How Wire Bonding Parameters Transfer From Coupons To Complex SiP Layouts?

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wire Bonding Technology Evolution and Objectives

Wire bonding technology has evolved significantly since its inception in the 1950s, transforming from rudimentary manual processes to sophisticated automated systems. Initially developed for simple semiconductor packaging, wire bonding has become the backbone of modern microelectronics interconnection, accounting for over 90% of all semiconductor interconnections globally. The evolution trajectory has been marked by continuous improvements in bonding speed, reliability, and miniaturization capabilities to meet increasingly complex packaging demands.

The 1970s witnessed the transition from manual to semi-automated bonding processes, while the 1980s brought fully automated systems with rudimentary process control. The 1990s marked a significant advancement with the introduction of digital control systems and real-time monitoring capabilities. By the 2000s, wire bonding technology had evolved to accommodate fine-pitch applications below 50 μm, enabling higher density packaging solutions.

Recent technological advancements have focused on enhancing parameter control precision, with modern wire bonders capable of placement accuracy within ±1.0 μm and consistent loop formation. This precision has become crucial as System-in-Package (SiP) designs grow increasingly complex, integrating multiple die types with varying heights and interconnection requirements within a single package.

The fundamental challenge in wire bonding parameter transfer lies in the significant disparity between coupon-based development environments and actual production SiP layouts. Coupons—simplified test structures used for initial process development—typically feature uniform pad metallization, consistent die heights, and standardized geometries. In contrast, complex SiP implementations present variable die heights, diverse pad metallizations, and intricate geometric constraints that significantly impact bonding parameters.

The primary objective of modern wire bonding technology development is to establish robust methodologies for translating bonding parameters from simplified coupon environments to complex SiP implementations without compromising reliability or yield. This includes developing adaptive algorithms that can automatically adjust critical parameters such as ultrasonic power, bonding force, and time based on specific layout characteristics.

Additional objectives include enhancing real-time monitoring capabilities to detect parameter drift during production, implementing machine learning systems for predictive maintenance and process optimization, and developing comprehensive simulation tools that can accurately predict bonding behavior across different substrate configurations. These advancements aim to reduce development cycles, minimize production defects, and enable increasingly complex SiP designs that support emerging applications in 5G communications, automotive electronics, and wearable technologies.

The 1970s witnessed the transition from manual to semi-automated bonding processes, while the 1980s brought fully automated systems with rudimentary process control. The 1990s marked a significant advancement with the introduction of digital control systems and real-time monitoring capabilities. By the 2000s, wire bonding technology had evolved to accommodate fine-pitch applications below 50 μm, enabling higher density packaging solutions.

Recent technological advancements have focused on enhancing parameter control precision, with modern wire bonders capable of placement accuracy within ±1.0 μm and consistent loop formation. This precision has become crucial as System-in-Package (SiP) designs grow increasingly complex, integrating multiple die types with varying heights and interconnection requirements within a single package.

The fundamental challenge in wire bonding parameter transfer lies in the significant disparity between coupon-based development environments and actual production SiP layouts. Coupons—simplified test structures used for initial process development—typically feature uniform pad metallization, consistent die heights, and standardized geometries. In contrast, complex SiP implementations present variable die heights, diverse pad metallizations, and intricate geometric constraints that significantly impact bonding parameters.

The primary objective of modern wire bonding technology development is to establish robust methodologies for translating bonding parameters from simplified coupon environments to complex SiP implementations without compromising reliability or yield. This includes developing adaptive algorithms that can automatically adjust critical parameters such as ultrasonic power, bonding force, and time based on specific layout characteristics.

Additional objectives include enhancing real-time monitoring capabilities to detect parameter drift during production, implementing machine learning systems for predictive maintenance and process optimization, and developing comprehensive simulation tools that can accurately predict bonding behavior across different substrate configurations. These advancements aim to reduce development cycles, minimize production defects, and enable increasingly complex SiP designs that support emerging applications in 5G communications, automotive electronics, and wearable technologies.

Market Demand for Advanced SiP Packaging Solutions

The global market for System-in-Package (SiP) technology has experienced substantial growth in recent years, driven primarily by the increasing demand for miniaturized electronic devices with enhanced functionality. The SiP market was valued at approximately $13.5 billion in 2022 and is projected to reach $23.4 billion by 2028, representing a compound annual growth rate (CAGR) of 9.6% during the forecast period.

