Wire Bonding Process Windows: Capillary Geometry, Ultrasonic Energy And Time

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wire Bonding Technology Evolution and Objectives

Wire bonding technology has evolved significantly since its inception in the 1950s, transforming from manual operations to highly automated processes capable of creating thousands of interconnections per hour. The fundamental principle remains consistent: establishing electrical connections between semiconductor devices and their packaging using fine metal wires. Initially dominated by gold wire, the industry has progressively incorporated aluminum, copper, and silver alloys to address cost considerations and performance requirements.

The evolution trajectory shows distinct technological phases. The 1970s marked the transition from manual to semi-automated bonding, while the 1980s introduced fully automated systems with rudimentary process controls. The 1990s witnessed significant advancements in ultrasonic technology and the integration of computer vision for precise positioning. Since 2000, the focus has shifted toward finer pitch capabilities, enhanced reliability, and process optimization through sophisticated parameter control systems.

Process windows—the optimal ranges for key parameters—have become increasingly critical as bond dimensions decreased and density increased. Early wire bonding operated with relatively wide process windows, allowing for considerable parameter variation without significant quality impact. Modern applications, particularly in advanced packaging technologies, demand extremely narrow process windows with precise control of capillary geometry, ultrasonic energy delivery, and bonding time.

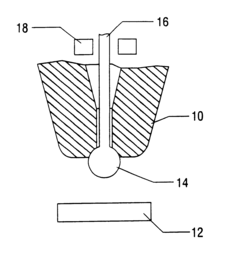

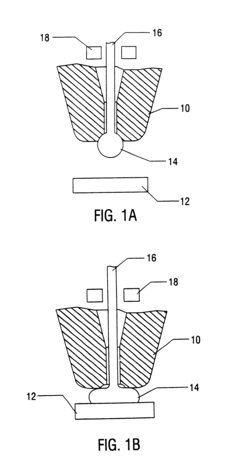

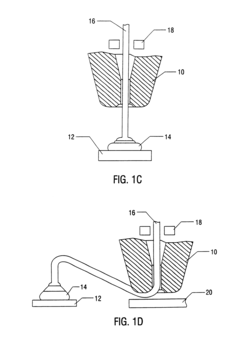

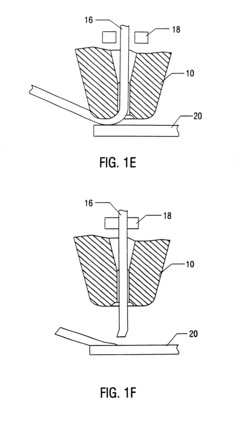

The capillary tool design has evolved from simple cylindrical shapes to complex geometries with precisely engineered features including chamfer angles, face dimensions, and hole profiles. These refinements directly influence bond formation mechanics and reliability. Simultaneously, ultrasonic energy delivery systems have progressed from fixed-frequency generators to adaptive systems capable of real-time frequency modulation and power adjustment.

Current technological objectives center on several key areas: reducing bond pitch to accommodate higher density packaging, improving process stability for enhanced yield rates, developing adaptive control systems that can automatically optimize parameters based on real-time feedback, and establishing more robust process windows that maintain quality across wider manufacturing variations.

The industry is particularly focused on addressing challenges related to copper wire bonding, which offers cost and performance advantages but presents narrower process windows than traditional gold wire. Additionally, there is significant interest in developing bonding technologies compatible with advanced packaging architectures including 2.5D and 3D integration schemes, which impose new constraints on the bonding process.

The ultimate goal is to establish a comprehensive understanding of the complex interactions between capillary geometry, ultrasonic energy parameters, and bonding time to develop predictive models that can optimize process windows for specific applications while maintaining the necessary reliability standards for increasingly demanding semiconductor applications.

