Wire Bonding Automotive/AEC-Q Qualification: THB, HAST And Power Cycling

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wire Bonding Automotive Qualification Background and Objectives

Wire bonding technology has evolved significantly over the past five decades, becoming a cornerstone of semiconductor packaging in automotive applications. Initially developed in the 1950s, wire bonding has transitioned from manual processes to highly automated systems capable of creating thousands of interconnections per hour. The automotive industry has embraced this technology due to its reliability, cost-effectiveness, and adaptability to harsh operating environments.

The evolution of wire bonding in automotive applications has been driven by increasing electronic content in vehicles, with modern cars containing up to 150 electronic control units. This proliferation has necessitated more robust qualification standards, particularly as vehicles incorporate advanced driver assistance systems (ADAS) and autonomous driving capabilities that demand zero-failure tolerance.

AEC-Q qualification, established by the Automotive Electronics Council, has become the industry benchmark for ensuring semiconductor components can withstand automotive operating conditions. Within this framework, Temperature Humidity Bias (THB), Highly Accelerated Stress Test (HAST), and Power Cycling have emerged as critical testing methodologies for wire bonding reliability assessment.

THB testing evaluates a component's resistance to moisture penetration under bias conditions, typically at 85°C and 85% relative humidity for 1000 hours. HAST accelerates this process by increasing temperature and pressure, providing faster results while maintaining correlation with traditional humidity tests. Power cycling assesses thermal fatigue resistance by subjecting components to repeated heating and cooling cycles that simulate real-world operation.

The primary objective of wire bonding qualification for automotive applications is to ensure long-term reliability under extreme conditions. Vehicles must operate reliably across temperature ranges from -40°C to 125°C, withstand vibration, thermal cycling, and exposure to various chemicals and contaminants. Additionally, automotive components must maintain functionality for 15+ years and 150,000+ miles without significant degradation.

Recent technological advancements have introduced copper wire as an alternative to gold, offering cost benefits and improved electrical and thermal performance. However, this transition has introduced new challenges in oxidation resistance and bonding parameters that must be addressed through refined qualification processes.

The industry is currently focused on developing qualification methodologies that accurately predict field performance while accommodating emerging technologies like wide bandgap semiconductors (SiC and GaN) that operate at higher temperatures and power densities. These advanced applications require enhanced wire bonding solutions and corresponding qualification standards to ensure reliability in next-generation automotive systems.

The evolution of wire bonding in automotive applications has been driven by increasing electronic content in vehicles, with modern cars containing up to 150 electronic control units. This proliferation has necessitated more robust qualification standards, particularly as vehicles incorporate advanced driver assistance systems (ADAS) and autonomous driving capabilities that demand zero-failure tolerance.

AEC-Q qualification, established by the Automotive Electronics Council, has become the industry benchmark for ensuring semiconductor components can withstand automotive operating conditions. Within this framework, Temperature Humidity Bias (THB), Highly Accelerated Stress Test (HAST), and Power Cycling have emerged as critical testing methodologies for wire bonding reliability assessment.

THB testing evaluates a component's resistance to moisture penetration under bias conditions, typically at 85°C and 85% relative humidity for 1000 hours. HAST accelerates this process by increasing temperature and pressure, providing faster results while maintaining correlation with traditional humidity tests. Power cycling assesses thermal fatigue resistance by subjecting components to repeated heating and cooling cycles that simulate real-world operation.

The primary objective of wire bonding qualification for automotive applications is to ensure long-term reliability under extreme conditions. Vehicles must operate reliably across temperature ranges from -40°C to 125°C, withstand vibration, thermal cycling, and exposure to various chemicals and contaminants. Additionally, automotive components must maintain functionality for 15+ years and 150,000+ miles without significant degradation.

Recent technological advancements have introduced copper wire as an alternative to gold, offering cost benefits and improved electrical and thermal performance. However, this transition has introduced new challenges in oxidation resistance and bonding parameters that must be addressed through refined qualification processes.

The industry is currently focused on developing qualification methodologies that accurately predict field performance while accommodating emerging technologies like wide bandgap semiconductors (SiC and GaN) that operate at higher temperatures and power densities. These advanced applications require enhanced wire bonding solutions and corresponding qualification standards to ensure reliability in next-generation automotive systems.

Market Demand Analysis for AEC-Q Qualified Wire Bonding

The automotive semiconductor market is experiencing robust growth, with wire bonding technology playing a crucial role in connecting semiconductor devices to their packages. The demand for AEC-Q qualified wire bonding solutions is primarily driven by the increasing electronic content in modern vehicles, particularly in advanced driver-assistance systems (ADAS), infotainment systems, and powertrain control modules.

Market research indicates that the global automotive semiconductor market is projected to grow at a compound annual growth rate of 8.5% through 2028, with wire bonding representing a significant portion of the packaging technologies employed. The electrification trend in the automotive industry has further accelerated this demand, as electric vehicles require approximately twice the semiconductor content of traditional internal combustion engine vehicles.

