily relied on manual inspections and basic mechanical measurements, which were time-consuming and prone to human error.

As computerization began to take hold in the automotive industry, the first wave of digital QC frameworks emerged. These systems introduced automated data collection and analysis, allowing for more consistent and accurate measurements of engine components. This shift marked a crucial turning point, enabling manufacturers to detect defects and variations with greater precision.

The advent of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies in the 1980s and 1990s further revolutionized V8 engine QC. These tools allowed for the creation of detailed digital models, which could be used to simulate engine performance and identify potential issues before physical prototypes were built. This predictive capability significantly reduced development time and costs while improving overall quality.

The integration of sensors and real-time monitoring systems in the early 2000s brought about another leap in QC capabilities. These technologies enabled continuous data collection throughout the manufacturing process, providing instant feedback on production parameters and allowing for immediate adjustments to maintain quality standards.

More recently, the implementation of Industry 4.0 principles has ushered in a new era of V8 engine QC. Advanced digital frameworks now incorporate artificial intelligence (AI) and machine learning algorithms, capable of analyzing vast amounts of data to identify patterns and predict potential quality issues before they occur. These systems can adapt and learn from historical data, continuously improving their accuracy and effectiveness.

The latest digital QC frameworks for V8 engines also leverage Internet of Things (IoT) technologies, creating interconnected networks of sensors, machines, and data systems. This connectivity allows for comprehensive monitoring of the entire production ecosystem, from raw material quality to final assembly, ensuring a holistic approach to quality control.

As we look to the future, emerging technologies such as augmented reality (AR) and digital twins promise to further enhance V8 engine QC. These innovations will enable real-time visualization of complex engine data and facilitate more intuitive interaction between human operators and digital systems, pushing the boundaries of what is possible in engine quality assurance.

As computerization began to take hold in the automotive industry, the first wave of digital QC frameworks emerged. These systems introduced automated data collection and analysis, allowing for more consistent and accurate measurements of engine components. This shift marked a crucial turning point, enabling manufacturers to detect defects and variations with greater precision.

The advent of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies in the 1980s and 1990s further revolutionized V8 engine QC. These tools allowed for the creation of detailed digital models, which could be used to simulate engine performance and identify potential issues before physical prototypes were built. This predictive capability significantly reduced development time and costs while improving overall quality.

The integration of sensors and real-time monitoring systems in the early 2000s brought about another leap in QC capabilities. These technologies enabled continuous data collection throughout the manufacturing process, providing instant feedback on production parameters and allowing for immediate adjustments to maintain quality standards.

More recently, the implementation of Industry 4.0 principles has ushered in a new era of V8 engine QC. Advanced digital frameworks now incorporate artificial intelligence (AI) and machine learning algorithms, capable of analyzing vast amounts of data to identify patterns and predict potential quality issues before they occur. These systems can adapt and learn from historical data, continuously improving their accuracy and effectiveness.

The latest digital QC frameworks for V8 engines also leverage Internet of Things (IoT) technologies, creating interconnected networks of sensors, machines, and data systems. This connectivity allows for comprehensive monitoring of the entire production ecosystem, from raw material quality to final assembly, ensuring a holistic approach to quality control.

As we look to the future, emerging technologies such as augmented reality (AR) and digital twins promise to further enhance V8 engine QC. These innovations will enable real-time visualization of complex engine data and facilitate more intuitive interaction between human operators and digital systems, pushing the boundaries of what is possible in engine quality assurance.

Digital QC Market Demand

The digital quality control (QC) market for V8 engines is experiencing significant growth, driven by the increasing demand for high-performance vehicles and the need for more efficient and reliable manufacturing processes. As automotive manufacturers strive to meet stringent emissions standards and consumer expectations for power and fuel efficiency, the adoption of digital frameworks for quality control in V8 engine production has become crucial.

The market demand for digital QC solutions in V8 engine manufacturing is primarily fueled by the automotive industry's shift towards Industry 4.0 principles. This transition involves the integration of advanced technologies such as artificial intelligence, machine learning, and Internet of Things (IoT) devices into the production process. These digital frameworks enable real-time monitoring, data analysis, and predictive maintenance, which are essential for maintaining the high precision and consistency required in V8 engine production.

One of the key drivers of market demand is the potential for cost reduction and improved efficiency. Digital QC systems can significantly reduce the time and resources required for quality inspections, minimize human error, and identify potential issues before they escalate into costly problems. This proactive approach to quality control is particularly valuable in the production of complex V8 engines, where even minor defects can have substantial impacts on performance and reliability.

