Wire Bonding Copper Wire: PCC Coatings, Oxidation Control And Reliability

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Copper Wire Bonding Technology Evolution and Objectives

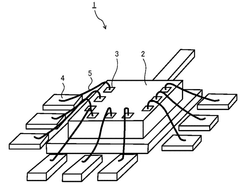

Wire bonding technology has evolved significantly since its inception in the 1950s, with copper wire emerging as a prominent alternative to gold in the semiconductor packaging industry. The transition from gold to copper wire bonding began in earnest during the early 2000s, driven primarily by the escalating cost of gold and the semiconductor industry's relentless pursuit of cost reduction. Copper, with its superior electrical and thermal conductivity, combined with its substantially lower cost, presented a compelling economic case for this transition.

The evolution of copper wire bonding technology has been marked by several key milestones. Initially, the industry faced significant challenges related to copper's inherent properties, particularly its susceptibility to oxidation and higher hardness compared to gold. These characteristics necessitated the development of specialized bonding equipment capable of delivering higher ultrasonic energy and force. Early implementations in the mid-2000s demonstrated the feasibility of copper wire bonding, but reliability concerns persisted.

By the late 2000s, significant advancements in palladium-coated copper (PCC) wire technology emerged as a pivotal development. These coatings provided enhanced oxidation resistance while maintaining the economic advantages of copper. The industry subsequently witnessed rapid adoption across various semiconductor packaging applications, particularly in consumer electronics and automotive sectors.

The current technological landscape features sophisticated PCC wire solutions with optimized coating compositions and thicknesses, designed to balance oxidation protection with bondability characteristics. Advanced process control systems have been developed to manage the more stringent bonding parameters required for copper wire, ensuring consistent bond quality across high-volume manufacturing environments.

Looking forward, the primary objectives for copper wire bonding technology center around several key areas. First, enhancing the reliability of copper wire bonds under increasingly demanding environmental conditions, particularly for automotive and industrial applications where extended temperature ranges and longer operational lifetimes are required. Second, developing more effective oxidation control strategies beyond current PCC technologies to further improve shelf life and process windows.

Additionally, the industry aims to refine bonding processes for ultra-fine pitch applications as semiconductor devices continue to shrink. This includes optimizing wire diameters below 15 micrometers while maintaining mechanical integrity and electrical performance. Finally, there is a focused effort on developing environmentally sustainable manufacturing processes that reduce chemical usage and energy consumption during the wire bonding operation, aligning with broader industry sustainability initiatives.

The evolution of copper wire bonding technology has been marked by several key milestones. Initially, the industry faced significant challenges related to copper's inherent properties, particularly its susceptibility to oxidation and higher hardness compared to gold. These characteristics necessitated the development of specialized bonding equipment capable of delivering higher ultrasonic energy and force. Early implementations in the mid-2000s demonstrated the feasibility of copper wire bonding, but reliability concerns persisted.

By the late 2000s, significant advancements in palladium-coated copper (PCC) wire technology emerged as a pivotal development. These coatings provided enhanced oxidation resistance while maintaining the economic advantages of copper. The industry subsequently witnessed rapid adoption across various semiconductor packaging applications, particularly in consumer electronics and automotive sectors.

The current technological landscape features sophisticated PCC wire solutions with optimized coating compositions and thicknesses, designed to balance oxidation protection with bondability characteristics. Advanced process control systems have been developed to manage the more stringent bonding parameters required for copper wire, ensuring consistent bond quality across high-volume manufacturing environments.

Looking forward, the primary objectives for copper wire bonding technology center around several key areas. First, enhancing the reliability of copper wire bonds under increasingly demanding environmental conditions, particularly for automotive and industrial applications where extended temperature ranges and longer operational lifetimes are required. Second, developing more effective oxidation control strategies beyond current PCC technologies to further improve shelf life and process windows.

Additionally, the industry aims to refine bonding processes for ultra-fine pitch applications as semiconductor devices continue to shrink. This includes optimizing wire diameters below 15 micrometers while maintaining mechanical integrity and electrical performance. Finally, there is a focused effort on developing environmentally sustainable manufacturing processes that reduce chemical usage and energy consumption during the wire bonding operation, aligning with broader industry sustainability initiatives.

