Wire Bonding Stitch And Heel Integrity: Pull/Shear Correlations And Crack Prevention

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wire Bonding Technology Background and Objectives

Wire bonding technology has evolved significantly since its inception in the 1950s, becoming the most widely used interconnection method in semiconductor packaging. This technique establishes electrical connections between integrated circuits and their packaging using fine metal wires, typically gold, aluminum, or copper. The evolution of wire bonding has been driven by the semiconductor industry's continuous pursuit of miniaturization, higher performance, and increased reliability while maintaining cost-effectiveness.

The fundamental wire bonding process involves two critical connection points: the first bond (ball bond) and the second bond (stitch or wedge bond). The integrity of these bonds, particularly the stitch bond and its heel area, directly impacts the reliability and performance of semiconductor devices. As device dimensions continue to shrink and packaging densities increase, ensuring robust bond integrity has become increasingly challenging yet crucial.

Recent technological advancements have focused on enhancing bond strength, preventing heel cracks, and developing more precise quality assessment methods. The correlation between pull and shear testing results has emerged as a significant area of research, as these mechanical tests provide complementary insights into bond integrity. Understanding these correlations enables more comprehensive quality control and failure analysis protocols.

The semiconductor industry has witnessed a transition from gold to copper wire bonding due to cost considerations and performance advantages. However, this transition has introduced new challenges related to stitch bond formation and heel crack prevention, necessitating innovations in bonding parameters, tool designs, and surface treatments.

The primary objectives of current wire bonding technology research include developing quantitative models that correlate pull and shear test results to predict bond reliability, identifying optimal bonding parameters that minimize heel crack formation while maintaining adequate bond strength, and creating advanced in-line inspection techniques capable of detecting potential bond integrity issues before device failure.

Additionally, research aims to establish standardized methodologies for evaluating stitch and heel integrity across different wire materials, bond pad metallizations, and device architectures. This standardization would facilitate industry-wide quality benchmarking and accelerate the adoption of best practices.

As packaging technologies continue to evolve toward heterogeneous integration and advanced 3D architectures, wire bonding must adapt to new challenges while maintaining its cost advantage. The development of ultra-fine pitch bonding capabilities and compatibility with novel substrate materials represents another critical objective for ensuring wire bonding remains relevant in next-generation semiconductor packages.

The fundamental wire bonding process involves two critical connection points: the first bond (ball bond) and the second bond (stitch or wedge bond). The integrity of these bonds, particularly the stitch bond and its heel area, directly impacts the reliability and performance of semiconductor devices. As device dimensions continue to shrink and packaging densities increase, ensuring robust bond integrity has become increasingly challenging yet crucial.

Recent technological advancements have focused on enhancing bond strength, preventing heel cracks, and developing more precise quality assessment methods. The correlation between pull and shear testing results has emerged as a significant area of research, as these mechanical tests provide complementary insights into bond integrity. Understanding these correlations enables more comprehensive quality control and failure analysis protocols.

The semiconductor industry has witnessed a transition from gold to copper wire bonding due to cost considerations and performance advantages. However, this transition has introduced new challenges related to stitch bond formation and heel crack prevention, necessitating innovations in bonding parameters, tool designs, and surface treatments.

The primary objectives of current wire bonding technology research include developing quantitative models that correlate pull and shear test results to predict bond reliability, identifying optimal bonding parameters that minimize heel crack formation while maintaining adequate bond strength, and creating advanced in-line inspection techniques capable of detecting potential bond integrity issues before device failure.

Additionally, research aims to establish standardized methodologies for evaluating stitch and heel integrity across different wire materials, bond pad metallizations, and device architectures. This standardization would facilitate industry-wide quality benchmarking and accelerate the adoption of best practices.

As packaging technologies continue to evolve toward heterogeneous integration and advanced 3D architectures, wire bonding must adapt to new challenges while maintaining its cost advantage. The development of ultra-fine pitch bonding capabilities and compatibility with novel substrate materials represents another critical objective for ensuring wire bonding remains relevant in next-generation semiconductor packages.

Market Demand Analysis for High-Integrity Wire Bonding

The global wire bonding market is experiencing robust growth, driven primarily by the expanding semiconductor and electronics industries. Current market valuations place the wire bonding segment at approximately $4.5 billion in 2023, with projections indicating a compound annual growth rate of 5.7% through 2028. This growth trajectory is underpinned by increasing demand for miniaturized electronic devices across consumer electronics, automotive, and industrial sectors.

