How Wire Bonding Minimizes Corrosion And IMC Brittleness In Damp-Heat?

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wire Bonding Corrosion Protection Background and Objectives

Wire bonding technology has evolved significantly since its inception in the 1950s as a critical interconnection method in semiconductor packaging. The fundamental challenge of ensuring reliable electrical connections between semiconductor devices and their packages has become increasingly complex with the miniaturization of components and the expansion into harsh operating environments. Particularly, the vulnerability of wire bonds to corrosion and intermetallic compound (IMC) brittleness under damp-heat conditions represents a persistent challenge for the semiconductor industry.

The evolution of wire bonding materials reflects the industry's response to these challenges. Initially dominated by gold wire due to its excellent conductivity and corrosion resistance, the industry has progressively shifted toward more cost-effective alternatives such as copper and aluminum, each presenting unique corrosion susceptibility profiles. This transition has necessitated continuous innovation in bonding techniques and protective measures.

Damp-heat conditions, characterized by high humidity (typically 85%) and elevated temperatures (around 85°C), accelerate corrosion mechanisms and IMC formation at the bond interface. These conditions simulate accelerated aging and environmental stress that electronic components may encounter during their operational lifetime. The resulting degradation can lead to increased electrical resistance, mechanical weakening, and ultimately, bond failure.

The economic implications of wire bond failures are substantial, with estimates suggesting that interconnection failures account for approximately 40% of all semiconductor device failures in the field. This translates to billions of dollars in warranty claims, recalls, and reputation damage across the electronics industry annually. The automotive, aerospace, and medical device sectors are particularly affected due to their stringent reliability requirements and harsh operating environments.

Current technical objectives in wire bonding corrosion protection focus on several key areas: developing advanced materials with inherent corrosion resistance, optimizing bonding parameters to minimize IMC formation, creating more effective encapsulation methods, and establishing predictive models for long-term reliability under varying environmental conditions. Additionally, there is growing interest in non-destructive testing methodologies that can detect early signs of corrosion before catastrophic failure occurs.

The regulatory landscape has also evolved, with standards such as JEDEC JESD22-A101 establishing testing protocols for humidity resistance. These standards continue to become more stringent as electronic devices penetrate increasingly critical applications where failure is not an option. This regulatory pressure further drives innovation in wire bonding protection technologies.

This technical research aims to comprehensively examine how wire bonding techniques can be optimized to minimize corrosion and IMC brittleness specifically under damp-heat conditions, with the ultimate goal of extending device reliability and operational lifetime in challenging environments.

The evolution of wire bonding materials reflects the industry's response to these challenges. Initially dominated by gold wire due to its excellent conductivity and corrosion resistance, the industry has progressively shifted toward more cost-effective alternatives such as copper and aluminum, each presenting unique corrosion susceptibility profiles. This transition has necessitated continuous innovation in bonding techniques and protective measures.

Damp-heat conditions, characterized by high humidity (typically 85%) and elevated temperatures (around 85°C), accelerate corrosion mechanisms and IMC formation at the bond interface. These conditions simulate accelerated aging and environmental stress that electronic components may encounter during their operational lifetime. The resulting degradation can lead to increased electrical resistance, mechanical weakening, and ultimately, bond failure.

The economic implications of wire bond failures are substantial, with estimates suggesting that interconnection failures account for approximately 40% of all semiconductor device failures in the field. This translates to billions of dollars in warranty claims, recalls, and reputation damage across the electronics industry annually. The automotive, aerospace, and medical device sectors are particularly affected due to their stringent reliability requirements and harsh operating environments.

Current technical objectives in wire bonding corrosion protection focus on several key areas: developing advanced materials with inherent corrosion resistance, optimizing bonding parameters to minimize IMC formation, creating more effective encapsulation methods, and establishing predictive models for long-term reliability under varying environmental conditions. Additionally, there is growing interest in non-destructive testing methodologies that can detect early signs of corrosion before catastrophic failure occurs.