The automotive industry's focus on sustainability and environmental regulations is another factor contributing to the demand for digital QC solutions. V8 engines, known for their power output, are under increasing scrutiny regarding fuel efficiency and emissions. Digital frameworks enable manufacturers to optimize engine designs and production processes to meet these challenges while maintaining performance standards. This capability is crucial for ensuring that V8 engines remain viable in an increasingly environmentally conscious market.

Furthermore, the growing trend of vehicle customization and the need for flexible manufacturing processes have amplified the demand for digital QC systems. These frameworks allow for rapid adjustments in production parameters and quality checks, enabling manufacturers to efficiently produce various V8 engine configurations while maintaining consistent quality standards across all variants.

The market for digital QC in V8 engine production is also influenced by the increasing complexity of engine designs. Modern V8 engines often incorporate advanced technologies such as direct injection, variable valve timing, and turbocharging. These complex systems require sophisticated quality control measures that can only be effectively implemented through digital frameworks, further driving market demand.

As the automotive industry continues to evolve, the demand for digital QC solutions in V8 engine manufacturing is expected to grow. This trend is likely to be reinforced by the ongoing development of electric and hybrid powertrains, which may lead to new applications for V8 engines in high-performance and specialized vehicle segments, necessitating even more advanced quality control measures.

The market demand for digital QC solutions in V8 engine manufacturing is primarily fueled by the automotive industry's shift towards Industry 4.0 principles. This transition involves the integration of advanced technologies such as artificial intelligence, machine learning, and Internet of Things (IoT) devices into the production process. These digital frameworks enable real-time monitoring, data analysis, and predictive maintenance, which are essential for maintaining the high precision and consistency required in V8 engine production.

One of the key drivers of market demand is the potential for cost reduction and improved efficiency. Digital QC systems can significantly reduce the time and resources required for quality inspections, minimize human error, and identify potential issues before they escalate into costly problems. This proactive approach to quality control is particularly valuable in the production of complex V8 engines, where even minor defects can have substantial impacts on performance and reliability.

The automotive industry's focus on sustainability and environmental regulations is another factor contributing to the demand for digital QC solutions. V8 engines, known for their power output, are under increasing scrutiny regarding fuel efficiency and emissions. Digital frameworks enable manufacturers to optimize engine designs and production processes to meet these challenges while maintaining performance standards. This capability is crucial for ensuring that V8 engines remain viable in an increasingly environmentally conscious market.

Furthermore, the growing trend of vehicle customization and the need for flexible manufacturing processes have amplified the demand for digital QC systems. These frameworks allow for rapid adjustments in production parameters and quality checks, enabling manufacturers to efficiently produce various V8 engine configurations while maintaining consistent quality standards across all variants.

The market for digital QC in V8 engine production is also influenced by the increasing complexity of engine designs. Modern V8 engines often incorporate advanced technologies such as direct injection, variable valve timing, and turbocharging. These complex systems require sophisticated quality control measures that can only be effectively implemented through digital frameworks, further driving market demand.

As the automotive industry continues to evolve, the demand for digital QC solutions in V8 engine manufacturing is expected to grow. This trend is likely to be reinforced by the ongoing development of electric and hybrid powertrains, which may lead to new applications for V8 engines in high-performance and specialized vehicle segments, necessitating even more advanced quality control measures.

V8 QC Tech Challenges

Quality control in V8 engine manufacturing faces several significant challenges due to the complexity of these high-performance powerplants. One of the primary hurdles is maintaining consistent precision across numerous components. V8 engines comprise hundreds of intricate parts, each requiring exact specifications to ensure optimal performance and longevity. Even minor deviations can lead to reduced efficiency, increased wear, or catastrophic failure.

Another major challenge is the dynamic nature of engine operation. V8 engines undergo extreme temperature fluctuations, high-pressure conditions, and rapid mechanical movements. Ensuring that all components can withstand these stresses over extended periods demands rigorous testing and validation processes. Traditional quality control methods often struggle to simulate real-world conditions accurately, potentially missing critical issues that may only manifest after prolonged use.

The integration of advanced materials and technologies in modern V8 engines further complicates quality control efforts. As manufacturers incorporate lightweight alloys, composite materials, and cutting-edge coatings to enhance performance and efficiency, quality control procedures must evolve to effectively evaluate these novel components. Developing reliable testing methodologies for these materials often requires significant research and development investment.

