Exploring isotonic solutions in protein crystallization processes

AUG 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isotonic Solutions in Protein Crystallization: Background and Objectives

Protein crystallization is a critical process in structural biology, enabling researchers to determine the three-dimensional structures of proteins. This process has been instrumental in advancing our understanding of protein function, drug design, and various biological mechanisms. The use of isotonic solutions in protein crystallization has emerged as a significant area of study, aiming to optimize the crystallization process and improve the quality of protein crystals.

Isotonic solutions, which have the same osmotic pressure as the cellular environment, play a crucial role in maintaining protein stability during the crystallization process. These solutions help prevent osmotic shock to proteins, preserving their native conformation and enhancing the likelihood of successful crystal formation. The exploration of isotonic solutions in protein crystallization processes represents a convergence of biochemistry, biophysics, and materials science, with the potential to revolutionize structural biology research.

The evolution of protein crystallization techniques has been marked by continuous improvements in methodology and understanding of the underlying principles. From early methods involving simple vapor diffusion to more sophisticated approaches utilizing robotics and high-throughput screening, the field has seen significant advancements. The incorporation of isotonic solutions into these processes represents the latest frontier in this ongoing evolution, promising to address longstanding challenges in protein crystallization.

One of the primary objectives in exploring isotonic solutions for protein crystallization is to enhance the reproducibility and success rate of crystal formation. By mimicking the natural cellular environment, these solutions aim to provide optimal conditions for proteins to arrange themselves into ordered crystalline structures. This approach has the potential to overcome issues such as protein denaturation, aggregation, and the formation of amorphous precipitates, which have historically hindered crystallization efforts.

Another key goal is to improve the quality and resolution of the resulting protein crystals. High-quality crystals are essential for obtaining accurate structural information through X-ray crystallography or other diffraction methods. Isotonic solutions may contribute to the growth of larger, more uniform crystals with fewer defects, ultimately leading to higher-resolution structural data and more reliable insights into protein function and interactions.

Furthermore, the exploration of isotonic solutions in protein crystallization processes aims to expand the range of proteins that can be successfully crystallized. Many proteins, particularly membrane proteins and large protein complexes, have proven challenging to crystallize using traditional methods. By providing a more physiologically relevant environment, isotonic solutions may facilitate the crystallization of these recalcitrant proteins, opening new avenues for structural studies and drug discovery efforts.

Isotonic solutions, which have the same osmotic pressure as the cellular environment, play a crucial role in maintaining protein stability during the crystallization process. These solutions help prevent osmotic shock to proteins, preserving their native conformation and enhancing the likelihood of successful crystal formation. The exploration of isotonic solutions in protein crystallization processes represents a convergence of biochemistry, biophysics, and materials science, with the potential to revolutionize structural biology research.

The evolution of protein crystallization techniques has been marked by continuous improvements in methodology and understanding of the underlying principles. From early methods involving simple vapor diffusion to more sophisticated approaches utilizing robotics and high-throughput screening, the field has seen significant advancements. The incorporation of isotonic solutions into these processes represents the latest frontier in this ongoing evolution, promising to address longstanding challenges in protein crystallization.

One of the primary objectives in exploring isotonic solutions for protein crystallization is to enhance the reproducibility and success rate of crystal formation. By mimicking the natural cellular environment, these solutions aim to provide optimal conditions for proteins to arrange themselves into ordered crystalline structures. This approach has the potential to overcome issues such as protein denaturation, aggregation, and the formation of amorphous precipitates, which have historically hindered crystallization efforts.

Another key goal is to improve the quality and resolution of the resulting protein crystals. High-quality crystals are essential for obtaining accurate structural information through X-ray crystallography or other diffraction methods. Isotonic solutions may contribute to the growth of larger, more uniform crystals with fewer defects, ultimately leading to higher-resolution structural data and more reliable insights into protein function and interactions.

Furthermore, the exploration of isotonic solutions in protein crystallization processes aims to expand the range of proteins that can be successfully crystallized. Many proteins, particularly membrane proteins and large protein complexes, have proven challenging to crystallize using traditional methods. By providing a more physiologically relevant environment, isotonic solutions may facilitate the crystallization of these recalcitrant proteins, opening new avenues for structural studies and drug discovery efforts.

