Influence of isotonic solutions on protein formulation stability

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isotonic Solutions in Protein Formulations

Isotonic solutions play a crucial role in maintaining protein formulation stability. These solutions are designed to have the same osmotic pressure as the surrounding environment, typically matching that of human blood or other bodily fluids. This isotonicity is essential for preventing osmotic stress on proteins, which can lead to denaturation, aggregation, or other forms of instability.

The primary function of isotonic solutions in protein formulations is to create an environment that mimics physiological conditions. This is particularly important for therapeutic proteins, as it helps maintain their native structure and function. Common isotonic agents used in protein formulations include sodium chloride, dextrose, and mannitol. These agents contribute to the overall tonicity of the solution without directly interacting with the protein molecules.

The choice of isotonic agent can significantly impact protein stability. For instance, sodium chloride is widely used due to its effectiveness and low cost. However, in some cases, it may promote protein aggregation through charge shielding effects. Alternatively, sugar-based isotonic agents like dextrose or sucrose can offer additional stabilizing effects through preferential exclusion mechanisms, where they are excluded from the protein's surface, leading to preferential hydration of the protein.

Isotonic solutions also play a role in controlling the pH of the formulation. The buffer capacity of these solutions helps maintain a stable pH environment, which is critical for protein stability. Many proteins have a specific pH range where they exhibit optimal stability, and deviations from this range can lead to structural changes or loss of activity.

Furthermore, the use of isotonic solutions in protein formulations is essential for ensuring patient comfort and safety during administration. Solutions that are not isotonic can cause pain or tissue damage at the injection site, as well as potentially altering the pharmacokinetics of the protein drug.

The concentration of isotonic agents must be carefully balanced to achieve the desired osmolality without adversely affecting protein stability. Excessive concentrations can lead to increased ionic strength, potentially disrupting protein-protein interactions or promoting aggregation. Conversely, insufficient concentrations may not provide adequate protection against osmotic stress.

In recent years, there has been growing interest in developing novel isotonic agents that offer additional stabilizing properties. These include amino acids, polyols, and other osmolytes that can enhance protein stability through various mechanisms, such as preferential exclusion or direct interaction with the protein surface.

The primary function of isotonic solutions in protein formulations is to create an environment that mimics physiological conditions. This is particularly important for therapeutic proteins, as it helps maintain their native structure and function. Common isotonic agents used in protein formulations include sodium chloride, dextrose, and mannitol. These agents contribute to the overall tonicity of the solution without directly interacting with the protein molecules.

The choice of isotonic agent can significantly impact protein stability. For instance, sodium chloride is widely used due to its effectiveness and low cost. However, in some cases, it may promote protein aggregation through charge shielding effects. Alternatively, sugar-based isotonic agents like dextrose or sucrose can offer additional stabilizing effects through preferential exclusion mechanisms, where they are excluded from the protein's surface, leading to preferential hydration of the protein.

Isotonic solutions also play a role in controlling the pH of the formulation. The buffer capacity of these solutions helps maintain a stable pH environment, which is critical for protein stability. Many proteins have a specific pH range where they exhibit optimal stability, and deviations from this range can lead to structural changes or loss of activity.

Furthermore, the use of isotonic solutions in protein formulations is essential for ensuring patient comfort and safety during administration. Solutions that are not isotonic can cause pain or tissue damage at the injection site, as well as potentially altering the pharmacokinetics of the protein drug.

The concentration of isotonic agents must be carefully balanced to achieve the desired osmolality without adversely affecting protein stability. Excessive concentrations can lead to increased ionic strength, potentially disrupting protein-protein interactions or promoting aggregation. Conversely, insufficient concentrations may not provide adequate protection against osmotic stress.

In recent years, there has been growing interest in developing novel isotonic agents that offer additional stabilizing properties. These include amino acids, polyols, and other osmolytes that can enhance protein stability through various mechanisms, such as preferential exclusion or direct interaction with the protein surface.

Market Analysis for Stable Protein Formulations

The market for stable protein formulations has experienced significant growth in recent years, driven by the increasing demand for biopharmaceuticals and the need for improved drug delivery systems. The global protein therapeutics market, which heavily relies on stable formulations, is projected to reach $217.6 billion by 2026, growing at a CAGR of 6.8% from 2021 to 2026. This growth is primarily attributed to the rising prevalence of chronic diseases, advancements in protein engineering technologies, and the expanding applications of protein-based drugs in various therapeutic areas.