Market Demand Analysis for Advanced Copper Wire Bonding Solutions

The global market for copper wire bonding solutions has experienced significant growth in recent years, driven primarily by the semiconductor and electronics manufacturing industries. As of 2023, the copper wire bonding market is valued at approximately 2.5 billion USD, with projections indicating a compound annual growth rate of 5.7% through 2028. This growth trajectory is underpinned by the increasing demand for more reliable, cost-effective interconnection technologies in advanced semiconductor packaging.

The transition from gold to copper wire bonding represents one of the most significant shifts in semiconductor packaging technology over the past decade. Cost considerations remain a primary market driver, with copper wire offering up to 75% cost reduction compared to gold alternatives. This economic advantage has accelerated adoption across various semiconductor applications, particularly in consumer electronics, automotive systems, and industrial equipment.

Market research indicates that approximately 80% of all wire bonding applications now utilize copper wire, with the remaining 20% split between gold and silver alloys for specialized applications. This market penetration is expected to increase further as technical challenges related to copper oxidation and reliability are addressed through advanced coating technologies like Palladium-Coated Copper (PCC) solutions.

The demand for PCC wire bonding solutions specifically has shown remarkable growth, with a market segment expansion of 15% annually since 2020. This surge is attributed to the superior oxidation resistance and reliability characteristics of PCC-coated copper wire, which addresses key concerns in high-reliability applications such as automotive electronics, medical devices, and aerospace systems.

Regional analysis reveals that Asia-Pacific dominates the copper wire bonding market, accounting for over 65% of global demand, with particular concentration in manufacturing hubs across China, Taiwan, South Korea, and Malaysia. North America and Europe follow with approximately 18% and 12% market share respectively, primarily driven by high-reliability applications in automotive, defense, and medical sectors.

Industry surveys indicate that manufacturers are increasingly prioritizing reliability over initial cost savings, with 78% of semiconductor packaging companies citing long-term reliability as their primary consideration when selecting wire bonding materials. This shift in priorities has created substantial market opportunities for advanced copper wire solutions with enhanced oxidation control capabilities.

The market for copper wire bonding is further segmented by wire diameter, with fine wire (≤20μm) applications growing at 9.3% annually, outpacing standard wire applications. This trend reflects the industry's move toward higher density packaging and miniaturization across multiple application domains.

AI and IoT applications are emerging as significant growth drivers, with these sectors expected to generate over 30% of new demand for advanced copper wire bonding solutions by 2025. These applications typically require higher reliability standards and improved thermal performance, characteristics that align well with the benefits offered by PCC-coated copper wire technologies.

The transition from gold to copper wire bonding represents one of the most significant shifts in semiconductor packaging technology over the past decade. Cost considerations remain a primary market driver, with copper wire offering up to 75% cost reduction compared to gold alternatives. This economic advantage has accelerated adoption across various semiconductor applications, particularly in consumer electronics, automotive systems, and industrial equipment.

Market research indicates that approximately 80% of all wire bonding applications now utilize copper wire, with the remaining 20% split between gold and silver alloys for specialized applications. This market penetration is expected to increase further as technical challenges related to copper oxidation and reliability are addressed through advanced coating technologies like Palladium-Coated Copper (PCC) solutions.

The demand for PCC wire bonding solutions specifically has shown remarkable growth, with a market segment expansion of 15% annually since 2020. This surge is attributed to the superior oxidation resistance and reliability characteristics of PCC-coated copper wire, which addresses key concerns in high-reliability applications such as automotive electronics, medical devices, and aerospace systems.

Regional analysis reveals that Asia-Pacific dominates the copper wire bonding market, accounting for over 65% of global demand, with particular concentration in manufacturing hubs across China, Taiwan, South Korea, and Malaysia. North America and Europe follow with approximately 18% and 12% market share respectively, primarily driven by high-reliability applications in automotive, defense, and medical sectors.