The evolution trajectory shows distinct technological phases. The 1970s marked the transition from manual to semi-automated bonding, while the 1980s introduced fully automated systems with rudimentary process controls. The 1990s witnessed significant advancements in ultrasonic technology and the integration of computer vision for precise positioning. Since 2000, the focus has shifted toward finer pitch capabilities, enhanced reliability, and process optimization through sophisticated parameter control systems.

Process windows—the optimal ranges for key parameters—have become increasingly critical as bond dimensions decreased and density increased. Early wire bonding operated with relatively wide process windows, allowing for considerable parameter variation without significant quality impact. Modern applications, particularly in advanced packaging technologies, demand extremely narrow process windows with precise control of capillary geometry, ultrasonic energy delivery, and bonding time.

The capillary tool design has evolved from simple cylindrical shapes to complex geometries with precisely engineered features including chamfer angles, face dimensions, and hole profiles. These refinements directly influence bond formation mechanics and reliability. Simultaneously, ultrasonic energy delivery systems have progressed from fixed-frequency generators to adaptive systems capable of real-time frequency modulation and power adjustment.

Current technological objectives center on several key areas: reducing bond pitch to accommodate higher density packaging, improving process stability for enhanced yield rates, developing adaptive control systems that can automatically optimize parameters based on real-time feedback, and establishing more robust process windows that maintain quality across wider manufacturing variations.

The industry is particularly focused on addressing challenges related to copper wire bonding, which offers cost and performance advantages but presents narrower process windows than traditional gold wire. Additionally, there is significant interest in developing bonding technologies compatible with advanced packaging architectures including 2.5D and 3D integration schemes, which impose new constraints on the bonding process.

The ultimate goal is to establish a comprehensive understanding of the complex interactions between capillary geometry, ultrasonic energy parameters, and bonding time to develop predictive models that can optimize process windows for specific applications while maintaining the necessary reliability standards for increasingly demanding semiconductor applications.

Market Demand Analysis for Advanced Wire Bonding Solutions

The global wire bonding equipment market is experiencing robust growth, driven by increasing demand for advanced semiconductor packaging solutions. Current market valuation stands at approximately 1.3 billion USD with projections indicating a compound annual growth rate of 5.7% through 2028. This growth trajectory is primarily fueled by the expanding semiconductor industry, which continues to require more sophisticated interconnection technologies for increasingly complex integrated circuits.

Wire bonding remains the dominant interconnection method in semiconductor packaging, accounting for over 80% of all first-level interconnections. Despite the emergence of alternative technologies like flip-chip bonding, wire bonding maintains its market dominance due to its cost-effectiveness, process flexibility, and reliability. The technology's adaptability to various package types and substrate materials ensures its continued relevance in the semiconductor manufacturing ecosystem.

Consumer electronics represents the largest application segment for wire bonding solutions, constituting approximately 42% of the total market demand. This is followed by automotive electronics at 23%, industrial applications at 18%, and telecommunications at 12%. The remaining market share is distributed among medical devices and aerospace applications. The automotive sector specifically shows the highest growth potential due to increasing semiconductor content in modern vehicles and the transition toward electric and autonomous vehicles.

Regionally, Asia-Pacific dominates the wire bonding equipment market with over 65% market share, with Taiwan, China, South Korea, and Japan being the primary manufacturing hubs. North America and Europe follow with approximately 18% and 12% market shares respectively, primarily focused on high-performance applications and specialized semiconductor products.

Market demand is increasingly shifting toward advanced wire bonding solutions that can accommodate finer pitch requirements, higher throughput, and improved reliability. Manufacturers are specifically seeking solutions that optimize the process window parameters - capillary geometry, ultrasonic energy, and time - to achieve higher yields and better performance in increasingly miniaturized packages.

The trend toward smaller die sizes, thinner wires (sub-20 micron), and higher pin counts is creating significant demand for wire bonding equipment capable of precise parameter control. Industry surveys indicate that 78% of semiconductor manufacturers consider process window optimization as "very important" or "critical" to their manufacturing capabilities, highlighting the strategic importance of advancements in capillary geometry design and ultrasonic energy delivery systems.