The regulatory landscape has also evolved, with standards such as JEDEC JESD22-A101 establishing testing protocols for humidity resistance. These standards continue to become more stringent as electronic devices penetrate increasingly critical applications where failure is not an option. This regulatory pressure further drives innovation in wire bonding protection technologies.

This technical research aims to comprehensively examine how wire bonding techniques can be optimized to minimize corrosion and IMC brittleness specifically under damp-heat conditions, with the ultimate goal of extending device reliability and operational lifetime in challenging environments.

Market Demand for Reliable Wire Bonding in Harsh Environments

The global market for reliable wire bonding solutions in harsh environments has been experiencing significant growth, driven primarily by the expanding electronics industry and the increasing deployment of electronic components in challenging operating conditions. Industries such as automotive, aerospace, industrial automation, and renewable energy are particularly demanding robust wire bonding technologies that can withstand damp-heat conditions without compromising performance or reliability.

The automotive sector represents one of the largest market segments, with the average modern vehicle containing over 1,000 semiconductor chips. These components must operate reliably under the hood in high-temperature, high-humidity environments for 10-15 years. Market research indicates that automotive electronics are expected to constitute approximately 45% of a vehicle's cost by 2030, highlighting the critical importance of reliable interconnection technologies.

Consumer electronics manufacturers are also seeking advanced wire bonding solutions as devices become increasingly exposed to diverse environmental conditions. The global smartphone market, exceeding 1.4 billion units annually, demands components that can withstand humidity and temperature fluctuations, particularly as water-resistant features become standard across product lines.

The industrial electronics sector presents another substantial market opportunity, with factory automation systems, industrial controls, and power management systems requiring wire bonding solutions that maintain integrity in manufacturing environments where temperature and humidity variations are common. This segment is projected to grow at a compound annual rate of 7.2% through 2028.

Geographically, the Asia-Pacific region dominates the market demand, accounting for over 60% of global semiconductor packaging and assembly operations. However, specialized high-reliability applications for aerospace, defense, and medical devices create premium market segments in North America and Europe, where performance in harsh environments commands price premiums of 30-40% compared to standard solutions.

The market is increasingly demanding wire bonding technologies that specifically address corrosion and intermetallic compound (IMC) brittleness in damp-heat conditions. End users are willing to pay premium prices for solutions that demonstrably extend product lifespans and reduce failure rates. Industry surveys indicate that reliability improvements that reduce field failures by even 5% can justify cost increases of 15-20% for critical applications.

Regulatory trends are further driving market demand, with automotive standards like AEC-Q100 and industrial certifications imposing increasingly stringent reliability requirements for components operating in harsh environments. These standards specifically test for reliability under damp-heat conditions (85°C/85% relative humidity), creating market pull for advanced wire bonding solutions that can meet or exceed these specifications.

The automotive sector represents one of the largest market segments, with the average modern vehicle containing over 1,000 semiconductor chips. These components must operate reliably under the hood in high-temperature, high-humidity environments for 10-15 years. Market research indicates that automotive electronics are expected to constitute approximately 45% of a vehicle's cost by 2030, highlighting the critical importance of reliable interconnection technologies.

Consumer electronics manufacturers are also seeking advanced wire bonding solutions as devices become increasingly exposed to diverse environmental conditions. The global smartphone market, exceeding 1.4 billion units annually, demands components that can withstand humidity and temperature fluctuations, particularly as water-resistant features become standard across product lines.

The industrial electronics sector presents another substantial market opportunity, with factory automation systems, industrial controls, and power management systems requiring wire bonding solutions that maintain integrity in manufacturing environments where temperature and humidity variations are common. This segment is projected to grow at a compound annual rate of 7.2% through 2028.