Consumer electronics remains the dominant application segment, accounting for over 40% of the total market share. This is largely attributed to the widespread adoption of smartphones, wearables, and IoT devices that require compact, high-performance packaging solutions. The automotive sector is emerging as the fastest-growing segment, with an estimated CAGR of 12.3% through 2028, fueled by the increasing integration of advanced driver-assistance systems (ADAS) and infotainment systems.

Wire bonding continues to be a critical interconnection technology within SiP solutions, despite advances in alternative technologies such as flip-chip and through-silicon vias (TSVs). The wire bonding segment constitutes approximately 35% of the overall SiP interconnection market, valued at $4.7 billion in 2022. Industry analysts predict this segment will maintain steady growth at a CAGR of 7.2% through 2028.

The demand for reliable wire bonding parameter transfer methodologies from test coupons to complex SiP layouts is intensifying as manufacturers face mounting pressure to reduce development cycles and improve first-pass yields. According to a recent industry survey, 78% of semiconductor packaging companies identified parameter optimization as a significant challenge in their SiP development process, with 63% specifically highlighting the difficulties in translating wire bonding parameters from simple test structures to production designs.

Regional analysis reveals that Asia-Pacific dominates the SiP market with a 65% share, led by manufacturing powerhouses in Taiwan, South Korea, and China. North America follows with approximately 20% market share, primarily driven by innovation in high-performance computing and telecommunications applications.

The increasing complexity of SiP designs, with some advanced packages incorporating more than 1,000 wire bonds, has created a substantial market need for sophisticated modeling and simulation tools. The SiP design software market, valued at $1.2 billion in 2022, is expected to grow at a CAGR of 11.5% through 2028, with wire bonding simulation capabilities representing a key competitive differentiator among tool providers.

Industry stakeholders are increasingly recognizing the economic impact of optimized wire bonding parameter transfer, with studies indicating that effective methodologies can reduce development costs by up to 30% and decrease time-to-market by approximately 25% for complex SiP products.

Consumer electronics remains the dominant application segment, accounting for over 40% of the total market share. This is largely attributed to the widespread adoption of smartphones, wearables, and IoT devices that require compact, high-performance packaging solutions. The automotive sector is emerging as the fastest-growing segment, with an estimated CAGR of 12.3% through 2028, fueled by the increasing integration of advanced driver-assistance systems (ADAS) and infotainment systems.

Wire bonding continues to be a critical interconnection technology within SiP solutions, despite advances in alternative technologies such as flip-chip and through-silicon vias (TSVs). The wire bonding segment constitutes approximately 35% of the overall SiP interconnection market, valued at $4.7 billion in 2022. Industry analysts predict this segment will maintain steady growth at a CAGR of 7.2% through 2028.

The demand for reliable wire bonding parameter transfer methodologies from test coupons to complex SiP layouts is intensifying as manufacturers face mounting pressure to reduce development cycles and improve first-pass yields. According to a recent industry survey, 78% of semiconductor packaging companies identified parameter optimization as a significant challenge in their SiP development process, with 63% specifically highlighting the difficulties in translating wire bonding parameters from simple test structures to production designs.

Regional analysis reveals that Asia-Pacific dominates the SiP market with a 65% share, led by manufacturing powerhouses in Taiwan, South Korea, and China. North America follows with approximately 20% market share, primarily driven by innovation in high-performance computing and telecommunications applications.

The increasing complexity of SiP designs, with some advanced packages incorporating more than 1,000 wire bonds, has created a substantial market need for sophisticated modeling and simulation tools. The SiP design software market, valued at $1.2 billion in 2022, is expected to grow at a CAGR of 11.5% through 2028, with wire bonding simulation capabilities representing a key competitive differentiator among tool providers.

Industry stakeholders are increasingly recognizing the economic impact of optimized wire bonding parameter transfer, with studies indicating that effective methodologies can reduce development costs by up to 30% and decrease time-to-market by approximately 25% for complex SiP products.

Current Challenges in Wire Bonding Parameter Transfer

The transfer of wire bonding parameters from test coupons to complex System-in-Package (SiP) layouts represents a significant technical challenge in semiconductor packaging. Despite advancements in wire bonding technology, the industry continues to struggle with achieving consistent and reliable parameter translation across different substrate configurations and design complexities.