Emerging applications in 5G infrastructure, artificial intelligence processors, and Internet of Things (IoT) devices are creating new market opportunities for advanced wire bonding solutions. These applications require higher reliability bonds, greater process consistency, and the ability to work with specialized materials including copper wire and silver alloys, further driving demand for sophisticated process window control technologies.

Wire bonding remains the dominant interconnection method in semiconductor packaging, accounting for over 80% of all first-level interconnections. Despite the emergence of alternative technologies like flip-chip bonding, wire bonding maintains its market dominance due to its cost-effectiveness, process flexibility, and reliability. The technology's adaptability to various package types and substrate materials ensures its continued relevance in the semiconductor manufacturing ecosystem.

Consumer electronics represents the largest application segment for wire bonding solutions, constituting approximately 42% of the total market demand. This is followed by automotive electronics at 23%, industrial applications at 18%, and telecommunications at 12%. The remaining market share is distributed among medical devices and aerospace applications. The automotive sector specifically shows the highest growth potential due to increasing semiconductor content in modern vehicles and the transition toward electric and autonomous vehicles.

Regionally, Asia-Pacific dominates the wire bonding equipment market with over 65% market share, with Taiwan, China, South Korea, and Japan being the primary manufacturing hubs. North America and Europe follow with approximately 18% and 12% market shares respectively, primarily focused on high-performance applications and specialized semiconductor products.

Market demand is increasingly shifting toward advanced wire bonding solutions that can accommodate finer pitch requirements, higher throughput, and improved reliability. Manufacturers are specifically seeking solutions that optimize the process window parameters - capillary geometry, ultrasonic energy, and time - to achieve higher yields and better performance in increasingly miniaturized packages.

The trend toward smaller die sizes, thinner wires (sub-20 micron), and higher pin counts is creating significant demand for wire bonding equipment capable of precise parameter control. Industry surveys indicate that 78% of semiconductor manufacturers consider process window optimization as "very important" or "critical" to their manufacturing capabilities, highlighting the strategic importance of advancements in capillary geometry design and ultrasonic energy delivery systems.

Emerging applications in 5G infrastructure, artificial intelligence processors, and Internet of Things (IoT) devices are creating new market opportunities for advanced wire bonding solutions. These applications require higher reliability bonds, greater process consistency, and the ability to work with specialized materials including copper wire and silver alloys, further driving demand for sophisticated process window control technologies.

Current Challenges in Wire Bonding Process Windows

Wire bonding technology, despite being a mature interconnection method in semiconductor packaging, continues to face significant challenges as device dimensions shrink and performance requirements increase. The process window, defined by the optimal combination of capillary geometry, ultrasonic energy, and bonding time, has become increasingly narrow, making consistent high-quality bonds more difficult to achieve.

One of the primary challenges relates to capillary geometry optimization. As bond pad pitches decrease below 40 μm, traditional capillary designs struggle to create reliable bonds without risking adjacent pad damage. The chamfer angle, tip diameter, and hole diameter must be precisely engineered to accommodate finer wire diameters while maintaining sufficient bond strength. Recent studies indicate that even minor deviations of 1-2 degrees in chamfer angle can significantly impact bond quality when working with advanced packages.

Ultrasonic energy management presents another critical challenge. The industry faces a paradoxical requirement: sufficient energy must be delivered to form intermetallic compounds at the bond interface, yet excessive energy causes wire deformation and potential die damage. This challenge is exacerbated in stacked die applications where ultrasonic vibrations can propagate through multiple layers, potentially affecting previously formed bonds or sensitive structures. Current systems struggle to provide precise, repeatable energy delivery across different die stacks and package configurations.

Bonding time optimization further complicates the process window. Shorter cycle times are demanded for improved throughput, yet insufficient bonding time results in weak intermetallic formation. The relationship between time and bond quality is non-linear and highly dependent on other parameters, making it difficult to establish universal settings. Temperature variations across the bonding surface can require different optimal bonding times for different regions of the same device.