Within this market, the demand for stable protein formulations is particularly strong in the biotechnology and pharmaceutical industries. These sectors are continuously seeking innovative solutions to enhance the stability, efficacy, and shelf-life of protein-based drugs. The use of isotonic solutions in protein formulations has emerged as a critical factor in achieving these goals, as they help maintain the structural integrity and biological activity of proteins during storage and administration.

The market for stable protein formulations is segmented based on protein type, formulation technique, and therapeutic application. Monoclonal antibodies represent the largest segment, accounting for approximately 45% of the market share, followed by other protein types such as hormones, growth factors, and enzymes. In terms of formulation techniques, lyophilization and liquid formulations dominate the market, with increasing interest in novel approaches like spray-drying and nanoencapsulation.

Geographically, North America leads the market for stable protein formulations, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to its robust biopharmaceutical industry and high investment in research and development. However, emerging markets in Asia-Pacific, especially China and India, are expected to witness the fastest growth in the coming years, driven by improving healthcare infrastructure and increasing focus on biosimilars.

Key market trends include the growing adoption of personalized medicine, which requires more sophisticated and stable protein formulations, and the increasing focus on developing biobetters with enhanced stability profiles. Additionally, there is a rising demand for ready-to-use liquid formulations that offer convenience and reduce the risk of dosing errors.

The competitive landscape of the stable protein formulations market is characterized by the presence of major pharmaceutical and biotechnology companies, as well as specialized formulation development firms. These players are investing heavily in research and development to develop novel formulation strategies and overcome challenges associated with protein stability. Collaborations between pharmaceutical companies and academic institutions are also becoming more prevalent, fostering innovation in this field.

Within this market, the demand for stable protein formulations is particularly strong in the biotechnology and pharmaceutical industries. These sectors are continuously seeking innovative solutions to enhance the stability, efficacy, and shelf-life of protein-based drugs. The use of isotonic solutions in protein formulations has emerged as a critical factor in achieving these goals, as they help maintain the structural integrity and biological activity of proteins during storage and administration.

The market for stable protein formulations is segmented based on protein type, formulation technique, and therapeutic application. Monoclonal antibodies represent the largest segment, accounting for approximately 45% of the market share, followed by other protein types such as hormones, growth factors, and enzymes. In terms of formulation techniques, lyophilization and liquid formulations dominate the market, with increasing interest in novel approaches like spray-drying and nanoencapsulation.

Geographically, North America leads the market for stable protein formulations, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to its robust biopharmaceutical industry and high investment in research and development. However, emerging markets in Asia-Pacific, especially China and India, are expected to witness the fastest growth in the coming years, driven by improving healthcare infrastructure and increasing focus on biosimilars.

Key market trends include the growing adoption of personalized medicine, which requires more sophisticated and stable protein formulations, and the increasing focus on developing biobetters with enhanced stability profiles. Additionally, there is a rising demand for ready-to-use liquid formulations that offer convenience and reduce the risk of dosing errors.

The competitive landscape of the stable protein formulations market is characterized by the presence of major pharmaceutical and biotechnology companies, as well as specialized formulation development firms. These players are investing heavily in research and development to develop novel formulation strategies and overcome challenges associated with protein stability. Collaborations between pharmaceutical companies and academic institutions are also becoming more prevalent, fostering innovation in this field.

Current Challenges in Protein Stability

Protein stability remains a critical challenge in biopharmaceutical development, with numerous factors influencing the stability of protein formulations. One of the primary concerns is the maintenance of protein structure and function in isotonic solutions, which are essential for ensuring the safety and efficacy of protein-based therapeutics.

A significant challenge lies in the complex interactions between proteins and the components of isotonic solutions. These interactions can lead to various forms of instability, including aggregation, denaturation, and chemical degradation. The presence of salts, sugars, and other excipients in isotonic solutions can significantly impact protein stability through mechanisms such as charge shielding, preferential hydration, and osmotic stress.

The pH of isotonic solutions presents another crucial challenge. Proteins typically have a narrow pH range in which they maintain optimal stability. Deviations from this range can lead to changes in protein charge distribution, affecting intermolecular interactions and potentially causing aggregation or precipitation. Balancing the need for isotonicity with optimal pH conditions remains a delicate task in formulation development.

Temperature fluctuations during storage and transportation pose additional challenges to protein stability in isotonic solutions. Temperature changes can alter the solubility of proteins and excipients, potentially leading to phase separation or precipitation. Moreover, elevated temperatures can accelerate chemical degradation processes, such as oxidation and deamidation, further compromising protein stability.