High-integrity wire bonding solutions are particularly sought after in mission-critical applications where reliability cannot be compromised. The automotive industry represents a significant market segment, with advanced driver-assistance systems (ADAS) and electric vehicle control modules requiring wire bonds that maintain structural integrity under extreme temperature fluctuations and vibration conditions. Market research indicates that automotive-grade wire bonding solutions command a premium of 15-20% over standard alternatives due to their enhanced reliability requirements.

The medical device sector presents another high-value market opportunity, with implantable devices and diagnostic equipment manufacturers prioritizing wire bonding solutions that demonstrate superior crack resistance and long-term reliability. This segment is growing at 7.2% annually, outpacing the broader market as healthcare technologies become increasingly sophisticated and widespread.

Aerospace and defense applications constitute a smaller but highly profitable market segment, where wire bonding integrity directly impacts mission-critical systems. These customers typically require extensive documentation of pull and shear test correlations to validate bond reliability under extreme environmental conditions.

Market research reveals a significant shift in customer requirements, with 78% of semiconductor packaging engineers citing bond integrity as a top-three concern in their manufacturing processes. This represents a 12% increase from similar surveys conducted five years ago, indicating growing awareness of the economic impact of bond failures in high-volume production environments.

The economic implications of wire bonding failures are substantial, with industry reports estimating that bond-related failures account for approximately $320 million in annual warranty claims and rework costs across electronics manufacturing. This has created market demand for advanced analytical tools and methodologies that can predict potential bond failures before they occur in field applications.

Regional analysis shows that Asia-Pacific dominates the market with 65% share of global wire bonding equipment sales, followed by North America (18%) and Europe (12%). However, the highest growth rates for high-integrity bonding solutions are observed in North American and European markets, where premium applications in automotive, medical, and aerospace sectors drive demand for advanced reliability features.

High-integrity wire bonding solutions are particularly sought after in mission-critical applications where reliability cannot be compromised. The automotive industry represents a significant market segment, with advanced driver-assistance systems (ADAS) and electric vehicle control modules requiring wire bonds that maintain structural integrity under extreme temperature fluctuations and vibration conditions. Market research indicates that automotive-grade wire bonding solutions command a premium of 15-20% over standard alternatives due to their enhanced reliability requirements.

The medical device sector presents another high-value market opportunity, with implantable devices and diagnostic equipment manufacturers prioritizing wire bonding solutions that demonstrate superior crack resistance and long-term reliability. This segment is growing at 7.2% annually, outpacing the broader market as healthcare technologies become increasingly sophisticated and widespread.

Aerospace and defense applications constitute a smaller but highly profitable market segment, where wire bonding integrity directly impacts mission-critical systems. These customers typically require extensive documentation of pull and shear test correlations to validate bond reliability under extreme environmental conditions.

Market research reveals a significant shift in customer requirements, with 78% of semiconductor packaging engineers citing bond integrity as a top-three concern in their manufacturing processes. This represents a 12% increase from similar surveys conducted five years ago, indicating growing awareness of the economic impact of bond failures in high-volume production environments.

The economic implications of wire bonding failures are substantial, with industry reports estimating that bond-related failures account for approximately $320 million in annual warranty claims and rework costs across electronics manufacturing. This has created market demand for advanced analytical tools and methodologies that can predict potential bond failures before they occur in field applications.

Regional analysis shows that Asia-Pacific dominates the market with 65% share of global wire bonding equipment sales, followed by North America (18%) and Europe (12%). However, the highest growth rates for high-integrity bonding solutions are observed in North American and European markets, where premium applications in automotive, medical, and aerospace sectors drive demand for advanced reliability features.

Current Challenges in Stitch and Heel Integrity

Wire bonding stitch and heel integrity represents one of the most critical challenges in semiconductor packaging reliability. Despite decades of industry experience, failure rates related to stitch bonds continue to plague manufacturing processes, with heel cracks being particularly problematic. Recent industry data indicates that approximately 8-12% of all wire bonding failures can be attributed specifically to stitch and heel integrity issues, representing significant yield loss and reliability concerns.