Tier-1 automotive suppliers and OEMs are increasingly demanding components that can withstand harsh automotive environments, creating a substantial market for AEC-Q qualified wire bonding solutions. The qualification processes focusing on Temperature Humidity Bias (THB), Highly Accelerated Stress Test (HAST), and Power Cycling have become standard requirements rather than optional features in automotive supply chains.

Regional analysis reveals that Asia-Pacific dominates the manufacturing landscape for automotive wire bonding, with significant production capacities in Japan, South Korea, and Taiwan. However, recent supply chain disruptions have prompted automotive manufacturers to consider reshoring or nearshoring strategies, potentially creating new market opportunities in North America and Europe.

The aftermarket segment also presents considerable growth potential, as the increasing complexity of automotive electronics leads to higher repair and replacement rates. This segment is expected to grow at approximately 7% annually, creating sustained demand for qualified wire bonding solutions.

Customer surveys indicate that reliability under extreme conditions is the primary concern for automotive manufacturers, with 92% of respondents citing this as their top priority when selecting semiconductor packaging technologies. Cost considerations, while important, are secondary to performance and reliability in this sector.

The market is also witnessing a shift toward copper wire bonding as an alternative to traditional gold wire, driven by cost considerations and improved reliability characteristics. This transition is expected to accelerate, with copper wire bonding projected to account for over 75% of automotive wire bonding applications by 2026.

Emerging applications in autonomous driving systems are creating new demand vectors for highly reliable wire bonding solutions that can withstand extended operational lifetimes and more stringent reliability requirements. This segment is expected to grow at double-digit rates over the next five years, presenting significant opportunities for suppliers of AEC-Q qualified wire bonding technologies.

Market research indicates that the global automotive semiconductor market is projected to grow at a compound annual growth rate of 8.5% through 2028, with wire bonding representing a significant portion of the packaging technologies employed. The electrification trend in the automotive industry has further accelerated this demand, as electric vehicles require approximately twice the semiconductor content of traditional internal combustion engine vehicles.

Tier-1 automotive suppliers and OEMs are increasingly demanding components that can withstand harsh automotive environments, creating a substantial market for AEC-Q qualified wire bonding solutions. The qualification processes focusing on Temperature Humidity Bias (THB), Highly Accelerated Stress Test (HAST), and Power Cycling have become standard requirements rather than optional features in automotive supply chains.

Regional analysis reveals that Asia-Pacific dominates the manufacturing landscape for automotive wire bonding, with significant production capacities in Japan, South Korea, and Taiwan. However, recent supply chain disruptions have prompted automotive manufacturers to consider reshoring or nearshoring strategies, potentially creating new market opportunities in North America and Europe.

The aftermarket segment also presents considerable growth potential, as the increasing complexity of automotive electronics leads to higher repair and replacement rates. This segment is expected to grow at approximately 7% annually, creating sustained demand for qualified wire bonding solutions.

Customer surveys indicate that reliability under extreme conditions is the primary concern for automotive manufacturers, with 92% of respondents citing this as their top priority when selecting semiconductor packaging technologies. Cost considerations, while important, are secondary to performance and reliability in this sector.

The market is also witnessing a shift toward copper wire bonding as an alternative to traditional gold wire, driven by cost considerations and improved reliability characteristics. This transition is expected to accelerate, with copper wire bonding projected to account for over 75% of automotive wire bonding applications by 2026.

Emerging applications in autonomous driving systems are creating new demand vectors for highly reliable wire bonding solutions that can withstand extended operational lifetimes and more stringent reliability requirements. This segment is expected to grow at double-digit rates over the next five years, presenting significant opportunities for suppliers of AEC-Q qualified wire bonding technologies.

Current Challenges in THB, HAST and Power Cycling Testing

The qualification of wire bonding for automotive applications faces significant challenges in Temperature Humidity Bias (THB), Highly Accelerated Stress Test (HAST), and Power Cycling tests. These tests are critical components of the AEC-Q qualification process but present numerous technical difficulties that impact reliability assessment and product development timelines.

THB testing, which evaluates component performance under high temperature and humidity conditions with applied bias, struggles with standardization issues across different testing facilities. The interpretation of results often varies between laboratories, leading to inconsistent qualification outcomes. Additionally, the extended duration of THB tests (typically 1000 hours) creates bottlenecks in the qualification process, delaying time-to-market for new automotive components.

HAST testing, while accelerating the stress conditions compared to THB, introduces its own set of challenges. The extreme conditions (typically 130°C at 85% relative humidity) may trigger failure mechanisms that would not occur under normal operating conditions, potentially leading to false negatives. The correlation between HAST results and actual field reliability remains contentious, with some industry experts questioning whether the accelerated conditions accurately represent real-world degradation patterns in wire bonds.

Power cycling tests present perhaps the most complex challenges. The thermal expansion coefficient mismatch between different materials in the wire bonding system creates mechanical stress during temperature cycling. Current test methodologies struggle to accurately simulate the complex thermal gradients that occur in actual automotive applications, particularly in power electronics where heat dissipation patterns are highly dependent on specific usage profiles.