One of the primary challenges lies in the geometric differences between test coupons and actual SiP designs. Test coupons typically feature simplified, uniform pad arrangements with standardized spacing and dimensions. In contrast, real-world SiP layouts contain varied pad geometries, irregular spacing, and complex multi-tier structures that create fundamentally different bonding conditions. These differences in physical layout directly impact critical bonding parameters such as ultrasonic energy transfer, bond force distribution, and wire loop formation.

Material inconsistencies further complicate parameter transfer efforts. While test coupons often utilize homogeneous materials with uniform properties, actual SiP implementations incorporate diverse substrate materials, varying metallization layers, and different surface finishes. These material variations significantly alter the thermal and mechanical responses during the bonding process, rendering direct parameter translation ineffective without substantial adjustments.

The thermal profile discrepancy between test environments and production settings presents another major obstacle. Temperature distribution across complex SiP layouts is rarely uniform, creating localized hot spots and cool zones that affect bonding quality. Test coupons, being smaller and more thermally consistent, fail to replicate these thermal gradients, leading to unexpected bonding behavior when parameters are transferred to production environments.

Signal integrity and electrical performance requirements introduce additional complexity. In high-frequency applications, wire bond parameters must be optimized not only for mechanical strength but also for electrical performance. The electrical characteristics of bonds in complex layouts differ substantially from those in simplified test coupons, necessitating parameter adjustments that balance mechanical reliability with electrical performance.

Manufacturing variability compounds these challenges. Production-scale wire bonding processes are subject to machine-to-machine variations, tool wear, and environmental fluctuations that are difficult to account for in coupon-based parameter development. These variations often necessitate real-time parameter adjustments during production, undermining the reliability of pre-established parameter sets.

The industry also faces significant knowledge gaps in understanding the complex interactions between multiple bonding parameters across different design configurations. Current modeling approaches often fail to capture the non-linear relationships between parameters like ultrasonic power, bond force, and time when applied to diverse geometric arrangements, limiting the predictive capability of parameter transfer methodologies.

One of the primary challenges lies in the geometric differences between test coupons and actual SiP designs. Test coupons typically feature simplified, uniform pad arrangements with standardized spacing and dimensions. In contrast, real-world SiP layouts contain varied pad geometries, irregular spacing, and complex multi-tier structures that create fundamentally different bonding conditions. These differences in physical layout directly impact critical bonding parameters such as ultrasonic energy transfer, bond force distribution, and wire loop formation.

Material inconsistencies further complicate parameter transfer efforts. While test coupons often utilize homogeneous materials with uniform properties, actual SiP implementations incorporate diverse substrate materials, varying metallization layers, and different surface finishes. These material variations significantly alter the thermal and mechanical responses during the bonding process, rendering direct parameter translation ineffective without substantial adjustments.

The thermal profile discrepancy between test environments and production settings presents another major obstacle. Temperature distribution across complex SiP layouts is rarely uniform, creating localized hot spots and cool zones that affect bonding quality. Test coupons, being smaller and more thermally consistent, fail to replicate these thermal gradients, leading to unexpected bonding behavior when parameters are transferred to production environments.

Signal integrity and electrical performance requirements introduce additional complexity. In high-frequency applications, wire bond parameters must be optimized not only for mechanical strength but also for electrical performance. The electrical characteristics of bonds in complex layouts differ substantially from those in simplified test coupons, necessitating parameter adjustments that balance mechanical reliability with electrical performance.

Manufacturing variability compounds these challenges. Production-scale wire bonding processes are subject to machine-to-machine variations, tool wear, and environmental fluctuations that are difficult to account for in coupon-based parameter development. These variations often necessitate real-time parameter adjustments during production, undermining the reliability of pre-established parameter sets.

The industry also faces significant knowledge gaps in understanding the complex interactions between multiple bonding parameters across different design configurations. Current modeling approaches often fail to capture the non-linear relationships between parameters like ultrasonic power, bond force, and time when applied to diverse geometric arrangements, limiting the predictive capability of parameter transfer methodologies.