Geographically, the Asia-Pacific region dominates the market demand, accounting for over 60% of global semiconductor packaging and assembly operations. However, specialized high-reliability applications for aerospace, defense, and medical devices create premium market segments in North America and Europe, where performance in harsh environments commands price premiums of 30-40% compared to standard solutions.

The market is increasingly demanding wire bonding technologies that specifically address corrosion and intermetallic compound (IMC) brittleness in damp-heat conditions. End users are willing to pay premium prices for solutions that demonstrably extend product lifespans and reduce failure rates. Industry surveys indicate that reliability improvements that reduce field failures by even 5% can justify cost increases of 15-20% for critical applications.

Regulatory trends are further driving market demand, with automotive standards like AEC-Q100 and industrial certifications imposing increasingly stringent reliability requirements for components operating in harsh environments. These standards specifically test for reliability under damp-heat conditions (85°C/85% relative humidity), creating market pull for advanced wire bonding solutions that can meet or exceed these specifications.

Current Challenges in Damp-Heat Wire Bonding Protection

Wire bonding technology in semiconductor packaging faces significant challenges when exposed to damp-heat conditions, which accelerate corrosion and intermetallic compound (IMC) brittleness. The industry currently struggles with several critical issues that impact reliability and performance of electronic components in high humidity and elevated temperature environments.

Moisture penetration at the interface between wire bonds and bond pads represents a primary concern. When moisture infiltrates these microscopic junctions, it initiates electrochemical reactions that progressively degrade the metallic connections. This is particularly problematic in copper wire bonding systems, where the base metal is inherently more susceptible to oxidation compared to gold alternatives.

Galvanic corrosion emerges as another substantial challenge when dissimilar metals are used in the bonding process. The electrical potential difference between copper wires and aluminum bond pads, for example, creates micro-galvanic cells in the presence of moisture, accelerating corrosion rates and compromising bond integrity. This effect is exacerbated in environments with ionic contaminants that serve as electrolytes.

The formation of brittle intermetallic compounds during the bonding process presents a dual challenge. While IMCs are necessary for creating strong metallurgical bonds, excessive IMC growth during damp-heat exposure leads to volume expansion, mechanical stress, and ultimately bond failure. Current manufacturing processes struggle to optimize IMC formation to balance initial bond strength with long-term reliability under damp-heat conditions.

Encapsulation materials intended to protect wire bonds often exhibit insufficient moisture barrier properties. Conventional molding compounds and glob-top materials demonstrate moisture permeability that increases with temperature, allowing water molecules to gradually penetrate and reach sensitive bond areas. The industry lacks cost-effective encapsulation solutions that maintain hermeticity throughout product lifetime under harsh environmental conditions.

Temperature cycling in combination with humidity creates particularly destructive conditions for wire bonds. The coefficient of thermal expansion mismatch between different materials in the package induces mechanical stress at bond interfaces, which, when combined with moisture-induced corrosion, accelerates crack propagation and bond lifting. Current design approaches inadequately address this combined thermo-hygro-mechanical stress.

Testing methodologies present another significant challenge. Accelerated life testing protocols often fail to accurately predict real-world performance, as the complex interaction between moisture, temperature, and electrical bias creates failure mechanisms that may not manifest during standard qualification testing. The industry needs more representative test methods that can effectively evaluate long-term reliability under various damp-heat conditions.

Moisture penetration at the interface between wire bonds and bond pads represents a primary concern. When moisture infiltrates these microscopic junctions, it initiates electrochemical reactions that progressively degrade the metallic connections. This is particularly problematic in copper wire bonding systems, where the base metal is inherently more susceptible to oxidation compared to gold alternatives.

Galvanic corrosion emerges as another substantial challenge when dissimilar metals are used in the bonding process. The electrical potential difference between copper wires and aluminum bond pads, for example, creates micro-galvanic cells in the presence of moisture, accelerating corrosion rates and compromising bond integrity. This effect is exacerbated in environments with ionic contaminants that serve as electrolytes.