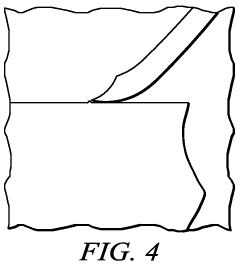

The fundamental challenge lies in the mechanical stress concentration at the heel region during the bonding process. When the capillary tool deforms the wire against the substrate, it creates inherent stress gradients that can lead to microcrack initiation. These microcracks, often invisible during initial quality control, propagate under thermal cycling and mechanical stress during device operation, eventually causing complete bond failure.

Current pull and shear testing methodologies show inconsistent correlation between test results and actual field reliability. Studies from major semiconductor manufacturers reveal that bonds passing standard pull tests at 5-7 grams force may still develop heel cracks during thermal cycling. This disconnect between testing and real-world performance represents a significant gap in quality assurance protocols.

Material interface challenges further complicate stitch integrity. The interaction between wire materials (typically gold, copper, or aluminum) and substrate metallization creates complex intermetallic compounds at the bond interface. These compounds, while necessary for proper adhesion, can become brittle and susceptible to cracking under certain conditions. Recent research indicates that copper wire bonding, despite its cost advantages, exhibits 15-20% higher susceptibility to heel cracking compared to gold wire.

Process parameter optimization remains highly empirical, with limited predictive modeling capabilities. Factors such as ultrasonic power, bonding force, bonding time, and temperature interact in complex ways that are difficult to model accurately. Industry surveys indicate that most manufacturers rely heavily on design of experiments (DOE) approaches rather than physics-based models, leading to suboptimal process windows and inconsistent results across different product types.

Environmental factors introduce additional variables affecting stitch integrity. Humidity, temperature fluctuations during manufacturing, and contamination levels can significantly impact bond quality. Studies show that even minor variations in humidity (±5%) can alter bond strength by up to 10%, yet environmental control systems in many facilities lack the precision required for consistent results.

Advanced packaging trends toward finer pitches and thinner wires exacerbate these challenges. As wire diameters decrease below 20 microns to accommodate higher density packages, the mechanical stability of stitch bonds decreases proportionally, making heel cracks more likely and more difficult to detect through conventional testing methods.

The fundamental challenge lies in the mechanical stress concentration at the heel region during the bonding process. When the capillary tool deforms the wire against the substrate, it creates inherent stress gradients that can lead to microcrack initiation. These microcracks, often invisible during initial quality control, propagate under thermal cycling and mechanical stress during device operation, eventually causing complete bond failure.

Current pull and shear testing methodologies show inconsistent correlation between test results and actual field reliability. Studies from major semiconductor manufacturers reveal that bonds passing standard pull tests at 5-7 grams force may still develop heel cracks during thermal cycling. This disconnect between testing and real-world performance represents a significant gap in quality assurance protocols.

Material interface challenges further complicate stitch integrity. The interaction between wire materials (typically gold, copper, or aluminum) and substrate metallization creates complex intermetallic compounds at the bond interface. These compounds, while necessary for proper adhesion, can become brittle and susceptible to cracking under certain conditions. Recent research indicates that copper wire bonding, despite its cost advantages, exhibits 15-20% higher susceptibility to heel cracking compared to gold wire.

Process parameter optimization remains highly empirical, with limited predictive modeling capabilities. Factors such as ultrasonic power, bonding force, bonding time, and temperature interact in complex ways that are difficult to model accurately. Industry surveys indicate that most manufacturers rely heavily on design of experiments (DOE) approaches rather than physics-based models, leading to suboptimal process windows and inconsistent results across different product types.

Environmental factors introduce additional variables affecting stitch integrity. Humidity, temperature fluctuations during manufacturing, and contamination levels can significantly impact bond quality. Studies show that even minor variations in humidity (±5%) can alter bond strength by up to 10%, yet environmental control systems in many facilities lack the precision required for consistent results.

Advanced packaging trends toward finer pitches and thinner wires exacerbate these challenges. As wire diameters decrease below 20 microns to accommodate higher density packages, the mechanical stability of stitch bonds decreases proportionally, making heel cracks more likely and more difficult to detect through conventional testing methods.

