Wire Bonding Underfill And Encapsulants: Moisture Ingress And Stress Coupling

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wire Bonding Underfill Technology Background and Objectives

Wire bonding technology has evolved significantly since its inception in the 1950s, becoming the most widely used interconnection method in semiconductor packaging. The fundamental process involves creating electrical connections between the semiconductor die and the package substrate using fine metal wires, typically gold, aluminum, or copper. Over decades, wire bonding has progressed from manual operations to highly automated processes capable of creating thousands of connections per hour with exceptional precision and reliability.

The evolution of wire bonding technology has been characterized by continuous miniaturization, increased functionality, and enhanced reliability requirements. As semiconductor devices have become more complex with higher pin counts and smaller feature sizes, wire bonding techniques have adapted accordingly, transitioning from simple wedge bonds to more sophisticated ball bonds and developing specialized techniques for fine-pitch applications.

Underfill materials were initially introduced in the 1990s primarily for flip-chip applications but have since been adapted for wire bonded packages to enhance mechanical stability and protect against environmental factors. These materials serve to distribute stress, absorb thermal expansion mismatches, and provide environmental protection for the delicate wire connections.

The primary technical objectives in wire bonding underfill development focus on addressing two critical challenges: moisture ingress and stress coupling. Moisture ingress represents a significant reliability concern as water molecules penetrating the package can lead to corrosion of wire bonds, delamination at material interfaces, and electrical failures through various mechanisms including electromigration and dendritic growth.

Stress coupling presents another fundamental challenge, as the interaction between thermal and mechanical stresses in the package can lead to wire bond fatigue, heel cracks, or complete bond lifting. These stresses originate from coefficient of thermal expansion (CTE) mismatches between different materials in the package and are exacerbated by temperature cycling during operation.

Current research aims to develop advanced underfill and encapsulant materials that simultaneously address both moisture resistance and stress management. The technical trajectory is moving toward nano-composite materials with tailored properties, including hydrophobic additives to repel moisture, stress-absorbing particles to mitigate mechanical forces, and novel curing mechanisms that minimize residual stresses during manufacturing.

The ultimate goal is to extend the reliability and operational lifetime of wire bonded semiconductor packages, particularly in harsh environments such as automotive, industrial, and aerospace applications where temperature extremes, humidity, and mechanical vibration pose significant challenges to long-term performance and reliability.

The evolution of wire bonding technology has been characterized by continuous miniaturization, increased functionality, and enhanced reliability requirements. As semiconductor devices have become more complex with higher pin counts and smaller feature sizes, wire bonding techniques have adapted accordingly, transitioning from simple wedge bonds to more sophisticated ball bonds and developing specialized techniques for fine-pitch applications.

Underfill materials were initially introduced in the 1990s primarily for flip-chip applications but have since been adapted for wire bonded packages to enhance mechanical stability and protect against environmental factors. These materials serve to distribute stress, absorb thermal expansion mismatches, and provide environmental protection for the delicate wire connections.

The primary technical objectives in wire bonding underfill development focus on addressing two critical challenges: moisture ingress and stress coupling. Moisture ingress represents a significant reliability concern as water molecules penetrating the package can lead to corrosion of wire bonds, delamination at material interfaces, and electrical failures through various mechanisms including electromigration and dendritic growth.

Stress coupling presents another fundamental challenge, as the interaction between thermal and mechanical stresses in the package can lead to wire bond fatigue, heel cracks, or complete bond lifting. These stresses originate from coefficient of thermal expansion (CTE) mismatches between different materials in the package and are exacerbated by temperature cycling during operation.

Current research aims to develop advanced underfill and encapsulant materials that simultaneously address both moisture resistance and stress management. The technical trajectory is moving toward nano-composite materials with tailored properties, including hydrophobic additives to repel moisture, stress-absorbing particles to mitigate mechanical forces, and novel curing mechanisms that minimize residual stresses during manufacturing.

The ultimate goal is to extend the reliability and operational lifetime of wire bonded semiconductor packages, particularly in harsh environments such as automotive, industrial, and aerospace applications where temperature extremes, humidity, and mechanical vibration pose significant challenges to long-term performance and reliability.