Test-to-test correlation represents another significant hurdle. The relationship between results from THB, HAST, and power cycling tests is not always clear, making it difficult for manufacturers to optimize designs that can simultaneously pass all qualification requirements. This often leads to over-engineering of components, increasing costs without necessarily improving real-world reliability.

Data interpretation challenges further complicate qualification efforts. Determining appropriate acceleration factors to translate test results to expected field lifetimes involves complex models with numerous variables. The industry lacks consensus on the most appropriate models for different wire bonding technologies, particularly for newer materials like copper wire bonds or sintered connections that are increasingly replacing traditional aluminum wire bonds.

Equipment limitations also impact testing efficacy. Current test chambers often struggle to maintain precise humidity levels at elevated temperatures, introducing variability in test conditions. Similarly, power cycling equipment may not accurately replicate the rapid thermal transients experienced in automotive applications, particularly in emerging high-power applications like electric vehicle inverters.

THB testing, which evaluates component performance under high temperature and humidity conditions with applied bias, struggles with standardization issues across different testing facilities. The interpretation of results often varies between laboratories, leading to inconsistent qualification outcomes. Additionally, the extended duration of THB tests (typically 1000 hours) creates bottlenecks in the qualification process, delaying time-to-market for new automotive components.

HAST testing, while accelerating the stress conditions compared to THB, introduces its own set of challenges. The extreme conditions (typically 130°C at 85% relative humidity) may trigger failure mechanisms that would not occur under normal operating conditions, potentially leading to false negatives. The correlation between HAST results and actual field reliability remains contentious, with some industry experts questioning whether the accelerated conditions accurately represent real-world degradation patterns in wire bonds.

Power cycling tests present perhaps the most complex challenges. The thermal expansion coefficient mismatch between different materials in the wire bonding system creates mechanical stress during temperature cycling. Current test methodologies struggle to accurately simulate the complex thermal gradients that occur in actual automotive applications, particularly in power electronics where heat dissipation patterns are highly dependent on specific usage profiles.

Test-to-test correlation represents another significant hurdle. The relationship between results from THB, HAST, and power cycling tests is not always clear, making it difficult for manufacturers to optimize designs that can simultaneously pass all qualification requirements. This often leads to over-engineering of components, increasing costs without necessarily improving real-world reliability.

Data interpretation challenges further complicate qualification efforts. Determining appropriate acceleration factors to translate test results to expected field lifetimes involves complex models with numerous variables. The industry lacks consensus on the most appropriate models for different wire bonding technologies, particularly for newer materials like copper wire bonds or sintered connections that are increasingly replacing traditional aluminum wire bonds.

Equipment limitations also impact testing efficacy. Current test chambers often struggle to maintain precise humidity levels at elevated temperatures, introducing variability in test conditions. Similarly, power cycling equipment may not accurately replicate the rapid thermal transients experienced in automotive applications, particularly in emerging high-power applications like electric vehicle inverters.

Current Wire Bonding Solutions for Automotive Applications

01 Wire bonding techniques and apparatus

Various techniques and apparatus for wire bonding in semiconductor packaging are disclosed. These include specialized bonding tools, automated bonding systems, and methods for forming reliable electrical connections between semiconductor chips and package substrates. The techniques focus on improving bond strength, reliability, and production efficiency in the wire bonding process.- Wire bonding techniques and apparatus: Various techniques and apparatus for wire bonding in semiconductor packaging are disclosed. These include specialized bonding tools, automated bonding systems, and methods for forming reliable electrical connections between semiconductor chips and package substrates. The techniques focus on improving bond strength, reliability, and production efficiency in the wire bonding process.

- Materials for wire bonding applications: Specific materials and compositions are used in wire bonding to enhance performance and reliability. These include specialized wire materials, bonding pad compositions, and surface treatments that improve adhesion and electrical conductivity. The materials are selected to withstand thermal cycling, prevent corrosion, and ensure long-term reliability of the bonded connections in semiconductor devices.

- Advanced wire bonding for semiconductor packaging: Advanced wire bonding technologies specifically designed for modern semiconductor packaging requirements are presented. These include fine-pitch bonding techniques, multi-tier bonding approaches, and specialized methods for handling complex package geometries. The technologies address challenges in high-density packaging, 3D integration, and advanced chip architectures requiring sophisticated interconnection solutions.

- Process optimization for wire bonding: Methods and systems for optimizing the wire bonding process to improve yield, reliability, and throughput are described. These include parameter optimization techniques, statistical process control methods, and automated inspection systems. The approaches focus on reducing defects, ensuring consistent bond quality, and maximizing production efficiency in high-volume manufacturing environments.

- Novel wire bonding structures and configurations: Innovative wire bonding structures and configurations that address specific technical challenges are presented. These include specialized loop profiles, stacked wire arrangements, and novel interconnection architectures. The structures are designed to minimize wire sweep, reduce electrical interference, optimize thermal performance, and accommodate increasingly complex chip designs with higher I/O counts.