Industry surveys indicate that manufacturers are increasingly prioritizing reliability over initial cost savings, with 78% of semiconductor packaging companies citing long-term reliability as their primary consideration when selecting wire bonding materials. This shift in priorities has created substantial market opportunities for advanced copper wire solutions with enhanced oxidation control capabilities.

The market for copper wire bonding is further segmented by wire diameter, with fine wire (≤20μm) applications growing at 9.3% annually, outpacing standard wire applications. This trend reflects the industry's move toward higher density packaging and miniaturization across multiple application domains.

AI and IoT applications are emerging as significant growth drivers, with these sectors expected to generate over 30% of new demand for advanced copper wire bonding solutions by 2025. These applications typically require higher reliability standards and improved thermal performance, characteristics that align well with the benefits offered by PCC-coated copper wire technologies.

Current Challenges in Copper Wire Bonding and PCC Coating Technologies

Copper wire bonding has become the predominant interconnection technology in semiconductor packaging due to its cost-effectiveness compared to gold wire. However, this transition has introduced significant technical challenges that continue to impact manufacturing processes and long-term reliability. The primary concern with copper wire is its high susceptibility to oxidation when exposed to atmospheric conditions, which drastically affects bondability and reliability performance.

The oxidation of copper wire occurs rapidly at room temperature and accelerates at elevated temperatures during the bonding process, forming copper oxide layers that interfere with proper metallic bonding. This oxidation challenge necessitates specialized handling protocols, including inert gas environments during storage and transportation, which adds complexity and cost to manufacturing operations.

Palladium-coated copper (PCC) wire emerged as a solution to address these oxidation issues. The palladium coating provides a protective barrier that significantly reduces copper oxidation while maintaining electrical conductivity. However, PCC wire introduces its own set of challenges. The coating thickness must be precisely controlled – too thin fails to provide adequate protection, while too thick affects the wire's mechanical properties and bondability characteristics.

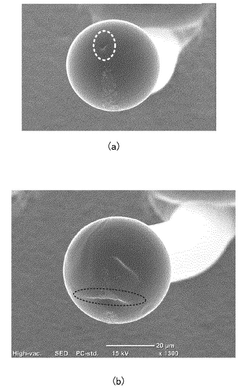

Uniformity of PCC coatings represents another critical challenge. Inconsistent coating distribution leads to variable performance across different sections of the wire, resulting in unpredictable bonding quality and reliability issues. Manufacturing processes must ensure homogeneous palladium distribution around the copper core, which requires sophisticated deposition techniques and quality control measures.

Intermetallic compound (IMC) formation between copper and aluminum bond pads presents additional reliability concerns. The rapid diffusion and formation of brittle Cu-Al intermetallics can lead to bond degradation over time, particularly under thermal cycling conditions. PCC wire must be engineered to moderate this IMC growth rate while maintaining strong initial bonds.

The industry also faces challenges with wire bonding parameters optimization for PCC wire. The presence of the palladium coating alters the thermosonic bonding dynamics, requiring different ultrasonic energy, bonding force, and temperature parameters compared to pure copper or gold wire. These parameters must be carefully calibrated for each specific application to achieve optimal bond strength and reliability.

Environmental testing has revealed that despite palladium coating protection, PCC wire bonds can still exhibit vulnerability to harsh conditions, particularly in automotive and industrial applications where extreme temperatures and corrosive environments are common. Enhancing the corrosion resistance of PCC wire bonds without compromising electrical performance remains an ongoing challenge for the industry.

The oxidation of copper wire occurs rapidly at room temperature and accelerates at elevated temperatures during the bonding process, forming copper oxide layers that interfere with proper metallic bonding. This oxidation challenge necessitates specialized handling protocols, including inert gas environments during storage and transportation, which adds complexity and cost to manufacturing operations.

Palladium-coated copper (PCC) wire emerged as a solution to address these oxidation issues. The palladium coating provides a protective barrier that significantly reduces copper oxidation while maintaining electrical conductivity. However, PCC wire introduces its own set of challenges. The coating thickness must be precisely controlled – too thin fails to provide adequate protection, while too thick affects the wire's mechanical properties and bondability characteristics.

