Wire Bonding Loop Design: Sag, Sweep And Resonance Under Vibration

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wire Bonding Technology Evolution and Objectives

Wire bonding technology has evolved significantly since its inception in the 1950s, transforming from rudimentary manual processes to sophisticated automated systems. Initially, the technology relied on thermocompression bonding, which required high temperatures and pressures. The 1970s witnessed a pivotal shift with the introduction of ultrasonic and thermosonic bonding techniques, dramatically improving reliability while reducing process temperatures and mechanical stress on semiconductor devices.

The evolution continued through the 1980s and 1990s with the development of automated wire bonders capable of handling increasingly fine wire diameters and achieving higher throughput rates. This period marked significant advancements in loop control algorithms and machine vision systems, enabling more precise bond placement and loop formation. The transition from gold to copper wire in the early 2000s represented another milestone, driven by cost considerations and performance advantages, despite introducing new technical challenges in bonding parameters.

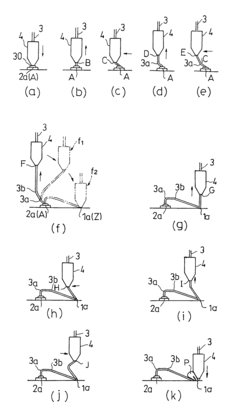

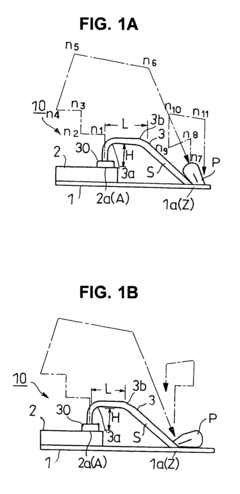

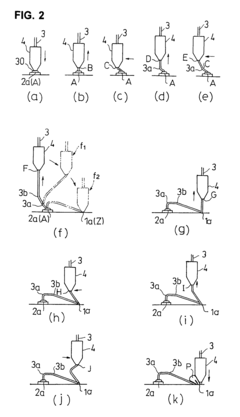

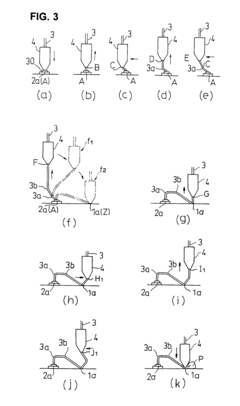

Recent technological developments have focused on optimizing wire loop designs to address the critical issues of sag, sweep, and resonance under vibration conditions. These phenomena have become increasingly problematic as wire diameters have decreased to below 20 microns and loop heights have been reduced to accommodate thinner package profiles. The industry has responded with advanced loop formation techniques, including specialized loop profiles such as low-loop, triangular, and optimized S-curve designs.

The primary objectives of current wire bonding research center on enhancing mechanical stability while maintaining electrical performance. This includes developing loop geometries that minimize wire sag under gravitational forces and reduce sweep during molding processes. Additionally, researchers aim to optimize loop resonance characteristics to withstand vibration environments in automotive, aerospace, and industrial applications where reliability under mechanical stress is paramount.

Another critical goal involves adapting wire bonding technology to emerging packaging architectures, including stacked die configurations and system-in-package solutions. These applications demand novel loop designs that can navigate complex three-dimensional spaces while maintaining consistent electrical and mechanical properties. Concurrently, the industry seeks to improve process monitoring capabilities through advanced sensors and real-time analysis systems that can detect subtle variations in loop formation.

Looking forward, wire bonding technology aims to achieve further miniaturization while enhancing reliability metrics. This includes developing predictive models for loop behavior under various environmental conditions and creating adaptive bonding algorithms that can automatically optimize loop parameters based on specific application requirements. The ultimate objective remains creating wire bond connections that combine mechanical robustness with excellent electrical characteristics across increasingly demanding operational environments.

