How Wire Bonding Controls Bond Lift And Non-Stick-On-Pad At Fine Pitch?

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wire Bonding Technology Evolution and Objectives

Wire bonding technology has evolved significantly since its inception in the 1950s, transforming from a rudimentary interconnection method to a sophisticated process critical for semiconductor packaging. Initially developed for simple device connections, wire bonding has undergone continuous refinement to meet the increasing demands of miniaturization and performance in the semiconductor industry. The evolution trajectory shows a clear progression from manual operations to fully automated systems capable of precise placement and control.

The fundamental shift in wire bonding technology occurred in the 1970s with the introduction of thermosonic bonding, which combined ultrasonic energy with heat to create more reliable connections. This innovation marked a pivotal moment, enabling higher throughput and improved bond quality. Subsequently, the 1990s witnessed the emergence of fine-pitch capabilities, allowing for wire bonding at increasingly smaller distances between bond pads.

Today's wire bonding technology operates at pitches below 40 microns, representing a remarkable achievement in precision engineering. This advancement has been driven by the relentless pursuit of higher integration densities in semiconductor devices, particularly in mobile and wearable electronics where space constraints are paramount. The reduction in pitch size has necessitated corresponding improvements in bonding parameters, wire materials, and process control methodologies.

The primary objective of modern wire bonding technology is to achieve reliable interconnections at fine pitches while minimizing defects such as bond lift and non-stick-on-pad (NSOP) failures. These failure modes become increasingly prevalent as pitch sizes decrease, presenting significant challenges for manufacturing yield and long-term reliability. Bond lift occurs when the wire connection separates from the bond pad after initial attachment, while NSOP represents a failure to establish a proper connection during the bonding process.

Controlling these defects requires precise management of multiple parameters including ultrasonic power, bonding force, temperature, and dwell time. The optimization of these parameters becomes increasingly critical as pitch sizes decrease, necessitating advanced process control systems and real-time monitoring capabilities. Additionally, wire material selection plays a crucial role, with gold, copper, and silver alloys each offering different advantages in terms of electrical performance, thermal conductivity, and bonding characteristics.

The technological objectives for future wire bonding development focus on enabling reliable connections at even finer pitches (sub-30 micron) while maintaining or improving throughput rates. This will require innovations in bonding tool design, wire materials, and process control algorithms. Particular emphasis is being placed on developing predictive maintenance capabilities and in-line quality monitoring systems to detect potential failures before they occur.

The fundamental shift in wire bonding technology occurred in the 1970s with the introduction of thermosonic bonding, which combined ultrasonic energy with heat to create more reliable connections. This innovation marked a pivotal moment, enabling higher throughput and improved bond quality. Subsequently, the 1990s witnessed the emergence of fine-pitch capabilities, allowing for wire bonding at increasingly smaller distances between bond pads.

Today's wire bonding technology operates at pitches below 40 microns, representing a remarkable achievement in precision engineering. This advancement has been driven by the relentless pursuit of higher integration densities in semiconductor devices, particularly in mobile and wearable electronics where space constraints are paramount. The reduction in pitch size has necessitated corresponding improvements in bonding parameters, wire materials, and process control methodologies.

The primary objective of modern wire bonding technology is to achieve reliable interconnections at fine pitches while minimizing defects such as bond lift and non-stick-on-pad (NSOP) failures. These failure modes become increasingly prevalent as pitch sizes decrease, presenting significant challenges for manufacturing yield and long-term reliability. Bond lift occurs when the wire connection separates from the bond pad after initial attachment, while NSOP represents a failure to establish a proper connection during the bonding process.

Controlling these defects requires precise management of multiple parameters including ultrasonic power, bonding force, temperature, and dwell time. The optimization of these parameters becomes increasingly critical as pitch sizes decrease, necessitating advanced process control systems and real-time monitoring capabilities. Additionally, wire material selection plays a crucial role, with gold, copper, and silver alloys each offering different advantages in terms of electrical performance, thermal conductivity, and bonding characteristics.

The technological objectives for future wire bonding development focus on enabling reliable connections at even finer pitches (sub-30 micron) while maintaining or improving throughput rates. This will require innovations in bonding tool design, wire materials, and process control algorithms. Particular emphasis is being placed on developing predictive maintenance capabilities and in-line quality monitoring systems to detect potential failures before they occur.