The formation of brittle intermetallic compounds during the bonding process presents a dual challenge. While IMCs are necessary for creating strong metallurgical bonds, excessive IMC growth during damp-heat exposure leads to volume expansion, mechanical stress, and ultimately bond failure. Current manufacturing processes struggle to optimize IMC formation to balance initial bond strength with long-term reliability under damp-heat conditions.

Encapsulation materials intended to protect wire bonds often exhibit insufficient moisture barrier properties. Conventional molding compounds and glob-top materials demonstrate moisture permeability that increases with temperature, allowing water molecules to gradually penetrate and reach sensitive bond areas. The industry lacks cost-effective encapsulation solutions that maintain hermeticity throughout product lifetime under harsh environmental conditions.

Temperature cycling in combination with humidity creates particularly destructive conditions for wire bonds. The coefficient of thermal expansion mismatch between different materials in the package induces mechanical stress at bond interfaces, which, when combined with moisture-induced corrosion, accelerates crack propagation and bond lifting. Current design approaches inadequately address this combined thermo-hygro-mechanical stress.

Testing methodologies present another significant challenge. Accelerated life testing protocols often fail to accurately predict real-world performance, as the complex interaction between moisture, temperature, and electrical bias creates failure mechanisms that may not manifest during standard qualification testing. The industry needs more representative test methods that can effectively evaluate long-term reliability under various damp-heat conditions.

Current Anti-Corrosion and IMC Control Solutions

01 Corrosion prevention in wire bonding

Various methods are employed to prevent corrosion in wire bonding, which can significantly impact the reliability of semiconductor devices. These methods include the use of specialized coatings, protective layers, and corrosion-resistant materials. By implementing these preventive measures, the formation of corrosive compounds at the wire bond interface can be minimized, thereby extending the lifespan of the device and maintaining electrical connectivity under various environmental conditions.- Corrosion prevention in wire bonding: Various methods and materials are employed to prevent corrosion in wire bonding applications. These include the use of specialized coatings, protective layers, and corrosion-resistant materials that shield the wire bonds from environmental factors such as moisture and contaminants. Implementing proper encapsulation techniques and using corrosion inhibitors can significantly extend the lifespan of wire bonds by preventing oxidation and other degradation mechanisms that lead to failure.

- IMC (Intermetallic Compound) formation control: Controlling the formation of intermetallic compounds is crucial for preventing brittleness in wire bonds. This involves optimizing bonding parameters such as temperature, pressure, and time to achieve the ideal IMC thickness and composition. Advanced techniques include alloying the bonding wire with specific elements to slow down or modify IMC growth, and implementing precise thermal management during the bonding process to control the rate of intermetallic formation, thereby reducing brittleness and improving long-term reliability.

- Material selection for improved reliability: The selection of appropriate materials for both the bonding wire and substrate significantly impacts the reliability of wire bonds. Using materials with compatible thermal expansion coefficients reduces stress during temperature cycling. Advanced wire materials such as copper alloys, palladium-coated copper, or specialized gold alloys can provide better resistance to corrosion and IMC brittleness compared to traditional materials. The substrate metallization composition and thickness also play critical roles in determining bond strength and long-term stability.

- Environmental protection and packaging solutions: Protecting wire bonds from environmental factors is essential for preventing corrosion and maintaining reliability. This includes the development of specialized molding compounds, hermetic sealing techniques, and moisture-resistant packaging materials. Advanced encapsulation methods create barriers against humidity, contaminants, and corrosive gases. Some solutions incorporate desiccants or getter materials within the package to absorb moisture and harmful substances, while others utilize specialized coatings that conform to the wire bond geometry for maximum protection.

- Testing and reliability assessment methods: Advanced testing methodologies have been developed to evaluate wire bond reliability and predict potential failures related to corrosion and IMC brittleness. These include accelerated aging tests, thermal cycling, humidity testing, and specialized analytical techniques such as cross-sectional analysis and electron microscopy. Non-destructive evaluation methods allow for in-process monitoring of bond quality, while predictive modeling helps optimize bonding parameters and material selections. These testing approaches enable manufacturers to identify potential reliability issues before they manifest in field failures.