Market Analysis for Protein Crystallization Technologies

The protein crystallization market has been experiencing steady growth, driven by the increasing demand for structural biology research and drug discovery applications. The global market for protein crystallization technologies is projected to reach significant value in the coming years, with a compound annual growth rate (CAGR) that reflects the expanding applications in pharmaceutical and biotechnology industries.

Key factors contributing to market growth include the rising prevalence of chronic diseases, which has intensified the need for novel drug development. This has led to increased investment in protein structure determination, a critical step in rational drug design. Additionally, advancements in crystallization techniques and automation have made the process more efficient and accessible to a broader range of researchers.

The market for protein crystallization technologies can be segmented based on products, end-users, and geography. Products include reagents, instruments, and consumables, with reagents holding a substantial market share due to their recurring nature in crystallization experiments. End-users primarily comprise pharmaceutical companies, biotechnology firms, and academic research institutions.

Geographically, North America dominates the market, followed by Europe and Asia-Pacific. The United States, in particular, leads in terms of market share, attributed to its robust pharmaceutical industry and significant research funding. However, emerging markets in Asia-Pacific, especially China and India, are expected to show rapid growth due to increasing investment in life sciences research and development.

Within the protein crystallization market, there is a growing focus on isotonic solutions for optimizing crystallization conditions. This niche segment is gaining traction as researchers seek to improve the success rate and quality of protein crystals. Isotonic solutions help maintain the osmotic balance of proteins during the crystallization process, potentially leading to more stable and well-diffracting crystals.

The demand for isotonic solutions in protein crystallization is driven by the need for higher-resolution protein structures, which are crucial for understanding protein function and designing targeted therapeutics. This specialized market segment is expected to grow as more researchers recognize the benefits of using isotonic conditions in their crystallization experiments.

Key players in the protein crystallization market are continuously innovating to meet the evolving needs of researchers. Companies are developing advanced crystallization screening kits, automated crystallization systems, and specialized reagents, including isotonic solutions. The competitive landscape includes both established life science companies and specialized crystallography firms, with ongoing research collaborations between industry and academia further driving innovation in the field.

Key factors contributing to market growth include the rising prevalence of chronic diseases, which has intensified the need for novel drug development. This has led to increased investment in protein structure determination, a critical step in rational drug design. Additionally, advancements in crystallization techniques and automation have made the process more efficient and accessible to a broader range of researchers.

The market for protein crystallization technologies can be segmented based on products, end-users, and geography. Products include reagents, instruments, and consumables, with reagents holding a substantial market share due to their recurring nature in crystallization experiments. End-users primarily comprise pharmaceutical companies, biotechnology firms, and academic research institutions.

Geographically, North America dominates the market, followed by Europe and Asia-Pacific. The United States, in particular, leads in terms of market share, attributed to its robust pharmaceutical industry and significant research funding. However, emerging markets in Asia-Pacific, especially China and India, are expected to show rapid growth due to increasing investment in life sciences research and development.

Within the protein crystallization market, there is a growing focus on isotonic solutions for optimizing crystallization conditions. This niche segment is gaining traction as researchers seek to improve the success rate and quality of protein crystals. Isotonic solutions help maintain the osmotic balance of proteins during the crystallization process, potentially leading to more stable and well-diffracting crystals.

The demand for isotonic solutions in protein crystallization is driven by the need for higher-resolution protein structures, which are crucial for understanding protein function and designing targeted therapeutics. This specialized market segment is expected to grow as more researchers recognize the benefits of using isotonic conditions in their crystallization experiments.

Key players in the protein crystallization market are continuously innovating to meet the evolving needs of researchers. Companies are developing advanced crystallization screening kits, automated crystallization systems, and specialized reagents, including isotonic solutions. The competitive landscape includes both established life science companies and specialized crystallography firms, with ongoing research collaborations between industry and academia further driving innovation in the field.

Current Challenges in Isotonic Solution Application

The application of isotonic solutions in protein crystallization processes faces several significant challenges that hinder optimal outcomes and limit the efficiency of crystal formation. One of the primary issues is maintaining precise osmotic balance throughout the crystallization process. Isotonic solutions are designed to match the osmotic pressure of the protein solution, but achieving and sustaining this balance is complex due to the dynamic nature of crystallization environments.