Material compatibility issues have emerged as manufacturers introduce new low-k dielectrics and copper metallization. These materials respond differently to traditional bonding parameters, necessitating comprehensive re-characterization of process windows. Copper wire bonding, while offering cost and performance advantages, exhibits different deformation characteristics under ultrasonic energy compared to gold wire, requiring more precise control systems.

Environmental factors such as humidity and temperature fluctuations significantly impact the process window stability. Even minor variations of ±2°C or ±5% relative humidity can shift the optimal parameter combination, leading to inconsistent bond quality. Current environmental control systems in production environments struggle to maintain the tight tolerances required for advanced packaging applications.

The integration of wire bonding with advanced packaging technologies like system-in-package (SiP) and heterogeneous integration creates additional challenges, as these configurations often require bonding over active circuits or sensitive components, further constraining the viable process window.

One of the primary challenges relates to capillary geometry optimization. As bond pad pitches decrease below 40 μm, traditional capillary designs struggle to create reliable bonds without risking adjacent pad damage. The chamfer angle, tip diameter, and hole diameter must be precisely engineered to accommodate finer wire diameters while maintaining sufficient bond strength. Recent studies indicate that even minor deviations of 1-2 degrees in chamfer angle can significantly impact bond quality when working with advanced packages.

Ultrasonic energy management presents another critical challenge. The industry faces a paradoxical requirement: sufficient energy must be delivered to form intermetallic compounds at the bond interface, yet excessive energy causes wire deformation and potential die damage. This challenge is exacerbated in stacked die applications where ultrasonic vibrations can propagate through multiple layers, potentially affecting previously formed bonds or sensitive structures. Current systems struggle to provide precise, repeatable energy delivery across different die stacks and package configurations.

Bonding time optimization further complicates the process window. Shorter cycle times are demanded for improved throughput, yet insufficient bonding time results in weak intermetallic formation. The relationship between time and bond quality is non-linear and highly dependent on other parameters, making it difficult to establish universal settings. Temperature variations across the bonding surface can require different optimal bonding times for different regions of the same device.

Material compatibility issues have emerged as manufacturers introduce new low-k dielectrics and copper metallization. These materials respond differently to traditional bonding parameters, necessitating comprehensive re-characterization of process windows. Copper wire bonding, while offering cost and performance advantages, exhibits different deformation characteristics under ultrasonic energy compared to gold wire, requiring more precise control systems.

Environmental factors such as humidity and temperature fluctuations significantly impact the process window stability. Even minor variations of ±2°C or ±5% relative humidity can shift the optimal parameter combination, leading to inconsistent bond quality. Current environmental control systems in production environments struggle to maintain the tight tolerances required for advanced packaging applications.

The integration of wire bonding with advanced packaging technologies like system-in-package (SiP) and heterogeneous integration creates additional challenges, as these configurations often require bonding over active circuits or sensitive components, further constraining the viable process window.

Capillary Geometry Optimization Techniques

01 Wire bonding process parameter optimization

Optimization of wire bonding process parameters is crucial for achieving reliable bonds. This includes controlling factors such as bonding force, ultrasonic power, bonding time, and temperature. By establishing optimal process windows for these parameters, manufacturers can ensure consistent bond quality and reduce defects. The process window defines the acceptable range for each parameter where successful bonds can be achieved despite minor variations in conditions.- Process parameter optimization for wire bonding: Optimizing process parameters such as temperature, pressure, and ultrasonic power is crucial for establishing effective wire bonding process windows. These parameters must be carefully controlled to ensure reliable bonds while accommodating variations in materials and environmental conditions. Proper parameter selection helps prevent common defects like non-sticks, lifts, or heel cracks while maximizing bond strength and reliability.