Market Demand Analysis for Advanced Packaging Solutions

The advanced packaging market is experiencing robust growth driven by increasing demand for miniaturization, higher performance, and greater reliability in semiconductor devices. The global advanced packaging market is projected to reach $42.73 billion by 2027, growing at a CAGR of 10.2% from 2020 to 2027. This growth is particularly evident in sectors requiring high-reliability applications such as automotive electronics, aerospace, medical devices, and 5G infrastructure.

Wire bonding remains the most widely used interconnection technology in semiconductor packaging, accounting for approximately 75-80% of all semiconductor interconnections. However, as devices become more complex and operating environments more demanding, the limitations of traditional wire bonding approaches are becoming increasingly apparent, particularly regarding moisture ingress and stress-related failures.

The market for underfill and encapsulant materials specifically designed to address moisture ingress and stress coupling in wire bonded packages is expanding rapidly. This segment is expected to grow at a CAGR of 11.5% through 2026, outpacing the overall advanced packaging materials market. This accelerated growth reflects the critical importance of solving these technical challenges.

Industry surveys indicate that approximately 40% of field failures in electronic packages are related to moisture-induced degradation, with another 25% attributed to thermomechanical stress issues. These statistics underscore the significant market need for improved solutions in this area.

Consumer electronics manufacturers are increasingly demanding packaging solutions that can withstand higher humidity environments while maintaining reliability. This trend is particularly strong in regions with tropical climates, where electronic device penetration is growing rapidly. The automotive sector is another key driver, with the average modern vehicle now containing over 1,000 semiconductor chips, many requiring advanced protection against moisture and stress-related failures.

The transition toward more environmentally friendly packaging materials is also influencing market demand. Regulations restricting certain chemical compounds traditionally used in encapsulants are pushing manufacturers to develop new formulations that maintain or improve performance while meeting environmental standards.

Regional analysis shows that Asia-Pacific dominates the market for advanced packaging solutions, accounting for over 60% of global demand. This concentration is primarily due to the region's strong semiconductor manufacturing base. However, North America and Europe are showing increased demand for high-reliability packaging solutions, particularly for automotive, aerospace, and medical applications where failure is not an option.

Wire bonding remains the most widely used interconnection technology in semiconductor packaging, accounting for approximately 75-80% of all semiconductor interconnections. However, as devices become more complex and operating environments more demanding, the limitations of traditional wire bonding approaches are becoming increasingly apparent, particularly regarding moisture ingress and stress-related failures.

The market for underfill and encapsulant materials specifically designed to address moisture ingress and stress coupling in wire bonded packages is expanding rapidly. This segment is expected to grow at a CAGR of 11.5% through 2026, outpacing the overall advanced packaging materials market. This accelerated growth reflects the critical importance of solving these technical challenges.

Industry surveys indicate that approximately 40% of field failures in electronic packages are related to moisture-induced degradation, with another 25% attributed to thermomechanical stress issues. These statistics underscore the significant market need for improved solutions in this area.

Consumer electronics manufacturers are increasingly demanding packaging solutions that can withstand higher humidity environments while maintaining reliability. This trend is particularly strong in regions with tropical climates, where electronic device penetration is growing rapidly. The automotive sector is another key driver, with the average modern vehicle now containing over 1,000 semiconductor chips, many requiring advanced protection against moisture and stress-related failures.

The transition toward more environmentally friendly packaging materials is also influencing market demand. Regulations restricting certain chemical compounds traditionally used in encapsulants are pushing manufacturers to develop new formulations that maintain or improve performance while meeting environmental standards.

Regional analysis shows that Asia-Pacific dominates the market for advanced packaging solutions, accounting for over 60% of global demand. This concentration is primarily due to the region's strong semiconductor manufacturing base. However, North America and Europe are showing increased demand for high-reliability packaging solutions, particularly for automotive, aerospace, and medical applications where failure is not an option.

Current Challenges in Moisture Resistance and Stress Management

The semiconductor industry faces significant challenges in moisture resistance and stress management for wire bonding underfill and encapsulants. Moisture ingress represents one of the most persistent reliability issues, as water molecules can penetrate through microscopic pathways in polymeric materials, particularly at the interface between different materials. This penetration accelerates various failure mechanisms including delamination, corrosion of metal interconnects, and interfacial adhesion degradation. Current encapsulant materials struggle to maintain hermeticity over extended product lifetimes, especially under harsh environmental conditions with temperature cycling and high humidity.