Variability in protein samples presents another major challenge. Different proteins exhibit diverse behaviors in isotonic conditions, making it difficult to establish standardized protocols. This variability necessitates extensive trial-and-error approaches, consuming valuable time and resources in the crystallization process. Furthermore, the interaction between isotonic solutions and various crystallization additives is not fully understood, potentially leading to unexpected outcomes or interference with crystal formation.

Temperature fluctuations pose a significant obstacle in maintaining isotonicity. Even minor temperature changes can alter the osmotic properties of the solution, disrupting the delicate balance required for optimal crystal growth. This sensitivity to temperature makes it challenging to scale up crystallization processes or transfer protocols between different laboratory environments.

The long-term stability of isotonic solutions during extended crystallization periods is another area of concern. Over time, these solutions may undergo chemical changes or degradation, potentially altering their isotonic properties and affecting crystal quality. This instability can lead to inconsistent results and reduced reproducibility in crystallization experiments.

Achieving uniform diffusion of isotonic solutions in crystallization setups, particularly in larger-scale operations, remains problematic. Uneven distribution can result in localized areas of non-isotonicity, leading to irregular crystal growth or formation of unwanted crystal polymorphs. This challenge is especially pronounced in high-throughput crystallization methods where maintaining consistent conditions across multiple samples is crucial.

The cost and availability of high-quality, contamination-free isotonic solutions suitable for protein crystallization are additional hurdles. Many commercially available solutions may not meet the stringent purity requirements for sensitive crystallization experiments, necessitating time-consuming in-house preparation or expensive specialized products.

Lastly, the integration of isotonic solutions with advanced crystallization techniques, such as microfluidics or in situ X-ray analysis, presents unique challenges. These innovative approaches often require specialized adaptations of isotonic solutions to be compatible with the constraints of the experimental setup, adding another layer of complexity to the crystallization process.

Variability in protein samples presents another major challenge. Different proteins exhibit diverse behaviors in isotonic conditions, making it difficult to establish standardized protocols. This variability necessitates extensive trial-and-error approaches, consuming valuable time and resources in the crystallization process. Furthermore, the interaction between isotonic solutions and various crystallization additives is not fully understood, potentially leading to unexpected outcomes or interference with crystal formation.

Temperature fluctuations pose a significant obstacle in maintaining isotonicity. Even minor temperature changes can alter the osmotic properties of the solution, disrupting the delicate balance required for optimal crystal growth. This sensitivity to temperature makes it challenging to scale up crystallization processes or transfer protocols between different laboratory environments.

The long-term stability of isotonic solutions during extended crystallization periods is another area of concern. Over time, these solutions may undergo chemical changes or degradation, potentially altering their isotonic properties and affecting crystal quality. This instability can lead to inconsistent results and reduced reproducibility in crystallization experiments.

Achieving uniform diffusion of isotonic solutions in crystallization setups, particularly in larger-scale operations, remains problematic. Uneven distribution can result in localized areas of non-isotonicity, leading to irregular crystal growth or formation of unwanted crystal polymorphs. This challenge is especially pronounced in high-throughput crystallization methods where maintaining consistent conditions across multiple samples is crucial.

The cost and availability of high-quality, contamination-free isotonic solutions suitable for protein crystallization are additional hurdles. Many commercially available solutions may not meet the stringent purity requirements for sensitive crystallization experiments, necessitating time-consuming in-house preparation or expensive specialized products.

Lastly, the integration of isotonic solutions with advanced crystallization techniques, such as microfluidics or in situ X-ray analysis, presents unique challenges. These innovative approaches often require specialized adaptations of isotonic solutions to be compatible with the constraints of the experimental setup, adding another layer of complexity to the crystallization process.

Existing Isotonic Solution Methodologies

01 Composition of isotonic solutions

Isotonic solutions are formulated to have the same osmotic pressure as body fluids, typically containing a balance of electrolytes and other solutes. These solutions are crucial in medical applications, including intravenous therapy and cell culture media, as they maintain cellular integrity and prevent osmotic shock.- Composition of isotonic solutions: Isotonic solutions are formulated to have the same osmotic pressure as body fluids, typically containing a balance of electrolytes and other solutes. These solutions are crucial in medical applications, including intravenous therapy and cell culture media, as they maintain cellular integrity and prevent osmotic shock.