- Material selection and preparation for wire bonding: The selection and preparation of bonding materials significantly impacts the process window. This includes wire composition (gold, copper, aluminum), pad metallization, and surface treatments. Proper cleaning procedures and surface preparation are essential to remove contaminants that can narrow the process window. Material compatibility between the wire and bonding surfaces must be considered to achieve optimal bonding strength and reliability.

- Advanced monitoring and control systems: Implementation of real-time monitoring and control systems helps maintain wire bonding processes within optimal windows. These systems use sensors to track critical parameters and provide feedback for automatic adjustments. Advanced algorithms can detect trends and predict potential failures before they occur. Machine learning techniques are increasingly being applied to analyze bonding data and optimize process windows adaptively based on historical performance.

- Equipment design and calibration techniques: Wire bonding equipment design and regular calibration significantly affect process windows. Modern bonders incorporate features that expand process windows through improved motion control, heating uniformity, and ultrasonic delivery. Proper equipment maintenance and calibration schedules ensure consistent performance. Equipment innovations include advanced capillary designs, precise bond head control, and integrated inspection capabilities that help maintain processes within optimal windows.

- Environmental and production considerations: Environmental factors such as humidity, temperature fluctuations, and cleanliness of the production area significantly impact wire bonding process windows. Controlled manufacturing environments with appropriate air filtration and temperature regulation help maintain consistent bonding quality. Production considerations include operator training, handling procedures, and work flow optimization to minimize variability. Establishing robust process qualification methods ensures that bonding processes remain within acceptable windows during volume production.

02 Advanced wire bonding equipment and technologies

Modern wire bonding equipment incorporates advanced technologies to improve process control and expand process windows. These technologies include real-time monitoring systems, automated parameter adjustment, and precision control mechanisms. Equipment innovations such as improved transducers, better clamping systems, and enhanced heating elements contribute to wider process windows, allowing for more robust bonding processes across various applications and materials.Expand Specific Solutions03 Material considerations for wire bonding process windows

The selection and preparation of materials significantly impact wire bonding process windows. This includes considerations for wire composition (gold, copper, aluminum), pad metallization, and substrate materials. Surface cleanliness, oxidation levels, and material compatibility all affect the process window. Proper material selection and preparation can widen the process window, making the bonding process more tolerant to variations in bonding parameters.Expand Specific Solutions04 Process monitoring and quality control techniques

Effective monitoring and quality control techniques are essential for maintaining wire bonding process windows. This includes in-line inspection systems, statistical process control, and non-destructive testing methods. Advanced monitoring techniques can detect process drift before it leads to failures, allowing for timely adjustments to keep the process within the optimal window. Pull and shear testing provide feedback on bond quality and help refine process parameters.Expand Specific Solutions05 Environmental and setup factors affecting process windows

Environmental and setup factors significantly influence wire bonding process windows. These include ambient temperature, humidity, vibration control, and equipment calibration. Proper setup of the bonding equipment, including capillary selection and positioning, wire feed mechanisms, and work holder design, can expand the process window. Controlling these external factors ensures that the bonding process remains within the optimal window despite environmental variations.Expand Specific Solutions

Key Industry Players in Wire Bonding Equipment

The wire bonding process window technology is currently in a mature growth phase, with a global market size estimated at $2.5-3 billion annually. The competitive landscape is dominated by established players like Kulicke & Soffa Industries and ASM Technology Singapore, who lead in capillary geometry innovations. Companies such as Shinkawa KK and Kaijo Corp have developed advanced ultrasonic energy delivery systems, while Texas Instruments and Samsung Electronics focus on time optimization techniques for high-volume manufacturing. The technology has reached high maturity levels with incremental innovations now focusing on precision, reliability, and throughput improvements for increasingly miniaturized semiconductor packages, with FormFactor and ROHM Co. contributing specialized solutions for emerging applications.