Uniformity of PCC coatings represents another critical challenge. Inconsistent coating distribution leads to variable performance across different sections of the wire, resulting in unpredictable bonding quality and reliability issues. Manufacturing processes must ensure homogeneous palladium distribution around the copper core, which requires sophisticated deposition techniques and quality control measures.

Intermetallic compound (IMC) formation between copper and aluminum bond pads presents additional reliability concerns. The rapid diffusion and formation of brittle Cu-Al intermetallics can lead to bond degradation over time, particularly under thermal cycling conditions. PCC wire must be engineered to moderate this IMC growth rate while maintaining strong initial bonds.

The industry also faces challenges with wire bonding parameters optimization for PCC wire. The presence of the palladium coating alters the thermosonic bonding dynamics, requiring different ultrasonic energy, bonding force, and temperature parameters compared to pure copper or gold wire. These parameters must be carefully calibrated for each specific application to achieve optimal bond strength and reliability.

Environmental testing has revealed that despite palladium coating protection, PCC wire bonds can still exhibit vulnerability to harsh conditions, particularly in automotive and industrial applications where extreme temperatures and corrosive environments are common. Enhancing the corrosion resistance of PCC wire bonds without compromising electrical performance remains an ongoing challenge for the industry.

Current PCC Coating and Oxidation Control Methodologies

01 PCC coatings for copper wire oxidation control

Palladium-coated copper (PCC) wire bonding technology provides effective oxidation control for copper wires used in semiconductor packaging. The palladium coating acts as a protective layer that prevents copper oxidation during storage and processing, enhancing reliability and extending shelf life. These coatings are typically applied through electroplating or electroless deposition methods to achieve uniform coverage while maintaining the electrical and mechanical properties of the copper wire.- PCC coatings for copper wire oxidation control: Palladium-coated copper (PCC) wire bonding technology provides effective oxidation control for copper wires used in semiconductor packaging. The palladium coating acts as a barrier that prevents copper oxidation, which is crucial for maintaining wire bonding reliability. These coatings are typically applied through electroplating or other deposition methods to create a thin, uniform layer that protects the copper core while maintaining good electrical conductivity and mechanical properties.

- Wire bonding process optimization for coated copper wires: Optimizing the wire bonding process for PCC-coated copper wires involves controlling key parameters such as bonding force, ultrasonic power, bonding time, and temperature. These parameters must be carefully calibrated to accommodate the unique properties of coated copper wires. Advanced bonding techniques may include specialized capillary designs, optimized bonding profiles, and controlled atmospheric conditions during the bonding process to enhance bond reliability and prevent coating damage while ensuring proper intermetallic formation between the wire and bond pad.

- Reliability enhancement techniques for copper wire bonds: Various techniques can be employed to enhance the reliability of copper wire bonds with protective coatings. These include surface preparation methods for bond pads, post-bond heat treatments to improve intermetallic compound formation, encapsulation technologies to prevent environmental degradation, and stress relief designs to accommodate coefficient of thermal expansion mismatches. Additionally, specialized loop profiles and multi-tier bonding approaches can be implemented to reduce mechanical stress on the bonds during thermal cycling and other reliability tests.

- Advanced coating compositions and structures: Advanced coating compositions for copper wire bonding applications feature multi-layer structures or specialized alloy formulations. These may include palladium-based alloys with additional elements like gold, silver, or platinum to enhance specific properties. Some coatings utilize gradient compositions or sandwich structures with different metals to optimize both oxidation resistance and bondability. Nano-engineered coating structures can provide superior protection while maintaining the necessary ductility and electrical performance required for reliable wire bonding applications.

- Testing and quality control methods for coated copper wire bonds: Specialized testing and quality control methods are essential for ensuring the reliability of PCC-coated copper wire bonds. These include accelerated aging tests, thermal cycling, high-temperature storage tests, and humidity tests to evaluate long-term performance. Advanced analytical techniques such as scanning electron microscopy, energy-dispersive X-ray spectroscopy, and focused ion beam analysis are used to characterize the coating integrity, intermetallic formation, and failure mechanisms. In-line process monitoring systems may employ real-time bond quality assessment through parameters like ultrasonic response and deformation characteristics.