Market Demands for Fine Pitch Wire Bonding Solutions

The global semiconductor packaging market is experiencing unprecedented demand for fine pitch wire bonding solutions, driven primarily by the continuous miniaturization of electronic devices. As consumer electronics, automotive systems, and IoT devices become increasingly compact while requiring enhanced functionality, manufacturers are pushing the boundaries of interconnection technologies. Market research indicates that the fine pitch wire bonding segment is growing at a compound annual growth rate of approximately 7.5% through 2025, outpacing the broader semiconductor packaging market.

This accelerated growth is particularly evident in mobile devices, where manufacturers are striving to incorporate more features into thinner form factors. The smartphone industry alone consumes over 40% of fine pitch wire bonding solutions, with requirements for pitches below 40 micrometers becoming increasingly common. Wearable technology represents another rapidly expanding market segment, with projected growth exceeding 15% annually and driving demand for ultra-fine pitch solutions below 35 micrometers.

The automotive electronics sector presents another significant market driver, as vehicles incorporate more advanced driver assistance systems (ADAS) and infotainment features. This sector demands exceptional reliability under harsh operating conditions, creating unique challenges for fine pitch wire bonding. Industry reports suggest that automotive-grade semiconductor packages with fine pitch wire bonding are experiencing demand growth exceeding 12% annually.

Medical device miniaturization represents a specialized but rapidly growing market segment. Implantable devices, hearing aids, and portable diagnostic equipment all require extremely reliable fine pitch interconnections in increasingly compact packages. This segment values reliability above all other factors, with failure rates often required to be below one part per million.

The industrial IoT market is similarly driving demand for fine pitch solutions that can withstand harsh environmental conditions while maintaining long-term reliability. As factories deploy more sensors and edge computing devices, the need for cost-effective yet reliable packaging solutions continues to expand, with particular emphasis on solutions that can withstand vibration, temperature cycling, and chemical exposure.

Consumer demand for thinner devices with longer battery life is indirectly influencing wire bonding requirements. As device manufacturers reduce package heights to accommodate larger batteries, the tolerance for bond lift and non-stick-on-pad failures diminishes. Market research indicates that manufacturers are willing to pay premiums of 5-10% for wire bonding solutions that demonstrate significantly improved reliability at fine pitches.

This accelerated growth is particularly evident in mobile devices, where manufacturers are striving to incorporate more features into thinner form factors. The smartphone industry alone consumes over 40% of fine pitch wire bonding solutions, with requirements for pitches below 40 micrometers becoming increasingly common. Wearable technology represents another rapidly expanding market segment, with projected growth exceeding 15% annually and driving demand for ultra-fine pitch solutions below 35 micrometers.

The automotive electronics sector presents another significant market driver, as vehicles incorporate more advanced driver assistance systems (ADAS) and infotainment features. This sector demands exceptional reliability under harsh operating conditions, creating unique challenges for fine pitch wire bonding. Industry reports suggest that automotive-grade semiconductor packages with fine pitch wire bonding are experiencing demand growth exceeding 12% annually.

Medical device miniaturization represents a specialized but rapidly growing market segment. Implantable devices, hearing aids, and portable diagnostic equipment all require extremely reliable fine pitch interconnections in increasingly compact packages. This segment values reliability above all other factors, with failure rates often required to be below one part per million.

The industrial IoT market is similarly driving demand for fine pitch solutions that can withstand harsh environmental conditions while maintaining long-term reliability. As factories deploy more sensors and edge computing devices, the need for cost-effective yet reliable packaging solutions continues to expand, with particular emphasis on solutions that can withstand vibration, temperature cycling, and chemical exposure.

Consumer demand for thinner devices with longer battery life is indirectly influencing wire bonding requirements. As device manufacturers reduce package heights to accommodate larger batteries, the tolerance for bond lift and non-stick-on-pad failures diminishes. Market research indicates that manufacturers are willing to pay premiums of 5-10% for wire bonding solutions that demonstrate significantly improved reliability at fine pitches.

Current Challenges in Bond Lift and NSOP Prevention

Wire bonding at fine pitch dimensions presents significant technical challenges, particularly regarding bond lift and Non-Stick-On-Pad (NSOP) failures. As semiconductor devices continue to shrink, with bond pad pitches now commonly below 40μm, the margin for error in wire bonding processes has dramatically decreased. These miniaturization trends have intensified the complexity of maintaining reliable interconnections while preventing these common failure modes.