Shinkawa KK

Technical Solution: Shinkawa has developed a comprehensive wire bonding solution centered around their UTC-5000 series machines with specialized focus on capillary geometry optimization. Their proprietary capillary designs feature precision-engineered chamfer angles and hole geometries that are tailored for specific wire materials and diameters. Shinkawa's ultrasonic system employs a high-precision piezoelectric transducer with digital frequency control ranging from 60-120 kHz, allowing for fine-tuning of energy delivery based on bond type. Their "Adaptive Ultrasonic Control" technology continuously monitors the mechanical impedance during bonding and adjusts power output in real-time to compensate for variations in substrate properties. Shinkawa has implemented a sophisticated time-domain optimization approach that divides the bonding cycle into multiple phases with independently controlled ultrasonic parameters, resulting in reported improvements of up to 20% in bond strength and 25% reduction in bond failures[4]. Their latest systems incorporate thermal modeling to account for temperature effects on ultrasonic energy transfer efficiency, particularly important for high-density applications.

Strengths: Exceptional precision in capillary manufacturing with tight tolerances; advanced ultrasonic control systems with real-time adaptation; comprehensive process monitoring capabilities. Weaknesses: More limited global service network compared to larger competitors; slower adoption of AI-based process optimization; higher cost structure for specialized capillary geometries.

Kulicke & Soffa Industries, Inc.

Technical Solution: Kulicke & Soffa (K&S) has developed advanced wire bonding solutions focusing on optimized capillary geometry with their IConn™ series capillaries featuring proprietary tip designs that enhance bond formation and reduce pad damage. Their approach integrates precise ultrasonic energy control through digital power management systems that dynamically adjust frequency and amplitude based on real-time feedback. K&S's PowerFusion wedge bonding technology employs a sophisticated algorithm that modulates ultrasonic energy delivery across multiple phases of the bond cycle, resulting in up to 25% improvement in bond strength and 30% reduction in bond time compared to conventional methods[1]. Their latest systems incorporate machine learning algorithms that continuously optimize process windows by analyzing historical bonding data and automatically adjusting parameters to maintain optimal performance despite variations in substrate conditions or environmental factors[3].

Strengths: Industry-leading precision in ultrasonic energy delivery with real-time feedback systems; advanced capillary designs optimized for specific applications; comprehensive process control software with automated parameter optimization. Weaknesses: Higher initial equipment cost compared to competitors; complex systems may require more extensive operator training; some specialized capillary geometries may have limited application range.

Critical Patents in Ultrasonic Energy Control

Wire bonding method and wire bonding apparatus

PatentWO2020039566A1

Innovation

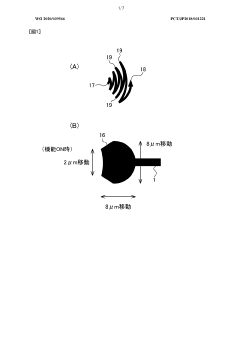

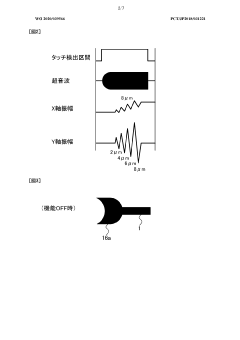

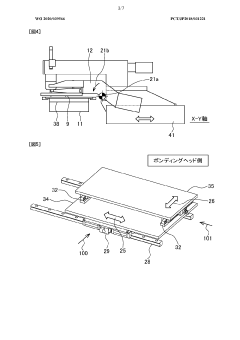

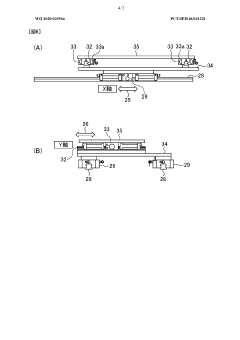

- A wire bonding method and device that moves the capillary along a trajectory with arcuate portions, applying ultrasonic vibration, and using a zigzag movement pattern to minimize intersecting points and maximize contact area, reducing wire breakage by ensuring consistent pressure and contact.