02 Materials for wire bonding applications

Different materials are used in wire bonding to enhance performance and reliability. These include specialized wire compositions, bonding pad materials, and surface treatments that improve adhesion and electrical conductivity. The selection of appropriate materials is crucial for ensuring strong bonds, preventing corrosion, and maintaining electrical performance over the device lifetime.Expand Specific Solutions03 Advanced wire bonding for semiconductor packages

Advanced wire bonding techniques specifically designed for modern semiconductor packages are presented. These include fine-pitch bonding, multi-tier bonding architectures, and specialized loop profiles for high-density packages. The innovations address challenges in miniaturization, thermal management, and signal integrity in advanced semiconductor devices.Expand Specific Solutions04 Process optimization for wire bonding

Methods for optimizing the wire bonding process to improve yield, reliability, and throughput are described. These include parameter optimization, real-time monitoring systems, and statistical process control techniques. The approaches focus on reducing defects, ensuring consistent bond quality, and maximizing production efficiency in high-volume manufacturing environments.Expand Specific Solutions05 Novel wire bonding structures and configurations

Innovative wire bonding structures and configurations that address specific packaging challenges are presented. These include stacked die arrangements, specialized loop profiles for RF applications, and novel interconnect architectures. The structures are designed to improve electrical performance, thermal management, and mechanical reliability in various semiconductor package types.Expand Specific Solutions

Key Semiconductor Manufacturers and Automotive Suppliers

Wire bonding automotive qualification is currently in a mature growth phase, with the market expanding steadily due to increasing electronic content in vehicles. The global market size for automotive wire bonding is estimated at $3-4 billion annually, driven by electrification trends and advanced driver assistance systems. Technologically, the industry has reached high maturity levels with established reliability standards for THB (Temperature Humidity Bias), HAST (Highly Accelerated Stress Test), and power cycling. Key players demonstrate varying levels of specialization: Texas Instruments, STMicroelectronics, and Mitsubishi Electric lead in semiconductor applications; Tanaka Denshi Kogyo and Nippon Micrometal excel in bonding wire manufacturing; while automotive OEMs like Toyota, GM, Ford, and Volkswagen drive qualification requirements through their tier-one suppliers to ensure AEC-Q compliance across their supply chains.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed comprehensive wire bonding solutions specifically designed to meet AEC-Q100 qualification standards for automotive applications. Their approach integrates advanced copper wire bonding technology with specialized molding compounds to enhance reliability under Temperature Humidity Bias (THB) and Highly Accelerated Stress Test (HAST) conditions. TI's wire bonding technology incorporates optimized loop profiles and bond parameters that minimize mechanical stress during power cycling tests. Their automotive-grade packages undergo rigorous testing including 1000 hours of THB at 85°C/85% RH, HAST testing at 130°C/85% RH, and power cycling for up to 10,000 cycles with temperature deltas of 165°C. TI has also implemented specialized bond pad metallization compatible with both gold and copper wire bonding to prevent intermetallic compound formation that typically leads to bond failures under extreme conditions.

Strengths: Industry-leading qualification methodology exceeding AEC-Q100 requirements; proprietary bond pad metallization technology; extensive automotive qualification experience. Weaknesses: Higher manufacturing costs compared to non-automotive solutions; longer qualification timelines that may delay time-to-market for new products.

Nippon Micrometal Corp.

Technical Solution: Nippon Micrometal has established itself as a leader in specialized bonding wire solutions for automotive applications requiring stringent AEC-Q qualification. Their technology focuses on advanced metallurgical compositions and manufacturing processes that enhance wire reliability under extreme THB, HAST, and power cycling conditions. Nippon's automotive-grade wire portfolio includes specialized copper alloys with precisely controlled dopant levels that optimize both bondability and long-term reliability. Their proprietary manufacturing process creates wire with uniform grain structure and optimized mechanical properties specifically engineered to withstand the thermal expansion stresses encountered during power cycling. For THB and HAST resistance, Nippon has developed specialized surface treatments and coatings that minimize oxidation and corrosion under high humidity conditions. Their qualification methodology includes extended testing protocols that exceed standard AEC-Q requirements, with THB testing extended to 1500 hours and power cycling to 15,000 cycles.

Strengths: Industry-leading metallurgical expertise in bonding wire manufacturing; specialized alloy compositions optimized for automotive reliability requirements; comprehensive qualification methodology exceeding industry standards. Weaknesses: Higher cost compared to standard bonding wires; limited global manufacturing capacity; requires specialized bonding parameters.

Critical Technologies in THB, HAST and Power Cycling Testing

Al BONDING WIRE FOR SEMICONDUCTOR DEVICES

PatentPendingUS20240071978A1

Innovation

- An Al bonding wire with a specific composition containing 3-500 mass ppm of Pd and Pt, with a crystal orientation ratio of 30-90% angled at 15 degrees or less to the wire axis, and optionally including Si, Au, Ag, Fe, and Mg, to enhance tensile strength and corrosion resistance.