The evolution continued through the 1980s and 1990s with the development of automated wire bonders capable of handling increasingly fine wire diameters and achieving higher throughput rates. This period marked significant advancements in loop control algorithms and machine vision systems, enabling more precise bond placement and loop formation. The transition from gold to copper wire in the early 2000s represented another milestone, driven by cost considerations and performance advantages, despite introducing new technical challenges in bonding parameters.

Recent technological developments have focused on optimizing wire loop designs to address the critical issues of sag, sweep, and resonance under vibration conditions. These phenomena have become increasingly problematic as wire diameters have decreased to below 20 microns and loop heights have been reduced to accommodate thinner package profiles. The industry has responded with advanced loop formation techniques, including specialized loop profiles such as low-loop, triangular, and optimized S-curve designs.

The primary objectives of current wire bonding research center on enhancing mechanical stability while maintaining electrical performance. This includes developing loop geometries that minimize wire sag under gravitational forces and reduce sweep during molding processes. Additionally, researchers aim to optimize loop resonance characteristics to withstand vibration environments in automotive, aerospace, and industrial applications where reliability under mechanical stress is paramount.

Another critical goal involves adapting wire bonding technology to emerging packaging architectures, including stacked die configurations and system-in-package solutions. These applications demand novel loop designs that can navigate complex three-dimensional spaces while maintaining consistent electrical and mechanical properties. Concurrently, the industry seeks to improve process monitoring capabilities through advanced sensors and real-time analysis systems that can detect subtle variations in loop formation.

Looking forward, wire bonding technology aims to achieve further miniaturization while enhancing reliability metrics. This includes developing predictive models for loop behavior under various environmental conditions and creating adaptive bonding algorithms that can automatically optimize loop parameters based on specific application requirements. The ultimate objective remains creating wire bond connections that combine mechanical robustness with excellent electrical characteristics across increasingly demanding operational environments.

Market Requirements for Advanced Wire Bonding Solutions

The semiconductor packaging industry is witnessing unprecedented demand for advanced wire bonding solutions driven by several converging market forces. As electronic devices continue to shrink while simultaneously increasing in functionality, manufacturers require wire bonding technologies that can accommodate higher pin counts, finer pitches, and improved reliability under increasingly demanding operating conditions.

Automotive electronics represents one of the fastest-growing segments demanding enhanced wire bonding solutions. With the proliferation of advanced driver-assistance systems (ADAS) and autonomous driving technologies, automotive components must withstand extreme vibration environments while maintaining perfect electrical connectivity. The industry standard has evolved to require wire bonds that can endure vibration testing at frequencies ranging from 10Hz to 2000Hz without exhibiting significant sag or sweep phenomena.

Consumer electronics manufacturers are pushing for wire bonding solutions that enable thinner package profiles while maintaining bond integrity. Market research indicates that next-generation mobile devices are targeting overall package heights below 0.5mm, placing stringent requirements on wire loop profiles and their mechanical stability. This trend is particularly evident in wearable technology, where space constraints are even more severe.

The telecommunications infrastructure sector, particularly with 5G deployment, demands wire bonding solutions capable of handling high-frequency signals without degradation. This market segment requires specialized wire loop designs that minimize signal interference and maintain consistent electrical performance even when subjected to environmental vibrations during operation.

Industrial IoT applications present another significant market driver, with requirements for wire bonds that can withstand harsh operating environments including continuous vibration from machinery. These applications typically specify wire bonds capable of maintaining integrity through 10+ years of continuous operation under varying vibration profiles.

Medical device manufacturers represent a premium segment of the market, demanding wire bonding solutions with zero-failure tolerance. For implantable devices, wire bonds must demonstrate exceptional resistance to the natural vibrations of the human body while maintaining biocompatibility and long-term reliability measured in decades rather than years.