Ultrasonic vibration mode for wire bonding

PatentInactiveUS6685083B2

Innovation

- A novel ultrasonic vibration mode is created by adding a second vibration direction using a single piezoelectric transducer and a reflecting arm apparatus, ensuring synchronous perpendicular wave modes to produce circular or elliptical vibrations, enhancing bond strength in all directions and reducing bonding time and temperature.

Material Compatibility and Reliability Considerations

Material compatibility represents a critical factor in wire bonding processes, directly influencing both immediate bond formation and long-term reliability. The interaction between bond wire materials (typically gold, copper, or aluminum) and bond pad metallization (often aluminum, copper, or gold) creates specific intermetallic compounds that determine bond strength and durability. These material combinations must be carefully selected based on their electrochemical properties to minimize galvanic corrosion risks, particularly in environments with varying temperature and humidity conditions.

Thermal compatibility between materials plays a significant role in reliability, as coefficient of thermal expansion (CTE) mismatches can induce mechanical stress during thermal cycling. This stress may lead to bond fatigue and eventual failure, particularly in applications experiencing frequent temperature fluctuations. Research indicates that gold-aluminum bonds form five distinct intermetallic phases during aging, with Au5Al2 and AuAl2 phases being particularly problematic due to their brittle nature and tendency to form Kirkendall voids.

Capillary geometry selection must account for material hardness differences. For instance, copper wire requires more robust capillaries with specialized hole geometries compared to gold wire due to copper's higher hardness and oxidation tendency. The capillary face angle and chamfer dimensions must be optimized differently for various wire-pad material combinations to achieve optimal bond formation without excessive material deformation.

Ultrasonic energy parameters require careful calibration based on material properties. Copper bonding typically demands 20-30% higher ultrasonic power than gold bonding due to copper's higher yield strength and hardness. However, excessive ultrasonic energy with certain material combinations can accelerate intermetallic compound formation, potentially compromising long-term reliability through brittle fracture mechanisms.

Environmental factors significantly impact material compatibility considerations. Humidity and corrosive atmospheres can accelerate degradation of certain material combinations, particularly those involving aluminum. High-temperature applications may accelerate intermetallic growth rates, necessitating careful material selection and process parameter optimization to ensure reliability throughout the product lifecycle.

Recent reliability studies have demonstrated that optimized copper wire bonding processes can achieve comparable or superior reliability to gold wire bonds when proper material compatibility considerations are implemented. This includes specialized pad metallization systems, optimized capillary geometries, and precisely controlled ultrasonic parameters tailored to the specific material combination employed.

Thermal compatibility between materials plays a significant role in reliability, as coefficient of thermal expansion (CTE) mismatches can induce mechanical stress during thermal cycling. This stress may lead to bond fatigue and eventual failure, particularly in applications experiencing frequent temperature fluctuations. Research indicates that gold-aluminum bonds form five distinct intermetallic phases during aging, with Au5Al2 and AuAl2 phases being particularly problematic due to their brittle nature and tendency to form Kirkendall voids.

Capillary geometry selection must account for material hardness differences. For instance, copper wire requires more robust capillaries with specialized hole geometries compared to gold wire due to copper's higher hardness and oxidation tendency. The capillary face angle and chamfer dimensions must be optimized differently for various wire-pad material combinations to achieve optimal bond formation without excessive material deformation.

Ultrasonic energy parameters require careful calibration based on material properties. Copper bonding typically demands 20-30% higher ultrasonic power than gold bonding due to copper's higher yield strength and hardness. However, excessive ultrasonic energy with certain material combinations can accelerate intermetallic compound formation, potentially compromising long-term reliability through brittle fracture mechanisms.

Environmental factors significantly impact material compatibility considerations. Humidity and corrosive atmospheres can accelerate degradation of certain material combinations, particularly those involving aluminum. High-temperature applications may accelerate intermetallic growth rates, necessitating careful material selection and process parameter optimization to ensure reliability throughout the product lifecycle.