02 Wire bonding process optimization for coated copper wires

Optimizing the wire bonding process for PCC-coated copper wires involves controlling key parameters such as bonding force, ultrasonic power, bonding time, and temperature. These parameters must be carefully adjusted to accommodate the unique properties of coated copper wires compared to traditional gold or uncoated copper wires. Advanced bonding techniques and equipment modifications help ensure reliable intermetallic connections while preventing coating damage during the bonding process, resulting in improved bond strength and long-term reliability.Expand Specific Solutions03 Multi-layer coating structures for enhanced reliability

Multi-layer coating structures on copper bonding wires provide enhanced reliability through complementary protective mechanisms. These structures typically consist of a palladium base layer for oxidation resistance, combined with additional metal layers such as gold, silver, or platinum to improve bondability and corrosion resistance. The thickness and composition of each layer are carefully engineered to optimize performance while maintaining wire ductility and electrical conductivity. This approach addresses multiple reliability concerns including oxidation control, intermetallic formation, and environmental stability.Expand Specific Solutions04 Heat treatment and surface preparation techniques

Heat treatment and surface preparation techniques are critical for optimizing the performance of PCC-coated copper bonding wires. Controlled annealing processes help relieve internal stresses in the wire and promote uniform coating adhesion. Surface cleaning and activation treatments prior to coating application ensure strong metallurgical bonding between the copper core and palladium coating. Post-coating heat treatments can further enhance coating integrity and optimize the microstructure for improved reliability during subsequent bonding operations and in-service conditions.Expand Specific Solutions05 Reliability testing and failure analysis methods

Comprehensive reliability testing and failure analysis methods are essential for validating PCC-coated copper wire performance in semiconductor applications. These include high-temperature storage tests, temperature cycling, humidity testing, and electromigration evaluation to assess long-term stability. Advanced analytical techniques such as scanning electron microscopy, energy-dispersive X-ray spectroscopy, and focused ion beam analysis help identify failure mechanisms related to coating defects, intermetallic compound formation, or oxidation breakthrough. Standardized testing protocols enable meaningful comparison between different coating technologies and process optimizations.Expand Specific Solutions

Key Industry Players in Copper Wire Bonding and Coating Solutions

The wire bonding copper wire market is currently in a growth phase, driven by increasing demand for cost-effective semiconductor packaging solutions. The global market size is expanding steadily, with Asia-Pacific dominating production and consumption. Technologically, the industry is maturing with innovations focused on PCC coatings and oxidation control to enhance reliability. Key players include established Japanese manufacturers like Nippon Micrometal, Tanaka Denshi Kogyo, and Sumitomo Electric Industries, alongside emerging competitors such as MK Electron and Wuhu Changrun. European presence is maintained by Heraeus and Atotech, while research institutions like IMEC and the Institute of Metal Research are advancing next-generation solutions. The competitive landscape features increasing collaboration between material suppliers and semiconductor manufacturers to address reliability challenges in high-performance applications.

Nippon Micrometal Corp.

