Impact of Battery Management Systems on Fleet Management Solutions

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Evolution and Goals

Battery Management Systems (BMS) have undergone significant evolution since their inception, driven by the rapid advancement of electric vehicle (EV) technology and the growing demand for more efficient and reliable energy storage solutions. The primary goal of BMS development has been to optimize battery performance, extend battery life, and enhance overall safety in various applications, including fleet management.

In the early stages, BMS focused primarily on basic monitoring and protection functions. These systems were designed to prevent overcharging, over-discharging, and overheating of battery cells. As the technology progressed, BMS capabilities expanded to include more sophisticated features such as cell balancing, state of charge (SOC) estimation, and state of health (SOH) monitoring.

The evolution of BMS has been closely tied to advancements in battery chemistry and design. With the introduction of lithium-ion batteries, which offered higher energy density and longer cycle life compared to traditional lead-acid batteries, BMS technology had to adapt to manage these more complex and sensitive energy storage systems. This led to the development of more advanced algorithms for accurate SOC and SOH estimation, as well as improved thermal management strategies.

In recent years, the integration of artificial intelligence (AI) and machine learning (ML) techniques has marked a significant milestone in BMS evolution. These technologies have enabled more accurate predictions of battery behavior, adaptive charging strategies, and predictive maintenance capabilities. AI-powered BMS can analyze vast amounts of data from battery usage patterns, environmental conditions, and historical performance to optimize charging cycles and extend battery lifespan.

The goals of modern BMS in the context of fleet management solutions are multifaceted. Firstly, they aim to maximize the operational efficiency of electric vehicle fleets by ensuring optimal battery performance and longevity. This includes real-time monitoring of battery health, predictive maintenance scheduling, and dynamic range estimation based on various factors such as driving conditions and load.

Secondly, BMS technology seeks to enhance safety and reliability in fleet operations. Advanced systems can detect potential battery failures or anomalies before they occur, allowing for proactive maintenance and reducing the risk of vehicle downtime or safety incidents. This is particularly crucial for large-scale fleet operations where the consequences of battery-related issues can be significant.

Another key objective of BMS evolution is to support the integration of electric vehicles into smart grid systems. This involves developing bidirectional charging capabilities and vehicle-to-grid (V2G) technologies, allowing fleet vehicles to serve as mobile energy storage units. Such advancements aim to create more resilient and flexible energy ecosystems, potentially generating additional revenue streams for fleet operators.

Looking ahead, the future goals of BMS in fleet management include further improvements in battery life prediction accuracy, the development of self-healing battery systems, and seamless integration with autonomous vehicle technologies. These advancements will play a crucial role in accelerating the adoption of electric vehicles in commercial and public transportation sectors, ultimately contributing to more sustainable and efficient fleet management solutions.

In the early stages, BMS focused primarily on basic monitoring and protection functions. These systems were designed to prevent overcharging, over-discharging, and overheating of battery cells. As the technology progressed, BMS capabilities expanded to include more sophisticated features such as cell balancing, state of charge (SOC) estimation, and state of health (SOH) monitoring.

The evolution of BMS has been closely tied to advancements in battery chemistry and design. With the introduction of lithium-ion batteries, which offered higher energy density and longer cycle life compared to traditional lead-acid batteries, BMS technology had to adapt to manage these more complex and sensitive energy storage systems. This led to the development of more advanced algorithms for accurate SOC and SOH estimation, as well as improved thermal management strategies.

In recent years, the integration of artificial intelligence (AI) and machine learning (ML) techniques has marked a significant milestone in BMS evolution. These technologies have enabled more accurate predictions of battery behavior, adaptive charging strategies, and predictive maintenance capabilities. AI-powered BMS can analyze vast amounts of data from battery usage patterns, environmental conditions, and historical performance to optimize charging cycles and extend battery lifespan.

The goals of modern BMS in the context of fleet management solutions are multifaceted. Firstly, they aim to maximize the operational efficiency of electric vehicle fleets by ensuring optimal battery performance and longevity. This includes real-time monitoring of battery health, predictive maintenance scheduling, and dynamic range estimation based on various factors such as driving conditions and load.