Bond lift failures typically occur when the wire bond separates from the pad surface after the bonding process is complete. This separation can happen immediately after bonding or during subsequent manufacturing steps, reliability testing, or even during field operation. The root causes include insufficient bond strength, contaminated pad surfaces, improper bonding parameters, and thermal-mechanical stresses that exceed the bond interface strength.

NSOP failures represent an even more immediate challenge, occurring when the wire fails to adhere to the bond pad during the initial bonding attempt. This failure mode is particularly problematic at fine pitches where pad sizes are reduced, providing less surface area for bonding. NSOP issues are frequently attributed to pad surface contamination, oxidation, inadequate surface preparation, or improper bonding parameters that fail to create sufficient metallurgical bonds.

The reduction in pad size at fine pitches exacerbates these challenges by decreasing the contact area available for bonding. This smaller bonding area results in reduced overall bond strength, making connections more susceptible to both lift and NSOP failures. Additionally, the decreased spacing between adjacent pads increases the risk of wire sweep and short circuits, further complicating the bonding process.

Material challenges also contribute significantly to these failure modes. Advanced semiconductor devices often utilize low-k dielectric materials that are mechanically weaker than traditional dielectrics. These materials can crack or delaminate under the force applied during wire bonding, leading to pad cratering and subsequent bond failures. Similarly, the trend toward copper metallization introduces oxidation concerns that can impede proper bond formation.

Process control becomes increasingly critical at fine pitches. Even minor variations in bonding parameters—temperature, force, ultrasonic power, and time—can dramatically impact bond quality. The narrow process windows at these dimensions leave little room for deviation, requiring exceptional precision in equipment calibration and maintenance.

Environmental factors further complicate fine pitch bonding. Humidity, temperature fluctuations, and airborne molecular contamination can all compromise pad surfaces and lead to inconsistent bonding results. These factors necessitate stringent clean room controls and environmental monitoring to maintain process stability.

Bond lift failures typically occur when the wire bond separates from the pad surface after the bonding process is complete. This separation can happen immediately after bonding or during subsequent manufacturing steps, reliability testing, or even during field operation. The root causes include insufficient bond strength, contaminated pad surfaces, improper bonding parameters, and thermal-mechanical stresses that exceed the bond interface strength.

NSOP failures represent an even more immediate challenge, occurring when the wire fails to adhere to the bond pad during the initial bonding attempt. This failure mode is particularly problematic at fine pitches where pad sizes are reduced, providing less surface area for bonding. NSOP issues are frequently attributed to pad surface contamination, oxidation, inadequate surface preparation, or improper bonding parameters that fail to create sufficient metallurgical bonds.

The reduction in pad size at fine pitches exacerbates these challenges by decreasing the contact area available for bonding. This smaller bonding area results in reduced overall bond strength, making connections more susceptible to both lift and NSOP failures. Additionally, the decreased spacing between adjacent pads increases the risk of wire sweep and short circuits, further complicating the bonding process.

Material challenges also contribute significantly to these failure modes. Advanced semiconductor devices often utilize low-k dielectric materials that are mechanically weaker than traditional dielectrics. These materials can crack or delaminate under the force applied during wire bonding, leading to pad cratering and subsequent bond failures. Similarly, the trend toward copper metallization introduces oxidation concerns that can impede proper bond formation.

Process control becomes increasingly critical at fine pitches. Even minor variations in bonding parameters—temperature, force, ultrasonic power, and time—can dramatically impact bond quality. The narrow process windows at these dimensions leave little room for deviation, requiring exceptional precision in equipment calibration and maintenance.

Environmental factors further complicate fine pitch bonding. Humidity, temperature fluctuations, and airborne molecular contamination can all compromise pad surfaces and lead to inconsistent bonding results. These factors necessitate stringent clean room controls and environmental monitoring to maintain process stability.

Advanced Bond Lift and NSOP Control Methodologies

01 Surface treatment methods to prevent bond lift

Various surface treatment methods can be applied to bond pads to enhance adhesion and prevent bond lift or non-stick-on-pad issues. These treatments include plasma cleaning, chemical etching, and application of specialized coatings that improve the metallurgical bond between the wire and pad surface. Such treatments remove contaminants and oxides that can interfere with proper bonding, creating a more reliable interface for wire bonding processes.- Surface treatment methods to improve wire bond adhesion: Various surface treatment methods can be applied to bond pads to enhance wire bond adhesion and prevent bond lift issues. These treatments include plasma cleaning, chemical etching, and surface roughening techniques that remove contaminants and oxides while creating a more favorable surface topography for bonding. Improved surface preparation leads to stronger metallurgical bonds between the wire and pad, significantly reducing the occurrence of non-stick-on-pad failures during the wire bonding process.