The long-term stability of proteins in isotonic solutions is another area of concern. Over time, proteins may undergo subtle conformational changes or form small aggregates that are difficult to detect but can significantly impact their biological activity and immunogenicity. Developing reliable predictive models for long-term stability remains a challenge due to the complexity of protein-solution interactions and the multitude of factors involved.

Freeze-thaw stability is a critical consideration for many protein formulations, particularly those requiring cold chain storage. The process of freezing and thawing can induce significant stress on proteins, leading to denaturation and aggregation. The presence of isotonic agents can either exacerbate or mitigate these effects, depending on their nature and concentration, making the development of freeze-thaw resistant formulations a complex endeavor.

Finally, the increasing complexity of protein therapeutics, such as bispecific antibodies and fusion proteins, introduces new challenges in maintaining stability in isotonic solutions. These novel protein formats often have unique structural features and stability profiles that may not be adequately addressed by traditional formulation approaches, necessitating innovative strategies for ensuring their stability in isotonic environments.

A significant challenge lies in the complex interactions between proteins and the components of isotonic solutions. These interactions can lead to various forms of instability, including aggregation, denaturation, and chemical degradation. The presence of salts, sugars, and other excipients in isotonic solutions can significantly impact protein stability through mechanisms such as charge shielding, preferential hydration, and osmotic stress.

The pH of isotonic solutions presents another crucial challenge. Proteins typically have a narrow pH range in which they maintain optimal stability. Deviations from this range can lead to changes in protein charge distribution, affecting intermolecular interactions and potentially causing aggregation or precipitation. Balancing the need for isotonicity with optimal pH conditions remains a delicate task in formulation development.

Temperature fluctuations during storage and transportation pose additional challenges to protein stability in isotonic solutions. Temperature changes can alter the solubility of proteins and excipients, potentially leading to phase separation or precipitation. Moreover, elevated temperatures can accelerate chemical degradation processes, such as oxidation and deamidation, further compromising protein stability.

The long-term stability of proteins in isotonic solutions is another area of concern. Over time, proteins may undergo subtle conformational changes or form small aggregates that are difficult to detect but can significantly impact their biological activity and immunogenicity. Developing reliable predictive models for long-term stability remains a challenge due to the complexity of protein-solution interactions and the multitude of factors involved.

Freeze-thaw stability is a critical consideration for many protein formulations, particularly those requiring cold chain storage. The process of freezing and thawing can induce significant stress on proteins, leading to denaturation and aggregation. The presence of isotonic agents can either exacerbate or mitigate these effects, depending on their nature and concentration, making the development of freeze-thaw resistant formulations a complex endeavor.

Finally, the increasing complexity of protein therapeutics, such as bispecific antibodies and fusion proteins, introduces new challenges in maintaining stability in isotonic solutions. These novel protein formats often have unique structural features and stability profiles that may not be adequately addressed by traditional formulation approaches, necessitating innovative strategies for ensuring their stability in isotonic environments.

Existing Isotonic Stabilization Techniques

01 Stabilization of isotonic solutions using buffer systems

Buffer systems are employed to maintain the pH and stability of isotonic solutions. These systems help prevent degradation of active ingredients and ensure the solution remains isotonic over time. Common buffer components include phosphates, citrates, and acetates, which work together to resist changes in pH and maintain the osmotic balance of the solution.- Stabilization of isotonic solutions using buffer systems: Buffer systems are employed to maintain the pH and stability of isotonic solutions. These systems help prevent degradation of active ingredients and ensure the solution remains isotonic over time. Common buffer components include phosphates, citrates, and acetates, which work together to resist changes in pH and maintain the osmotic balance of the solution.

- Antioxidants for enhancing stability of isotonic solutions: Antioxidants are added to isotonic solutions to prevent oxidation and degradation of sensitive components. These additives help maintain the stability and efficacy of the solution during storage and use. Common antioxidants used include ascorbic acid, tocopherols, and sulfites, which scavenge free radicals and protect against oxidative stress.

- Temperature control for isotonic solution stability: Proper temperature control during manufacturing, storage, and transportation is crucial for maintaining the stability of isotonic solutions. Specific temperature ranges are established to prevent degradation of active ingredients and maintain the solution's isotonicity. Cold chain management and temperature-controlled environments are often employed to ensure product stability.