Corrosion-resistant copper-to-aluminum bonds

PatentInactiveUS20120001336A1

Innovation

- Doping copper wires with a small amount of noble metals like gold or palladium to form a protective layer that acts as a barrier against electrochemical attack, allowing a thin layer of copper/aluminum intermetallics to form and enriching the copper ball with noble metals, which enhances its electrode potential and prevents oxidation.

Automotive Industry Standards and Compliance Requirements

The automotive industry maintains stringent standards for electronic components used in vehicles, particularly for wire bonding technologies that are critical to the reliability of semiconductor devices. AEC-Q100 (Automotive Electronics Council) serves as the primary qualification standard for integrated circuits in automotive applications, with specific stress tests designed to ensure reliability under extreme conditions. These standards are mandatory for suppliers seeking to provide components to automotive manufacturers globally.

Temperature Humidity Bias (THB) testing represents a cornerstone of automotive qualification, requiring components to withstand 85°C temperature and 85% relative humidity under bias conditions for 1000 hours. This test simulates long-term exposure to humid environments while the device is operating, revealing potential corrosion issues or electrical leakage paths that might develop over time.

Highly Accelerated Stress Test (HAST) provides an accelerated alternative to THB, utilizing higher temperatures (typically 130°C) and pressurized humidity (85% RH) to expedite the testing process. While HAST can reduce qualification time from weeks to days, automotive standards often require both tests as they stress different failure mechanisms in wire bonding interfaces.

Power cycling qualification requirements have become increasingly stringent as electric vehicles gain market share. Components must withstand thousands of on-off cycles while experiencing temperature fluctuations from -40°C to 150°C. The JEDEC standard JESD22-A105 provides the framework for these tests, with automotive applications typically requiring 1000-3000 cycles depending on the component's criticality.

International standards organizations including ISO 26262 (functional safety) and ISO/TS 16949 (quality management) complement AEC-Q standards by establishing comprehensive frameworks for automotive electronics development. Wire bonding technologies must comply with these standards through documented validation processes and traceability requirements.

Regional compliance variations exist despite harmonization efforts. European vehicles following ECE regulations may have different wire bonding qualification requirements than those following North American or Asian standards. Manufacturers must navigate these differences when developing globally distributed components, often defaulting to the most stringent requirements to ensure universal compliance.

Environmental legislation, particularly RoHS and REACH directives, further impacts wire bonding qualification by restricting certain materials traditionally used in bonding processes. Lead-free solder requirements have necessitated higher temperature profiles during manufacturing, creating additional reliability challenges that must be addressed through enhanced qualification protocols.

Temperature Humidity Bias (THB) testing represents a cornerstone of automotive qualification, requiring components to withstand 85°C temperature and 85% relative humidity under bias conditions for 1000 hours. This test simulates long-term exposure to humid environments while the device is operating, revealing potential corrosion issues or electrical leakage paths that might develop over time.

Highly Accelerated Stress Test (HAST) provides an accelerated alternative to THB, utilizing higher temperatures (typically 130°C) and pressurized humidity (85% RH) to expedite the testing process. While HAST can reduce qualification time from weeks to days, automotive standards often require both tests as they stress different failure mechanisms in wire bonding interfaces.

Power cycling qualification requirements have become increasingly stringent as electric vehicles gain market share. Components must withstand thousands of on-off cycles while experiencing temperature fluctuations from -40°C to 150°C. The JEDEC standard JESD22-A105 provides the framework for these tests, with automotive applications typically requiring 1000-3000 cycles depending on the component's criticality.

International standards organizations including ISO 26262 (functional safety) and ISO/TS 16949 (quality management) complement AEC-Q standards by establishing comprehensive frameworks for automotive electronics development. Wire bonding technologies must comply with these standards through documented validation processes and traceability requirements.

Regional compliance variations exist despite harmonization efforts. European vehicles following ECE regulations may have different wire bonding qualification requirements than those following North American or Asian standards. Manufacturers must navigate these differences when developing globally distributed components, often defaulting to the most stringent requirements to ensure universal compliance.

Environmental legislation, particularly RoHS and REACH directives, further impacts wire bonding qualification by restricting certain materials traditionally used in bonding processes. Lead-free solder requirements have necessitated higher temperature profiles during manufacturing, creating additional reliability challenges that must be addressed through enhanced qualification protocols.

Failure Analysis Methodologies for Wire Bonding Qualification

Failure analysis methodologies for wire bonding qualification in automotive applications require systematic approaches to identify, analyze, and address potential failure mechanisms. These methodologies are essential for ensuring the reliability of wire bonds under extreme conditions specified by AEC-Q standards, particularly during Temperature Humidity Bias (THB), Highly Accelerated Stress Test (HAST), and Power Cycling tests.