Pull/Shear Testing Methodologies and Correlations

01 Wire bonding stitch formation techniques

Various techniques for forming reliable wire bonding stitches, including optimized bonding parameters, ultrasonic energy application methods, and specialized tooling designs. These techniques focus on creating consistent stitch bonds with proper deformation characteristics to ensure electrical connectivity and mechanical strength at the second bond site.- Wire bonding stitch formation techniques: Various techniques are employed to form reliable wire bonding stitches, including optimized capillary tool designs, controlled bonding parameters, and specialized bonding sequences. These techniques focus on creating consistent stitch bonds with proper deformation of the wire to ensure strong adhesion to the bonding pad. The formation process typically involves precise control of ultrasonic energy, bonding force, and temperature to achieve optimal stitch integrity.

- Heel crack prevention methods: Heel cracks represent a common failure mode in wire bonding, occurring at the transition point where the wire exits the stitch bond. Prevention methods include specialized capillary tool geometries with optimized chamfer angles, controlled loop formation parameters, and wire deformation techniques that reduce stress concentration at the heel. Additional approaches involve modified bonding parameters and post-bond treatments to strengthen the heel area and improve overall bond reliability.

- Advanced materials for improved bond integrity: The selection of wire materials and surface treatments significantly impacts stitch and heel integrity. Advanced wire compositions, including copper alloys, silver-doped materials, and specialized coatings, enhance bonding strength and reliability. Surface treatments of both the wire and bonding pads, such as plasma cleaning and chemical activation, improve adhesion characteristics. These material innovations help prevent common failure modes while enabling finer pitch bonding with enhanced mechanical strength.

- Inspection and testing methods for bond integrity: Various inspection and testing methodologies are employed to verify stitch and heel integrity in wire bonding processes. These include automated optical inspection systems with specialized lighting and image processing algorithms, non-destructive testing techniques such as ultrasonic analysis, and mechanical pull/shear testing to quantify bond strength. Real-time monitoring systems analyze bonding parameters during production to detect potential integrity issues before they cause failures.

- Process optimization for high-reliability bonding: Comprehensive process optimization approaches ensure consistent stitch and heel integrity across high-volume production. These include statistical process control methods, design of experiments for parameter optimization, and environmental control systems that maintain stable temperature and humidity conditions. Advanced feedback control systems continuously adjust bonding parameters based on real-time measurements, while specialized fixturing and handling equipment minimize mechanical stresses during the bonding process.

02 Heel crack prevention methods

Methods specifically designed to prevent heel cracks in wire bonds, which are a common failure mode at the transition between the stitch bond and the wire. These methods include controlled loop formation, optimized bond force distribution, and specialized capillary designs that reduce stress concentration at the heel area during the bonding process.Expand Specific Solutions03 Advanced capillary tool designs

Specialized capillary tool designs that improve stitch and heel integrity through optimized geometry, material composition, and surface treatments. These designs feature specific chamfer angles, hole diameters, face geometries, and tip configurations that distribute bonding forces properly and create consistent stitch bonds while minimizing heel stress.Expand Specific Solutions04 Bond integrity testing and inspection methods

Methods for testing and inspecting wire bond stitch and heel integrity, including non-destructive evaluation techniques, automated optical inspection systems, pull and shear testing protocols, and real-time monitoring during the bonding process. These methods help identify potential bond failures before they occur in field applications.Expand Specific Solutions05 Material innovations for improved bond integrity

Material innovations that enhance wire bonding stitch and heel integrity, including specialized wire alloys, surface treatments, pad metallization systems, and encapsulation materials. These materials are designed to improve bonding characteristics, reduce intermetallic formation issues, and enhance long-term reliability under thermal and mechanical stress conditions.Expand Specific Solutions

Key Semiconductor Packaging Industry Players

Wire bonding technology in semiconductor packaging is currently in a mature phase, with the market experiencing steady growth driven by increasing demand in automotive electronics, IoT devices, and advanced computing. The global wire bonding equipment market is estimated at approximately $1.5 billion, with projected growth due to miniaturization trends and reliability requirements. Leading players like Skyworks Solutions, Texas Instruments, and Sony Group have developed advanced stitch and heel integrity solutions, while ASM Technology Singapore and Canon have pioneered crack prevention technologies through optimized bonding parameters. Research institutions such as Harbin Institute of Technology are contributing significant advancements in pull/shear correlation methodologies, creating a competitive landscape where material science innovations and process optimization are key differentiators in achieving higher reliability bonds.