Market analysis reveals that manufacturers are increasingly willing to pay premium prices for wire bonding solutions that can demonstrate quantifiable improvements in vibration resistance. The ability to predict and mitigate sag, sweep, and resonance issues before production represents a key competitive advantage in winning contracts from top-tier electronics manufacturers.

Automotive electronics represents one of the fastest-growing segments demanding enhanced wire bonding solutions. With the proliferation of advanced driver-assistance systems (ADAS) and autonomous driving technologies, automotive components must withstand extreme vibration environments while maintaining perfect electrical connectivity. The industry standard has evolved to require wire bonds that can endure vibration testing at frequencies ranging from 10Hz to 2000Hz without exhibiting significant sag or sweep phenomena.

Consumer electronics manufacturers are pushing for wire bonding solutions that enable thinner package profiles while maintaining bond integrity. Market research indicates that next-generation mobile devices are targeting overall package heights below 0.5mm, placing stringent requirements on wire loop profiles and their mechanical stability. This trend is particularly evident in wearable technology, where space constraints are even more severe.

The telecommunications infrastructure sector, particularly with 5G deployment, demands wire bonding solutions capable of handling high-frequency signals without degradation. This market segment requires specialized wire loop designs that minimize signal interference and maintain consistent electrical performance even when subjected to environmental vibrations during operation.

Industrial IoT applications present another significant market driver, with requirements for wire bonds that can withstand harsh operating environments including continuous vibration from machinery. These applications typically specify wire bonds capable of maintaining integrity through 10+ years of continuous operation under varying vibration profiles.

Medical device manufacturers represent a premium segment of the market, demanding wire bonding solutions with zero-failure tolerance. For implantable devices, wire bonds must demonstrate exceptional resistance to the natural vibrations of the human body while maintaining biocompatibility and long-term reliability measured in decades rather than years.

Market analysis reveals that manufacturers are increasingly willing to pay premium prices for wire bonding solutions that can demonstrate quantifiable improvements in vibration resistance. The ability to predict and mitigate sag, sweep, and resonance issues before production represents a key competitive advantage in winning contracts from top-tier electronics manufacturers.

Current Challenges in Wire Loop Stability and Performance

Wire bonding technology faces significant challenges in maintaining loop stability and performance under various operational conditions. The primary issues revolve around three critical phenomena: sag, sweep, and resonance during vibration, which collectively impact the reliability and functionality of semiconductor packages.

Sag refers to the vertical displacement of wire bonds due to gravitational forces and thermal cycling. As semiconductor packages become increasingly miniaturized, even minor sag can lead to short circuits or signal integrity issues. Current wire bonding processes struggle to consistently maintain optimal loop heights across different wire lengths and diameters, particularly in fine-pitch applications where clearance tolerances are extremely tight.

Sweep presents another formidable challenge, characterized by horizontal displacement of wire bonds during the encapsulation process. When molding compound flows around the wires, it exerts forces that can displace them laterally. This issue becomes more pronounced with longer wire spans and thinner wire diameters, which are increasingly common in advanced packaging solutions. The industry currently lacks robust predictive models that accurately account for the complex fluid dynamics involved in the encapsulation process.

Resonance under vibration represents perhaps the most complex challenge. Wire bonds have natural resonant frequencies that, when excited by external vibrations matching these frequencies, can lead to amplified oscillations and eventual fatigue failure. This is particularly problematic in automotive, aerospace, and industrial applications where devices are subjected to continuous vibration. Current testing methodologies often fail to adequately simulate real-world vibration profiles, leading to unexpected field failures.

Material limitations further compound these challenges. Gold wire, while offering excellent electrical conductivity and corrosion resistance, is increasingly cost-prohibitive. Alternative materials like copper and silver alloys present their own complications, including increased hardness (leading to potential cratering of bond pads) and oxidation concerns that affect long-term reliability.