- Packaging innovations for improved stability: Advanced packaging technologies are developed to enhance the stability of isotonic solutions. These innovations include barrier materials, modified atmosphere packaging, and multi-layer containers that protect against light, moisture, and oxygen. Specialized closures and sealing methods are also employed to maintain product integrity and extend shelf life.

- Stabilizing agents for isotonic solutions: Various stabilizing agents are incorporated into isotonic solutions to improve their overall stability. These agents can include chelating compounds, surfactants, and polymers that help prevent degradation, maintain homogeneity, and enhance the solution's resistance to environmental factors. The choice of stabilizing agents depends on the specific formulation and intended use of the isotonic solution.

02 Antioxidants for enhancing stability of isotonic solutions

Antioxidants are added to isotonic solutions to prevent oxidation and degradation of sensitive components. These additives help maintain the stability and efficacy of the solution during storage and use. Common antioxidants used include ascorbic acid, tocopherols, and butylated hydroxyanisole (BHA), which scavenge free radicals and inhibit oxidative processes.Expand Specific Solutions03 Temperature control for isotonic solution stability

Proper temperature control during manufacturing, storage, and transportation is crucial for maintaining the stability of isotonic solutions. Specific temperature ranges are established to prevent degradation of active ingredients and maintain the solution's isotonicity. Cold chain management and temperature-controlled environments are often employed to ensure product stability throughout its lifecycle.Expand Specific Solutions04 Packaging innovations for improved stability

Advanced packaging materials and designs are utilized to enhance the stability of isotonic solutions. These innovations include barrier materials to prevent moisture and oxygen permeation, light-protective containers to minimize photodegradation, and single-dose packaging to maintain sterility and reduce contamination risks. Such packaging solutions contribute to extended shelf life and improved product stability.Expand Specific Solutions05 Stabilizing agents for isotonic solutions

Various stabilizing agents are incorporated into isotonic solutions to improve their overall stability. These agents can include chelating compounds, surfactants, and polymers that help prevent degradation, maintain pH, and ensure uniform distribution of active ingredients. The selection of appropriate stabilizing agents depends on the specific formulation and intended use of the isotonic solution.Expand Specific Solutions

Key Players in Biopharmaceutical Formulation

The influence of isotonic solutions on protein formulation stability is a critical area of research in the biopharmaceutical industry, currently in a mature development stage. The market for stable protein formulations is substantial, driven by the growing demand for biologic drugs. Major players like Genentech, Novartis, and AbbVie are at the forefront of this field, leveraging their extensive R&D capabilities and market presence. The technology is well-established, with ongoing refinements focusing on enhancing long-term stability and optimizing delivery methods. Emerging companies such as Comera Life Sciences are also contributing innovative approaches, indicating a competitive and dynamic landscape in this crucial aspect of drug development.

Genentech, Inc.

Technical Solution: Genentech has developed a novel approach to enhance protein formulation stability using isotonic solutions. Their method involves the use of carefully selected osmolytes and buffer systems to maintain protein structure and function in isotonic environments. The company has implemented a high-throughput screening platform to identify optimal combinations of excipients that minimize protein aggregation and denaturation[1]. Additionally, Genentech has pioneered the use of molecular dynamics simulations to predict the behavior of proteins in various isotonic solutions, allowing for rapid optimization of formulation conditions[3]. Their technology also incorporates the use of stabilizing agents such as amino acids and sugars to counteract the destabilizing effects of isotonic conditions on protein structure[5].

Strengths: Advanced computational modeling capabilities, extensive experience in protein therapeutics, and a robust high-throughput screening platform. Weaknesses: Potential high costs associated with complex formulation development and the need for specialized equipment and expertise.

Novartis AG

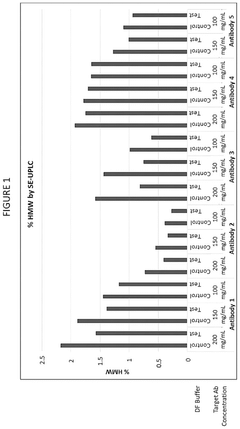

Technical Solution: Novartis has developed a comprehensive approach to address the influence of isotonic solutions on protein formulation stability. Their strategy involves the use of a proprietary blend of stabilizing agents, including specific amino acids and polyols, which have been shown to significantly reduce protein aggregation in isotonic conditions[2]. The company has also implemented advanced analytical techniques, such as dynamic light scattering and size-exclusion chromatography, to monitor protein stability in real-time during formulation development[4]. Novartis has further enhanced their approach by incorporating machine learning algorithms to predict optimal formulation compositions based on protein characteristics and desired isotonicity[6]. This data-driven approach has allowed for more efficient and targeted formulation development processes.