Existing Parameter Transfer Methodologies

01 Automated wire bonding parameter optimization systems

Systems that automatically optimize wire bonding parameters through machine learning algorithms and statistical analysis. These systems collect data from previous bonding operations, analyze the results, and adjust parameters accordingly to improve bond quality and consistency. The automation reduces manual intervention and enables efficient parameter transfer between different machines or production lines.- Automated wire bonding parameter optimization: Systems and methods for automatically optimizing wire bonding parameters to improve bonding quality and efficiency. These systems utilize machine learning algorithms and statistical analysis to determine optimal bonding parameters such as force, time, temperature, and ultrasonic power. The automated optimization reduces manual intervention, minimizes defects, and ensures consistent bond quality across different production runs.

- Parameter transfer between different bonding machines: Technologies for transferring wire bonding parameters between different bonding machines or production lines to maintain consistency. These solutions include standardized parameter conversion algorithms, machine-specific calibration methods, and database systems that store and translate parameters across equipment from different manufacturers. This enables seamless transfer of proven bonding recipes between machines while accounting for equipment-specific characteristics.

- Real-time monitoring and adjustment of bonding parameters: Systems for real-time monitoring of wire bonding processes that can detect deviations and automatically adjust parameters during operation. These systems utilize sensors to measure bond quality indicators such as deformation, shear strength, and electrical characteristics, then make immediate parameter adjustments to maintain quality. The real-time feedback loops help prevent defects and reduce scrap rates during production.

- Parameter optimization for different substrate materials: Methods for optimizing wire bonding parameters based on specific substrate materials and surface conditions. These approaches involve analyzing material properties such as hardness, surface roughness, and metallization characteristics to determine appropriate bonding parameters. Specialized algorithms can recommend optimal parameter sets for different material combinations, ensuring strong bonds while preventing damage to delicate substrates.

- Database systems for wire bonding parameter management: Comprehensive database systems designed to store, manage, and retrieve wire bonding parameters across multiple production facilities. These systems maintain historical records of successful bonding parameters, track parameter changes over time, and provide searchable libraries of proven bonding recipes. The databases enable knowledge sharing between engineers, facilitate troubleshooting, and support continuous process improvement through parameter refinement.

02 Wire bonding parameter transfer between different machines

Methods for transferring optimized wire bonding parameters between different bonding machines or across production facilities. These techniques ensure consistency in bonding quality regardless of equipment variations. The transfer processes typically involve standardization protocols, parameter conversion algorithms, and validation procedures to account for machine-specific characteristics while maintaining bond integrity.Expand Specific Solutions03 Real-time monitoring and adjustment of wire bonding parameters

Systems that continuously monitor wire bonding processes and make real-time adjustments to parameters based on feedback. These systems use sensors to detect variations in bonding conditions and automatically modify parameters such as force, time, temperature, and ultrasonic power to maintain optimal bond quality. Real-time monitoring helps prevent defects and ensures consistent bonding performance across production runs.Expand Specific Solutions04 Database systems for wire bonding parameter management

Comprehensive database systems designed to store, manage, and retrieve wire bonding parameters. These systems maintain historical records of successful bonding parameters for different materials, wire types, and device configurations. The databases enable quick parameter retrieval for similar applications, facilitate parameter optimization through data mining, and support knowledge transfer between engineering teams.Expand Specific Solutions05 Wire bonding parameter verification and validation methods

Methodologies to verify and validate transferred wire bonding parameters before full production implementation. These methods include test bonding procedures, statistical analysis of bond quality, pull and shear testing protocols, and visual inspection techniques. Verification ensures that transferred parameters produce bonds meeting quality and reliability standards, reducing the risk of defects in production.Expand Specific Solutions

Key Players in SiP Packaging and Wire Bonding Industry

The wire bonding parameter transfer landscape is currently in a mature growth phase, with the market expanding due to increasing SiP adoption in consumer electronics and automotive applications. The global market is projected to reach significant scale as complex SiP designs become mainstream. Leading semiconductor manufacturers like TSMC, Samsung, and Intel are advancing wire bonding technologies with automated parameter optimization systems. Specialized packaging companies including ASE, JCET Group, and Shinko Electric have developed proprietary transfer methodologies. Renesas, NXP, and Micron are focusing on application-specific parameter optimization for automotive and high-reliability applications, while equipment providers like Tokyo Electron are integrating AI-driven solutions to improve parameter transfer accuracy between test coupons and production layouts.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed an integrated wire bonding parameter transfer system specifically designed for advanced SiP applications. Their methodology employs a hierarchical approach that categorizes SiP layouts based on complexity factors including die count, stacking configuration, and thermal characteristics. For each category, TSMC has created specialized transfer functions that accurately translate bonding parameters from standardized test coupons to production environments. Their system incorporates advanced thermal modeling that accounts for heat dissipation differences between simple coupons and complex multi-die arrangements, a critical factor affecting bond integrity. TSMC's approach includes comprehensive material characterization databases that track how different substrate compositions, metallization layers, and wire materials interact during the bonding process, enabling precise parameter adjustments when transitioning from coupons to production.