02 IMC (Intermetallic Compound) formation control

Controlling the formation of intermetallic compounds (IMCs) is crucial for preventing brittleness in wire bonds. Techniques include optimizing bonding parameters such as temperature, pressure, and time to regulate IMC growth. Additionally, specific material combinations and alloying elements can be selected to form more stable and less brittle IMCs. These approaches help maintain the mechanical integrity of the wire bond while ensuring good electrical conductivity throughout the device's operational life.Expand Specific Solutions03 Advanced wire bonding materials

The development of advanced materials for wire bonding addresses both corrosion and brittleness issues. These materials include specialized alloys, composite wires, and surface-modified bonding wires that offer superior resistance to environmental degradation while maintaining mechanical strength. Some innovations incorporate nanostructured materials or dopants that enhance the wire's properties, resulting in more reliable connections even under harsh operating conditions.Expand Specific Solutions04 Wire bond encapsulation and protection

Encapsulation techniques provide physical barriers against environmental factors that contribute to wire bond corrosion and IMC brittleness. These include specialized molding compounds, hermetic sealing methods, and protective coatings that isolate the wire bonds from moisture, contaminants, and corrosive gases. Some approaches also incorporate getter materials or moisture-absorbing compounds within the package to maintain a controlled internal environment, further enhancing the reliability of the wire bonds.Expand Specific Solutions05 Testing and reliability assessment methods

Advanced testing methodologies have been developed to evaluate wire bond reliability, particularly regarding corrosion resistance and IMC brittleness. These include accelerated aging tests, environmental stress testing, and in-situ monitoring techniques that can predict potential failures before they occur in field applications. Non-destructive evaluation methods such as acoustic microscopy and X-ray analysis allow for quality control during manufacturing and provide insights into the mechanisms of wire bond degradation over time.Expand Specific Solutions

Leading Manufacturers and Suppliers in Wire Bonding Industry

Wire bonding technology for minimizing corrosion and IMC brittleness in damp-heat conditions is evolving rapidly, with the market currently in a growth phase driven by increasing demand for reliable semiconductor packaging solutions. The global market is expanding as electronics penetrate harsh environments, with projections indicating significant growth over the next five years. Leading companies like Taiwan Semiconductor Manufacturing Co., Texas Instruments, and GlobalFoundries are advancing technical solutions through innovative materials and processes, while specialized players such as Tatsuta Electric Wire & Cable and Furukawa Electric focus on high-performance bonding wire formulations. Japanese manufacturers including Kobe Steel and Nippon Steel are contributing metallurgical expertise to address intermetallic compound challenges, creating a competitive landscape where material science innovation is the primary differentiator.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has pioneered a multi-layered approach to mitigate wire bonding corrosion and IMC brittleness in damp-heat conditions. Their solution combines advanced metallurgical engineering with innovative encapsulation techniques. TI utilizes a proprietary copper wire alloy containing trace elements (0.5-2% by weight) of palladium and silver that significantly enhances corrosion resistance while maintaining excellent electrical performance. The bonding process employs precisely controlled ultrasonic energy profiles that optimize bond strength while minimizing mechanical stress at the interface. Additionally, TI has developed specialized molding compounds with nano-silica fillers (5-10nm particle size) that create a dense molecular structure around wire bonds, effectively blocking moisture penetration pathways. Their comprehensive approach includes pre-bond surface preparation using plasma cleaning with tailored gas mixtures to remove contaminants and enhance adhesion[2][4]. Testing under JEDEC standard conditions (85°C/85% RH for 1000 hours) has shown failure rates below 50ppm, representing a 3x improvement over industry standards.