Strengths: Strong analytical capabilities, innovative use of machine learning in formulation development, and a diverse portfolio of stabilizing agents. Weaknesses: Potential reliance on proprietary technology may limit flexibility in some applications.

Innovative Approaches to Protein Stability

Antibody formulations

PatentPendingUS20240343795A1

Innovation

- Development of isotonic liquid compositions containing monoclonal antibodies at concentrations above 100 mg/mL, formulated with arginine glutamate or proline, and a surfactant, maintaining a pH of 4.5 to 5.5, which reduces viscosity and aggregation, and is stable for extended storage periods.

Protein stabilization in solution

PatentInactiveUS20060160720A1

Innovation

- Using specific materials like silica-coated glass, silicone-coated glass, polymers of non-cyclic olefins, cycloolefin polymers, and cycloolefin/linear olefin copolymers as inner wall materials in containers to minimize protein aggregation and maintain stability by controlling metal ion release.

Regulatory Considerations for Biopharmaceuticals

The regulatory landscape for biopharmaceuticals, including protein formulations, is complex and constantly evolving. Regulatory bodies such as the FDA, EMA, and other national authorities play a crucial role in ensuring the safety, efficacy, and quality of these products. When considering the influence of isotonic solutions on protein formulation stability, several regulatory aspects must be addressed.

Firstly, the choice of excipients, including isotonic agents, must comply with regulatory guidelines. Manufacturers must demonstrate that the selected isotonic solutions are safe for use in the intended formulation and do not adversely affect the stability or efficacy of the protein. This involves providing comprehensive data on the compatibility of the isotonic agent with the protein, as well as its impact on the overall formulation stability.

Stability testing is a critical regulatory requirement for biopharmaceuticals. The impact of isotonic solutions on protein stability must be thoroughly evaluated and documented. This includes conducting long-term stability studies under various storage conditions to assess the formulation's shelf life and potential degradation pathways. Regulatory agencies typically require stability data for the duration of the proposed shelf life, plus additional time to account for potential delays in distribution.

The manufacturing process and quality control measures for protein formulations containing isotonic solutions must adhere to Good Manufacturing Practice (GMP) guidelines. This includes validating the manufacturing process, establishing appropriate in-process controls, and implementing robust analytical methods to ensure consistent product quality. Regulatory authorities will scrutinize these aspects during the review process and subsequent inspections.

Characterization of the protein formulation, including its physicochemical properties and biological activity in the presence of isotonic solutions, is essential for regulatory approval. Manufacturers must provide detailed information on the formulation composition, including the concentration and type of isotonic agent used, and demonstrate that the formulation maintains its intended characteristics throughout its shelf life.

Changes to the formulation, including modifications to the isotonic solution or its concentration, may require regulatory notification or approval. The extent of regulatory oversight depends on the nature and potential impact of the change. Manufacturers should be prepared to provide supporting data demonstrating that any changes do not adversely affect the product's quality, safety, or efficacy.

Labeling and packaging requirements must also be considered from a regulatory perspective. The presence of specific isotonic agents may need to be declared on the product label, particularly if they are known to cause allergic reactions or have other safety implications. Additionally, the storage conditions and handling instructions may need to be adjusted based on the stability profile of the protein formulation in the presence of the isotonic solution.

Firstly, the choice of excipients, including isotonic agents, must comply with regulatory guidelines. Manufacturers must demonstrate that the selected isotonic solutions are safe for use in the intended formulation and do not adversely affect the stability or efficacy of the protein. This involves providing comprehensive data on the compatibility of the isotonic agent with the protein, as well as its impact on the overall formulation stability.

Stability testing is a critical regulatory requirement for biopharmaceuticals. The impact of isotonic solutions on protein stability must be thoroughly evaluated and documented. This includes conducting long-term stability studies under various storage conditions to assess the formulation's shelf life and potential degradation pathways. Regulatory agencies typically require stability data for the duration of the proposed shelf life, plus additional time to account for potential delays in distribution.

The manufacturing process and quality control measures for protein formulations containing isotonic solutions must adhere to Good Manufacturing Practice (GMP) guidelines. This includes validating the manufacturing process, establishing appropriate in-process controls, and implementing robust analytical methods to ensure consistent product quality. Regulatory authorities will scrutinize these aspects during the review process and subsequent inspections.