Stress coupling presents another critical challenge, as the mismatch in coefficient of thermal expansion (CTE) between different materials creates significant thermomechanical stress during temperature fluctuations. Wire bonds are particularly vulnerable at the heel and neck regions, where stress concentration can lead to fatigue failure. The industry has observed that moisture absorption exacerbates these stress-related failures by plasticizing the encapsulant material, altering its mechanical properties and creating additional hygroscopic swelling stresses.

Advanced packaging technologies with finer pitches and thinner wire diameters have intensified these challenges. As bond pad pitches decrease below 40μm, the mechanical robustness of wire bonds diminishes, making them more susceptible to stress-induced failures. Additionally, the trend toward thinner packages with reduced encapsulant thickness compromises moisture barrier properties, accelerating moisture penetration rates by up to 40% compared to traditional packaging.

The interaction between moisture and stress represents a complex coupled phenomenon that current simulation models struggle to accurately predict. Most existing models treat moisture diffusion and stress development as separate phenomena, failing to capture their synergistic effects. Research indicates that stress can enhance moisture diffusion pathways, while moisture can simultaneously alter the stress distribution within the package, creating a feedback loop that accelerates failure mechanisms.

Temperature cycling further complicates these issues, as repeated thermal excursions create micro-cracks and voids that serve as preferential pathways for moisture ingress. Studies have shown that after 1000 temperature cycles (-40°C to 125°C), moisture penetration rates can increase by 25-30% due to the formation of these defects, even in materials that initially demonstrated excellent moisture resistance properties.

Current industry standards for reliability testing, such as JEDEC's JESD22-A110 (Highly Accelerated Temperature and Humidity Stress Test), may not adequately predict long-term field reliability, as they often fail to capture the complex interactions between moisture, temperature, and mechanical stress that occur over extended timeframes in real-world applications.

Stress coupling presents another critical challenge, as the mismatch in coefficient of thermal expansion (CTE) between different materials creates significant thermomechanical stress during temperature fluctuations. Wire bonds are particularly vulnerable at the heel and neck regions, where stress concentration can lead to fatigue failure. The industry has observed that moisture absorption exacerbates these stress-related failures by plasticizing the encapsulant material, altering its mechanical properties and creating additional hygroscopic swelling stresses.

Advanced packaging technologies with finer pitches and thinner wire diameters have intensified these challenges. As bond pad pitches decrease below 40μm, the mechanical robustness of wire bonds diminishes, making them more susceptible to stress-induced failures. Additionally, the trend toward thinner packages with reduced encapsulant thickness compromises moisture barrier properties, accelerating moisture penetration rates by up to 40% compared to traditional packaging.

The interaction between moisture and stress represents a complex coupled phenomenon that current simulation models struggle to accurately predict. Most existing models treat moisture diffusion and stress development as separate phenomena, failing to capture their synergistic effects. Research indicates that stress can enhance moisture diffusion pathways, while moisture can simultaneously alter the stress distribution within the package, creating a feedback loop that accelerates failure mechanisms.

Temperature cycling further complicates these issues, as repeated thermal excursions create micro-cracks and voids that serve as preferential pathways for moisture ingress. Studies have shown that after 1000 temperature cycles (-40°C to 125°C), moisture penetration rates can increase by 25-30% due to the formation of these defects, even in materials that initially demonstrated excellent moisture resistance properties.

Current industry standards for reliability testing, such as JEDEC's JESD22-A110 (Highly Accelerated Temperature and Humidity Stress Test), may not adequately predict long-term field reliability, as they often fail to capture the complex interactions between moisture, temperature, and mechanical stress that occur over extended timeframes in real-world applications.