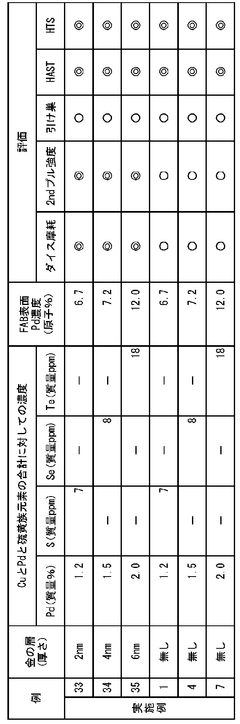

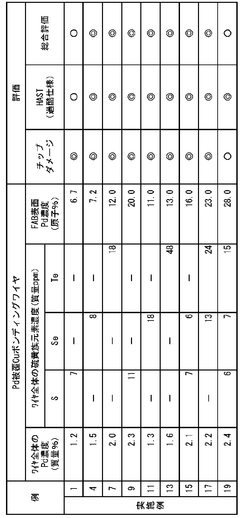

Technical Solution: Nippon Micrometal has developed advanced PCC (Palladium-Coated Copper) wire bonding solutions that address oxidation challenges in copper wire bonding. Their proprietary coating technology applies an ultra-thin palladium layer (typically 0.01-0.05 μm) on copper wire surfaces, effectively preventing oxidation while maintaining excellent electrical conductivity. The company's latest generation PCC wire features a multi-layer coating structure with optimized palladium distribution that enhances bond reliability under high-temperature conditions. Their technology includes specialized surface treatment processes that improve adhesion between the palladium coating and copper substrate, preventing delamination during the wire bonding process. Nippon Micrometal has also developed unique annealing techniques that reduce internal stress in the coated wire, resulting in improved loop formability and reduced risk of wire breakage during the bonding process.

Strengths: Superior oxidation resistance while maintaining high electrical conductivity; excellent bond reliability under high-temperature conditions; improved loop control and formability. Weaknesses: Higher cost compared to uncoated copper wire; requires specialized bonding parameters; potential for palladium price volatility affecting manufacturing costs.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric has developed an advanced PCC wire bonding solution called "SEI-Cu-Pd" that addresses copper oxidation challenges through innovative coating technology. Their approach utilizes a precisely controlled palladium coating process that creates an ultra-thin protective layer (typically 0.02-0.04 μm) while maintaining the wire's mechanical integrity and electrical performance. Sumitomo's proprietary coating technology employs a specialized electrochemical deposition process that ensures uniform palladium distribution across the wire surface, eliminating potential weak points for oxidation. Their technology incorporates a unique pre-coating surface treatment that enhances palladium adhesion to the copper substrate, preventing delamination during thermal cycling and mechanical stress. Sumitomo has also developed specialized annealing techniques that optimize the microstructure of both the copper core and palladium coating, resulting in improved wire ductility and loop formability. Additionally, their latest generation SEI-Cu-Pd wire features trace element doping in the copper core that enhances mechanical strength and fatigue resistance without compromising electrical conductivity.

Strengths: Excellent oxidation resistance with minimal impact on electrical performance; superior bond reliability under high-temperature conditions; consistent wire looping characteristics; good compatibility with existing bonding equipment. Weaknesses: Higher cost compared to standard copper wire; requires specific bonding parameters for optimal performance; potential for increased brittleness if coating thickness is not precisely controlled.

Critical Patents and Innovations in Copper Wire Bonding Technology

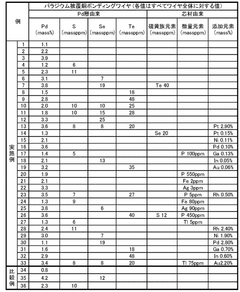

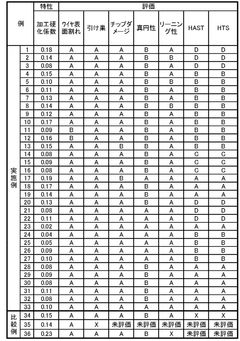

Palladium-coated copper bonding wire, method for producing palladium-coated copper bonding wire, semiconductor device using same, and method for producing same

PatentWO2020246094A1

Innovation

- A palladium-coated copper bonding wire with a palladium concentration of 1.0 to 4.0% and a work hardening coefficient of 0.20 or less, containing sulfur group elements and trace elements like Au, Pd, Pt, Rh, Ni, In, Ga, P, Ag, Fe, and Tl, is developed, along with a manufacturing method that includes intermediate heat treatment and gold layer coating to enhance bonding reliability and prevent leaning.

Palladium-coated copper bonding wire and method for manufacturing same

PatentWO2020110313A1

Innovation

- A palladium-coated copper bonding wire with a sulfur group element, where the palladium concentration is between 1.0% to 4.0% by mass and the sulfur group element concentration is 50 mass ppm or less, forming a palladium-enriched region on the wire tip to prevent shrinkage cavities and enhance bonding reliability.