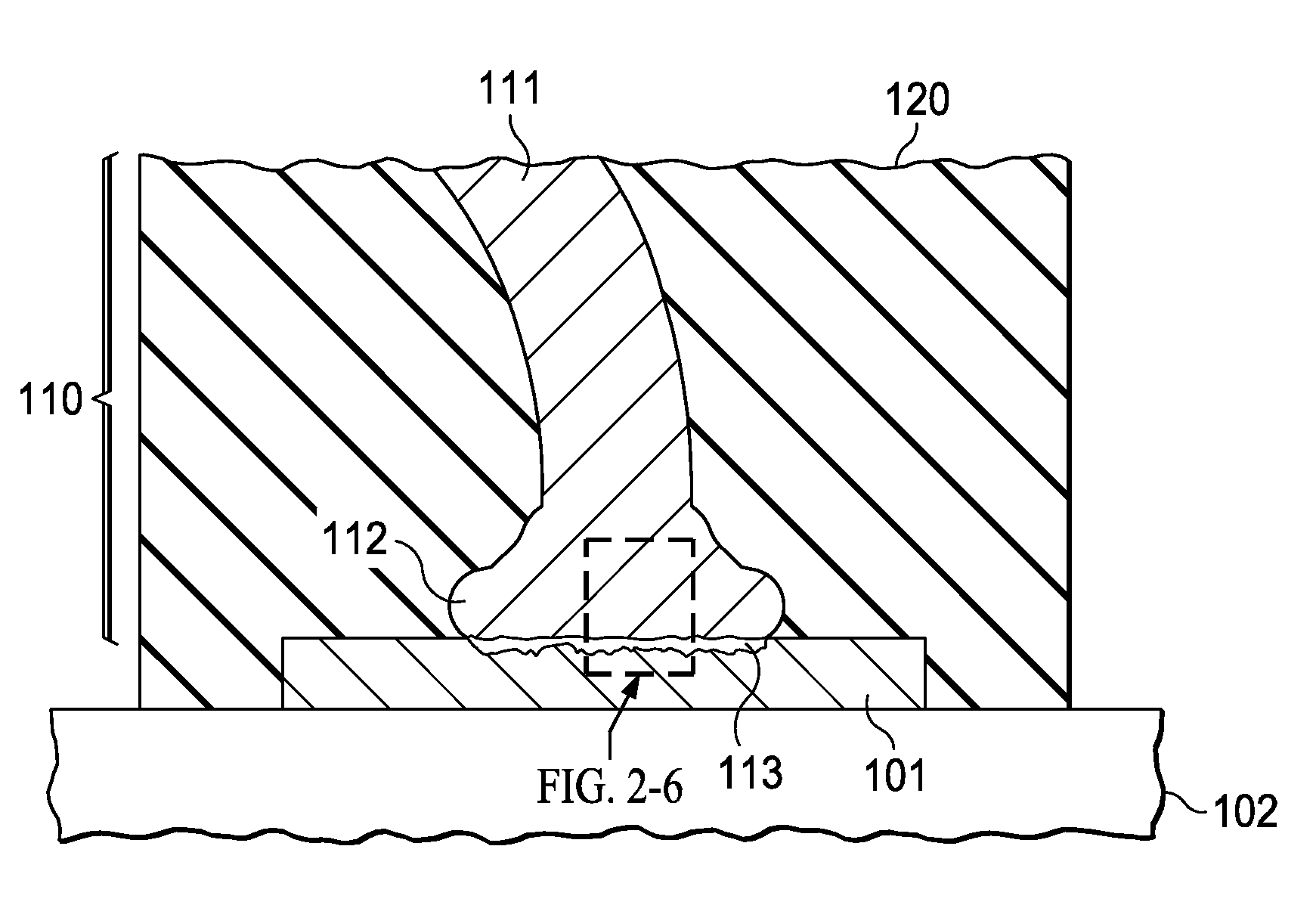

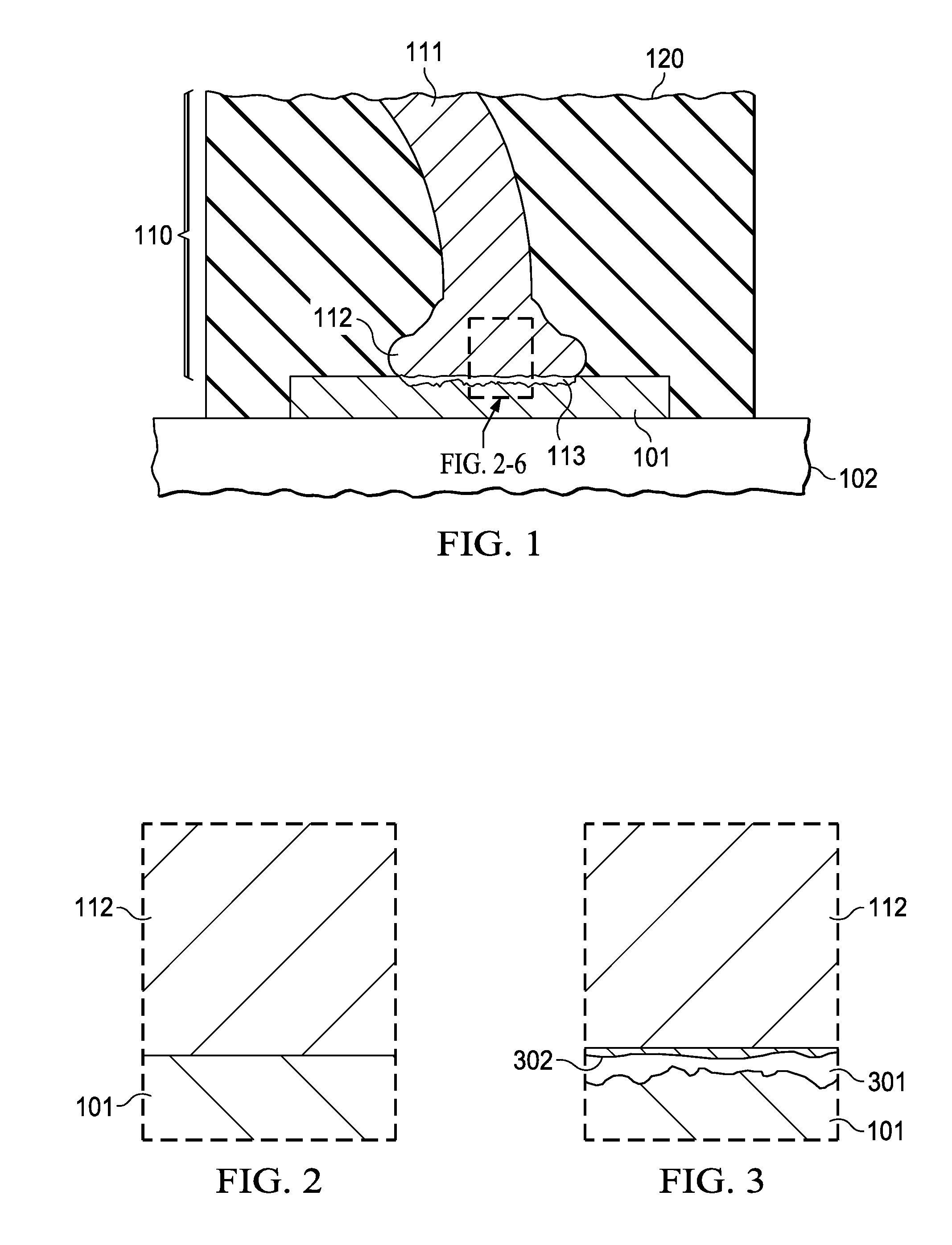

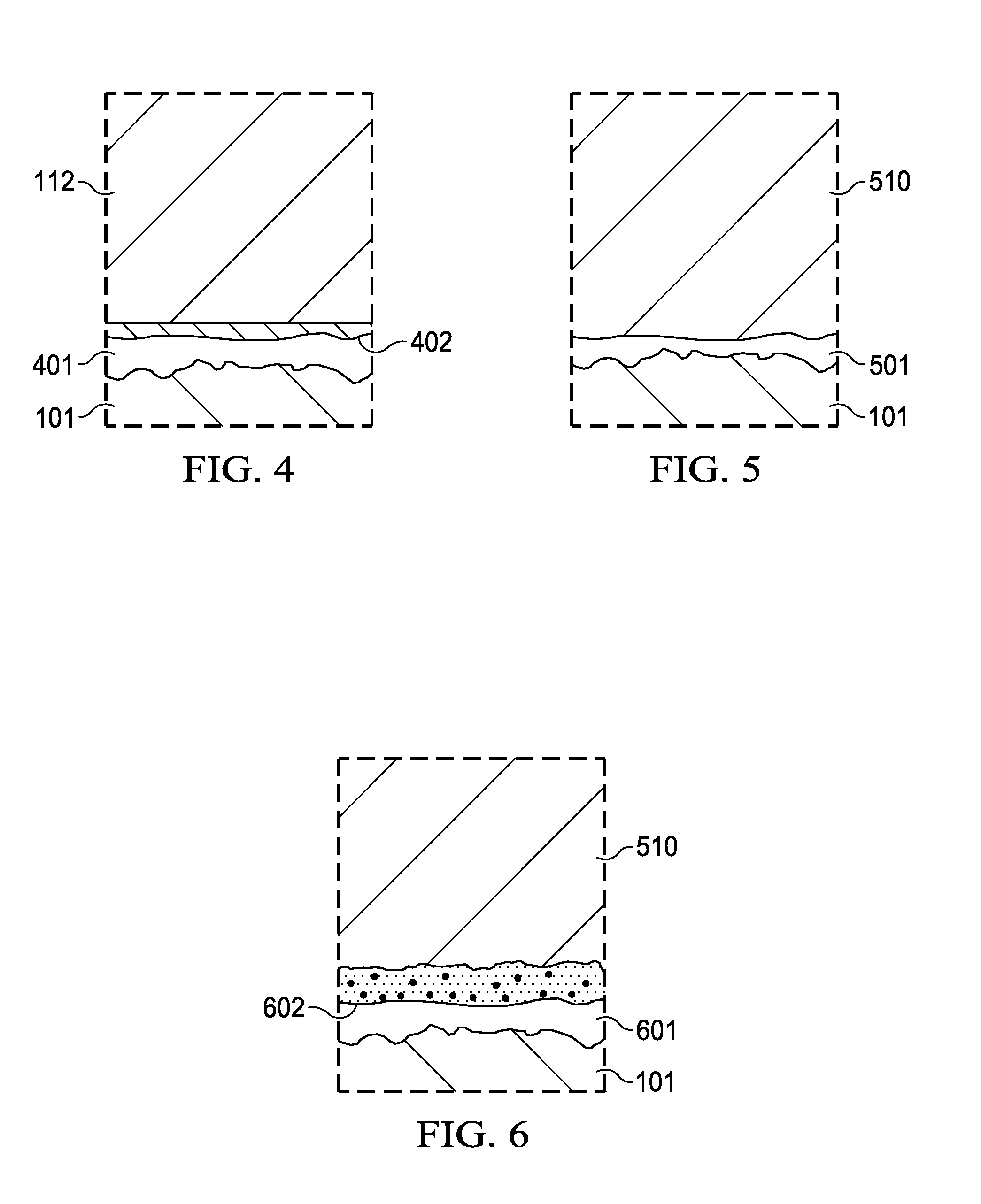

The fundamental methodology begins with non-destructive evaluation techniques, including acoustic microscopy and X-ray inspection. These techniques allow engineers to detect internal defects such as voids, cracks, or delamination without compromising the integrity of the sample. Scanning acoustic microscopy (SAM) has proven particularly effective for detecting delamination at the interface between the wire bond and the die or substrate.

Electrical characterization forms the second pillar of failure analysis, involving resistance measurements, current-voltage (I-V) curve analysis, and capacitance-voltage (C-V) profiling. These measurements can reveal subtle changes in electrical properties that often precede catastrophic failures. For automotive-grade components, these measurements must be performed across the extended temperature range (-40°C to 150°C) to ensure compliance with AEC-Q standards.

Cross-sectional analysis represents a critical destructive technique that provides direct visualization of the wire bond interface. This involves precision cutting, grinding, polishing, and etching to expose the bond interface for microscopic examination. Advanced facilities employ focused ion beam (FIB) techniques to create precise cross-sections with minimal damage to surrounding structures.

Electron microscopy techniques, including Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM), enable high-resolution imaging of failure sites. When coupled with Energy Dispersive X-ray Spectroscopy (EDX), these techniques can identify elemental composition changes at the bond interface, revealing contamination or intermetallic compound formation that may contribute to failure.