Secondly, BMS technology seeks to enhance safety and reliability in fleet operations. Advanced systems can detect potential battery failures or anomalies before they occur, allowing for proactive maintenance and reducing the risk of vehicle downtime or safety incidents. This is particularly crucial for large-scale fleet operations where the consequences of battery-related issues can be significant.

Another key objective of BMS evolution is to support the integration of electric vehicles into smart grid systems. This involves developing bidirectional charging capabilities and vehicle-to-grid (V2G) technologies, allowing fleet vehicles to serve as mobile energy storage units. Such advancements aim to create more resilient and flexible energy ecosystems, potentially generating additional revenue streams for fleet operators.

Looking ahead, the future goals of BMS in fleet management include further improvements in battery life prediction accuracy, the development of self-healing battery systems, and seamless integration with autonomous vehicle technologies. These advancements will play a crucial role in accelerating the adoption of electric vehicles in commercial and public transportation sectors, ultimately contributing to more sustainable and efficient fleet management solutions.

Fleet Management Needs

Fleet management solutions are increasingly relying on advanced technologies to optimize operations, reduce costs, and improve overall efficiency. Battery Management Systems (BMS) have emerged as a critical component in this landscape, particularly with the growing adoption of electric vehicles (EVs) in commercial fleets. The integration of BMS into fleet management solutions addresses several key needs of fleet operators and managers.

Firstly, BMS provides real-time monitoring and reporting of battery health and performance. This capability is crucial for fleet managers who need to ensure the operational readiness of their vehicles. By continuously tracking battery state of charge, temperature, and overall condition, BMS enables proactive maintenance scheduling and helps prevent unexpected vehicle downtime. This level of insight allows fleet operators to optimize their vehicle utilization and route planning, ensuring that vehicles are deployed efficiently based on their battery status and charging requirements.

Secondly, BMS plays a vital role in extending battery life and maximizing the return on investment in electric fleet vehicles. Through intelligent charging and discharging algorithms, BMS can prevent overcharging, deep discharging, and other harmful battery usage patterns. This not only prolongs the lifespan of expensive battery packs but also maintains their performance over time, ensuring consistent range and reliability for fleet operations.

Another critical need addressed by BMS is the optimization of energy consumption. Fleet managers are under increasing pressure to reduce operational costs and meet sustainability targets. BMS contributes to these goals by providing detailed energy usage data, enabling managers to identify inefficiencies and implement strategies to reduce energy consumption. This data-driven approach allows for more accurate forecasting of energy needs and helps in planning for charging infrastructure investments.

Safety is a paramount concern in fleet management, and BMS addresses this need by continuously monitoring for potential battery-related issues. Advanced BMS can detect anomalies such as thermal runaway, short circuits, or other malfunctions before they escalate into serious safety hazards. This proactive approach to safety not only protects valuable assets but also ensures the well-being of drivers and compliance with safety regulations.

Lastly, the integration of BMS with fleet management solutions enables more sophisticated predictive maintenance capabilities. By analyzing historical battery performance data and current usage patterns, these systems can predict when a battery is likely to fail or require replacement. This predictive approach allows fleet managers to schedule maintenance during off-peak hours, minimizing disruptions to operations and reducing overall maintenance costs.

In conclusion, the impact of Battery Management Systems on fleet management solutions is profound, addressing critical needs in efficiency, cost management, safety, and sustainability. As the electrification of commercial fleets continues to accelerate, the role of BMS in meeting these fleet management needs will only grow in importance.

Firstly, BMS provides real-time monitoring and reporting of battery health and performance. This capability is crucial for fleet managers who need to ensure the operational readiness of their vehicles. By continuously tracking battery state of charge, temperature, and overall condition, BMS enables proactive maintenance scheduling and helps prevent unexpected vehicle downtime. This level of insight allows fleet operators to optimize their vehicle utilization and route planning, ensuring that vehicles are deployed efficiently based on their battery status and charging requirements.

Secondly, BMS plays a vital role in extending battery life and maximizing the return on investment in electric fleet vehicles. Through intelligent charging and discharging algorithms, BMS can prevent overcharging, deep discharging, and other harmful battery usage patterns. This not only prolongs the lifespan of expensive battery packs but also maintains their performance over time, ensuring consistent range and reliability for fleet operations.