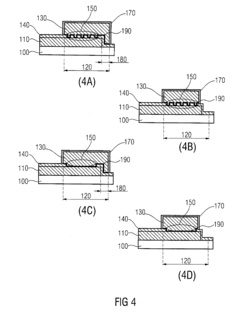

- Bond pad metallization composition and structure: The composition and structure of bond pad metallization significantly impact wire bonding reliability. Multi-layer metallization schemes incorporating adhesion layers, diffusion barriers, and noble metal finishes can prevent bond lift failures. Optimized pad structures with materials such as aluminum-copper alloys, titanium-tungsten barriers, and gold or palladium cap layers provide better intermetallic formation with bonding wires. The thickness ratios and deposition methods of these layers are critical factors in preventing non-stick-on-pad issues.

- Wire bonding process parameter optimization: Optimizing wire bonding process parameters is essential for preventing bond lift and non-stick-on-pad failures. Critical parameters include ultrasonic power, bonding force, bonding time, and temperature. Proper calibration of these parameters based on specific materials and equipment characteristics ensures sufficient energy transfer for intermetallic formation without causing damage to the underlying structures. Advanced process control systems with real-time monitoring capabilities can detect and adjust parameters to maintain consistent bond quality.

- Wire material selection and preparation: The selection and preparation of bonding wire materials significantly influence bond reliability. Gold, copper, aluminum, and silver alloy wires with specific dopants can be chosen based on the application requirements and pad metallization. Wire diameter, hardness, elongation properties, and surface cleanliness all affect bonding performance. Pre-bonding treatments such as annealing and cleaning processes can improve wire ductility and remove contaminants that might interfere with proper bond formation.

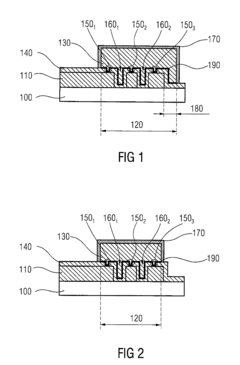

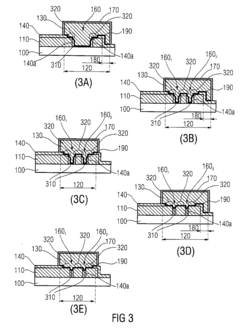

- Advanced packaging designs to mitigate bond failures: Advanced packaging designs incorporate features specifically aimed at preventing wire bond failures. These include optimized pad geometries, stress-relief structures, and protective encapsulation techniques. Bond pad designs with stepped or recessed structures can improve mechanical interlocking. Stress buffer layers between the pad and underlying structures help absorb thermal and mechanical stresses. Post-bond encapsulation methods using specialized polymers provide additional protection against environmental factors that could lead to bond degradation over time.

02 Bond pad metallization composition and structure

The composition and structure of bond pad metallization significantly affects wire bonding reliability and resistance to bond lift. Multi-layer metallization schemes incorporating materials such as aluminum, copper, gold, nickel, and palladium in specific configurations can enhance bonding strength. The thickness, grain structure, and hardness of these metallization layers play crucial roles in preventing non-stick-on-pad failures by providing optimal surfaces for intermetallic formation during the bonding process.Expand Specific Solutions03 Wire bonding process parameter optimization

Optimizing wire bonding process parameters is essential for preventing bond lift issues. Critical parameters include bonding force, ultrasonic power, bonding time, and temperature. These parameters must be carefully calibrated based on the specific materials involved to ensure proper intermetallic formation without causing damage to the underlying structures. Advanced monitoring and control systems can detect and adjust parameters in real-time to maintain consistent bonding quality across different conditions.Expand Specific Solutions04 Wire material selection and preparation

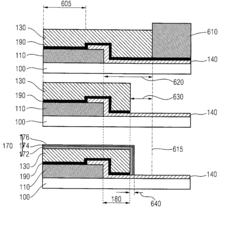

The selection and preparation of bonding wire materials significantly impact bond reliability. Gold, copper, aluminum, and silver alloy wires with specific dopants can be used to enhance bonding characteristics for different pad materials. Wire diameter, hardness, elongation properties, and surface cleanliness all affect the formation of reliable bonds. Pre-bonding treatments such as annealing or surface activation can further improve bonding performance and reduce the likelihood of non-stick-on-pad failures.Expand Specific Solutions05 Bond pad design and semiconductor package structure