Variability in manufacturing processes presents another substantial challenge. Even with highly automated production lines, subtle differences in raw materials, environmental conditions, or equipment wear can introduce inconsistencies. Detecting and mitigating these variations demands sophisticated monitoring systems and adaptive quality control strategies.

The increasing complexity of engine management systems and electronic components in V8 engines adds another layer of difficulty to quality control processes. These systems must be thoroughly tested for both hardware reliability and software integrity, requiring expertise in both mechanical and electronic quality assurance methodologies.

Balancing thoroughness with production efficiency is an ongoing challenge in V8 engine quality control. Comprehensive testing is essential to ensure reliability, but excessive quality control measures can significantly impact production timelines and costs. Striking the right balance between rigorous inspection and manufacturing efficiency requires continuous optimization of quality control protocols.

Lastly, the global nature of automotive supply chains introduces challenges in maintaining consistent quality standards across different manufacturing locations and suppliers. Ensuring that all components meet the same exacting specifications, regardless of their origin, demands robust supplier management systems and standardized quality control practices throughout the supply network.

Another major challenge is the dynamic nature of engine operation. V8 engines undergo extreme temperature fluctuations, high-pressure conditions, and rapid mechanical movements. Ensuring that all components can withstand these stresses over extended periods demands rigorous testing and validation processes. Traditional quality control methods often struggle to simulate real-world conditions accurately, potentially missing critical issues that may only manifest after prolonged use.

The integration of advanced materials and technologies in modern V8 engines further complicates quality control efforts. As manufacturers incorporate lightweight alloys, composite materials, and cutting-edge coatings to enhance performance and efficiency, quality control procedures must evolve to effectively evaluate these novel components. Developing reliable testing methodologies for these materials often requires significant research and development investment.

Variability in manufacturing processes presents another substantial challenge. Even with highly automated production lines, subtle differences in raw materials, environmental conditions, or equipment wear can introduce inconsistencies. Detecting and mitigating these variations demands sophisticated monitoring systems and adaptive quality control strategies.

The increasing complexity of engine management systems and electronic components in V8 engines adds another layer of difficulty to quality control processes. These systems must be thoroughly tested for both hardware reliability and software integrity, requiring expertise in both mechanical and electronic quality assurance methodologies.

Balancing thoroughness with production efficiency is an ongoing challenge in V8 engine quality control. Comprehensive testing is essential to ensure reliability, but excessive quality control measures can significantly impact production timelines and costs. Striking the right balance between rigorous inspection and manufacturing efficiency requires continuous optimization of quality control protocols.

Lastly, the global nature of automotive supply chains introduces challenges in maintaining consistent quality standards across different manufacturing locations and suppliers. Ensuring that all components meet the same exacting specifications, regardless of their origin, demands robust supplier management systems and standardized quality control practices throughout the supply network.

Current Digital QC Methods

01 Engine performance testing and monitoring

Quality control for V8 engines involves comprehensive performance testing and monitoring systems. These systems can measure various parameters such as power output, fuel efficiency, and emissions to ensure the engine meets required standards. Advanced diagnostic tools and sensors are used to collect real-time data during operation, allowing for early detection of potential issues and optimization of engine performance.- Engine performance testing and monitoring: Various methods and systems for testing and monitoring V8 engine performance are employed in quality control. These include real-time data collection, analysis of engine parameters, and advanced diagnostic techniques to ensure optimal engine operation and identify potential issues early in the production process.

- Vibration analysis and noise reduction: Quality control measures for V8 engines involve sophisticated vibration analysis and noise reduction techniques. These methods help identify and mitigate unwanted vibrations and noise, ensuring smoother engine operation and improved overall quality of the final product.

- Fuel efficiency and emissions control: Quality control processes focus on optimizing fuel efficiency and reducing emissions in V8 engines. This involves testing and fine-tuning engine components, fuel injection systems, and exhaust systems to meet stringent environmental standards while maintaining high performance.

- Advanced manufacturing and assembly techniques: Innovative manufacturing and assembly methods are employed to ensure the quality of V8 engines. These include precision machining, automated assembly processes, and rigorous quality checks at various stages of production to maintain consistency and reliability in engine manufacturing.

- Durability and longevity testing: Comprehensive durability and longevity tests are conducted as part of V8 engine quality control. These tests simulate various operating conditions and stress factors to ensure the engine's reliability and performance over extended periods, identifying potential weaknesses and areas for improvement.