- Medical applications of isotonic solutions: Isotonic solutions are widely used in various medical procedures and treatments. They serve as intravenous fluids for hydration, electrolyte replacement, and as carriers for drug delivery. These solutions are also employed in wound irrigation, dialysis, and as a base for ophthalmic preparations.

- Isotonic solutions in cell culture and biotechnology: In biotechnology and cell culture applications, isotonic solutions play a crucial role in maintaining cell viability and function. They provide a suitable environment for cell growth, preservation, and experimentation by mimicking physiological conditions and preventing osmotic stress on cells.

- Isotonic sports drinks and beverages: Isotonic beverages are designed to quickly replace fluids and electrolytes lost during intense physical activity. These drinks typically contain a specific concentration of carbohydrates and electrolytes to match the body's osmolality, facilitating rapid absorption and hydration for athletes and active individuals.

- Measurement and control of isotonicity: Accurate measurement and control of isotonicity are essential in the production and quality assurance of isotonic solutions. Various methods and devices are employed to ensure the correct osmolality and electrolyte balance, including osmometers, conductivity meters, and advanced analytical techniques.

02 Medical applications of isotonic solutions

Isotonic solutions are widely used in various medical procedures, such as wound irrigation, eye care, and intravenous fluid replacement. They help maintain proper hydration, electrolyte balance, and cellular function in patients, particularly during surgeries or in cases of dehydration.Expand Specific Solutions03 Isotonic solutions in biotechnology

In biotechnology, isotonic solutions play a crucial role in cell culture, tissue preservation, and genetic engineering processes. These solutions provide an optimal environment for maintaining cell viability and function during experiments and production of biological products.Expand Specific Solutions04 Isotonic solution delivery systems

Advanced delivery systems for isotonic solutions have been developed to improve administration accuracy and patient comfort. These systems may include smart pumps, controlled release mechanisms, and specialized containers designed to maintain solution integrity and sterility.Expand Specific Solutions05 Quality control and monitoring of isotonic solutions

Ensuring the quality and stability of isotonic solutions is critical for their effectiveness and safety. Advanced monitoring systems and analytical techniques have been developed to maintain proper osmolality, pH, and sterility of these solutions throughout their production, storage, and use.Expand Specific Solutions

Key Players in Protein Crystallization Industry

The field of isotonic solutions in protein crystallization processes is in a mature stage of development, with a significant market size driven by pharmaceutical and biotechnology industries. The technology has reached a high level of sophistication, as evidenced by the involvement of major players like Genentech, Novartis, and Thermo Fisher Scientific. Academic institutions such as Johns Hopkins University and the University of Surrey are contributing to ongoing research and innovation. The competitive landscape is characterized by a mix of established pharmaceutical companies, specialized biotechnology firms, and research institutions, indicating a robust ecosystem for further advancements in this critical area of structural biology and drug discovery.

Genentech, Inc.

Technical Solution: Genentech has developed a high-throughput screening approach for isotonic solutions in protein crystallization. Their method utilizes a combination of dynamic light scattering and differential scanning fluorimetry to rapidly assess protein stability in various isotonic conditions[1]. They have also implemented machine learning algorithms to predict optimal crystallization conditions based on protein sequence and structural features[2]. Additionally, Genentech has pioneered the use of microfluidic devices for miniaturized crystallization trials, allowing for the exploration of a wider range of isotonic solutions with minimal protein consumption[3].

Strengths: Advanced high-throughput screening capabilities, integration of machine learning for prediction, and innovative microfluidic technologies. Weaknesses: Potential high costs associated with specialized equipment and the need for extensive computational resources.

Novartis AG

Technical Solution: Novartis has developed a novel approach to exploring isotonic solutions in protein crystallization processes, focusing on the use of osmolytes and crowding agents. Their method involves systematically screening a diverse array of naturally occurring osmolytes, such as glycine betaine and trehalose, in combination with synthetic polymers to create isotonic environments that promote protein stability and crystal growth[4]. Novartis has also implemented a unique vapor diffusion technique that allows for precise control of osmolality during the crystallization process, enabling the formation of high-quality crystals for structure determination[5]. Furthermore, they have developed a proprietary software platform that integrates crystallization data with molecular dynamics simulations to optimize isotonic conditions for specific protein targets[6].