Thermomechanical analysis methodologies are particularly relevant for automotive applications, where components experience extreme temperature fluctuations. Techniques such as nanoindentation and microtensile testing quantify mechanical properties at the bond interface, while thermal imaging during power cycling tests identifies hotspots and thermal gradients that may accelerate failure.

Statistical analysis forms the final component of comprehensive failure analysis methodologies. Weibull analysis and other reliability statistics help translate accelerated test results into meaningful lifetime predictions under actual operating conditions. For automotive qualification, these analyses must demonstrate compliance with the stringent reliability requirements of AEC-Q100 standards, typically requiring less than 100 FIT (Failures In Time) rates.

The fundamental methodology begins with non-destructive evaluation techniques, including acoustic microscopy and X-ray inspection. These techniques allow engineers to detect internal defects such as voids, cracks, or delamination without compromising the integrity of the sample. Scanning acoustic microscopy (SAM) has proven particularly effective for detecting delamination at the interface between the wire bond and the die or substrate.

Electrical characterization forms the second pillar of failure analysis, involving resistance measurements, current-voltage (I-V) curve analysis, and capacitance-voltage (C-V) profiling. These measurements can reveal subtle changes in electrical properties that often precede catastrophic failures. For automotive-grade components, these measurements must be performed across the extended temperature range (-40°C to 150°C) to ensure compliance with AEC-Q standards.

Cross-sectional analysis represents a critical destructive technique that provides direct visualization of the wire bond interface. This involves precision cutting, grinding, polishing, and etching to expose the bond interface for microscopic examination. Advanced facilities employ focused ion beam (FIB) techniques to create precise cross-sections with minimal damage to surrounding structures.

Electron microscopy techniques, including Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM), enable high-resolution imaging of failure sites. When coupled with Energy Dispersive X-ray Spectroscopy (EDX), these techniques can identify elemental composition changes at the bond interface, revealing contamination or intermetallic compound formation that may contribute to failure.

Thermomechanical analysis methodologies are particularly relevant for automotive applications, where components experience extreme temperature fluctuations. Techniques such as nanoindentation and microtensile testing quantify mechanical properties at the bond interface, while thermal imaging during power cycling tests identifies hotspots and thermal gradients that may accelerate failure.

Statistical analysis forms the final component of comprehensive failure analysis methodologies. Weibull analysis and other reliability statistics help translate accelerated test results into meaningful lifetime predictions under actual operating conditions. For automotive qualification, these analyses must demonstrate compliance with the stringent reliability requirements of AEC-Q100 standards, typically requiring less than 100 FIT (Failures In Time) rates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!