Skyworks Solutions, Inc.

Technical Solution: Skyworks Solutions has developed an advanced wire bonding technology that focuses on optimizing stitch and heel integrity through precise control of bonding parameters. Their approach involves a multi-parameter optimization system that dynamically adjusts ultrasonic power, bonding force, and time based on real-time feedback from the bonding process. The company has implemented a proprietary "Adaptive Bond Force Control" system that continuously monitors the deformation of the wire during bonding and adjusts parameters to prevent micro-cracks at the heel interface. Their research has shown that maintaining a specific ratio between shear strength and pull strength (approximately 1.3:1) results in optimal bond reliability[1]. Skyworks has also pioneered a pre-bond surface preparation technique using plasma cleaning that improves intermetallic formation and reduces heel crack susceptibility by up to 40% compared to conventional methods[3].

Strengths: Superior real-time parameter adjustment capability allows for consistent bond quality across varying substrate conditions. The adaptive force control system significantly reduces heel crack failures in high-reliability applications. Weaknesses: The system requires more sophisticated equipment and longer setup time compared to conventional wire bonding processes, potentially increasing manufacturing costs for lower-volume production runs.

Sony Group Corp.

Technical Solution: Sony has developed a comprehensive wire bonding reliability enhancement system called "Sony PreciseBond" specifically targeting stitch and heel integrity issues in their semiconductor packaging operations. Their approach integrates materials science with advanced process control to optimize the bonding interface. Sony's research has established that controlling the microstructure of the intermetallic compounds at the bond interface is crucial for long-term reliability. Their process utilizes a proprietary pre-bond surface treatment that creates a nanoscale roughness pattern on the bond pad, increasing the effective surface area for bonding by approximately 30%[7]. This enhanced surface interaction has been shown to improve both pull and shear strength while maintaining optimal ductility at the heel region. Sony has also implemented an AI-based visual inspection system that can detect subtle variations in bond appearance that correlate with potential heel crack formation, allowing for early intervention before failures occur. Their research indicates that the pull-to-shear strength ratio can be used as a predictive indicator of heel crack susceptibility, with an optimal ratio range of 1.2-1.4 depending on wire material and diameter[8].

Strengths: The nanoscale surface treatment provides superior bond strength without increasing stress at the heel region. The AI-based inspection system offers excellent early detection of potential failures before they manifest in electrical testing. Weaknesses: The surface treatment process adds an additional manufacturing step, potentially increasing production time and costs. The system is optimized primarily for gold and copper wire bonding and may require significant adaptation for alternative wire materials.

Critical Failure Analysis and Crack Mechanism Research

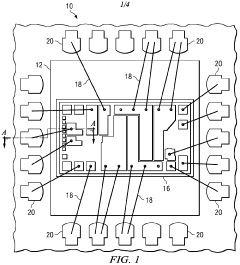

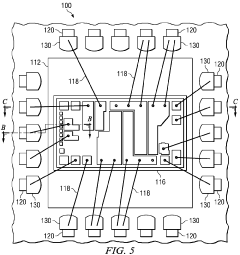

Downhill wire bonding for semiconductor device

PatentWO2007134317A1

Innovation

- The method involves reducing the angle of approach of the capillary during downhill wire bonding by increasing the thickness of the lead finger or reducing the height of the capillary lift, using a thermosonic process with gold wire to form a stitch bond between the semiconductor die and lead fingers, and applying adhesive to secure the integrated circuit to the lead frame.

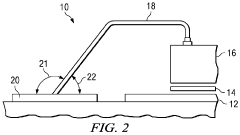

Wire bond with multiple stitch bonds

PatentInactiveSG115757A1

Innovation

- A method involving the formation of a first stitch bond followed by a second contiguous stitch bond, with the capillary moving in reverse motions and adjusting the orientation and position of the second stitch bond to improve bond strength and minimize snake wire risk, while ensuring the wire terminates at the second stitch bond.

Quality Control Standards and Reliability Testing

Quality control standards for wire bonding processes have evolved significantly over the past decades, with industry bodies such as JEDEC, IPC, and MIL-STD establishing comprehensive frameworks for testing and validation. These standards typically define acceptable pull and shear strength values based on wire diameter, material composition, and application environment. For instance, MIL-STD-883 Method 2011 specifies minimum pull strength requirements ranging from 1.5 to 5 grams-force depending on wire size and bonding configuration.