The geometric complexity of modern semiconductor packages also contributes to wire bonding difficulties. Three-dimensional packaging, stacked dies, and complex multi-tier designs create scenarios where wire loops must navigate intricate paths while maintaining consistent electrical performance and mechanical stability. Current automated bonding equipment struggles to optimize loop formations for these complex geometries while maintaining high throughput.

Temperature cycling effects represent another significant challenge, as the coefficient of thermal expansion mismatch between wire materials, die substrates, and packaging compounds creates stress that can accelerate sag, sweep, and resonance failures over time. This becomes particularly critical in high-reliability applications where devices must function across extreme temperature ranges.

Sag refers to the vertical displacement of wire bonds due to gravitational forces and thermal cycling. As semiconductor packages become increasingly miniaturized, even minor sag can lead to short circuits or signal integrity issues. Current wire bonding processes struggle to consistently maintain optimal loop heights across different wire lengths and diameters, particularly in fine-pitch applications where clearance tolerances are extremely tight.

Sweep presents another formidable challenge, characterized by horizontal displacement of wire bonds during the encapsulation process. When molding compound flows around the wires, it exerts forces that can displace them laterally. This issue becomes more pronounced with longer wire spans and thinner wire diameters, which are increasingly common in advanced packaging solutions. The industry currently lacks robust predictive models that accurately account for the complex fluid dynamics involved in the encapsulation process.

Resonance under vibration represents perhaps the most complex challenge. Wire bonds have natural resonant frequencies that, when excited by external vibrations matching these frequencies, can lead to amplified oscillations and eventual fatigue failure. This is particularly problematic in automotive, aerospace, and industrial applications where devices are subjected to continuous vibration. Current testing methodologies often fail to adequately simulate real-world vibration profiles, leading to unexpected field failures.

Material limitations further compound these challenges. Gold wire, while offering excellent electrical conductivity and corrosion resistance, is increasingly cost-prohibitive. Alternative materials like copper and silver alloys present their own complications, including increased hardness (leading to potential cratering of bond pads) and oxidation concerns that affect long-term reliability.

The geometric complexity of modern semiconductor packages also contributes to wire bonding difficulties. Three-dimensional packaging, stacked dies, and complex multi-tier designs create scenarios where wire loops must navigate intricate paths while maintaining consistent electrical performance and mechanical stability. Current automated bonding equipment struggles to optimize loop formations for these complex geometries while maintaining high throughput.

Temperature cycling effects represent another significant challenge, as the coefficient of thermal expansion mismatch between wire materials, die substrates, and packaging compounds creates stress that can accelerate sag, sweep, and resonance failures over time. This becomes particularly critical in high-reliability applications where devices must function across extreme temperature ranges.

Contemporary Loop Design Methodologies for Vibration Resistance

01 Wire bonding loop design to reduce sag and sweep

Specific wire bonding loop designs can be implemented to minimize sag and sweep issues. These designs include optimized loop height, loop shape, and wire trajectory to enhance mechanical stability. By carefully controlling the loop formation process, the susceptibility to deformation during subsequent manufacturing processes can be reduced. Various loop profiles such as triangular, trapezoidal, or curved shapes can be employed depending on the specific application requirements.- Wire bonding loop design to minimize sag and sweep: Various wire bonding loop designs can be implemented to minimize sag and sweep issues. These designs include optimized loop height profiles, specialized loop geometries, and controlled wire trajectories that maintain structural integrity under external forces. Properly designed wire loops can significantly reduce the tendency for sagging and lateral displacement (sweep) during manufacturing processes and in operation, improving overall reliability of semiconductor packages.

- Wire material and properties for resonance reduction: The selection of wire materials and their physical properties plays a crucial role in reducing resonance issues in wire bonding. Materials with appropriate stiffness, elasticity, and damping characteristics can minimize vibration amplitudes at resonant frequencies. Specialized wire compositions, coatings, and treatments can enhance mechanical stability while maintaining electrical performance, thereby reducing susceptibility to resonance-induced failures in semiconductor interconnects.