Another critical need addressed by BMS is the optimization of energy consumption. Fleet managers are under increasing pressure to reduce operational costs and meet sustainability targets. BMS contributes to these goals by providing detailed energy usage data, enabling managers to identify inefficiencies and implement strategies to reduce energy consumption. This data-driven approach allows for more accurate forecasting of energy needs and helps in planning for charging infrastructure investments.

Safety is a paramount concern in fleet management, and BMS addresses this need by continuously monitoring for potential battery-related issues. Advanced BMS can detect anomalies such as thermal runaway, short circuits, or other malfunctions before they escalate into serious safety hazards. This proactive approach to safety not only protects valuable assets but also ensures the well-being of drivers and compliance with safety regulations.

Lastly, the integration of BMS with fleet management solutions enables more sophisticated predictive maintenance capabilities. By analyzing historical battery performance data and current usage patterns, these systems can predict when a battery is likely to fail or require replacement. This predictive approach allows fleet managers to schedule maintenance during off-peak hours, minimizing disruptions to operations and reducing overall maintenance costs.

In conclusion, the impact of Battery Management Systems on fleet management solutions is profound, addressing critical needs in efficiency, cost management, safety, and sustainability. As the electrification of commercial fleets continues to accelerate, the role of BMS in meeting these fleet management needs will only grow in importance.

BMS Challenges in Fleets

Battery Management Systems (BMS) play a crucial role in fleet management solutions, but they also present several challenges that need to be addressed for optimal performance and efficiency. One of the primary challenges is the complexity of managing diverse battery types and chemistries across a fleet. Different vehicles may utilize various battery technologies, each with unique charging and discharging characteristics, making it difficult to implement a standardized BMS approach.

Another significant challenge is the accurate prediction of battery state of charge (SOC) and state of health (SOH) in real-time fleet operations. Fleet managers require precise information about the remaining range and overall battery condition to make informed decisions about vehicle deployment and maintenance schedules. However, factors such as varying driving conditions, temperature fluctuations, and battery degradation over time can complicate these predictions, leading to potential inefficiencies in fleet management.

The integration of BMS data with existing fleet management systems poses another hurdle. Many fleet management solutions were not initially designed to handle the extensive data generated by modern BMS, creating compatibility issues and data silos. This integration challenge can hinder the ability to leverage BMS insights for optimizing route planning, charging schedules, and overall fleet performance.

Scalability is a critical concern as fleets transition to electric vehicles. BMS must be capable of managing an increasing number of batteries across a growing fleet while maintaining performance and reliability. This scalability challenge extends to the supporting infrastructure, including charging stations and data management systems, which must evolve to accommodate the expanding electrified fleet.

Cybersecurity presents a unique challenge in BMS for fleet management. As BMS become more sophisticated and interconnected, they become potential targets for cyber attacks. Protecting sensitive battery data and preventing unauthorized access to BMS controls is crucial for maintaining fleet safety and operational integrity.

Lastly, the regulatory landscape surrounding BMS in fleet applications is evolving rapidly. Compliance with emerging standards and regulations related to battery safety, performance, and data management adds another layer of complexity to BMS implementation in fleet management solutions. Fleet operators must stay abreast of these changes and ensure their BMS strategies align with current and future regulatory requirements.

Another significant challenge is the accurate prediction of battery state of charge (SOC) and state of health (SOH) in real-time fleet operations. Fleet managers require precise information about the remaining range and overall battery condition to make informed decisions about vehicle deployment and maintenance schedules. However, factors such as varying driving conditions, temperature fluctuations, and battery degradation over time can complicate these predictions, leading to potential inefficiencies in fleet management.

The integration of BMS data with existing fleet management systems poses another hurdle. Many fleet management solutions were not initially designed to handle the extensive data generated by modern BMS, creating compatibility issues and data silos. This integration challenge can hinder the ability to leverage BMS insights for optimizing route planning, charging schedules, and overall fleet performance.