Environmental Impact and Sustainability of Copper Wire Bonding Processes

The copper wire bonding industry has been evolving toward more environmentally sustainable practices in response to global environmental regulations and corporate sustainability initiatives. Traditional gold wire bonding processes have been largely replaced by copper wire alternatives, primarily due to cost considerations, but this transition has also yielded significant environmental benefits that warrant examination.

Copper wire bonding processes demonstrate substantially lower environmental impact compared to gold wire alternatives when assessed through comprehensive life cycle analysis. The extraction and processing of copper requires approximately 85% less energy than gold, resulting in a significantly reduced carbon footprint across the semiconductor manufacturing supply chain. This energy efficiency translates to an estimated reduction of 40-60% in greenhouse gas emissions for equivalent production volumes.

Water consumption represents another critical environmental consideration in wire bonding operations. Copper processing typically consumes 30-45% less water than gold extraction and refinement processes. However, copper oxidation prevention measures, particularly PCC (Palladium-Coated Copper) coating applications, introduce additional chemical processes that partially offset these water conservation advantages.

The chemical waste profile of copper wire bonding presents both challenges and opportunities for sustainability improvement. While copper itself is less environmentally persistent than gold, the oxidation control chemicals used in manufacturing—including various acids, solvents, and palladium compounds—require sophisticated waste management protocols. Advanced facilities have implemented closed-loop chemical recovery systems that recapture and reuse up to 70% of process chemicals, substantially reducing hazardous waste generation.

Regulatory compliance frameworks worldwide are increasingly emphasizing reduced heavy metal usage in electronic components. Copper wire bonding aligns with these directives, including the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations. The industry has responded by developing PCC coating formulations with minimized environmental persistence and bioaccumulation potential.

End-of-life considerations reveal additional sustainability advantages for copper wire bonded components. The recyclability of copper exceeds 90% with minimal quality degradation through multiple recycling cycles, compared to more complex recovery processes required for gold. This circular economy potential significantly reduces the life-cycle environmental impact of semiconductor devices utilizing copper wire bonding technology.

Recent innovations in PCC coating technologies have focused on developing water-based formulations that eliminate volatile organic compounds (VOCs) while maintaining oxidation protection performance. These next-generation coatings reduce air quality impacts during manufacturing while enhancing workplace safety conditions. Industry leaders have reported VOC emission reductions exceeding 65% through implementation of these advanced coating systems.

Copper wire bonding processes demonstrate substantially lower environmental impact compared to gold wire alternatives when assessed through comprehensive life cycle analysis. The extraction and processing of copper requires approximately 85% less energy than gold, resulting in a significantly reduced carbon footprint across the semiconductor manufacturing supply chain. This energy efficiency translates to an estimated reduction of 40-60% in greenhouse gas emissions for equivalent production volumes.

Water consumption represents another critical environmental consideration in wire bonding operations. Copper processing typically consumes 30-45% less water than gold extraction and refinement processes. However, copper oxidation prevention measures, particularly PCC (Palladium-Coated Copper) coating applications, introduce additional chemical processes that partially offset these water conservation advantages.

The chemical waste profile of copper wire bonding presents both challenges and opportunities for sustainability improvement. While copper itself is less environmentally persistent than gold, the oxidation control chemicals used in manufacturing—including various acids, solvents, and palladium compounds—require sophisticated waste management protocols. Advanced facilities have implemented closed-loop chemical recovery systems that recapture and reuse up to 70% of process chemicals, substantially reducing hazardous waste generation.

Regulatory compliance frameworks worldwide are increasingly emphasizing reduced heavy metal usage in electronic components. Copper wire bonding aligns with these directives, including the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations. The industry has responded by developing PCC coating formulations with minimized environmental persistence and bioaccumulation potential.

End-of-life considerations reveal additional sustainability advantages for copper wire bonded components. The recyclability of copper exceeds 90% with minimal quality degradation through multiple recycling cycles, compared to more complex recovery processes required for gold. This circular economy potential significantly reduces the life-cycle environmental impact of semiconductor devices utilizing copper wire bonding technology.