- Bonding techniques to control loop stability: Advanced bonding techniques can be employed to enhance loop stability and reduce sag, sweep, and resonance issues. These techniques include optimized bonding parameters (force, time, temperature, ultrasonic power), specialized capillary designs, and precise control of wire feed and loop formation. By carefully controlling the bonding process, more stable wire loops with improved resistance to mechanical stresses can be achieved, resulting in higher reliability interconnections.

- Encapsulation and support structures for wire protection: Protective encapsulation materials and support structures can be implemented to minimize wire movement and prevent sag, sweep, and resonance issues. These include specialized molding compounds with optimized viscosity and flow characteristics, supporting elements that physically constrain wire movement, and strategic placement of structural features within the package. Such protective measures help maintain wire loop integrity during manufacturing processes and under operational stresses.

- Testing and simulation methods for wire loop reliability: Advanced testing and simulation methodologies can be employed to predict and mitigate wire bonding loop sag, sweep, and resonance issues. These include finite element analysis, vibration testing, accelerated stress testing, and real-time monitoring during manufacturing. By identifying potential failure modes before mass production, these methods enable optimization of wire loop designs and process parameters to enhance reliability and performance of semiconductor interconnections.

02 Wire material and properties to improve resistance to sweep

The selection of wire material and its properties significantly impacts the wire bond's resistance to sweep forces. Wires with higher tensile strength, appropriate hardness, and optimized diameter can better withstand external forces during molding and packaging processes. Some implementations use specialized alloys or composite materials that provide enhanced mechanical stability while maintaining good electrical conductivity. Surface treatments of the wire can also improve bonding strength and reduce susceptibility to environmental factors.Expand Specific Solutions03 Bonding techniques to minimize resonance effects

Advanced bonding techniques can be employed to minimize resonance effects in wire bonds. These techniques include optimized ultrasonic energy application, precise temperature control during the bonding process, and specialized bonding parameters that create stronger interfaces between the wire and bond pads. Some methods involve multi-stage bonding processes that create more robust connections with improved vibration damping characteristics. Controlling the bonding force and time also contributes to creating bonds that are less susceptible to resonance-induced failures.Expand Specific Solutions04 Encapsulation and packaging methods to stabilize wire bonds

Specialized encapsulation and packaging methods can be used to stabilize wire bonds against sag, sweep, and resonance. These include optimized molding compound formulations with appropriate viscosity and flow characteristics, controlled molding processes to minimize wire displacement, and strategic placement of support structures. Some approaches involve pre-coating the wires with protective materials or using partial encapsulation techniques before the final molding process. The curing profile of encapsulation materials can also be tailored to minimize stress on the wire bonds.Expand Specific Solutions05 Testing and simulation methods for wire bond reliability

Various testing and simulation methods have been developed to evaluate and predict wire bond reliability with respect to sag, sweep, and resonance. These include finite element analysis to simulate mechanical stresses, accelerated aging tests to assess long-term reliability, and specialized inspection techniques to detect potential failures. Some approaches involve real-time monitoring during the manufacturing process to identify and correct issues before they lead to failures. Advanced imaging techniques can be used to characterize wire bond geometry and detect subtle deformations that might lead to future reliability problems.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Wire Bonding

The wire bonding loop design market is in a mature growth phase, with an estimated global market size of $2-3 billion annually. The competitive landscape is dominated by established equipment manufacturers like Kulicke & Soffa Industries and ASM Technology Singapore, who lead in technological innovation addressing sag, sweep, and resonance challenges. The technology has reached high maturity levels, with companies like Texas Instruments, QUALCOMM, and NXP USA driving application-specific advancements. Asian players including Kaijo Corp. and STATS ChipPAC are gaining market share through specialized solutions. Academic institutions such as Southeast University and Shandong University contribute significant research to improve vibration resistance and reliability, creating a collaborative ecosystem between industry and academia that continues to refine this critical semiconductor packaging technology.