Scalability is a critical concern as fleets transition to electric vehicles. BMS must be capable of managing an increasing number of batteries across a growing fleet while maintaining performance and reliability. This scalability challenge extends to the supporting infrastructure, including charging stations and data management systems, which must evolve to accommodate the expanding electrified fleet.

Cybersecurity presents a unique challenge in BMS for fleet management. As BMS become more sophisticated and interconnected, they become potential targets for cyber attacks. Protecting sensitive battery data and preventing unauthorized access to BMS controls is crucial for maintaining fleet safety and operational integrity.

Lastly, the regulatory landscape surrounding BMS in fleet applications is evolving rapidly. Compliance with emerging standards and regulations related to battery safety, performance, and data management adds another layer of complexity to BMS implementation in fleet management solutions. Fleet operators must stay abreast of these changes and ensure their BMS strategies align with current and future regulatory requirements.

Current BMS Architectures

01 Battery monitoring and control systems

These systems monitor various parameters of batteries, such as voltage, current, temperature, and state of charge. They use this information to optimize battery performance, extend battery life, and ensure safe operation. Advanced algorithms are employed to estimate battery health and predict remaining useful life.- Battery monitoring and control systems: These systems monitor various parameters of batteries, such as voltage, current, temperature, and state of charge. They use this information to optimize battery performance, extend battery life, and ensure safe operation. Advanced algorithms are employed to estimate battery health and predict remaining useful life.

- Thermal management in battery systems: Thermal management is crucial for battery performance and safety. These systems regulate battery temperature through cooling or heating mechanisms, preventing overheating and maintaining optimal operating conditions. They may include sensors, cooling circuits, and control algorithms to manage heat distribution across battery packs.

- Cell balancing techniques: Cell balancing ensures that all cells in a battery pack maintain similar voltage levels, preventing overcharging or undercharging of individual cells. This can be achieved through passive or active balancing methods, improving overall battery pack performance and longevity.

- Battery management for electric vehicles: Specialized battery management systems for electric vehicles focus on optimizing range, charging efficiency, and overall vehicle performance. These systems integrate with vehicle controls, manage power distribution, and provide accurate state of charge information to the driver.

- Smart charging and energy management: These systems optimize charging processes based on various factors such as electricity rates, grid load, and user preferences. They may incorporate predictive algorithms to schedule charging, integrate with renewable energy sources, and support vehicle-to-grid (V2G) functionality for grid stabilization.

02 Thermal management in battery systems

Thermal management is crucial for battery performance and safety. These systems regulate battery temperature through cooling or heating mechanisms, preventing overheating and maintaining optimal operating conditions. They may include sensors, cooling circuits, and control algorithms to manage heat distribution across battery packs.Expand Specific Solutions03 Cell balancing techniques

Cell balancing ensures that all cells in a battery pack maintain similar voltage levels, preventing overcharging or undercharging of individual cells. This can be achieved through passive or active balancing methods, improving overall battery pack performance and longevity.Expand Specific Solutions04 State of charge and state of health estimation

Advanced algorithms and techniques are used to accurately estimate the state of charge (SoC) and state of health (SoH) of batteries. These estimations are crucial for effective battery management, helping to optimize charging strategies, predict remaining range in electric vehicles, and schedule maintenance.Expand Specific Solutions05 Battery management for electric vehicles

Specialized battery management systems for electric vehicles focus on optimizing range, fast charging capabilities, and integration with vehicle systems. These systems may include features like regenerative braking energy recovery, power distribution management, and driver interface for battery status information.Expand Specific Solutions

Key BMS Solution Providers

The Battery Management Systems (BMS) market in fleet management solutions is experiencing rapid growth, driven by increasing adoption of electric vehicles and demand for efficient energy management. The market is in an early growth stage, with significant potential for expansion as more fleets transition to electric powertrains. Key players like Toyota, Honda, and Cummins are leveraging their automotive expertise to develop advanced BMS solutions. Emerging companies such as IngeniArts Technologies and EVAR Inc. are introducing innovative approaches, including autonomous robotic chargers. The technology is maturing quickly, with established firms like IBM and LG Energy Solution contributing their R&D capabilities to enhance BMS functionality and integration with fleet management systems.

Amazon Technologies, Inc.