The design of bond pads and overall semiconductor package structure influences bonding reliability. Factors such as pad size, shape, thickness, and spacing affect bonding success. Additionally, the underlying substrate materials, dielectric layers, and mechanical support structures impact the pad's ability to withstand bonding forces without delamination. Advanced pad designs may incorporate special features like anchoring structures or stress-relief elements to enhance mechanical stability and prevent bond lift issues during thermal cycling or other stress conditions.Expand Specific Solutions

Leading Semiconductor Packaging Equipment Manufacturers

Wire bonding technology for fine pitch applications is currently in a mature growth phase, with the global market expected to reach $5.2 billion by 2025. The competitive landscape is characterized by established semiconductor manufacturers like Texas Instruments, NXP, and Samsung Electronics competing with specialized equipment providers such as Kulicke & Soffa Industries and F&S Bondtec. Technology maturity varies across players, with TSMC, Infineon, and Samsung leading in advanced bonding techniques that address bond lift and non-stick-on-pad challenges through optimized wire materials, precise temperature control, and automated inspection systems. The industry is seeing increased focus on AI-driven process control and nanoscale bonding innovations as device miniaturization continues to push technical boundaries in semiconductor packaging.

Shinkawa KK

Technical Solution: Shinkawa has pioneered the UTC (Ultra Thin Capillary) technology specifically designed for fine pitch wire bonding applications. Their approach focuses on precise ultrasonic energy delivery through advanced transducer designs that maintain consistent energy transfer even at reduced bond sizes. Shinkawa's proprietary SBAL (Shinkawa Bond Auto Learning) system employs machine learning algorithms to continuously optimize bonding parameters based on historical performance data, automatically adjusting for variations in surface conditions that typically cause non-stick issues. For addressing bond lift challenges, they've developed specialized wire deformation control that carefully manages the intermetallic compound formation process through precise temperature and pressure regulation. Their latest UTC-V series capillaries feature optimized tip geometries with chamfer angles specifically engineered for pitches below 35μm, reducing mechanical stress on the wire while ensuring proper material flow during the bonding process. Shinkawa's systems also incorporate advanced vision systems that detect subtle pad surface anomalies before bonding, allowing for parameter adjustments that prevent non-stick failures.

Strengths: Their machine learning-based parameter optimization provides exceptional adaptability to different substrate materials and surface conditions. The specialized UTC capillary design excels at maintaining bond integrity at extremely fine pitches. Weaknesses: The complex machine learning systems require substantial data collection periods before reaching optimal performance, creating a longer implementation timeline compared to conventional solutions.

ASM Technology Singapore Pte Ltd.

Technical Solution: ASM has developed the ASMPT ConnX wire bonder platform specifically addressing fine pitch challenges through their proprietary Active Bond Force Control technology. This system utilizes high-precision piezoelectric actuators that deliver microsecond-level force adjustments during the bonding process, critical for preventing both lift and non-stick issues at pitches below 40μm. Their approach incorporates real-time ultrasonic feedback mechanisms that continuously monitor energy transfer efficiency, automatically compensating for variations in substrate materials and surface conditions. For fine pitch applications, ASM implements specialized wire path control algorithms that optimize loop formation while minimizing wire stress, particularly important for preventing bond lift in thermally challenging environments. Their advanced capillary designs feature precisely engineered chamfer angles and hole geometries optimized for different wire diameters and pad metallizations, ensuring consistent intermetallic formation even on challenging surface finishes. ASM's systems also incorporate multi-point temperature monitoring and compensation, addressing the thermal gradient issues that commonly contribute to non-stick failures in fine pitch applications.

Strengths: Their Active Bond Force Control technology provides exceptional precision in force application, critical for fine pitch applications. The comprehensive thermal management system effectively addresses temperature-related bond failures across large substrates. Weaknesses: The highly sophisticated control systems require more extensive maintenance and calibration compared to simpler bonding platforms, potentially increasing operational costs.