Strengths: Innovative use of osmolytes and crowding agents, advanced vapor diffusion techniques, and integration of computational modeling. Weaknesses: Potential limitations in scaling up the process for industrial applications and the complexity of the software platform may require specialized expertise.

Innovative Approaches in Isotonic Solution Design

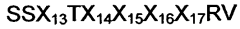

Anti-PD-l1 antibodies and uses thereof

PatentWO2013079174A1

Innovation

- Development of anti-PD-L1 antibodies with antibody-dependent cell-mediated cytotoxicity (ADCC) activity that specifically target PD-L1 on tumor cells, blocking interactions with PD-1 and other ligands, thereby enhancing T-cell function and immune responses without significant toxicity.

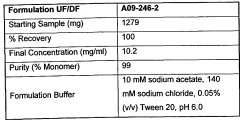

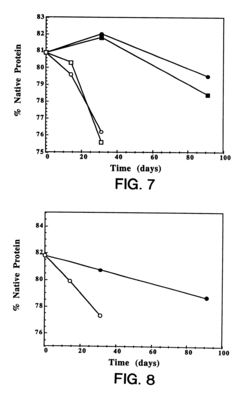

Protein formulation

PatentInactiveUS6685940B2

Innovation

- A stable lyophilized protein formulation is developed using a lyoprotectant like sucrose or trehalose, which, when reconstituted with a diluent, achieves a significantly higher protein concentration (2-40 times greater than initial) and maintains stability at 2-8°C for at least 30 days, suitable for subcutaneous administration, and can be used as a multi-use formulation.

Regulatory Considerations for Protein Crystal Production

Regulatory considerations play a crucial role in the production of protein crystals, especially when exploring isotonic solutions for crystallization processes. These considerations are essential to ensure the safety, efficacy, and quality of the final product, as well as compliance with relevant laws and regulations.

One of the primary regulatory concerns is the selection and use of appropriate materials for isotonic solutions. Regulatory bodies, such as the FDA and EMA, require that all components used in the crystallization process meet specific purity and quality standards. This includes the water used for preparing solutions, buffer components, and any additives or excipients. Manufacturers must ensure that these materials are sourced from approved suppliers and are free from contaminants that could affect the integrity of the protein crystals.

The manufacturing process itself is subject to strict regulatory oversight. Good Manufacturing Practices (GMP) must be followed throughout the production of protein crystals, including the preparation and use of isotonic solutions. This involves maintaining detailed documentation of all procedures, implementing quality control measures, and ensuring that all equipment is properly calibrated and maintained. Regular audits and inspections may be conducted to verify compliance with these standards.

Validation of the crystallization process is another critical regulatory consideration. Manufacturers must demonstrate that their method for producing protein crystals using isotonic solutions is consistent, reproducible, and yields crystals of the desired quality. This typically involves extensive testing and documentation of process parameters, such as temperature, pH, and concentration of components in the isotonic solution.

Safety considerations are paramount in regulatory compliance. The use of isotonic solutions in protein crystallization must not introduce any harmful substances or create conditions that could compromise the safety of the final product. This is particularly important if the protein crystals are intended for therapeutic applications. Toxicology studies and risk assessments may be required to evaluate the safety profile of the crystallization process and its components.

Regulatory bodies also focus on the characterization and analysis of the protein crystals produced. Manufacturers must develop and validate analytical methods to assess the purity, structure, and functionality of the crystals. This may include techniques such as X-ray crystallography, spectroscopy, and bioassays. The results of these analyses must be thoroughly documented and meet predetermined specifications to ensure consistent product quality.

Environmental considerations are becoming increasingly important in regulatory frameworks. The production of protein crystals using isotonic solutions should adhere to environmental regulations regarding waste disposal, energy consumption, and the use of potentially hazardous materials. Manufacturers may need to implement strategies to minimize environmental impact and demonstrate compliance with relevant environmental standards.

In conclusion, navigating the regulatory landscape for protein crystal production using isotonic solutions requires a comprehensive approach that addresses safety, quality, consistency, and environmental concerns. Manufacturers must stay informed about evolving regulations and work closely with regulatory agencies to ensure compliance throughout the development and production process.