Strengths: Exceptional parameter transfer accuracy for extremely complex heterogeneous integration scenarios, with demonstrated success in packages containing up to 12 different die types. Their hierarchical categorization approach simplifies implementation for new designs. Weaknesses: The system is optimized primarily for TSMC's own substrate materials and process technologies, potentially requiring significant adaptation for use with third-party components.

Advanced Semiconductor Engineering, Inc.

Technical Solution: ASE has developed a comprehensive wire bonding parameter transfer methodology specifically for complex SiP designs. Their approach involves creating standardized test coupons that accurately simulate the thermal and mechanical conditions of actual SiP layouts. ASE employs a three-phase transfer process: initial parameter optimization on test coupons, intermediate verification on simplified SiP structures, and final implementation on complex layouts with real-time monitoring systems. Their proprietary algorithms adjust for differences in substrate properties, die placement variations, and thermal gradients between test coupons and actual products. ASE's methodology includes advanced statistical process control (SPC) techniques that continuously refine bonding parameters based on production data, ensuring consistent bond quality across different package configurations.

Strengths: Industry-leading expertise in advanced packaging with comprehensive parameter transfer methodologies that minimize production delays. Their approach reduces development time by approximately 30% compared to traditional methods. Weaknesses: Their proprietary algorithms require significant computational resources and specialized equipment, potentially increasing implementation costs for smaller manufacturers.

Critical Patents in Wire Bonding Parameter Optimization

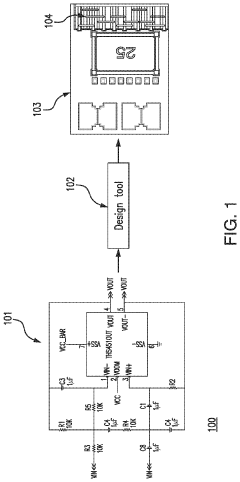

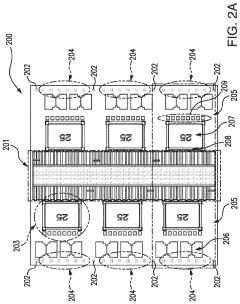

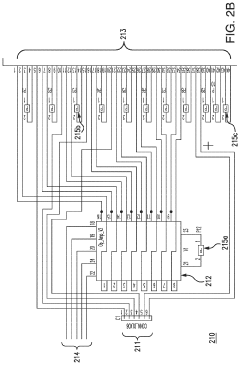

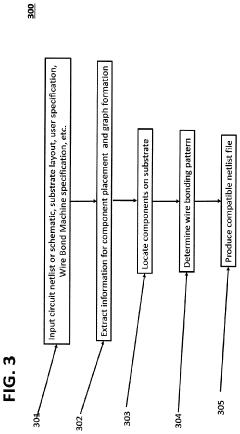

Method for routing bond wires in system in a package (SIP) devices

PatentActiveUS20190347378A1

Innovation

- The use of a substrate with one or more bond wire connection arrays or matrices that can be programmed differently to accommodate various systems by strategically placing bond wires on pads, allowing for unique electrical connections and reconfiguration, using a database to instruct a place and route machine for optimal component placement and wire bonding.