02 Vibration analysis and noise reduction

Quality control measures for V8 engines include vibration analysis and noise reduction techniques. Specialized equipment is used to measure and analyze engine vibrations, identifying potential sources of excessive noise or wear. This data is used to refine engine design and manufacturing processes, resulting in smoother operation and improved longevity of engine components.Expand Specific Solutions03 Combustion efficiency and emissions control

Ensuring optimal combustion efficiency and controlling emissions are crucial aspects of V8 engine quality control. Advanced fuel injection systems, exhaust gas recirculation, and catalytic converters are employed to minimize harmful emissions while maximizing power output. Rigorous testing procedures are implemented to verify compliance with environmental regulations and performance standards.Expand Specific Solutions04 Material quality and component inspection

Quality control for V8 engines involves thorough inspection of materials and components used in manufacturing. Advanced non-destructive testing methods, such as X-ray and ultrasonic inspections, are employed to detect defects in engine blocks, pistons, and other critical parts. Strict quality standards are maintained throughout the supply chain to ensure the reliability and durability of the final product.Expand Specific Solutions05 Assembly process automation and verification

Automation plays a significant role in V8 engine quality control during the assembly process. Robotic systems and computer-controlled equipment are used to ensure precise component placement and torque application. Automated verification systems, including vision-based inspections and electronic torque monitoring, are implemented to detect and prevent assembly errors, ensuring consistent quality across production runs.Expand Specific Solutions

V8 QC Industry Leaders

The V8 engine quality control market is in a mature stage, with established players leveraging digital frameworks to enhance efficiency and precision. The global market size for V8 engine quality control systems is estimated to be in the billions, driven by the automotive and aerospace industries. Technologically, companies like Toyota, Nissan, and BMW are at the forefront, integrating advanced sensors, machine learning, and real-time data analytics into their quality control processes. Emerging players such as SkyRyse are introducing innovative AI-driven solutions, while traditional manufacturers like Bosch and Eaton continue to refine their digital quality control offerings, creating a competitive and dynamic landscape.

Toyota Motor Corp.

Technical Solution: Toyota leverages advanced digital frameworks for quality control in their V8 engine production. They employ a comprehensive system that integrates IoT sensors, real-time data analytics, and machine learning algorithms to monitor and optimize the entire manufacturing process. The system collects data from multiple points along the production line, including assembly, testing, and final inspection stages[1]. This data is then processed using AI-powered analytics to identify potential quality issues before they become critical. Toyota's approach also includes predictive maintenance capabilities, which can forecast potential equipment failures and schedule maintenance proactively, reducing downtime and improving overall production efficiency[3]. Additionally, they utilize digital twin technology to create virtual replicas of their V8 engines, allowing for extensive simulations and testing without the need for physical prototypes[5].

Strengths: Comprehensive data collection and analysis, predictive maintenance capabilities, and use of digital twin technology for virtual testing. Weaknesses: High initial implementation costs and potential cybersecurity risks associated with extensive data collection and connectivity.

Robert Bosch GmbH

Technical Solution: Bosch has developed a sophisticated digital quality control framework for V8 engine production, focusing on precision and reliability. Their system incorporates advanced sensor technology and edge computing to perform real-time quality checks at each stage of the manufacturing process. Bosch's framework utilizes AI-driven image recognition and acoustic analysis to detect even minute defects in engine components[2]. The company has also implemented a blockchain-based traceability system that ensures the authenticity and quality of parts used in V8 engine assembly[4]. Furthermore, Bosch's quality control system includes a network of connected tools and equipment that automatically adjust their parameters based on real-time data, ensuring consistent quality across production batches[6]. This adaptive manufacturing approach allows for rapid response to any deviations in quality metrics.

Strengths: High precision defect detection, blockchain-based traceability, and adaptive manufacturing capabilities. Weaknesses: Complex system integration requirements and potential over-reliance on technology for quality assurance.

Key V8 QC Innovations

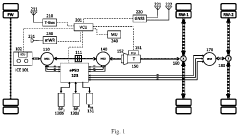

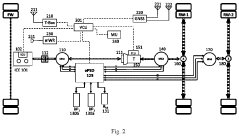

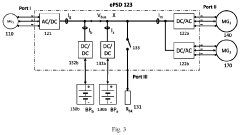

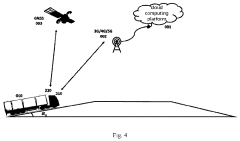

Heavy truck fuel-saving robot device and control method

PatentInactiveUS20220176965A1

Innovation

- The development of an Automated-Connected-Electrified (ACE) heavy duty truck with a double-motor and single-clutch mixed hybrid powertrain, integrating 100-kilowatt-class power electronic three-port network, Global Navigation Satellite System, 3D electronic navigation map, Internet of Things, and artificial intelligence to optimize energy management and reduce fuel consumption.