One of the primary regulatory concerns is the selection and use of appropriate materials for isotonic solutions. Regulatory bodies, such as the FDA and EMA, require that all components used in the crystallization process meet specific purity and quality standards. This includes the water used for preparing solutions, buffer components, and any additives or excipients. Manufacturers must ensure that these materials are sourced from approved suppliers and are free from contaminants that could affect the integrity of the protein crystals.

The manufacturing process itself is subject to strict regulatory oversight. Good Manufacturing Practices (GMP) must be followed throughout the production of protein crystals, including the preparation and use of isotonic solutions. This involves maintaining detailed documentation of all procedures, implementing quality control measures, and ensuring that all equipment is properly calibrated and maintained. Regular audits and inspections may be conducted to verify compliance with these standards.

Validation of the crystallization process is another critical regulatory consideration. Manufacturers must demonstrate that their method for producing protein crystals using isotonic solutions is consistent, reproducible, and yields crystals of the desired quality. This typically involves extensive testing and documentation of process parameters, such as temperature, pH, and concentration of components in the isotonic solution.

Safety considerations are paramount in regulatory compliance. The use of isotonic solutions in protein crystallization must not introduce any harmful substances or create conditions that could compromise the safety of the final product. This is particularly important if the protein crystals are intended for therapeutic applications. Toxicology studies and risk assessments may be required to evaluate the safety profile of the crystallization process and its components.

Regulatory bodies also focus on the characterization and analysis of the protein crystals produced. Manufacturers must develop and validate analytical methods to assess the purity, structure, and functionality of the crystals. This may include techniques such as X-ray crystallography, spectroscopy, and bioassays. The results of these analyses must be thoroughly documented and meet predetermined specifications to ensure consistent product quality.

Environmental considerations are becoming increasingly important in regulatory frameworks. The production of protein crystals using isotonic solutions should adhere to environmental regulations regarding waste disposal, energy consumption, and the use of potentially hazardous materials. Manufacturers may need to implement strategies to minimize environmental impact and demonstrate compliance with relevant environmental standards.

In conclusion, navigating the regulatory landscape for protein crystal production using isotonic solutions requires a comprehensive approach that addresses safety, quality, consistency, and environmental concerns. Manufacturers must stay informed about evolving regulations and work closely with regulatory agencies to ensure compliance throughout the development and production process.

Environmental Impact of Crystallization Processes

Protein crystallization processes, while essential for structural biology and drug discovery, can have significant environmental impacts that warrant careful consideration. The use of isotonic solutions in these processes introduces additional environmental factors that need to be addressed.

One of the primary environmental concerns associated with protein crystallization is the generation of chemical waste. The process typically involves the use of various buffers, salts, and precipitants, many of which are not easily biodegradable. When isotonic solutions are employed, the concentration of these chemicals may increase, potentially leading to a higher volume of waste that requires specialized disposal methods.

Water consumption is another critical environmental aspect of crystallization processes. Isotonic solutions often require precise control of solute concentrations, which may necessitate the use of purified water. The production and disposal of large volumes of purified water can strain local water resources and contribute to energy consumption through water treatment processes.

Energy usage is a significant factor in the environmental impact of crystallization processes. Maintaining precise temperature control, which is crucial for successful crystallization, requires continuous energy input. The use of isotonic solutions may necessitate even more stringent temperature regulation, potentially increasing energy demands and associated carbon emissions.

The materials used in crystallization experiments, including plastics for plates and disposable pipettes, contribute to solid waste generation. While efforts are being made to develop more sustainable lab plastics, the current reliance on single-use materials in many crystallization setups remains an environmental concern.

Scaling up protein crystallization processes for industrial applications can amplify these environmental impacts. Larger-scale operations may require more extensive use of chemicals, water, and energy, as well as generate greater volumes of waste. The environmental footprint of such operations can be substantial, particularly if not managed with sustainability in mind.

However, the use of isotonic solutions in protein crystallization can also offer some environmental benefits. By potentially improving the efficiency and success rate of crystallization experiments, isotonic solutions may reduce the need for repeated trials, thereby minimizing overall resource consumption and waste generation.

To mitigate the environmental impact of crystallization processes, researchers and industry professionals are exploring various strategies. These include the development of more environmentally friendly crystallization agents, implementation of recycling systems for buffers and precipitants, and the adoption of more energy-efficient equipment and processes. