Isotonic solutions role in controlling agglomeration in suspensions

AUG 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isotonic Solutions Background and Objectives

Isotonic solutions have played a crucial role in various industries, particularly in pharmaceutical and biomedical applications, for controlling agglomeration in suspensions. The concept of isotonicity has its roots in osmotic pressure regulation, which is fundamental to maintaining cellular integrity and stability in biological systems. Over the years, the application of isotonic solutions has expanded beyond medical use to include food processing, cosmetics, and materials science.

The evolution of isotonic solutions in suspension technology has been driven by the need to address the persistent challenge of particle agglomeration. Agglomeration, the process by which particles in a suspension cluster together, can significantly impact the stability, efficacy, and shelf-life of products. As industries sought more effective ways to maintain uniform dispersions, the potential of isotonic solutions to mitigate this issue became increasingly apparent.

The primary objective in utilizing isotonic solutions for controlling agglomeration is to create an environment where suspended particles remain evenly distributed without clumping or settling. This is achieved by balancing the osmotic pressure between the particles and the surrounding medium, effectively neutralizing the forces that typically lead to agglomeration. By maintaining this delicate equilibrium, isotonic solutions help preserve the intended properties and functionality of suspensions across various applications.

Recent technological advancements have further refined the use of isotonic solutions in suspension systems. Researchers have been exploring novel formulations and additives that enhance the stability-promoting properties of these solutions while also addressing specific industry requirements. These developments aim to extend the range of materials that can be effectively suspended and to improve the long-term stability of suspensions under diverse environmental conditions.

The growing interest in nanotechnology and advanced materials has also spurred innovation in isotonic solution applications. As particle sizes decrease and surface interactions become more complex, the role of isotonic solutions in maintaining stable nano-suspensions has become increasingly critical. This has led to a surge in research focused on tailoring isotonic environments for next-generation materials and drug delivery systems.

Looking ahead, the objectives for isotonic solutions in controlling agglomeration are multifaceted. There is a push towards developing more sustainable and biocompatible formulations that can meet stringent regulatory requirements across different sectors. Additionally, researchers are working on smart isotonic systems that can dynamically respond to changes in their environment, providing adaptive stability control for suspensions under varying conditions.

The evolution of isotonic solutions in suspension technology has been driven by the need to address the persistent challenge of particle agglomeration. Agglomeration, the process by which particles in a suspension cluster together, can significantly impact the stability, efficacy, and shelf-life of products. As industries sought more effective ways to maintain uniform dispersions, the potential of isotonic solutions to mitigate this issue became increasingly apparent.

The primary objective in utilizing isotonic solutions for controlling agglomeration is to create an environment where suspended particles remain evenly distributed without clumping or settling. This is achieved by balancing the osmotic pressure between the particles and the surrounding medium, effectively neutralizing the forces that typically lead to agglomeration. By maintaining this delicate equilibrium, isotonic solutions help preserve the intended properties and functionality of suspensions across various applications.

Recent technological advancements have further refined the use of isotonic solutions in suspension systems. Researchers have been exploring novel formulations and additives that enhance the stability-promoting properties of these solutions while also addressing specific industry requirements. These developments aim to extend the range of materials that can be effectively suspended and to improve the long-term stability of suspensions under diverse environmental conditions.

The growing interest in nanotechnology and advanced materials has also spurred innovation in isotonic solution applications. As particle sizes decrease and surface interactions become more complex, the role of isotonic solutions in maintaining stable nano-suspensions has become increasingly critical. This has led to a surge in research focused on tailoring isotonic environments for next-generation materials and drug delivery systems.

Looking ahead, the objectives for isotonic solutions in controlling agglomeration are multifaceted. There is a push towards developing more sustainable and biocompatible formulations that can meet stringent regulatory requirements across different sectors. Additionally, researchers are working on smart isotonic systems that can dynamically respond to changes in their environment, providing adaptive stability control for suspensions under varying conditions.

Market Analysis for Suspension Stability

The market for suspension stability solutions, particularly those utilizing isotonic solutions to control agglomeration, has shown significant growth in recent years. This trend is driven by the increasing demand for stable suspensions across various industries, including pharmaceuticals, food and beverages, cosmetics, and advanced materials.

In the pharmaceutical sector, the need for stable drug suspensions has become paramount, especially with the rise of complex formulations and biologics. Isotonic solutions play a crucial role in maintaining the stability of these suspensions, ensuring consistent drug delivery and efficacy. The global pharmaceutical suspension market is expected to grow steadily, with a particular focus on innovative formulations that enhance bioavailability and patient compliance.

The food and beverage industry has also witnessed a surge in demand for stable suspensions, particularly in functional foods, nutritional supplements, and fortified beverages. Isotonic solutions are increasingly being utilized to prevent ingredient separation and maintain product consistency, thereby extending shelf life and improving consumer appeal. This segment of the market is projected to experience robust growth, driven by consumer preferences for natural, clean-label products with extended stability.

In the cosmetics and personal care sector, suspension stability is critical for products such as lotions, creams, and sunscreens. The use of isotonic solutions in these formulations helps prevent the agglomeration of active ingredients, ensuring uniform distribution and efficacy. As consumers demand more sophisticated and multifunctional cosmetic products, the market for advanced suspension stability solutions is expected to expand significantly.

The advanced materials industry, encompassing areas such as nanotechnology and specialty coatings, represents another key growth area for suspension stability solutions. Isotonic formulations are increasingly being employed to control the agglomeration of nanoparticles and other advanced materials in suspension, enabling the development of novel products with enhanced properties.

Geographically, North America and Europe currently dominate the market for suspension stability solutions, owing to their well-established pharmaceutical and cosmetics industries. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, rising disposable incomes, and growing awareness of advanced formulation technologies.

Key market drivers include the ongoing research and development efforts to improve suspension stability techniques, the increasing adoption of nanotechnology across various industries, and the growing demand for personalized medicine and targeted drug delivery systems. Additionally, stringent regulatory requirements for product stability and safety are pushing manufacturers to invest in advanced suspension stability solutions.

In the pharmaceutical sector, the need for stable drug suspensions has become paramount, especially with the rise of complex formulations and biologics. Isotonic solutions play a crucial role in maintaining the stability of these suspensions, ensuring consistent drug delivery and efficacy. The global pharmaceutical suspension market is expected to grow steadily, with a particular focus on innovative formulations that enhance bioavailability and patient compliance.

The food and beverage industry has also witnessed a surge in demand for stable suspensions, particularly in functional foods, nutritional supplements, and fortified beverages. Isotonic solutions are increasingly being utilized to prevent ingredient separation and maintain product consistency, thereby extending shelf life and improving consumer appeal. This segment of the market is projected to experience robust growth, driven by consumer preferences for natural, clean-label products with extended stability.

In the cosmetics and personal care sector, suspension stability is critical for products such as lotions, creams, and sunscreens. The use of isotonic solutions in these formulations helps prevent the agglomeration of active ingredients, ensuring uniform distribution and efficacy. As consumers demand more sophisticated and multifunctional cosmetic products, the market for advanced suspension stability solutions is expected to expand significantly.

The advanced materials industry, encompassing areas such as nanotechnology and specialty coatings, represents another key growth area for suspension stability solutions. Isotonic formulations are increasingly being employed to control the agglomeration of nanoparticles and other advanced materials in suspension, enabling the development of novel products with enhanced properties.

Geographically, North America and Europe currently dominate the market for suspension stability solutions, owing to their well-established pharmaceutical and cosmetics industries. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, rising disposable incomes, and growing awareness of advanced formulation technologies.

Key market drivers include the ongoing research and development efforts to improve suspension stability techniques, the increasing adoption of nanotechnology across various industries, and the growing demand for personalized medicine and targeted drug delivery systems. Additionally, stringent regulatory requirements for product stability and safety are pushing manufacturers to invest in advanced suspension stability solutions.

Current Challenges in Suspension Agglomeration Control

Controlling agglomeration in suspensions remains a significant challenge in various industries, including pharmaceuticals, food processing, and materials science. Despite advancements in suspension technology, several obstacles persist in maintaining stable and well-dispersed particle systems.

One of the primary challenges is the inherent tendency of particles to aggregate due to attractive forces such as van der Waals interactions. These forces become increasingly dominant as particle size decreases, making it particularly problematic for nano- and micro-scale suspensions. Overcoming these attractive forces requires precise control of the suspension environment, which can be difficult to achieve and maintain in large-scale industrial processes.

The dynamic nature of suspension systems poses another significant hurdle. Environmental factors such as temperature fluctuations, pH changes, and mechanical stresses during processing can alter the delicate balance of forces within the suspension, leading to unexpected agglomeration. This sensitivity to external conditions makes it challenging to develop robust, universally applicable solutions for agglomeration control.

Formulation complexity is a further complicating factor. Many industrial suspensions contain multiple components, including active ingredients, excipients, and stabilizers. The interactions between these components can be intricate and sometimes unpredictable, making it difficult to design effective isotonic solutions that address agglomeration without compromising other critical properties of the suspension.

The long-term stability of suspensions is another area of concern. Even when initial dispersion is achieved, maintaining this state over extended periods remains challenging. Phenomena such as Ostwald ripening and gravitational settling can lead to gradual agglomeration over time, affecting the shelf life and efficacy of suspension-based products.

Moreover, the scalability of agglomeration control methods presents a significant challenge. Techniques that work effectively at laboratory scale may not translate directly to industrial production volumes. Factors such as mixing efficiency, heat transfer, and particle-wall interactions can differ substantially between small and large-scale systems, necessitating careful optimization and often compromises in formulation.

The regulatory landscape adds another layer of complexity, particularly in industries like pharmaceuticals and food production. The use of novel stabilizers or processing techniques to control agglomeration must navigate stringent safety and quality requirements, potentially limiting the range of available solutions.

Lastly, the development of predictive models for suspension behavior remains an ongoing challenge. While computational methods have advanced, accurately simulating the complex interplay of forces in real-world suspensions is still difficult. This gap in predictive capabilities hampers the efficient development and optimization of isotonic solutions for agglomeration control.

One of the primary challenges is the inherent tendency of particles to aggregate due to attractive forces such as van der Waals interactions. These forces become increasingly dominant as particle size decreases, making it particularly problematic for nano- and micro-scale suspensions. Overcoming these attractive forces requires precise control of the suspension environment, which can be difficult to achieve and maintain in large-scale industrial processes.

The dynamic nature of suspension systems poses another significant hurdle. Environmental factors such as temperature fluctuations, pH changes, and mechanical stresses during processing can alter the delicate balance of forces within the suspension, leading to unexpected agglomeration. This sensitivity to external conditions makes it challenging to develop robust, universally applicable solutions for agglomeration control.

Formulation complexity is a further complicating factor. Many industrial suspensions contain multiple components, including active ingredients, excipients, and stabilizers. The interactions between these components can be intricate and sometimes unpredictable, making it difficult to design effective isotonic solutions that address agglomeration without compromising other critical properties of the suspension.

The long-term stability of suspensions is another area of concern. Even when initial dispersion is achieved, maintaining this state over extended periods remains challenging. Phenomena such as Ostwald ripening and gravitational settling can lead to gradual agglomeration over time, affecting the shelf life and efficacy of suspension-based products.

Moreover, the scalability of agglomeration control methods presents a significant challenge. Techniques that work effectively at laboratory scale may not translate directly to industrial production volumes. Factors such as mixing efficiency, heat transfer, and particle-wall interactions can differ substantially between small and large-scale systems, necessitating careful optimization and often compromises in formulation.

The regulatory landscape adds another layer of complexity, particularly in industries like pharmaceuticals and food production. The use of novel stabilizers or processing techniques to control agglomeration must navigate stringent safety and quality requirements, potentially limiting the range of available solutions.

Lastly, the development of predictive models for suspension behavior remains an ongoing challenge. While computational methods have advanced, accurately simulating the complex interplay of forces in real-world suspensions is still difficult. This gap in predictive capabilities hampers the efficient development and optimization of isotonic solutions for agglomeration control.

Existing Isotonic Solutions for Agglomeration Prevention

01 Agglomeration techniques for isotonic solutions

Various agglomeration techniques are employed to improve the properties of isotonic solutions. These methods can enhance solubility, stability, and uniformity of the solution components. Agglomeration processes may involve spray drying, fluid bed granulation, or other specialized techniques to create particles with desired characteristics for isotonic formulations.- Agglomeration techniques for isotonic solutions: Various agglomeration techniques are employed to improve the properties of isotonic solutions. These methods can enhance solubility, stability, and uniformity of the solution components. Agglomeration processes may involve spray drying, fluid bed granulation, or other specialized techniques to create particles with desired characteristics for isotonic formulations.

- Composition of isotonic solutions with agglomerated components: Isotonic solutions can be formulated using agglomerated components to achieve specific properties. These compositions may include electrolytes, sugars, or other osmotically active substances. The agglomeration process allows for better control of particle size and dissolution rates, which can be crucial for maintaining the isotonicity of the solution.

- Manufacturing processes for agglomerated isotonic products: Specialized manufacturing processes are developed for producing agglomerated isotonic products. These processes may involve controlled agglomeration steps, precise mixing techniques, and specific equipment designed to ensure the uniformity and stability of the final isotonic solution. The manufacturing methods aim to maintain the isotonic properties while improving the product's overall quality.

- Stabilization of isotonic solutions through agglomeration: Agglomeration techniques can be used to stabilize isotonic solutions, particularly for long-term storage or challenging environmental conditions. By creating agglomerated particles, the stability of sensitive components in the isotonic solution can be enhanced, potentially extending shelf life and maintaining efficacy over time.

- Applications of agglomerated isotonic solutions: Agglomerated isotonic solutions find applications in various fields, including pharmaceuticals, medical devices, and biotechnology. These solutions can be used for intravenous administration, cell culture media, or as part of diagnostic kits. The agglomeration process allows for tailored properties that meet specific requirements in different applications, such as improved dissolution rates or controlled release of active ingredients.

02 Composition of isotonic solutions with agglomerated ingredients

Isotonic solutions can be formulated using agglomerated ingredients to achieve specific properties. These compositions may include electrolytes, sugars, amino acids, or other osmotically active substances. The agglomeration process helps in creating uniform particles that dissolve readily and maintain the isotonicity of the solution.Expand Specific Solutions03 Manufacturing processes for agglomerated isotonic products

Specialized manufacturing processes are developed for producing agglomerated isotonic products. These processes may involve controlled agglomeration steps, precise mixing techniques, and specific equipment designed to create consistent and stable isotonic formulations. The manufacturing methods aim to ensure product quality and reproducibility.Expand Specific Solutions04 Stabilization of isotonic solutions through agglomeration

Agglomeration techniques can be used to stabilize isotonic solutions, particularly those containing sensitive or reactive components. By creating agglomerated particles, the stability of individual ingredients can be improved, leading to enhanced shelf life and maintained isotonicity over time. This approach is particularly useful for pharmaceutical and medical applications.Expand Specific Solutions05 Applications of agglomerated isotonic solutions

Agglomerated isotonic solutions find applications in various fields, including pharmaceuticals, medical devices, and biotechnology. These solutions can be used for intravenous administration, cell culture media, wound irrigation, or as base components for other formulations. The agglomeration process allows for tailored properties suited to specific applications.Expand Specific Solutions

Key Players in Suspension Formulation Industry

The market for isotonic solutions in controlling agglomeration in suspensions is in a growth phase, driven by increasing demand in pharmaceutical and industrial applications. The global market size is estimated to be in the billions, with steady annual growth. Technologically, the field is moderately mature, with ongoing innovations. Key players like Novartis AG, Novo Nordisk A/S, and Bayer AG are investing in R&D to enhance solution efficacy and stability. Smaller companies such as Rhodia Chimie and EMD Millipore Corp. are also contributing to advancements. The competitive landscape is characterized by a mix of large pharmaceutical companies and specialized chemical firms, with opportunities for differentiation through formulation improvements and application-specific solutions.

Rhodia Chimie

Technical Solution: Rhodia Chimie has developed advanced isotonic solutions for controlling agglomeration in suspensions. Their approach involves using carefully selected electrolytes to create an isotonic environment that matches the osmotic pressure of the suspended particles. This balance helps prevent water movement between the particles and the surrounding medium, reducing the tendency for particles to aggregate. The company has also incorporated polymeric stabilizers that work synergistically with the isotonic solution to provide steric hindrance, further enhancing suspension stability[1][3]. Their formulations have shown particular success in pharmaceutical and cosmetic applications, where long-term stability of suspensions is crucial[5].

Strengths: Highly effective in preventing agglomeration, especially in sensitive formulations. Weaknesses: May require careful adjustment for each specific suspension system.

BASF Corp.

Technical Solution: BASF Corp. has pioneered a multi-faceted approach to using isotonic solutions for controlling agglomeration in suspensions. Their technology combines tailored electrolyte mixtures with advanced surfactants to create a stable isotonic environment. This approach not only matches the osmotic pressure of suspended particles but also modifies the interfacial properties to reduce particle-particle interactions. BASF has developed a range of customizable isotonic solutions that can be fine-tuned for various industrial applications, from paints and coatings to agricultural formulations[2][4]. Their solutions have demonstrated exceptional performance in maintaining suspension stability under a wide range of temperature and pH conditions[6].

Strengths: Versatile solutions applicable across multiple industries. Weaknesses: May require specialized expertise for optimal formulation in complex systems.

Core Innovations in Isotonic Suspension Stabilization

Suspension obtained from a multiple emulsion comprising a hydrophobic compound solid at room temperature and granules obtained by drying said suspension

PatentWO2002083288A1

Innovation

- A suspension is created through a multiple emulsion process involving an inverse water-in-oil emulsion with a hydrophobic compound solid at ambient temperature, using nonionic or cationic surfactants and polymers, which is then dispersed in an external aqueous phase, allowing for controlled release of active ingredients by adjusting temperature, and granules are formed by drying this suspension, eliminating the need for osmotic pressure balancing.

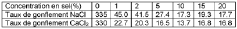

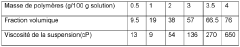

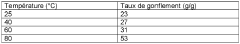

Suspension of associative polymers for treating underground formations

PatentWO2020178294A1

Innovation

- A suspension of associative polymers with a low viscosity that increases with temperature, comprising an aqueous phase and partially hydrated particles, allowing for easy preparation and injection, and subsequent gelation at the treatment site to inhibit fluid loss.

Regulatory Considerations for Isotonic Solutions

The regulatory landscape for isotonic solutions used in controlling agglomeration in suspensions is complex and multifaceted. Regulatory bodies, such as the FDA in the United States and the EMA in Europe, have established guidelines and requirements for the development, manufacturing, and use of isotonic solutions in pharmaceutical and medical applications. These regulations aim to ensure the safety, efficacy, and quality of products containing isotonic solutions.

One of the primary regulatory considerations is the classification of isotonic solutions. Depending on their intended use and formulation, they may be categorized as excipients, drug products, or medical devices. This classification determines the specific regulatory pathway and requirements that manufacturers must follow. For instance, isotonic solutions used as excipients in injectable suspensions may be subject to different regulations compared to those used as standalone products for ophthalmic applications.

Manufacturers must adhere to Good Manufacturing Practices (GMP) when producing isotonic solutions. This includes maintaining proper documentation, implementing quality control measures, and ensuring the consistency and purity of the final product. Regulatory agencies often conduct inspections to verify compliance with GMP standards and may require manufacturers to obtain certifications or licenses.

The composition and concentration of isotonic solutions are critical regulatory considerations. Regulatory bodies typically require detailed information on the formulation, including the type and quantity of solutes used to achieve isotonicity. The use of approved ingredients and adherence to established pharmacopeial standards are essential for regulatory compliance. Additionally, manufacturers must demonstrate the stability of the isotonic solution over time and under various storage conditions.

Safety and biocompatibility testing are crucial aspects of the regulatory process for isotonic solutions. Depending on the intended use, manufacturers may need to conduct toxicology studies, irritation tests, and compatibility assessments with other components of the suspension. The results of these studies must be submitted to regulatory authorities as part of the product approval process.

Labeling and packaging requirements for isotonic solutions are also subject to regulatory oversight. Manufacturers must provide accurate and comprehensive information on the product label, including composition, storage conditions, and expiration dates. In some cases, specific warnings or precautions may be required, particularly for solutions intended for parenteral or ophthalmic use.

Regulatory agencies often require post-market surveillance and reporting for products containing isotonic solutions. This includes monitoring adverse events, conducting periodic safety reviews, and implementing risk management strategies. Manufacturers may be required to submit regular reports on product performance and safety to regulatory authorities.

As the field of nanotechnology advances, regulatory considerations for isotonic solutions used in nanoparticle suspensions are evolving. Regulatory bodies are developing new guidelines to address the unique challenges posed by nanomaterials, including their potential impact on agglomeration and suspension stability. Manufacturers working with nanoparticle suspensions must stay informed about these emerging regulations and adapt their development and manufacturing processes accordingly.

One of the primary regulatory considerations is the classification of isotonic solutions. Depending on their intended use and formulation, they may be categorized as excipients, drug products, or medical devices. This classification determines the specific regulatory pathway and requirements that manufacturers must follow. For instance, isotonic solutions used as excipients in injectable suspensions may be subject to different regulations compared to those used as standalone products for ophthalmic applications.

Manufacturers must adhere to Good Manufacturing Practices (GMP) when producing isotonic solutions. This includes maintaining proper documentation, implementing quality control measures, and ensuring the consistency and purity of the final product. Regulatory agencies often conduct inspections to verify compliance with GMP standards and may require manufacturers to obtain certifications or licenses.

The composition and concentration of isotonic solutions are critical regulatory considerations. Regulatory bodies typically require detailed information on the formulation, including the type and quantity of solutes used to achieve isotonicity. The use of approved ingredients and adherence to established pharmacopeial standards are essential for regulatory compliance. Additionally, manufacturers must demonstrate the stability of the isotonic solution over time and under various storage conditions.

Safety and biocompatibility testing are crucial aspects of the regulatory process for isotonic solutions. Depending on the intended use, manufacturers may need to conduct toxicology studies, irritation tests, and compatibility assessments with other components of the suspension. The results of these studies must be submitted to regulatory authorities as part of the product approval process.

Labeling and packaging requirements for isotonic solutions are also subject to regulatory oversight. Manufacturers must provide accurate and comprehensive information on the product label, including composition, storage conditions, and expiration dates. In some cases, specific warnings or precautions may be required, particularly for solutions intended for parenteral or ophthalmic use.

Regulatory agencies often require post-market surveillance and reporting for products containing isotonic solutions. This includes monitoring adverse events, conducting periodic safety reviews, and implementing risk management strategies. Manufacturers may be required to submit regular reports on product performance and safety to regulatory authorities.

As the field of nanotechnology advances, regulatory considerations for isotonic solutions used in nanoparticle suspensions are evolving. Regulatory bodies are developing new guidelines to address the unique challenges posed by nanomaterials, including their potential impact on agglomeration and suspension stability. Manufacturers working with nanoparticle suspensions must stay informed about these emerging regulations and adapt their development and manufacturing processes accordingly.

Environmental Impact of Isotonic Suspension Technologies

The environmental impact of isotonic suspension technologies is a critical consideration in the development and application of these solutions. Isotonic suspensions, which are designed to maintain osmotic balance, have become increasingly prevalent in various industries, including pharmaceuticals, food processing, and cosmetics. As their usage expands, it is essential to evaluate their potential effects on the environment.