Critical Patents in Fine Pitch Wire Bonding

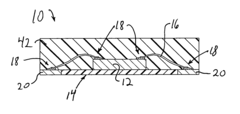

Aluminum bump bonding for fine aluminum wire

PatentInactiveUS20070216026A1

Innovation

- The use of an aluminum bump bond method, where a nickel-doped aluminum bump formed from a large diameter wire is bonded to the leadframe, allowing a fine aluminum wire to be securely attached, reducing sensitivity to surface conditions and bonding parameters.

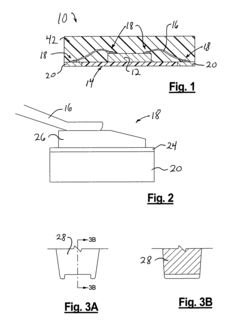

Bonding Pad for Contacting a Device

PatentActiveUS20080067682A1

Innovation

- A bonding pad design featuring a first soft metal structure covered by a harder second metal structure, with a passivation layer and an electrically conductive protective layer, where the harder layer is only deposited in the bonding area to prevent deformation and ensure a stable connection, and the force is distributed to the substrate during bonding.

Material Science Advancements for Wire Bonding

Recent advancements in material science have significantly transformed wire bonding technology, particularly addressing challenges related to bond lift and non-stick-on-pad issues at fine pitch applications. The evolution of bonding wire materials has moved from traditional gold wires to copper and silver alloys, offering enhanced mechanical strength and electrical conductivity while reducing costs.

Copper wire bonding has gained prominence due to its superior electrical and thermal conductivity compared to gold, though it presents oxidation challenges. Researchers have developed specialized coatings and surface treatments that mitigate oxidation while maintaining bondability. Palladium-coated copper wires represent a breakthrough, combining copper's conductivity with improved oxidation resistance.

Nano-composite bonding wires incorporate microscopic particles that enhance mechanical properties and reduce intermetallic compound formation at the bond interface. These materials demonstrate superior resistance to bond lift failures by creating stronger metallurgical bonds with pad surfaces, critical for fine pitch applications where bond areas are significantly reduced.

Surface modification technologies for bonding pads have evolved concurrently. Advanced metallization stacks incorporate nickel-palladium-gold layers that improve bondability while preventing pad peeling during the bonding process. Plasma cleaning and specialized surface activation treatments have been developed to enhance adhesion properties at the molecular level.

The introduction of low-temperature bonding processes, enabled by novel wire compositions, has reduced thermal stress during bonding. This advancement is particularly valuable for temperature-sensitive components in advanced packaging configurations where traditional high-temperature processes could damage surrounding materials.

Computational materials science has accelerated development through molecular dynamics simulations that predict intermetallic compound formation and bond strength. These models allow engineers to optimize material compositions before physical testing, significantly reducing development cycles for new bonding wire materials.

Emerging research focuses on self-healing wire bond interfaces that can recover from micro-fractures during thermal cycling. Additionally, graphene-enhanced bonding wires show promise for next-generation applications, potentially offering unprecedented conductivity and mechanical stability at extremely fine pitches below 30 microns.

Copper wire bonding has gained prominence due to its superior electrical and thermal conductivity compared to gold, though it presents oxidation challenges. Researchers have developed specialized coatings and surface treatments that mitigate oxidation while maintaining bondability. Palladium-coated copper wires represent a breakthrough, combining copper's conductivity with improved oxidation resistance.

Nano-composite bonding wires incorporate microscopic particles that enhance mechanical properties and reduce intermetallic compound formation at the bond interface. These materials demonstrate superior resistance to bond lift failures by creating stronger metallurgical bonds with pad surfaces, critical for fine pitch applications where bond areas are significantly reduced.

Surface modification technologies for bonding pads have evolved concurrently. Advanced metallization stacks incorporate nickel-palladium-gold layers that improve bondability while preventing pad peeling during the bonding process. Plasma cleaning and specialized surface activation treatments have been developed to enhance adhesion properties at the molecular level.

The introduction of low-temperature bonding processes, enabled by novel wire compositions, has reduced thermal stress during bonding. This advancement is particularly valuable for temperature-sensitive components in advanced packaging configurations where traditional high-temperature processes could damage surrounding materials.

Computational materials science has accelerated development through molecular dynamics simulations that predict intermetallic compound formation and bond strength. These models allow engineers to optimize material compositions before physical testing, significantly reducing development cycles for new bonding wire materials.