Kulicke & Soffa Industries, Inc.

Technical Solution: Kulicke & Soffa (K&S) has developed advanced wire bonding loop design solutions that specifically address sag, sweep, and resonance issues under vibration conditions. Their proprietary Hybrid Loop technology combines optimized loop geometry with controlled wire deformation to minimize sag while maintaining sufficient loop height. The company's IConn™ wire bonding platform incorporates real-time vibration analysis that predicts resonance frequencies and automatically adjusts loop parameters to avoid critical frequencies. K&S has implemented adaptive loop control algorithms that continuously monitor environmental conditions and make micro-adjustments to maintain loop stability. Their research has shown that properly designed loops with optimized inflection points can reduce sweep by up to 40% under standard vibration testing. Additionally, K&S has pioneered specialized wire materials with enhanced mechanical properties that provide superior vibration resistance while maintaining electrical performance.

Strengths: Industry-leading real-time vibration analysis capabilities; proprietary loop formation algorithms that dynamically adjust to environmental conditions; extensive material science expertise for specialized bonding wire development. Weaknesses: Higher implementation costs compared to standard solutions; requires more sophisticated equipment calibration; some solutions may be limited to specific wire materials.

Shinkawa KK

Technical Solution: Shinkawa has developed a comprehensive wire bonding loop design approach focused on vibration resistance through their VRS (Vibration Resistant System) technology. Their solution incorporates multi-point loop formation that creates strategically placed inflection points to disperse vibration energy and reduce harmonic amplification. Shinkawa's proprietary loop profile generator uses finite element analysis to simulate wire behavior under various vibration frequencies and amplitudes, allowing for predictive optimization before physical implementation. Their research has demonstrated that optimized S-curve loop designs with precisely controlled wire tension can reduce sag by up to 35% compared to conventional loops. Shinkawa has also pioneered adaptive bonding parameters that automatically adjust based on wire length and loop height to maintain consistent mechanical properties across different bond configurations. Their latest systems incorporate real-time monitoring that can detect early signs of resonance and make immediate adjustments to prevent wire failure.

Strengths: Sophisticated simulation capabilities that accurately predict wire behavior under complex vibration conditions; highly customizable loop profiles for different application requirements; excellent integration with automated production systems. Weaknesses: Requires significant operator training to fully utilize advanced features; some solutions optimized for specific wire diameters may not scale well across all applications.

Critical Patents and Research on Wire Loop Mechanics

Wire loop, semiconductor device having same and wire bonding method

PatentActiveUS8016182B2

Innovation

- A wire bonding method that forms additional wire loops at the extended portion of the wire bonded to the second bonding point without cutting the wire, enhancing the bonding strength by crushing part of the wire and enlarging the bonding area, while also reducing the time required for the process.

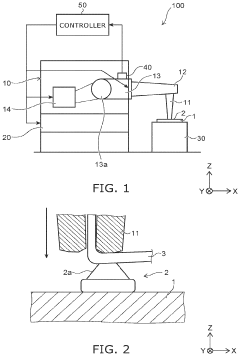

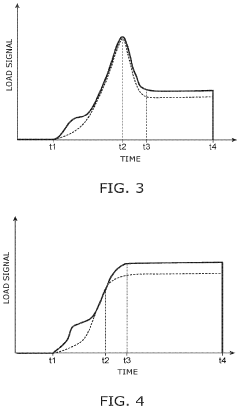

Wire bonding apparatus and wire bonding method

PatentActiveUS11610860B2

Innovation

- A wire bonding apparatus with a load sensor and controller that continuously detects the load applied during bonding and calculates a determination value to adjust the bonding operation, preventing defects by altering the bonding conditions based on the calculated value.