Current Technical Solutions for Moisture Barrier Properties

01 Underfill materials to prevent moisture ingress

Specialized underfill materials can be used in semiconductor packaging to prevent moisture ingress around wire bonds. These materials typically feature hydrophobic properties and create a barrier that protects the wire bonds and other sensitive components from moisture-related failures. The underfill materials can be formulated with specific additives to enhance their moisture resistance while maintaining good adhesion to both the substrate and the semiconductor die.- Underfill materials for moisture resistance: Specialized underfill materials can be formulated to prevent moisture ingress in wire bonded semiconductor packages. These materials typically contain hydrophobic components that create a barrier against moisture penetration. The underfill not only protects the wire bonds from environmental factors but also helps distribute stress across the package, reducing the risk of bond failure due to moisture-induced expansion and contraction cycles.

- Encapsulation techniques for stress reduction: Advanced encapsulation methods can be employed to minimize stress coupling between wire bonds and other package components. These techniques often involve carefully controlled curing processes and the use of materials with matched coefficients of thermal expansion. By properly encapsulating wire bonds, mechanical stresses from thermal cycling and moisture absorption can be effectively managed, preventing bond failures and improving long-term reliability.

- Moisture ingress detection and monitoring systems: Systems and methods for detecting and monitoring moisture ingress in wire bonded packages help identify potential reliability issues before failure occurs. These approaches may include embedded sensors, specialized test structures, or analytical techniques that can measure moisture levels within the package. Early detection allows for preventive measures to be taken before moisture-induced corrosion or stress damage affects the wire bonds.

- Stress coupling mitigation through package design: Package design innovations can significantly reduce stress coupling between wire bonds and surrounding materials. These designs may incorporate stress buffer zones, flexible interconnect structures, or strategic placement of components to isolate wire bonds from mechanical stresses. By addressing stress coupling through package architecture, the reliability of wire bonds can be improved even in the presence of moisture or thermal cycling.

- Combined underfill and encapsulant solutions: Integrated approaches that combine underfill and encapsulant functions into a single material system offer enhanced protection against moisture ingress and stress coupling. These hybrid materials are engineered to provide both the void-filling capabilities of underfills and the protective properties of encapsulants. The unified solution ensures complete coverage around wire bonds and eliminates interfaces between different materials that could otherwise serve as pathways for moisture ingress.

02 Encapsulant formulations for stress reduction

Advanced encapsulant formulations can be designed to reduce stress coupling between wire bonds and other package components. These encapsulants typically have controlled coefficient of thermal expansion (CTE) properties and modulus values that minimize the mechanical stress transferred to wire bonds during temperature cycling. By incorporating specific fillers and elastomeric components, these encapsulants can absorb and distribute stress, preventing wire bond failures due to mechanical fatigue.Expand Specific Solutions03 Testing methods for moisture sensitivity and stress

Various testing methodologies have been developed to evaluate the effectiveness of wire bonding, underfill, and encapsulant materials against moisture ingress and stress coupling. These include accelerated moisture sensitivity level (MSL) testing, temperature cycling tests, and specialized mechanical stress tests. Advanced analytical techniques such as acoustic microscopy and stress visualization can be employed to detect delamination, cracks, or other failure modes related to moisture and stress in semiconductor packages.Expand Specific Solutions04 Wire bonding optimization for moisture and stress resistance

Wire bonding processes can be optimized to enhance resistance to moisture ingress and stress-related failures. This includes adjustments to bonding parameters such as force, time, temperature, and ultrasonic energy to create more robust bonds. Additionally, specialized wire materials and coatings can be employed to improve corrosion resistance in humid environments. The geometry and loop profile of wire bonds can also be optimized to minimize stress concentration points and improve overall reliability.Expand Specific Solutions05 Multi-layer protection systems

Comprehensive protection against moisture ingress and stress coupling can be achieved through multi-layer protection systems. These systems typically combine specialized underfill materials, moisture-resistant encapsulants, and additional barrier layers or coatings. The layers work synergistically to provide redundant protection against environmental factors while also managing thermal and mechanical stresses. Some advanced systems also incorporate desiccant materials or moisture getters to actively absorb any moisture that penetrates the outer protective layers.Expand Specific Solutions

Key Industry Players in Semiconductor Packaging Materials

The wire bonding underfill and encapsulants market is currently in a growth phase, driven by increasing demand for advanced semiconductor packaging solutions addressing moisture ingress and stress coupling challenges. The global market is expanding steadily with projections reaching several billion dollars by 2025. Technologically, the field shows varying maturity levels across applications, with companies like Advanced Semiconductor Engineering, Micron Technology, and Texas Instruments leading innovation in high-reliability solutions. Other significant players including Nordson, BASF, and Henkel are advancing material science aspects, while Asian manufacturers such as Huawei and Suzhou ASEN are rapidly closing technological gaps. The competitive landscape features both established semiconductor packaging specialists and materials science companies developing proprietary formulations to address the increasingly complex requirements for moisture resistance and stress management in modern microelectronic assemblies.