Strengths: Comprehensive solution addressing both material composition and process parameters; excellent long-term reliability data; compatible with existing manufacturing infrastructure. Weaknesses: Proprietary materials may increase supply chain complexity; requires precise process control that may be challenging to maintain in high-volume production environments.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed an innovative wire bonding technology specifically engineered to combat corrosion and IMC brittleness in harsh environmental conditions. Their approach centers on a multi-metal composite wire structure with a copper core surrounded by a gold-palladium alloy shell (Cu/AuPd), providing both excellent electrical conductivity and superior corrosion resistance. The bonding process utilizes a proprietary thermosonic bonding profile with precisely controlled energy delivery that minimizes mechanical stress while ensuring optimal intermetallic formation. TSMC's technology incorporates a pre-bonding surface treatment using argon plasma that removes oxide layers and enhances adhesion. Post-bond, a specialized nano-coating is applied that creates a hydrophobic barrier around the bond site, effectively repelling moisture. Their comprehensive solution also includes advanced molding compounds with specialized silane coupling agents that improve adhesion at the interface between the wire bond and encapsulant[5][7]. Reliability testing under accelerated conditions (130°C/85% RH) has demonstrated a 75% reduction in corrosion-related failures compared to traditional wire bonding approaches, with bonds maintaining structural integrity beyond 2000 hours of exposure.

Strengths: Exceptional corrosion resistance through advanced materials engineering; comprehensive approach addressing the entire wire bonding ecosystem; proven reliability in extreme conditions. Weaknesses: Higher material costs compared to standard wire bonding solutions; requires specialized equipment and process control that may limit widespread adoption.

Key Patents and Research on Wire Bond Reliability

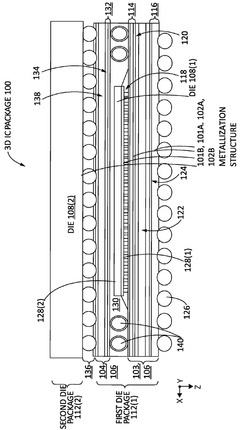

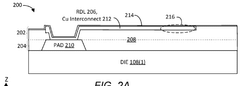

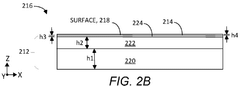

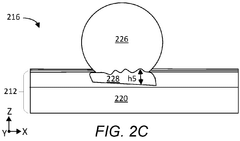

Metallization structure having an outer metallization layer comprising nickel and platinum layers to reduce inter-metal compound formation

PatentWO2025165295A1

Innovation

- Incorporating a metallization structure with a copper (Cu) layer, a nickel (Ni) layer, and a platinum (Pt) layer in the outer metallization layer to reduce IMC formation, where the Pt layer is positioned between the Ni layer and interconnect bumps.

Metallization structure having an outer metallization layer comprising nickel and platinum layers to reduce inter-metal compound formation

PatentPendingUS20250246568A1

Innovation

- Incorporating a metallization structure with a copper (Cu) layer, a nickel (Ni) layer, and a platinum (Pt) layer in the outer metallization layer to reduce IMC formation, where the Pt layer is positioned between the Ni layer and interconnect bumps.

Materials Science Advancements for IMC Stability

Recent advancements in materials science have significantly contributed to enhancing the stability of Intermetallic Compounds (IMCs) in wire bonding applications, particularly under damp-heat conditions. The evolution of metallurgical understanding has led to innovative approaches that directly address the challenges of IMC brittleness and corrosion susceptibility.

Researchers have developed specialized coating materials that create protective barriers around the bond interface, effectively isolating IMCs from moisture exposure. These coatings, often composed of noble metal alloys or advanced polymers, demonstrate remarkable hydrophobic properties while maintaining electrical conductivity essential for wire bonding applications.