Technical Solution: Amazon's Battery Management System for fleet solutions is designed to support their extensive logistics network. Their BMS focuses on optimizing battery performance for last-mile delivery vehicles, which often operate in stop-and-go urban environments[1]. Amazon's system utilizes machine learning algorithms to predict energy consumption based on route characteristics, package load, and driver behavior[2]. This allows for more accurate range estimations and efficient route planning. The BMS also incorporates a unique feature that adjusts battery charging patterns based on the next day's delivery schedule, ensuring that vehicles are optimally charged for their specific routes[3]. For fleet management, Amazon's system provides real-time monitoring and alerts, allowing operators to quickly address any battery-related issues and minimize vehicle downtime[4]. Additionally, the BMS integrates with Amazon's warehouse management systems to coordinate vehicle charging with package sorting and loading processes, further streamlining operations[5].

Strengths: Tailored for last-mile delivery operations, integration with broader logistics systems, and adaptive charging based on delivery schedules. Weaknesses: May be overly specialized for non-delivery fleets and potentially limited compatibility with non-Amazon systems.

Toyota Motor Corp.

Technical Solution: Toyota's approach to Battery Management Systems for fleet solutions emphasizes reliability and scalability. Their BMS incorporates a distributed architecture, with each battery module containing its own microcontroller for local management, while a central BMS coordinates overall performance[1]. This design improves fault tolerance and allows for easier battery pack scaling across different vehicle models in a fleet. Toyota's system also features advanced thermal management, using liquid cooling circuits that adapt to various climate conditions, ensuring consistent battery performance across diverse operating environments[2]. For fleet management, Toyota's BMS provides detailed lifecycle analysis, helping operators to optimize vehicle rotation and plan for battery replacements proactively[3]. The system also supports bi-directional charging, enabling fleet vehicles to participate in grid stabilization programs, potentially creating new revenue streams for fleet operators[4].

Strengths: Scalable and fault-tolerant architecture, advanced thermal management, and support for bi-directional charging. Weaknesses: Potentially higher hardware costs due to distributed architecture and specialized cooling systems.

BMS Innovations Analysis

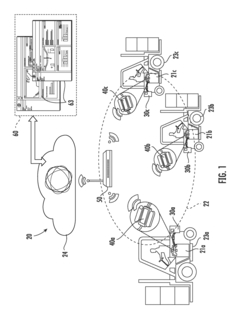

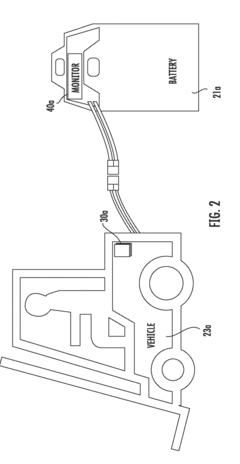

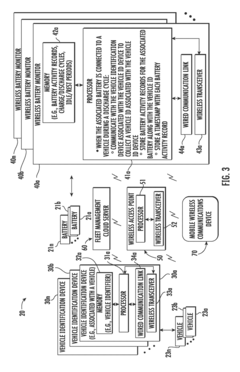

Fleet management system including cloud server for determining vehicle and battery utilization and related methods

PatentActiveUS20180300968A1

Innovation

- A cloud-based fleet management system that integrates vehicle identification devices and wireless battery monitors to collect and process battery activity records, determining vehicle and battery utilization, thereby reducing the need for separate systems and lowering costs by aggregating data and generating reports remotely.

Ev battery degradation in a fleet

PatentActiveUS20240403804A1

Innovation

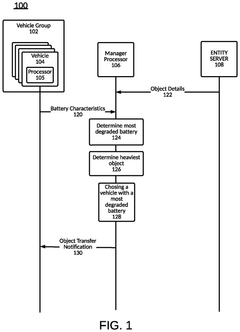

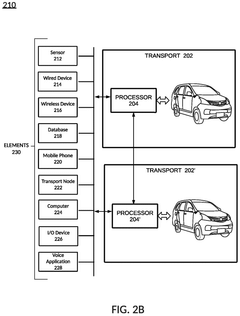

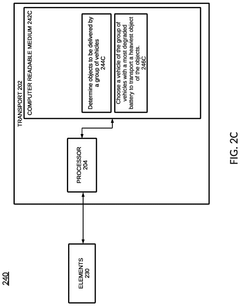

- A method and system that determine the most degraded battery among a group of vehicles and assign it to transport the heaviest objects, utilizing a blockchain-based decentralized database to optimize route planning and minimize battery degradation by routing vehicles with more degraded batteries on fewer routes with heavier loads.