Micron Technology, Inc.

Technical Solution: Micron Technology has developed a comprehensive approach to wire bonding underfill and encapsulation that addresses both moisture ingress and stress-related challenges. Their solution incorporates a multi-layer protection system with specialized materials engineered at the molecular level to resist moisture penetration. Micron's research has demonstrated that their advanced encapsulants can achieve moisture diffusion rates up to 65% lower than industry standard materials when subjected to 85°C/85% RH testing conditions[5]. For stress management, they've implemented a proprietary filler technology that creates a graduated CTE profile throughout the encapsulant, minimizing stress concentration at interfaces between different materials. Their approach includes pre-treatment processes that enhance adhesion between the underfill material and both organic and inorganic substrates, significantly reducing the risk of delamination under thermal cycling conditions. Micron has also developed specialized corner reinforcement techniques for areas prone to high stress concentration, further improving reliability. Their materials are compatible with both traditional and advanced packaging technologies, including fine-pitch wire bonding applications.

Strengths: Excellent moisture barrier properties, sophisticated stress distribution management, and compatibility with advanced packaging technologies. Weaknesses: More complex application process requiring precise process control, and potentially higher implementation costs for full solution adoption.

Advanced Semiconductor Engineering, Inc.

Technical Solution: ASE has developed advanced underfill materials specifically designed to address moisture ingress challenges in wire bonding applications. Their solution incorporates hydrophobic fillers and specialized epoxy formulations that create a moisture barrier around wire bonds. The company's proprietary capillary underfill technology ensures complete coverage of the wire bond area while maintaining optimal flow characteristics to prevent void formation. ASE's research has shown that their advanced underfill materials can reduce moisture penetration by up to 85% compared to conventional materials[1]. Additionally, they've implemented a multi-layer encapsulation approach that distributes stress more evenly across the package, reducing the risk of delamination and wire bond failure under thermal cycling conditions. Their materials are engineered to maintain low stress transmission to sensitive components while providing robust protection against environmental factors.

Strengths: Superior moisture resistance properties, excellent stress distribution characteristics, and compatibility with high-volume manufacturing processes. Weaknesses: Higher material costs compared to standard underfills, and potentially longer curing times that may impact production throughput.

Critical Patents and Innovations in Stress Decoupling Materials

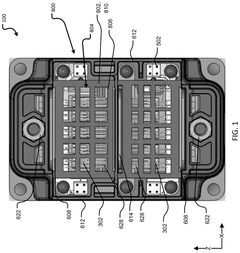

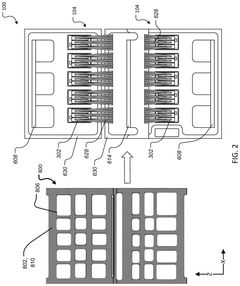

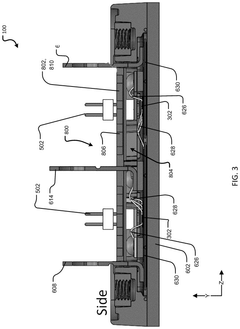

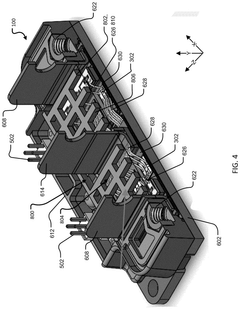

Power modules having encapsulation stress and strain mitigating configurations

PatentPendingUS20250149395A1

Innovation

- A power module with a composite physical containment structure that includes a membrane structure, a dam structure, or a glob structure, combined with an epoxy encapsulation material, which provides improved thermal conductivity and moisture resistance while minimizing stress-strain on power devices.