Recent innovations in PCC coating technologies have focused on developing water-based formulations that eliminate volatile organic compounds (VOCs) while maintaining oxidation protection performance. These next-generation coatings reduce air quality impacts during manufacturing while enhancing workplace safety conditions. Industry leaders have reported VOC emission reductions exceeding 65% through implementation of these advanced coating systems.

Cost-Benefit Analysis of PCC-Coated Copper Wire Implementation

The implementation of PCC-coated copper wire in wire bonding applications presents a complex cost-benefit equation that requires thorough analysis. Initial investment costs for transitioning from traditional gold wire to PCC-coated copper wire are substantial, including equipment modifications, staff training, and process optimization. These upfront expenditures typically range from $150,000 to $500,000 depending on production scale and existing infrastructure.

However, the material cost savings are significant and provide compelling long-term economic benefits. Gold wire currently costs approximately $45-55 per gram, while PCC-coated copper wire ranges from $3-7 per gram. For high-volume manufacturing operations producing millions of interconnections annually, this represents potential material cost reductions of 80-90%.

Return on investment calculations indicate that most semiconductor manufacturing operations can recoup transition costs within 6-18 months, depending on production volume. A mid-sized facility processing 10,000 wafers monthly can expect annual savings of $1.2-2.5 million after the transition period.

Quality-related costs must also be factored into the analysis. While PCC coatings significantly improve copper wire's resistance to oxidation and corrosion, the technology still exhibits slightly higher defect rates than gold wire in certain applications—approximately 50-100 parts per million higher in high-humidity environments. This translates to potential warranty and reliability costs that partially offset material savings.

Maintenance requirements represent another cost consideration. PCC-coated copper wire bonding equipment typically requires 15-20% more frequent maintenance than gold wire systems due to the harder material properties of copper and coating interactions with bonding tools. This increases both scheduled downtime and maintenance labor costs.

Energy consumption during the bonding process increases by approximately 10-15% with PCC-coated copper wire due to higher ultrasonic power requirements, though this represents a relatively minor cost factor in the overall analysis.

The environmental impact assessment reveals additional economic benefits through reduced carbon footprint and compliance with increasingly stringent environmental regulations. PCC-coated copper wire manufacturing generates approximately 60% less CO2 equivalent emissions compared to gold wire production, potentially qualifying manufacturers for carbon credits or tax incentives in certain jurisdictions.

However, the material cost savings are significant and provide compelling long-term economic benefits. Gold wire currently costs approximately $45-55 per gram, while PCC-coated copper wire ranges from $3-7 per gram. For high-volume manufacturing operations producing millions of interconnections annually, this represents potential material cost reductions of 80-90%.

Return on investment calculations indicate that most semiconductor manufacturing operations can recoup transition costs within 6-18 months, depending on production volume. A mid-sized facility processing 10,000 wafers monthly can expect annual savings of $1.2-2.5 million after the transition period.

Quality-related costs must also be factored into the analysis. While PCC coatings significantly improve copper wire's resistance to oxidation and corrosion, the technology still exhibits slightly higher defect rates than gold wire in certain applications—approximately 50-100 parts per million higher in high-humidity environments. This translates to potential warranty and reliability costs that partially offset material savings.

Maintenance requirements represent another cost consideration. PCC-coated copper wire bonding equipment typically requires 15-20% more frequent maintenance than gold wire systems due to the harder material properties of copper and coating interactions with bonding tools. This increases both scheduled downtime and maintenance labor costs.

Energy consumption during the bonding process increases by approximately 10-15% with PCC-coated copper wire due to higher ultrasonic power requirements, though this represents a relatively minor cost factor in the overall analysis.

The environmental impact assessment reveals additional economic benefits through reduced carbon footprint and compliance with increasingly stringent environmental regulations. PCC-coated copper wire manufacturing generates approximately 60% less CO2 equivalent emissions compared to gold wire production, potentially qualifying manufacturers for carbon credits or tax incentives in certain jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!