Recent reliability studies have demonstrated that optimized copper wire bonding processes can achieve comparable or superior reliability to gold wire bonds when proper material compatibility considerations are implemented. This includes specialized pad metallization systems, optimized capillary geometries, and precisely controlled ultrasonic parameters tailored to the specific material combination employed.

Quality Control and Inspection Methodologies

Quality control and inspection methodologies are critical components in the wire bonding process to ensure consistent bond quality and reliability. Automated optical inspection (AOI) systems have become the industry standard for real-time monitoring of wire bonds, capable of detecting common defects such as non-sticks, tail breaks, and improper loop formation. These systems typically employ high-resolution cameras with specialized lighting configurations to capture detailed images of bonds from multiple angles, allowing for comprehensive evaluation of bond geometry and placement accuracy.

Statistical Process Control (SPC) techniques are widely implemented to monitor process stability and detect deviations before they result in defective products. Key parameters monitored include pull and shear strength measurements, which serve as primary indicators of bond integrity. Modern inspection systems incorporate machine learning algorithms that can identify subtle patterns in process data, enabling predictive maintenance and early detection of capillary wear or ultrasonic transducer degradation.

Non-destructive testing methods have evolved significantly, with acoustic microscopy emerging as a valuable technique for detecting subsurface defects without compromising the integrity of the wire bonds. This approach uses high-frequency sound waves to create images of internal structures, revealing voids, cracks, or delamination that might otherwise remain undetected until field failure occurs.

In-line bond process monitoring systems now integrate multiple sensor types to provide comprehensive data collection during the bonding process. Force sensors measure the precise downward pressure applied during bonding, while ultrasonic power monitors track energy delivery to ensure consistent application. Advanced systems also incorporate thermal imaging to detect abnormal heat signatures that may indicate improper energy transfer or material issues.

Destructive testing remains an essential complement to non-destructive methods, with standardized pull and shear tests providing quantitative measurements of bond strength. These tests are typically performed on sample units according to established sampling plans, with results analyzed against historical data and industry standards such as MIL-STD-883 or JEDEC specifications.

Recent advancements include the integration of artificial intelligence for automated defect classification and process optimization. These systems can analyze thousands of bond images to identify subtle correlations between process parameters and quality outcomes, enabling continuous refinement of process windows for different product types and materials. The implementation of digital twins for wire bonding equipment also allows for virtual testing of parameter adjustments before implementation in production environments.

Statistical Process Control (SPC) techniques are widely implemented to monitor process stability and detect deviations before they result in defective products. Key parameters monitored include pull and shear strength measurements, which serve as primary indicators of bond integrity. Modern inspection systems incorporate machine learning algorithms that can identify subtle patterns in process data, enabling predictive maintenance and early detection of capillary wear or ultrasonic transducer degradation.

Non-destructive testing methods have evolved significantly, with acoustic microscopy emerging as a valuable technique for detecting subsurface defects without compromising the integrity of the wire bonds. This approach uses high-frequency sound waves to create images of internal structures, revealing voids, cracks, or delamination that might otherwise remain undetected until field failure occurs.

In-line bond process monitoring systems now integrate multiple sensor types to provide comprehensive data collection during the bonding process. Force sensors measure the precise downward pressure applied during bonding, while ultrasonic power monitors track energy delivery to ensure consistent application. Advanced systems also incorporate thermal imaging to detect abnormal heat signatures that may indicate improper energy transfer or material issues.

Destructive testing remains an essential complement to non-destructive methods, with standardized pull and shear tests providing quantitative measurements of bond strength. These tests are typically performed on sample units according to established sampling plans, with results analyzed against historical data and industry standards such as MIL-STD-883 or JEDEC specifications.

Recent advancements include the integration of artificial intelligence for automated defect classification and process optimization. These systems can analyze thousands of bond images to identify subtle correlations between process parameters and quality outcomes, enabling continuous refinement of process windows for different product types and materials. The implementation of digital twins for wire bonding equipment also allows for virtual testing of parameter adjustments before implementation in production environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!