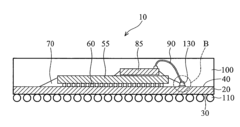

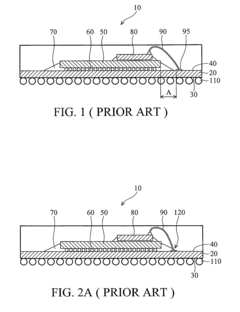

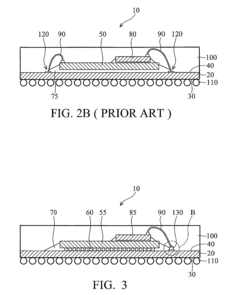

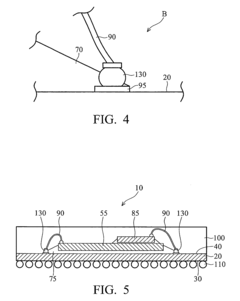

System-in-package packaging for minimizing bond wire contamination and yield loss

PatentInactiveUS7719122B2

Innovation

- The use of bond wire studs on the substrate surface, which are formed before mounting the chip, allows underfill material to encapsulate solder bumps without overflowing onto the studs, enabling proper wire bonding and reducing yield loss, while allowing for closer chip-to-pad spacing and more design flexibility.

Material Science Considerations for Wire Bonding

The material science aspects of wire bonding are fundamental to understanding parameter transfer from test coupons to complex SiP layouts. Wire bonding relies on the formation of intermetallic compounds (IMCs) at the interface between the bond wire and bond pad. These IMCs are critical for establishing reliable electrical and mechanical connections, with their formation being highly dependent on the material properties of both the wire and substrate.

Gold, copper, and aluminum remain the predominant wire materials in modern packaging applications, each offering distinct advantages. Gold wires provide excellent bondability and corrosion resistance but face cost constraints. Copper wires offer superior electrical conductivity and mechanical strength at lower cost, though they require more aggressive bonding parameters and controlled atmospheres to prevent oxidation. Aluminum wires are commonly used for their compatibility with aluminum bond pads but exhibit lower conductivity.

The metallurgy of bond pads significantly influences parameter transferability. Common pad materials include aluminum, copper, gold, and various alloys, each with unique mechanical properties and IMC formation characteristics. The thickness, hardness, and surface finish of these pads directly impact bondability and the required bonding parameters. Surface contamination, oxidation levels, and roughness further complicate parameter transfer from test coupons to actual devices.

Substrate properties introduce additional complexity in parameter transfer. The hardness and compliance of the underlying materials affect energy dissipation during the bonding process. Differences in thermal conductivity between test coupons and actual SiP layouts can lead to significant variations in heat distribution during thermosonic bonding, necessitating parameter adjustments. The mechanical resonance characteristics of different substrate configurations also influence ultrasonic energy transfer efficiency.

Environmental factors during bonding, including temperature and humidity, significantly affect material behavior. Higher temperatures generally enhance diffusion processes and IMC formation but may accelerate oxidation. Humidity can introduce moisture-related defects and alter surface chemistry. These environmental sensitivities often manifest differently between simple test coupons and complex SiP layouts due to differences in thermal mass and geometry.

The microstructural evolution of materials during and after bonding represents another critical consideration. Grain structure changes, recrystallization phenomena, and stress relaxation processes continue after the initial bond formation, affecting long-term reliability. These processes depend on the specific material combinations and can vary significantly between test environments and actual applications, necessitating comprehensive material characterization for successful parameter transfer.

Gold, copper, and aluminum remain the predominant wire materials in modern packaging applications, each offering distinct advantages. Gold wires provide excellent bondability and corrosion resistance but face cost constraints. Copper wires offer superior electrical conductivity and mechanical strength at lower cost, though they require more aggressive bonding parameters and controlled atmospheres to prevent oxidation. Aluminum wires are commonly used for their compatibility with aluminum bond pads but exhibit lower conductivity.

The metallurgy of bond pads significantly influences parameter transferability. Common pad materials include aluminum, copper, gold, and various alloys, each with unique mechanical properties and IMC formation characteristics. The thickness, hardness, and surface finish of these pads directly impact bondability and the required bonding parameters. Surface contamination, oxidation levels, and roughness further complicate parameter transfer from test coupons to actual devices.

Substrate properties introduce additional complexity in parameter transfer. The hardness and compliance of the underlying materials affect energy dissipation during the bonding process. Differences in thermal conductivity between test coupons and actual SiP layouts can lead to significant variations in heat distribution during thermosonic bonding, necessitating parameter adjustments. The mechanical resonance characteristics of different substrate configurations also influence ultrasonic energy transfer efficiency.

Environmental factors during bonding, including temperature and humidity, significantly affect material behavior. Higher temperatures generally enhance diffusion processes and IMC formation but may accelerate oxidation. Humidity can introduce moisture-related defects and alter surface chemistry. These environmental sensitivities often manifest differently between simple test coupons and complex SiP layouts due to differences in thermal mass and geometry.