Reliability Testing Standards for Wire Bonded Interconnects

Reliability testing standards for wire bonded interconnects have evolved significantly over the past decades to address the complex mechanical behaviors observed in wire bonding systems, particularly focusing on sag, sweep, and resonance under vibration conditions. The Joint Electron Device Engineering Council (JEDEC) has established comprehensive standards such as JESD22-B116 for wire bond shear testing and JESD22-B110 for wire bond pull testing, which serve as industry benchmarks for evaluating bond integrity and reliability.

The Military Standard MIL-STD-883 Method 2011 specifically addresses bond strength testing, providing detailed procedures for assessing the mechanical robustness of wire bonds under various stress conditions. This standard is particularly relevant for high-reliability applications in aerospace and defense sectors where vibration-induced failures must be minimized.

Automotive Electronics Council's AEC-Q100 standard incorporates specific requirements for wire bond reliability in harsh automotive environments, including temperature cycling (Test Method 1010) and vibration testing (Test Method 2007), which directly correlate to the sag and resonance behaviors in wire bond loops. These tests typically subject samples to frequency sweeps ranging from 10Hz to 2000Hz to identify potential resonance points.

International Electrotechnical Commission (IEC) standards, particularly IEC 60749-9 for mechanical shock and IEC 60749-12 for vibration testing, provide globally recognized methodologies for evaluating wire bond performance under dynamic loading conditions. These standards specify acceleration levels, duration, and frequency parameters that effectively simulate real-world operational stresses.

The ASTM F459 standard focuses on wire bond pull testing methodologies, offering precise guidelines for test equipment calibration and measurement techniques. This standard is crucial for quantifying the mechanical strength of bonds that might be compromised by sag or sweep phenomena during vibration.

Recent advancements in reliability standards have incorporated finite element analysis (FEA) validation requirements, where manufacturers must demonstrate correlation between simulation models and physical test results for wire loop designs. This approach has become increasingly important as wire diameters continue to decrease while loop heights and spans increase in modern packaging technologies.

Industry-specific standards such as those from SEMI (Semiconductor Equipment and Materials International) provide additional testing protocols focused on high-frequency vibration testing (>20kHz) that can identify micro-scale resonance issues in fine wire bonds before they manifest as failures in field applications.

The Military Standard MIL-STD-883 Method 2011 specifically addresses bond strength testing, providing detailed procedures for assessing the mechanical robustness of wire bonds under various stress conditions. This standard is particularly relevant for high-reliability applications in aerospace and defense sectors where vibration-induced failures must be minimized.

Automotive Electronics Council's AEC-Q100 standard incorporates specific requirements for wire bond reliability in harsh automotive environments, including temperature cycling (Test Method 1010) and vibration testing (Test Method 2007), which directly correlate to the sag and resonance behaviors in wire bond loops. These tests typically subject samples to frequency sweeps ranging from 10Hz to 2000Hz to identify potential resonance points.

International Electrotechnical Commission (IEC) standards, particularly IEC 60749-9 for mechanical shock and IEC 60749-12 for vibration testing, provide globally recognized methodologies for evaluating wire bond performance under dynamic loading conditions. These standards specify acceleration levels, duration, and frequency parameters that effectively simulate real-world operational stresses.

The ASTM F459 standard focuses on wire bond pull testing methodologies, offering precise guidelines for test equipment calibration and measurement techniques. This standard is crucial for quantifying the mechanical strength of bonds that might be compromised by sag or sweep phenomena during vibration.

Recent advancements in reliability standards have incorporated finite element analysis (FEA) validation requirements, where manufacturers must demonstrate correlation between simulation models and physical test results for wire loop designs. This approach has become increasingly important as wire diameters continue to decrease while loop heights and spans increase in modern packaging technologies.

Industry-specific standards such as those from SEMI (Semiconductor Equipment and Materials International) provide additional testing protocols focused on high-frequency vibration testing (>20kHz) that can identify micro-scale resonance issues in fine wire bonds before they manifest as failures in field applications.