One of the primary environmental concerns associated with isotonic suspension technologies is the release of suspended particles into aquatic ecosystems. When these suspensions are discharged into water bodies, they can contribute to increased turbidity and sedimentation. This can have detrimental effects on aquatic flora and fauna, potentially disrupting food chains and altering habitat conditions for various species.

Furthermore, the chemicals used to create isotonic conditions in suspensions may pose risks to the environment if not properly managed. Some of these compounds, such as salts and buffers, can accumulate in soil and water systems, potentially leading to changes in pH levels or mineral concentrations. This alteration of environmental chemistry may have far-reaching consequences for local ecosystems and biodiversity.

The production and disposal of isotonic suspension materials also contribute to the overall environmental footprint of these technologies. Manufacturing processes often require significant energy inputs and may generate waste products that need careful management. Additionally, the packaging and transportation of isotonic suspensions can lead to increased carbon emissions and plastic waste, further exacerbating environmental concerns.

However, it is important to note that advancements in isotonic suspension technologies have also led to more environmentally friendly formulations. Many companies are now focusing on developing biodegradable or naturally derived components for their suspensions, which can significantly reduce their environmental impact. These eco-friendly alternatives aim to maintain the desired isotonic properties while minimizing harm to ecosystems.

The recycling and proper disposal of isotonic suspension materials present both challenges and opportunities for environmental stewardship. Implementing effective waste management strategies, such as closed-loop systems and advanced filtration techniques, can help mitigate the release of potentially harmful substances into the environment. Moreover, the development of more efficient production methods and the use of renewable energy sources in manufacturing processes can further reduce the environmental footprint of these technologies.

As regulatory bodies become increasingly aware of the potential environmental impacts of isotonic suspension technologies, stricter guidelines and standards are being implemented. These regulations aim to ensure that the development and use of these solutions align with sustainable practices and environmental protection goals. Compliance with these standards not only helps safeguard ecosystems but also drives innovation towards more environmentally responsible formulations and processes.

One of the primary environmental concerns associated with isotonic suspension technologies is the release of suspended particles into aquatic ecosystems. When these suspensions are discharged into water bodies, they can contribute to increased turbidity and sedimentation. This can have detrimental effects on aquatic flora and fauna, potentially disrupting food chains and altering habitat conditions for various species.

Furthermore, the chemicals used to create isotonic conditions in suspensions may pose risks to the environment if not properly managed. Some of these compounds, such as salts and buffers, can accumulate in soil and water systems, potentially leading to changes in pH levels or mineral concentrations. This alteration of environmental chemistry may have far-reaching consequences for local ecosystems and biodiversity.

The production and disposal of isotonic suspension materials also contribute to the overall environmental footprint of these technologies. Manufacturing processes often require significant energy inputs and may generate waste products that need careful management. Additionally, the packaging and transportation of isotonic suspensions can lead to increased carbon emissions and plastic waste, further exacerbating environmental concerns.

However, it is important to note that advancements in isotonic suspension technologies have also led to more environmentally friendly formulations. Many companies are now focusing on developing biodegradable or naturally derived components for their suspensions, which can significantly reduce their environmental impact. These eco-friendly alternatives aim to maintain the desired isotonic properties while minimizing harm to ecosystems.

The recycling and proper disposal of isotonic suspension materials present both challenges and opportunities for environmental stewardship. Implementing effective waste management strategies, such as closed-loop systems and advanced filtration techniques, can help mitigate the release of potentially harmful substances into the environment. Moreover, the development of more efficient production methods and the use of renewable energy sources in manufacturing processes can further reduce the environmental footprint of these technologies.

As regulatory bodies become increasingly aware of the potential environmental impacts of isotonic suspension technologies, stricter guidelines and standards are being implemented. These regulations aim to ensure that the development and use of these solutions align with sustainable practices and environmental protection goals. Compliance with these standards not only helps safeguard ecosystems but also drives innovation towards more environmentally responsible formulations and processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!