System control

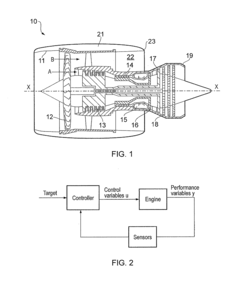

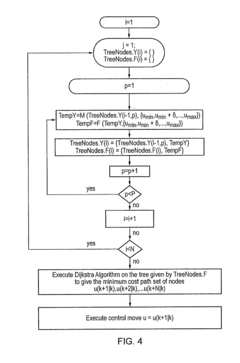

PatentActiveUS20120022838A1

Innovation

- A method using a deterministic algorithm with a system model in explicit form to optimize a cost function within a finite number of execution steps, ensuring control variables adhere to operational constraints, employing a Dijkstra algorithm or similar to identify optimal control combinations within predetermined limits.

V8 QC Data Analytics

V8 engines have increasingly adopted digital frameworks for quality control, leveraging advanced data analytics to enhance performance, reliability, and efficiency. These analytics platforms collect and process vast amounts of data from various sensors and systems throughout the engine's lifecycle, from manufacturing to real-time operation.

The integration of Internet of Things (IoT) devices and sensors within V8 engines has enabled the continuous monitoring of critical parameters such as temperature, pressure, vibration, and fuel consumption. This data is transmitted in real-time to centralized analytics platforms, where sophisticated algorithms process and analyze the information to detect anomalies, predict potential failures, and optimize engine performance.

Machine learning and artificial intelligence play a crucial role in these data analytics frameworks. By analyzing historical data and identifying patterns, these systems can predict maintenance needs, reducing downtime and extending engine life. Predictive maintenance algorithms can detect subtle changes in engine behavior that may indicate impending issues, allowing for proactive interventions before failures occur.

Real-time analytics also enable dynamic adjustments to engine parameters, optimizing performance based on current operating conditions. For example, fuel injection timing and air-fuel ratios can be fine-tuned on the fly to maximize efficiency and reduce emissions across various driving scenarios.

Quality control in manufacturing has been significantly enhanced through the use of data analytics. Advanced vision systems and sensor arrays monitor every step of the production process, ensuring precise tolerances are met and identifying potential defects before they reach the final product. This data-driven approach has led to substantial improvements in manufacturing consistency and overall engine quality.

Digital twin technology has emerged as a powerful tool in V8 engine quality control. By creating virtual replicas of physical engines, engineers can simulate various operating conditions and stress scenarios, predicting how the engine will perform over time. This allows for rapid iteration and optimization of designs without the need for costly physical prototypes.

The integration of blockchain technology in quality control data management ensures the integrity and traceability of engine data throughout its lifecycle. This is particularly crucial for maintaining accurate service records and verifying the authenticity of components in the aftermarket.

As V8 engines continue to evolve, the role of data analytics in quality control will only grow more significant. The ongoing development of more sophisticated sensors, faster data processing capabilities, and advanced machine learning algorithms promises to further enhance the reliability, performance, and efficiency of these powerful engines.

The integration of Internet of Things (IoT) devices and sensors within V8 engines has enabled the continuous monitoring of critical parameters such as temperature, pressure, vibration, and fuel consumption. This data is transmitted in real-time to centralized analytics platforms, where sophisticated algorithms process and analyze the information to detect anomalies, predict potential failures, and optimize engine performance.

Machine learning and artificial intelligence play a crucial role in these data analytics frameworks. By analyzing historical data and identifying patterns, these systems can predict maintenance needs, reducing downtime and extending engine life. Predictive maintenance algorithms can detect subtle changes in engine behavior that may indicate impending issues, allowing for proactive interventions before failures occur.

Real-time analytics also enable dynamic adjustments to engine parameters, optimizing performance based on current operating conditions. For example, fuel injection timing and air-fuel ratios can be fine-tuned on the fly to maximize efficiency and reduce emissions across various driving scenarios.

Quality control in manufacturing has been significantly enhanced through the use of data analytics. Advanced vision systems and sensor arrays monitor every step of the production process, ensuring precise tolerances are met and identifying potential defects before they reach the final product. This data-driven approach has led to substantial improvements in manufacturing consistency and overall engine quality.