BMS Integration Strategies

Battery Management Systems (BMS) integration strategies play a crucial role in enhancing the efficiency and effectiveness of fleet management solutions. As the automotive industry shifts towards electrification, the seamless integration of BMS into fleet management systems becomes increasingly important. This integration enables fleet operators to optimize vehicle performance, extend battery life, and reduce operational costs.

One key strategy for BMS integration involves real-time data collection and analysis. By continuously monitoring battery parameters such as state of charge, temperature, and voltage, fleet managers can make informed decisions about vehicle usage and maintenance. This data-driven approach allows for predictive maintenance, reducing unexpected downtime and extending the overall lifespan of the fleet's batteries.

Another important aspect of BMS integration is the development of standardized communication protocols. These protocols ensure that BMS data can be easily transmitted and interpreted across different vehicle models and fleet management platforms. Standardization facilitates interoperability and allows fleet operators to manage diverse vehicle types within a single system, streamlining operations and reducing complexity.

Cloud-based integration strategies have also gained prominence in recent years. By leveraging cloud computing, fleet managers can access BMS data remotely, enabling real-time monitoring and analysis of battery performance across entire fleets. This approach allows for centralized management and decision-making, improving overall fleet efficiency and reducing operational costs.

Advanced BMS integration strategies also incorporate machine learning and artificial intelligence algorithms. These technologies can analyze historical BMS data to predict battery degradation, optimize charging schedules, and recommend route planning based on battery performance. By leveraging AI-driven insights, fleet operators can maximize the utilization of their electric vehicles while minimizing battery wear and energy consumption.

Integration of BMS with telematics systems represents another critical strategy. This combination allows for the correlation of battery performance data with vehicle location, driving behavior, and environmental conditions. Such integration provides a holistic view of fleet operations, enabling managers to identify patterns and optimize routes based on battery efficiency and charging infrastructure availability.

Lastly, BMS integration strategies must consider cybersecurity measures to protect sensitive battery and vehicle data. Implementing robust encryption protocols and secure data transmission methods ensures that BMS information remains confidential and protected from potential cyber threats, maintaining the integrity of fleet management operations.

One key strategy for BMS integration involves real-time data collection and analysis. By continuously monitoring battery parameters such as state of charge, temperature, and voltage, fleet managers can make informed decisions about vehicle usage and maintenance. This data-driven approach allows for predictive maintenance, reducing unexpected downtime and extending the overall lifespan of the fleet's batteries.

Another important aspect of BMS integration is the development of standardized communication protocols. These protocols ensure that BMS data can be easily transmitted and interpreted across different vehicle models and fleet management platforms. Standardization facilitates interoperability and allows fleet operators to manage diverse vehicle types within a single system, streamlining operations and reducing complexity.

Cloud-based integration strategies have also gained prominence in recent years. By leveraging cloud computing, fleet managers can access BMS data remotely, enabling real-time monitoring and analysis of battery performance across entire fleets. This approach allows for centralized management and decision-making, improving overall fleet efficiency and reducing operational costs.

Advanced BMS integration strategies also incorporate machine learning and artificial intelligence algorithms. These technologies can analyze historical BMS data to predict battery degradation, optimize charging schedules, and recommend route planning based on battery performance. By leveraging AI-driven insights, fleet operators can maximize the utilization of their electric vehicles while minimizing battery wear and energy consumption.

Integration of BMS with telematics systems represents another critical strategy. This combination allows for the correlation of battery performance data with vehicle location, driving behavior, and environmental conditions. Such integration provides a holistic view of fleet operations, enabling managers to identify patterns and optimize routes based on battery efficiency and charging infrastructure availability.