Nano-engineered materials have emerged as promising solutions for IMC stability enhancement. By incorporating nanoparticles into bonding wire compositions, scientists have successfully modified the microstructure of resulting IMCs, creating more distributed and finer intermetallic formations that exhibit superior mechanical properties and reduced brittleness under thermal cycling conditions.

The introduction of dopants and alloying elements represents another significant advancement. Strategic addition of elements such as palladium, platinum, or rare earth metals in precise concentrations has been shown to alter IMC growth kinetics, resulting in more stable phases with improved resistance to moisture-induced degradation. These modified IMCs demonstrate up to 40% improvement in shear strength retention after extended damp-heat exposure.

Surface modification techniques have evolved to optimize the interface characteristics before bonding occurs. Advanced plasma treatments and chemical activation processes create ideal surface conditions that promote formation of more uniform and stable IMCs with enhanced adhesion properties, significantly reducing delamination risks in high-humidity environments.

Computational materials science has accelerated development through predictive modeling of IMC formation and behavior. Machine learning algorithms now enable researchers to simulate long-term IMC evolution under various environmental conditions, facilitating rapid screening of potential material combinations without extensive physical testing.

Diffusion barrier technologies represent another breakthrough area, where specially designed interlayers between bonding surfaces control atomic migration during IMC formation. These barriers regulate the growth rate and morphology of intermetallic phases, preventing the formation of brittle structures that typically emerge during prolonged exposure to elevated temperature and humidity.

These materials science advancements collectively contribute to a new generation of wire bonding solutions with enhanced reliability in challenging environmental conditions, extending device lifespans and enabling applications in increasingly demanding operational environments.

Researchers have developed specialized coating materials that create protective barriers around the bond interface, effectively isolating IMCs from moisture exposure. These coatings, often composed of noble metal alloys or advanced polymers, demonstrate remarkable hydrophobic properties while maintaining electrical conductivity essential for wire bonding applications.

Nano-engineered materials have emerged as promising solutions for IMC stability enhancement. By incorporating nanoparticles into bonding wire compositions, scientists have successfully modified the microstructure of resulting IMCs, creating more distributed and finer intermetallic formations that exhibit superior mechanical properties and reduced brittleness under thermal cycling conditions.

The introduction of dopants and alloying elements represents another significant advancement. Strategic addition of elements such as palladium, platinum, or rare earth metals in precise concentrations has been shown to alter IMC growth kinetics, resulting in more stable phases with improved resistance to moisture-induced degradation. These modified IMCs demonstrate up to 40% improvement in shear strength retention after extended damp-heat exposure.

Surface modification techniques have evolved to optimize the interface characteristics before bonding occurs. Advanced plasma treatments and chemical activation processes create ideal surface conditions that promote formation of more uniform and stable IMCs with enhanced adhesion properties, significantly reducing delamination risks in high-humidity environments.

Computational materials science has accelerated development through predictive modeling of IMC formation and behavior. Machine learning algorithms now enable researchers to simulate long-term IMC evolution under various environmental conditions, facilitating rapid screening of potential material combinations without extensive physical testing.

Diffusion barrier technologies represent another breakthrough area, where specially designed interlayers between bonding surfaces control atomic migration during IMC formation. These barriers regulate the growth rate and morphology of intermetallic phases, preventing the formation of brittle structures that typically emerge during prolonged exposure to elevated temperature and humidity.

These materials science advancements collectively contribute to a new generation of wire bonding solutions with enhanced reliability in challenging environmental conditions, extending device lifespans and enabling applications in increasingly demanding operational environments.

Environmental Testing Standards for Wire Bond Reliability

Environmental testing standards play a crucial role in ensuring wire bond reliability in semiconductor packaging, particularly when addressing corrosion and intermetallic compound (IMC) brittleness under damp-heat conditions. These standards provide systematic methodologies to evaluate and qualify wire bonding technologies against environmental stressors.