Emerging research focuses on self-healing wire bond interfaces that can recover from micro-fractures during thermal cycling. Additionally, graphene-enhanced bonding wires show promise for next-generation applications, potentially offering unprecedented conductivity and mechanical stability at extremely fine pitches below 30 microns.

Quality Control Systems for High-Yield Wire Bonding

Quality control systems are essential components in achieving high-yield wire bonding processes, particularly when addressing challenges like bond lift and non-stick-on-pad (NSOP) issues at fine pitch dimensions. These systems integrate sophisticated monitoring technologies with statistical process control methodologies to ensure consistent bonding quality.

Real-time monitoring capabilities form the foundation of modern wire bonding quality control. Advanced systems employ acoustic emission sensors that detect ultrasonic vibrations during the bonding process, providing immediate feedback on bond formation quality. This allows for the detection of potential NSOP issues before they manifest as visible defects.

Automated optical inspection (AOI) systems complement acoustic monitoring by providing high-resolution visual verification of bond placement accuracy and loop formation. These systems utilize machine vision algorithms to identify subtle deviations in bond positioning that could lead to reliability issues, particularly critical at fine pitch applications where tolerances are measured in micrometers.

Statistical Process Control (SPC) methodologies are integrated into quality control systems to establish process capability indices and control limits. By continuously analyzing bonding parameters such as ultrasonic power, bonding force, and time, these systems can identify process drift before it results in bond failures. The implementation of Six Sigma methodologies has proven particularly effective in reducing variability in fine pitch wire bonding processes.

Pull and shear testing automation has evolved significantly, allowing for non-destructive evaluation of bond strength through statistical sampling. Advanced systems incorporate machine learning algorithms that correlate pull test results with process parameters, enabling predictive maintenance and process optimization to prevent bond lift issues.

Temperature and humidity monitoring within the bonding environment has emerged as a critical quality control factor. Research has demonstrated that maintaining precise environmental conditions can significantly reduce NSOP occurrences, particularly when working with fine pitch applications where surface chemistry interactions become increasingly important.

Traceability systems that document the complete process history for each bonded component provide valuable data for root cause analysis when failures occur. These systems typically incorporate unique identifiers for each device and maintain comprehensive records of all process parameters, enabling manufacturers to quickly isolate and address quality issues.

Integration with Industry 4.0 principles has led to the development of interconnected quality control systems that share data across the manufacturing ecosystem. This holistic approach enables correlation between upstream processes like die attach and downstream testing, providing a comprehensive view of factors affecting wire bonding quality at fine pitch dimensions.

Real-time monitoring capabilities form the foundation of modern wire bonding quality control. Advanced systems employ acoustic emission sensors that detect ultrasonic vibrations during the bonding process, providing immediate feedback on bond formation quality. This allows for the detection of potential NSOP issues before they manifest as visible defects.

Automated optical inspection (AOI) systems complement acoustic monitoring by providing high-resolution visual verification of bond placement accuracy and loop formation. These systems utilize machine vision algorithms to identify subtle deviations in bond positioning that could lead to reliability issues, particularly critical at fine pitch applications where tolerances are measured in micrometers.

Statistical Process Control (SPC) methodologies are integrated into quality control systems to establish process capability indices and control limits. By continuously analyzing bonding parameters such as ultrasonic power, bonding force, and time, these systems can identify process drift before it results in bond failures. The implementation of Six Sigma methodologies has proven particularly effective in reducing variability in fine pitch wire bonding processes.

Pull and shear testing automation has evolved significantly, allowing for non-destructive evaluation of bond strength through statistical sampling. Advanced systems incorporate machine learning algorithms that correlate pull test results with process parameters, enabling predictive maintenance and process optimization to prevent bond lift issues.

Temperature and humidity monitoring within the bonding environment has emerged as a critical quality control factor. Research has demonstrated that maintaining precise environmental conditions can significantly reduce NSOP occurrences, particularly when working with fine pitch applications where surface chemistry interactions become increasingly important.

Traceability systems that document the complete process history for each bonded component provide valuable data for root cause analysis when failures occur. These systems typically incorporate unique identifiers for each device and maintain comprehensive records of all process parameters, enabling manufacturers to quickly isolate and address quality issues.

Integration with Industry 4.0 principles has led to the development of interconnected quality control systems that share data across the manufacturing ecosystem. This holistic approach enables correlation between upstream processes like die attach and downstream testing, providing a comprehensive view of factors affecting wire bonding quality at fine pitch dimensions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!