Lastly, BMS integration strategies must consider cybersecurity measures to protect sensitive battery and vehicle data. Implementing robust encryption protocols and secure data transmission methods ensures that BMS information remains confidential and protected from potential cyber threats, maintaining the integrity of fleet management operations.

BMS Data Security Measures

Battery Management Systems (BMS) play a crucial role in fleet management solutions, and ensuring the security of BMS data is paramount. As fleet operators increasingly rely on BMS for optimizing vehicle performance and maintenance, protecting sensitive information becomes a top priority. Robust data security measures are essential to safeguard against potential threats and maintain the integrity of fleet operations.

Encryption is a fundamental component of BMS data security. Advanced encryption algorithms are employed to protect data both at rest and in transit. This includes encrypting data stored within the BMS itself, as well as during transmission to fleet management systems. Secure communication protocols, such as Transport Layer Security (TLS), are implemented to establish encrypted connections between BMS units and central management servers.

Access control mechanisms form another critical layer of security. Multi-factor authentication is often implemented to ensure that only authorized personnel can access BMS data and make changes to system settings. Role-based access control (RBAC) further enhances security by limiting user privileges based on their specific responsibilities within the organization.

Regular security audits and vulnerability assessments are conducted to identify potential weaknesses in the BMS infrastructure. These assessments help fleet managers stay ahead of emerging threats and implement necessary security patches and updates promptly. Continuous monitoring of BMS networks allows for real-time threat detection and rapid response to any suspicious activities.

Data integrity measures are implemented to prevent unauthorized modifications to BMS data. This includes the use of digital signatures and checksums to verify the authenticity and integrity of data transmitted between BMS units and fleet management systems. Tamper-evident logging mechanisms are also employed to track any attempts to alter or manipulate BMS data.

Secure over-the-air (OTA) update processes are crucial for maintaining the security of BMS firmware and software. These updates are delivered through encrypted channels and verified before installation to prevent the introduction of malware or unauthorized modifications to the system.

Physical security measures are also considered in BMS data protection. This includes securing access to vehicles and BMS hardware components to prevent unauthorized physical tampering. Additionally, data center security protocols are implemented to protect the servers and infrastructure that store and process BMS data for fleet management purposes.

Compliance with data protection regulations, such as GDPR and CCPA, is an integral part of BMS data security measures. Fleet management solutions incorporate privacy-by-design principles to ensure that data collection and processing practices align with regulatory requirements and industry best practices.

Encryption is a fundamental component of BMS data security. Advanced encryption algorithms are employed to protect data both at rest and in transit. This includes encrypting data stored within the BMS itself, as well as during transmission to fleet management systems. Secure communication protocols, such as Transport Layer Security (TLS), are implemented to establish encrypted connections between BMS units and central management servers.

Access control mechanisms form another critical layer of security. Multi-factor authentication is often implemented to ensure that only authorized personnel can access BMS data and make changes to system settings. Role-based access control (RBAC) further enhances security by limiting user privileges based on their specific responsibilities within the organization.

Regular security audits and vulnerability assessments are conducted to identify potential weaknesses in the BMS infrastructure. These assessments help fleet managers stay ahead of emerging threats and implement necessary security patches and updates promptly. Continuous monitoring of BMS networks allows for real-time threat detection and rapid response to any suspicious activities.

Data integrity measures are implemented to prevent unauthorized modifications to BMS data. This includes the use of digital signatures and checksums to verify the authenticity and integrity of data transmitted between BMS units and fleet management systems. Tamper-evident logging mechanisms are also employed to track any attempts to alter or manipulate BMS data.

Secure over-the-air (OTA) update processes are crucial for maintaining the security of BMS firmware and software. These updates are delivered through encrypted channels and verified before installation to prevent the introduction of malware or unauthorized modifications to the system.

Physical security measures are also considered in BMS data protection. This includes securing access to vehicles and BMS hardware components to prevent unauthorized physical tampering. Additionally, data center security protocols are implemented to protect the servers and infrastructure that store and process BMS data for fleet management purposes.

Compliance with data protection regulations, such as GDPR and CCPA, is an integral part of BMS data security measures. Fleet management solutions incorporate privacy-by-design principles to ensure that data collection and processing practices align with regulatory requirements and industry best practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!