Characterization of the protein formulation, including its physicochemical properties and biological activity in the presence of isotonic solutions, is essential for regulatory approval. Manufacturers must provide detailed information on the formulation composition, including the concentration and type of isotonic agent used, and demonstrate that the formulation maintains its intended characteristics throughout its shelf life.

Changes to the formulation, including modifications to the isotonic solution or its concentration, may require regulatory notification or approval. The extent of regulatory oversight depends on the nature and potential impact of the change. Manufacturers should be prepared to provide supporting data demonstrating that any changes do not adversely affect the product's quality, safety, or efficacy.

Labeling and packaging requirements must also be considered from a regulatory perspective. The presence of specific isotonic agents may need to be declared on the product label, particularly if they are known to cause allergic reactions or have other safety implications. Additionally, the storage conditions and handling instructions may need to be adjusted based on the stability profile of the protein formulation in the presence of the isotonic solution.

Environmental Impact of Formulation Processes

The environmental impact of protein formulation processes, particularly those involving isotonic solutions, is a growing concern in the biopharmaceutical industry. These processes often require significant energy consumption and generate substantial waste, contributing to the overall environmental footprint of pharmaceutical manufacturing.

One of the primary environmental concerns is the extensive use of water in formulation processes. Isotonic solutions, by definition, require precise osmolality matching with physiological fluids, necessitating large volumes of purified water. The production and purification of this water consume considerable energy and may strain local water resources, especially in water-scarce regions.

Chemical usage in formulation processes also poses environmental challenges. Buffer components, stabilizers, and other excipients used in isotonic solutions can contribute to water pollution if not properly managed. Many of these chemicals are not easily biodegradable and may persist in the environment, potentially affecting aquatic ecosystems.

The disposal of unused or expired formulations is another significant environmental issue. Protein-based drugs are often sensitive to environmental conditions and have limited shelf lives. Improper disposal can lead to pharmaceutical residues in water systems, potentially impacting wildlife and human health.

Energy consumption in maintaining controlled environments for formulation processes is substantial. Strict temperature and humidity controls are essential for ensuring protein stability, but these systems are energy-intensive. The carbon footprint associated with this energy use contributes to global climate change concerns.

Packaging materials used for protein formulations, including vials, stoppers, and secondary packaging, also have environmental implications. Many of these materials are not easily recyclable due to contamination concerns, leading to increased plastic waste in landfills or incineration facilities.

To address these environmental challenges, the industry is exploring various sustainable practices. These include implementing closed-loop water systems to reduce water consumption, adopting green chemistry principles to minimize harmful chemical use, and investing in more energy-efficient facilities and equipment. Additionally, there is a growing focus on developing more stable protein formulations that require less stringent storage conditions, potentially reducing the environmental impact of cold chain logistics.

One of the primary environmental concerns is the extensive use of water in formulation processes. Isotonic solutions, by definition, require precise osmolality matching with physiological fluids, necessitating large volumes of purified water. The production and purification of this water consume considerable energy and may strain local water resources, especially in water-scarce regions.

Chemical usage in formulation processes also poses environmental challenges. Buffer components, stabilizers, and other excipients used in isotonic solutions can contribute to water pollution if not properly managed. Many of these chemicals are not easily biodegradable and may persist in the environment, potentially affecting aquatic ecosystems.

The disposal of unused or expired formulations is another significant environmental issue. Protein-based drugs are often sensitive to environmental conditions and have limited shelf lives. Improper disposal can lead to pharmaceutical residues in water systems, potentially impacting wildlife and human health.

Energy consumption in maintaining controlled environments for formulation processes is substantial. Strict temperature and humidity controls are essential for ensuring protein stability, but these systems are energy-intensive. The carbon footprint associated with this energy use contributes to global climate change concerns.

Packaging materials used for protein formulations, including vials, stoppers, and secondary packaging, also have environmental implications. Many of these materials are not easily recyclable due to contamination concerns, leading to increased plastic waste in landfills or incineration facilities.

To address these environmental challenges, the industry is exploring various sustainable practices. These include implementing closed-loop water systems to reduce water consumption, adopting green chemistry principles to minimize harmful chemical use, and investing in more energy-efficient facilities and equipment. Additionally, there is a growing focus on developing more stable protein formulations that require less stringent storage conditions, potentially reducing the environmental impact of cold chain logistics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!