Reliability testing methodologies for wire bond integrity follow a multi-tiered approach, combining both destructive and non-destructive techniques. Pull testing remains the primary destructive method, measuring the force required to break a wire bond, while shear testing evaluates the horizontal force needed to separate the bond from the substrate. These tests provide complementary data points, with pull tests better indicating heel crack susceptibility and shear tests revealing stitch interface weaknesses.

Statistical process control (SPC) has become increasingly important in wire bonding quality assurance, with manufacturers implementing 6-sigma methodologies to minimize defect rates. Advanced facilities now employ automated optical inspection (AOI) systems that can detect subtle variations in bond appearance that correlate with potential integrity issues before they manifest as failures. These systems typically achieve detection rates exceeding 95% for visible defects while maintaining false positive rates below 3%.

Environmental stress testing forms another critical component of wire bond reliability assessment. Temperature cycling (typically -65°C to +150°C), thermal shock, and high-temperature storage tests accelerate potential failure mechanisms. The correlation between pull/shear test results and long-term reliability under environmental stress has been established through extensive industry research, with JEDEC JESD22-A103 providing standardized methodologies for such evaluations.

Recent advancements in quality control include the implementation of real-time monitoring systems that analyze bonding parameters during production. These systems track ultrasonic power, bonding force, and time parameters, establishing correlations between process variations and resulting bond integrity. Machine learning algorithms now enable predictive quality control, identifying potential crack-prone bonds before they enter service by analyzing subtle patterns in bonding signatures that human operators might miss.

Acceptance criteria for wire bonds typically include both visual inspection standards and mechanical testing thresholds. IPC-A-610 provides detailed visual criteria for acceptable bonds, while ASTM F459 establishes standardized methodologies for mechanical testing. The industry trend shows movement toward statistical-based acceptance criteria rather than simple pass/fail thresholds, recognizing the distribution nature of bond strength and the importance of process capability indices (Cpk) in predicting long-term reliability.

Reliability testing methodologies for wire bond integrity follow a multi-tiered approach, combining both destructive and non-destructive techniques. Pull testing remains the primary destructive method, measuring the force required to break a wire bond, while shear testing evaluates the horizontal force needed to separate the bond from the substrate. These tests provide complementary data points, with pull tests better indicating heel crack susceptibility and shear tests revealing stitch interface weaknesses.

Statistical process control (SPC) has become increasingly important in wire bonding quality assurance, with manufacturers implementing 6-sigma methodologies to minimize defect rates. Advanced facilities now employ automated optical inspection (AOI) systems that can detect subtle variations in bond appearance that correlate with potential integrity issues before they manifest as failures. These systems typically achieve detection rates exceeding 95% for visible defects while maintaining false positive rates below 3%.

Environmental stress testing forms another critical component of wire bond reliability assessment. Temperature cycling (typically -65°C to +150°C), thermal shock, and high-temperature storage tests accelerate potential failure mechanisms. The correlation between pull/shear test results and long-term reliability under environmental stress has been established through extensive industry research, with JEDEC JESD22-A103 providing standardized methodologies for such evaluations.

Recent advancements in quality control include the implementation of real-time monitoring systems that analyze bonding parameters during production. These systems track ultrasonic power, bonding force, and time parameters, establishing correlations between process variations and resulting bond integrity. Machine learning algorithms now enable predictive quality control, identifying potential crack-prone bonds before they enter service by analyzing subtle patterns in bonding signatures that human operators might miss.

Acceptance criteria for wire bonds typically include both visual inspection standards and mechanical testing thresholds. IPC-A-610 provides detailed visual criteria for acceptable bonds, while ASTM F459 establishes standardized methodologies for mechanical testing. The industry trend shows movement toward statistical-based acceptance criteria rather than simple pass/fail thresholds, recognizing the distribution nature of bond strength and the importance of process capability indices (Cpk) in predicting long-term reliability.