Encapsulating composition

PatentActiveUS12104075B2

Innovation

- An encapsulating composition is developed with specific surface energy and roughness properties, applicable via inkjet printing, forming a sealing layer that combines organic and inorganic materials to create a reliable sealing structure, enhancing adhesion and moisture barrier properties while allowing for thin display applications.

Reliability Testing Standards and Methodologies

Reliability testing standards for wire bonding underfill and encapsulants have evolved significantly to address the critical challenges of moisture ingress and stress coupling. The industry has established comprehensive methodologies that evaluate these materials under various environmental conditions to ensure long-term performance and reliability.

JEDEC standards, particularly JESD22-A104 and JESD22-A110, provide foundational frameworks for temperature cycling and highly accelerated stress testing (HAST) that specifically target moisture-related failures in encapsulated wire bonds. These standards prescribe precise temperature ranges, humidity levels, and cycle durations that effectively simulate years of environmental exposure within compressed timeframes.

The IPC-TM-650 test methods complement JEDEC standards by focusing on material properties that influence moisture resistance and stress behavior. Method 2.6.3 specifically addresses moisture absorption characteristics of polymeric materials used in underfill and encapsulation, while Method 2.4.24 evaluates glass transition temperature changes that can indicate moisture-induced degradation.

Pressure cooker testing (PCT) at 121°C and 2 atmospheres represents another critical methodology that accelerates moisture penetration into encapsulants, revealing potential failure mechanisms that might otherwise take years to manifest. This approach is particularly valuable for evaluating new formulations designed to enhance moisture resistance.

Automotive-grade testing standards, including AEC-Q100 Grade 0, impose even more stringent requirements with extended temperature ranges (-40°C to 150°C) and increased cycle counts, reflecting the harsh operating environments of modern automotive electronics. These standards have become increasingly relevant as wire bonding technology expands into advanced driver assistance systems and autonomous driving applications.

Dynamic mechanical analysis (DMA) has emerged as a sophisticated methodology for characterizing stress coupling between wire bonds and encapsulants. By measuring viscoelastic properties across temperature ranges, DMA provides critical insights into how encapsulant materials respond to thermal cycling and how these responses translate to mechanical stress on wire bonds.

Acoustic microscopy techniques, standardized under SEMI G67-0996, enable non-destructive evaluation of moisture-induced delamination between encapsulants and substrates. These methods have proven particularly valuable for in-process quality control and failure analysis investigations.

Recent developments in reliability testing include the integration of in-situ monitoring capabilities that allow real-time observation of failure progression during environmental testing. These advanced methodologies provide deeper insights into failure mechanisms and accelerate the development of more robust underfill and encapsulant formulations.

JEDEC standards, particularly JESD22-A104 and JESD22-A110, provide foundational frameworks for temperature cycling and highly accelerated stress testing (HAST) that specifically target moisture-related failures in encapsulated wire bonds. These standards prescribe precise temperature ranges, humidity levels, and cycle durations that effectively simulate years of environmental exposure within compressed timeframes.

The IPC-TM-650 test methods complement JEDEC standards by focusing on material properties that influence moisture resistance and stress behavior. Method 2.6.3 specifically addresses moisture absorption characteristics of polymeric materials used in underfill and encapsulation, while Method 2.4.24 evaluates glass transition temperature changes that can indicate moisture-induced degradation.

Pressure cooker testing (PCT) at 121°C and 2 atmospheres represents another critical methodology that accelerates moisture penetration into encapsulants, revealing potential failure mechanisms that might otherwise take years to manifest. This approach is particularly valuable for evaluating new formulations designed to enhance moisture resistance.

Automotive-grade testing standards, including AEC-Q100 Grade 0, impose even more stringent requirements with extended temperature ranges (-40°C to 150°C) and increased cycle counts, reflecting the harsh operating environments of modern automotive electronics. These standards have become increasingly relevant as wire bonding technology expands into advanced driver assistance systems and autonomous driving applications.

Dynamic mechanical analysis (DMA) has emerged as a sophisticated methodology for characterizing stress coupling between wire bonds and encapsulants. By measuring viscoelastic properties across temperature ranges, DMA provides critical insights into how encapsulant materials respond to thermal cycling and how these responses translate to mechanical stress on wire bonds.