The microstructural evolution of materials during and after bonding represents another critical consideration. Grain structure changes, recrystallization phenomena, and stress relaxation processes continue after the initial bond formation, affecting long-term reliability. These processes depend on the specific material combinations and can vary significantly between test environments and actual applications, necessitating comprehensive material characterization for successful parameter transfer.

Quality Assurance Standards for SiP Wire Bonding

Quality assurance in System-in-Package (SiP) wire bonding requires comprehensive standards to ensure reliability across complex layouts. The industry has established several key standards that govern the transfer of wire bonding parameters from test coupons to actual SiP implementations. These standards include IPC/JEDEC J-STD-012, MIL-STD-883 Method 2011, and ASTM F459, which collectively define the quality metrics and testing methodologies.

The parameter transfer process necessitates rigorous validation through statistical process control (SPC) methods. Manufacturers must maintain Cpk values above 1.33 for critical parameters such as bond strength, loop height, and tail length when transitioning from coupon testing to production environments. This statistical approach ensures that the variability inherent in complex SiP layouts remains within acceptable limits.

Non-destructive testing protocols form a crucial component of quality assurance standards. These include automated optical inspection (AOI) systems capable of detecting misalignments as small as 3μm, and acoustic microscopy for identifying subsurface defects. The standards mandate 100% visual inspection for critical applications, with sampling plans following ANSI/ASQ Z1.4 for less critical scenarios.

Pull and shear testing requirements vary based on wire diameter and material composition. Gold wire bonds typically require minimum pull strengths of 3-5 grams-force for 25μm wire, while copper wire demands 20-30% higher values. These standards must be maintained when transferring parameters from simple coupon tests to complex SiP layouts, with appropriate adjustments for die-to-die variations and thermal considerations.

Environmental testing standards ensure reliability under various operating conditions. Temperature cycling tests (-65°C to +150°C) must demonstrate less than 100 parts per million failure rates after 1000 cycles. Similarly, high-temperature operating life tests at 125°C must show reliability for at least 1000 hours. These standards apply regardless of layout complexity, though more stringent requirements may be necessary for automotive or aerospace applications.

Traceability requirements mandate documentation of all parameter adjustments made during the transfer process. Each production lot must maintain records of wire bonding parameters, including ultrasonic power, bonding force, and time settings, with deviations from coupon test parameters clearly justified and documented. This documentation must be preserved for a minimum of five years according to ISO 9001 and automotive IATF 16949 standards.

The parameter transfer process necessitates rigorous validation through statistical process control (SPC) methods. Manufacturers must maintain Cpk values above 1.33 for critical parameters such as bond strength, loop height, and tail length when transitioning from coupon testing to production environments. This statistical approach ensures that the variability inherent in complex SiP layouts remains within acceptable limits.

Non-destructive testing protocols form a crucial component of quality assurance standards. These include automated optical inspection (AOI) systems capable of detecting misalignments as small as 3μm, and acoustic microscopy for identifying subsurface defects. The standards mandate 100% visual inspection for critical applications, with sampling plans following ANSI/ASQ Z1.4 for less critical scenarios.

Pull and shear testing requirements vary based on wire diameter and material composition. Gold wire bonds typically require minimum pull strengths of 3-5 grams-force for 25μm wire, while copper wire demands 20-30% higher values. These standards must be maintained when transferring parameters from simple coupon tests to complex SiP layouts, with appropriate adjustments for die-to-die variations and thermal considerations.

Environmental testing standards ensure reliability under various operating conditions. Temperature cycling tests (-65°C to +150°C) must demonstrate less than 100 parts per million failure rates after 1000 cycles. Similarly, high-temperature operating life tests at 125°C must show reliability for at least 1000 hours. These standards apply regardless of layout complexity, though more stringent requirements may be necessary for automotive or aerospace applications.

Traceability requirements mandate documentation of all parameter adjustments made during the transfer process. Each production lot must maintain records of wire bonding parameters, including ultrasonic power, bonding force, and time settings, with deviations from coupon test parameters clearly justified and documented. This documentation must be preserved for a minimum of five years according to ISO 9001 and automotive IATF 16949 standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!