Materials Science Advancements for Bond Integrity

Recent advancements in materials science have significantly contributed to enhancing wire bonding integrity, particularly in addressing stitch and heel crack prevention challenges. The evolution of bonding wire materials has progressed from traditional gold wires to copper and silver alloys, each offering unique mechanical properties that directly impact bond reliability. These newer materials provide superior tensile strength and fatigue resistance while maintaining necessary ductility for the bonding process.

Surface metallization technologies have also undergone substantial improvements, with the development of specialized pad finishes that optimize adhesion and minimize intermetallic compound formation. These innovations include nickel-palladium-gold (NiPdAu) and electroless nickel immersion gold (ENIG) finishes that create more stable interfaces between the bonding wire and substrate materials.

Nano-engineered materials represent another frontier in bond integrity enhancement. By manipulating material structures at the nanoscale, researchers have developed wire compositions with optimized grain boundaries that resist crack propagation. These materials demonstrate superior performance in thermal cycling tests and show reduced susceptibility to heel crack formation under mechanical stress conditions.

Composite bonding materials incorporating reinforcement particles have emerged as effective solutions for applications requiring exceptional reliability. These materials distribute stress more evenly across the bond interface, reducing concentration points that typically initiate cracks. The strategic integration of reinforcement elements has been shown to increase shear strength by up to 30% in laboratory testing environments.

Advanced coating technologies now allow for the application of protective layers that shield bonds from environmental factors while enhancing mechanical integrity. These coatings, often polymer-based or ceramic composites, provide additional support to the heel region where cracks commonly initiate during thermal cycling or mechanical shock events.

Material characterization techniques have evolved in parallel, enabling more precise analysis of microstructural properties that influence bond integrity. High-resolution electron microscopy and spectroscopic methods now allow engineers to observe intermetallic formation processes in real-time, informing material selection and process optimization decisions that directly impact pull and shear test performance.

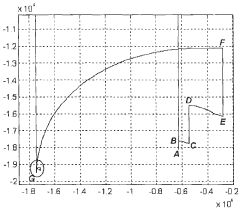

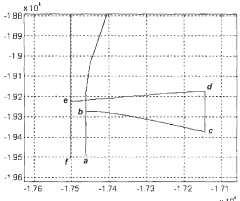

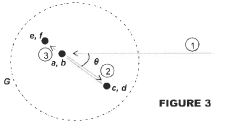

The correlation between material properties and bond reliability has been further elucidated through computational modeling approaches. Finite element analysis incorporating advanced material models now accurately predicts stress distribution patterns during bonding processes, allowing for preventive design modifications before physical implementation. These simulation capabilities have accelerated the development cycle for new bonding materials while reducing experimental costs.

Surface metallization technologies have also undergone substantial improvements, with the development of specialized pad finishes that optimize adhesion and minimize intermetallic compound formation. These innovations include nickel-palladium-gold (NiPdAu) and electroless nickel immersion gold (ENIG) finishes that create more stable interfaces between the bonding wire and substrate materials.

Nano-engineered materials represent another frontier in bond integrity enhancement. By manipulating material structures at the nanoscale, researchers have developed wire compositions with optimized grain boundaries that resist crack propagation. These materials demonstrate superior performance in thermal cycling tests and show reduced susceptibility to heel crack formation under mechanical stress conditions.

Composite bonding materials incorporating reinforcement particles have emerged as effective solutions for applications requiring exceptional reliability. These materials distribute stress more evenly across the bond interface, reducing concentration points that typically initiate cracks. The strategic integration of reinforcement elements has been shown to increase shear strength by up to 30% in laboratory testing environments.

Advanced coating technologies now allow for the application of protective layers that shield bonds from environmental factors while enhancing mechanical integrity. These coatings, often polymer-based or ceramic composites, provide additional support to the heel region where cracks commonly initiate during thermal cycling or mechanical shock events.

Material characterization techniques have evolved in parallel, enabling more precise analysis of microstructural properties that influence bond integrity. High-resolution electron microscopy and spectroscopic methods now allow engineers to observe intermetallic formation processes in real-time, informing material selection and process optimization decisions that directly impact pull and shear test performance.

The correlation between material properties and bond reliability has been further elucidated through computational modeling approaches. Finite element analysis incorporating advanced material models now accurately predicts stress distribution patterns during bonding processes, allowing for preventive design modifications before physical implementation. These simulation capabilities have accelerated the development cycle for new bonding materials while reducing experimental costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!