Digital twin technology has emerged as a powerful tool in V8 engine quality control. By creating virtual replicas of physical engines, engineers can simulate various operating conditions and stress scenarios, predicting how the engine will perform over time. This allows for rapid iteration and optimization of designs without the need for costly physical prototypes.

The integration of blockchain technology in quality control data management ensures the integrity and traceability of engine data throughout its lifecycle. This is particularly crucial for maintaining accurate service records and verifying the authenticity of components in the aftermarket.

As V8 engines continue to evolve, the role of data analytics in quality control will only grow more significant. The ongoing development of more sophisticated sensors, faster data processing capabilities, and advanced machine learning algorithms promises to further enhance the reliability, performance, and efficiency of these powerful engines.

QC Automation ROI

The implementation of quality control automation in V8 engine manufacturing processes offers significant return on investment (ROI) for automotive manufacturers. By leveraging digital frameworks and advanced technologies, companies can achieve substantial cost savings, improved product quality, and enhanced operational efficiency.

One of the primary benefits of QC automation is the reduction in labor costs. Traditional manual inspection methods require a large workforce of skilled technicians, which can be expensive and prone to human error. Automated systems, on the other hand, can perform inspections continuously with high precision and consistency, reducing the need for manual labor and minimizing errors. This leads to direct cost savings in terms of wages and benefits, as well as indirect savings from reduced training and turnover expenses.

Furthermore, automated quality control systems can significantly increase throughput and productivity. These systems can operate 24/7 without fatigue, allowing for higher production volumes and faster inspection cycles. This increased efficiency translates to better utilization of manufacturing resources and reduced production bottlenecks, ultimately leading to higher output and revenue potential.

Quality improvements resulting from automated inspections also contribute to a strong ROI. Advanced sensors and machine vision systems can detect defects and variations that may be imperceptible to the human eye, ensuring that only high-quality engines reach the market. This leads to reduced warranty claims, recalls, and customer complaints, which can be extremely costly for manufacturers. By preventing defective products from reaching customers, companies can protect their brand reputation and maintain customer loyalty.

The implementation of digital frameworks for quality control also enables real-time data collection and analysis. This wealth of information allows manufacturers to identify trends, predict potential issues, and make data-driven decisions to optimize their processes. By addressing problems proactively, companies can avoid costly production delays and improve overall operational efficiency.

While the initial investment in QC automation technology can be substantial, the long-term benefits often outweigh the costs. Many manufacturers report ROI periods of 12-24 months for their automation projects, with ongoing savings and improvements continuing well beyond the payback period. As technology advances and becomes more affordable, the barriers to entry for QC automation are decreasing, making it an increasingly attractive option for manufacturers of all sizes.

One of the primary benefits of QC automation is the reduction in labor costs. Traditional manual inspection methods require a large workforce of skilled technicians, which can be expensive and prone to human error. Automated systems, on the other hand, can perform inspections continuously with high precision and consistency, reducing the need for manual labor and minimizing errors. This leads to direct cost savings in terms of wages and benefits, as well as indirect savings from reduced training and turnover expenses.

Furthermore, automated quality control systems can significantly increase throughput and productivity. These systems can operate 24/7 without fatigue, allowing for higher production volumes and faster inspection cycles. This increased efficiency translates to better utilization of manufacturing resources and reduced production bottlenecks, ultimately leading to higher output and revenue potential.

Quality improvements resulting from automated inspections also contribute to a strong ROI. Advanced sensors and machine vision systems can detect defects and variations that may be imperceptible to the human eye, ensuring that only high-quality engines reach the market. This leads to reduced warranty claims, recalls, and customer complaints, which can be extremely costly for manufacturers. By preventing defective products from reaching customers, companies can protect their brand reputation and maintain customer loyalty.

The implementation of digital frameworks for quality control also enables real-time data collection and analysis. This wealth of information allows manufacturers to identify trends, predict potential issues, and make data-driven decisions to optimize their processes. By addressing problems proactively, companies can avoid costly production delays and improve overall operational efficiency.

While the initial investment in QC automation technology can be substantial, the long-term benefits often outweigh the costs. Many manufacturers report ROI periods of 12-24 months for their automation projects, with ongoing savings and improvements continuing well beyond the payback period. As technology advances and becomes more affordable, the barriers to entry for QC automation are decreasing, making it an increasingly attractive option for manufacturers of all sizes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!