Acoustic microscopy techniques, standardized under SEMI G67-0996, enable non-destructive evaluation of moisture-induced delamination between encapsulants and substrates. These methods have proven particularly valuable for in-process quality control and failure analysis investigations.

Recent developments in reliability testing include the integration of in-situ monitoring capabilities that allow real-time observation of failure progression during environmental testing. These advanced methodologies provide deeper insights into failure mechanisms and accelerate the development of more robust underfill and encapsulant formulations.

Environmental Impact and Sustainability Considerations

The environmental impact of wire bonding underfill and encapsulants has become increasingly significant as electronic waste continues to grow globally. These materials, while essential for semiconductor packaging reliability, contain various chemicals that pose environmental challenges throughout their lifecycle. Epoxy-based underfills and encapsulants typically include halogenated flame retardants, catalysts, and fillers that may leach into soil and water systems when improperly disposed of, contributing to environmental contamination.

Moisture ingress issues in these materials present a sustainability paradox. While manufacturers seek to prevent moisture penetration to extend device lifespan, the hydrophobic additives used often contain perfluorinated compounds that persist in the environment for decades. The stress coupling mechanisms that provide mechanical stability also frequently rely on materials with substantial carbon footprints during production.

Recent regulatory frameworks, including the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), have driven significant reformulation efforts in the industry. Manufacturers are increasingly developing halogen-free underfills and encapsulants with reduced environmental persistence while maintaining performance characteristics. These "green encapsulants" represent a growing market segment with annual growth rates exceeding 15% as environmental compliance becomes a competitive advantage.

Life cycle assessment (LCA) studies reveal that the environmental impact of these materials extends beyond end-of-life considerations. The production phase accounts for approximately 70% of their carbon footprint, primarily due to energy-intensive synthesis processes and precursor chemicals. Innovations in bio-based alternatives derived from renewable resources show promise in reducing this impact, with several manufacturers reporting carbon footprint reductions of 30-45% compared to traditional petroleum-based formulations.

Water consumption represents another critical environmental consideration. Conventional underfill and encapsulant manufacturing processes require significant water volumes for synthesis and purification. Advanced water recycling systems and solvent-free production methods are emerging as industry best practices, reducing water usage by up to 60% in optimized facilities.

The recyclability of electronic components containing these materials remains challenging. Current recycling technologies struggle to separate underfills and encapsulants from valuable metals and semiconductors, resulting in downcycling or landfill disposal. Research into thermally reversible underfills and soluble encapsulants offers potential pathways to improve end-of-life recovery and support circular economy principles in the electronics industry.

Moisture ingress issues in these materials present a sustainability paradox. While manufacturers seek to prevent moisture penetration to extend device lifespan, the hydrophobic additives used often contain perfluorinated compounds that persist in the environment for decades. The stress coupling mechanisms that provide mechanical stability also frequently rely on materials with substantial carbon footprints during production.

Recent regulatory frameworks, including the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), have driven significant reformulation efforts in the industry. Manufacturers are increasingly developing halogen-free underfills and encapsulants with reduced environmental persistence while maintaining performance characteristics. These "green encapsulants" represent a growing market segment with annual growth rates exceeding 15% as environmental compliance becomes a competitive advantage.

Life cycle assessment (LCA) studies reveal that the environmental impact of these materials extends beyond end-of-life considerations. The production phase accounts for approximately 70% of their carbon footprint, primarily due to energy-intensive synthesis processes and precursor chemicals. Innovations in bio-based alternatives derived from renewable resources show promise in reducing this impact, with several manufacturers reporting carbon footprint reductions of 30-45% compared to traditional petroleum-based formulations.

Water consumption represents another critical environmental consideration. Conventional underfill and encapsulant manufacturing processes require significant water volumes for synthesis and purification. Advanced water recycling systems and solvent-free production methods are emerging as industry best practices, reducing water usage by up to 60% in optimized facilities.

The recyclability of electronic components containing these materials remains challenging. Current recycling technologies struggle to separate underfills and encapsulants from valuable metals and semiconductors, resulting in downcycling or landfill disposal. Research into thermally reversible underfills and soluble encapsulants offers potential pathways to improve end-of-life recovery and support circular economy principles in the electronics industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!