The primary international standards governing wire bond reliability testing include JEDEC JESD22-A101, IPC-TM-650, and MIL-STD-883. JEDEC JESD22-A101 specifically addresses the accelerated moisture resistance test, commonly known as the "85/85 test" (85°C/85% RH), which has become the industry benchmark for evaluating wire bond performance in humid environments.

For damp-heat testing specifically related to wire bond corrosion and IMC brittleness, the standards typically require exposure periods ranging from 96 hours to 1000 hours under controlled temperature and humidity conditions. The test parameters are designed to accelerate the natural aging process, revealing potential failure mechanisms that might occur over years of normal operation within a compressed timeframe.

Testing protocols generally include pre-conditioning steps to simulate manufacturing processes, followed by environmental exposure and subsequent reliability assessment. Wire pull and ball shear tests, conducted according to ASTM F459 and JEDEC JESD22-B116, serve as quantitative measures of bond integrity before and after environmental exposure.

Recent updates to these standards have incorporated more stringent requirements for advanced packaging technologies. For instance, the automotive industry standard AEC-Q100 Grade 0 now requires damp-heat testing at 85°C/85% RH for 1000 hours, reflecting the increasing reliability demands for automotive electronics operating in harsh environments.

Failure criteria within these standards typically define acceptable degradation limits for bond strength, which generally should not decrease by more than 20% after environmental exposure. Additionally, visual inspection requirements mandate examination for corrosion products, discoloration, or cracking at the bond interface at magnifications between 100x and 1000x.

The correlation between accelerated testing and real-world performance remains a challenge in the industry. Therefore, standards organizations continuously refine test methodologies based on field data. Recent revisions have introduced power cycling during damp-heat exposure to better simulate actual operating conditions, as thermal cycling combined with humidity has proven more effective at revealing potential failure modes in wire bonds.

Compliance with these environmental testing standards has become mandatory for semiconductor manufacturers serving critical applications in automotive, aerospace, and medical industries, where wire bond reliability directly impacts system safety and longevity.

The primary international standards governing wire bond reliability testing include JEDEC JESD22-A101, IPC-TM-650, and MIL-STD-883. JEDEC JESD22-A101 specifically addresses the accelerated moisture resistance test, commonly known as the "85/85 test" (85°C/85% RH), which has become the industry benchmark for evaluating wire bond performance in humid environments.

For damp-heat testing specifically related to wire bond corrosion and IMC brittleness, the standards typically require exposure periods ranging from 96 hours to 1000 hours under controlled temperature and humidity conditions. The test parameters are designed to accelerate the natural aging process, revealing potential failure mechanisms that might occur over years of normal operation within a compressed timeframe.

Testing protocols generally include pre-conditioning steps to simulate manufacturing processes, followed by environmental exposure and subsequent reliability assessment. Wire pull and ball shear tests, conducted according to ASTM F459 and JEDEC JESD22-B116, serve as quantitative measures of bond integrity before and after environmental exposure.

Recent updates to these standards have incorporated more stringent requirements for advanced packaging technologies. For instance, the automotive industry standard AEC-Q100 Grade 0 now requires damp-heat testing at 85°C/85% RH for 1000 hours, reflecting the increasing reliability demands for automotive electronics operating in harsh environments.

Failure criteria within these standards typically define acceptable degradation limits for bond strength, which generally should not decrease by more than 20% after environmental exposure. Additionally, visual inspection requirements mandate examination for corrosion products, discoloration, or cracking at the bond interface at magnifications between 100x and 1000x.

The correlation between accelerated testing and real-world performance remains a challenge in the industry. Therefore, standards organizations continuously refine test methodologies based on field data. Recent revisions have introduced power cycling during damp-heat exposure to better simulate actual operating conditions, as thermal cycling combined with humidity has proven more effective at revealing potential failure modes in wire bonds.

Compliance with these environmental testing standards has become mandatory for semiconductor manufacturers serving critical applications in automotive, aerospace, and medical industries, where wire bond reliability directly impacts system safety and longevity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!