Materials Science Advancements for Wire Bonding Applications

The evolution of wire bonding technology has been significantly influenced by advancements in materials science. Traditional gold wire bonding has been the industry standard for decades due to gold's excellent electrical conductivity, corrosion resistance, and bondability. However, cost considerations have driven research into alternative materials such as copper, silver, and aluminum alloys.

Copper wire has emerged as a prominent alternative, offering superior electrical and thermal conductivity compared to gold while being considerably more cost-effective. The challenge with copper lies in its susceptibility to oxidation, requiring specialized bonding environments and surface treatments. Recent developments in copper wire composition have introduced dopants and alloying elements that enhance oxidation resistance while maintaining mechanical integrity.

Silver alloy wires represent another promising direction, combining excellent electrical properties with better oxidation resistance than copper. Silver-palladium and silver-gold alloys have shown particular promise in applications requiring high reliability under vibration conditions, as they maintain structural integrity while providing sufficient ductility for loop formation.

The mechanical properties of bonding wires have been engineered specifically to address sag, sweep, and resonance issues. Advanced metallurgical processes now enable precise control of grain structure and crystallographic orientation, resulting in wires with optimized elastic modulus and yield strength. These properties directly influence the wire's resistance to deformation under vibration and thermal cycling.

Nano-composite wire materials represent the cutting edge of materials science in this field. By incorporating nanoscale reinforcement particles into the wire matrix, researchers have developed wires with enhanced mechanical stability under vibration while maintaining electrical performance. These composites demonstrate superior resistance to fatigue failure, a critical factor in environments with persistent vibration.

Surface coating technologies have also evolved to improve bonding interfaces. Specialized metallic and non-metallic coatings can enhance adhesion strength between the wire and bond pads while providing additional protection against environmental factors. These coatings are engineered at the nanometer scale to optimize both mechanical anchoring and intermetallic compound formation at the bond interface.

The relationship between material composition and loop geometry has become increasingly understood through advanced characterization techniques. Electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM) analyses have revealed how microstructural features influence wire deformation behavior under stress, enabling materials scientists to design alloy compositions specifically optimized for vibration resistance in complex loop geometries.

Copper wire has emerged as a prominent alternative, offering superior electrical and thermal conductivity compared to gold while being considerably more cost-effective. The challenge with copper lies in its susceptibility to oxidation, requiring specialized bonding environments and surface treatments. Recent developments in copper wire composition have introduced dopants and alloying elements that enhance oxidation resistance while maintaining mechanical integrity.

Silver alloy wires represent another promising direction, combining excellent electrical properties with better oxidation resistance than copper. Silver-palladium and silver-gold alloys have shown particular promise in applications requiring high reliability under vibration conditions, as they maintain structural integrity while providing sufficient ductility for loop formation.

The mechanical properties of bonding wires have been engineered specifically to address sag, sweep, and resonance issues. Advanced metallurgical processes now enable precise control of grain structure and crystallographic orientation, resulting in wires with optimized elastic modulus and yield strength. These properties directly influence the wire's resistance to deformation under vibration and thermal cycling.

Nano-composite wire materials represent the cutting edge of materials science in this field. By incorporating nanoscale reinforcement particles into the wire matrix, researchers have developed wires with enhanced mechanical stability under vibration while maintaining electrical performance. These composites demonstrate superior resistance to fatigue failure, a critical factor in environments with persistent vibration.

Surface coating technologies have also evolved to improve bonding interfaces. Specialized metallic and non-metallic coatings can enhance adhesion strength between the wire and bond pads while providing additional protection against environmental factors. These coatings are engineered at the nanometer scale to optimize both mechanical anchoring and intermetallic compound formation at the bond interface.

The relationship between material composition and loop geometry has become increasingly understood through advanced characterization techniques. Electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM) analyses have revealed how microstructural features influence wire deformation behavior under stress, enabling materials scientists to design alloy compositions specifically optimized for vibration resistance in complex loop geometries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!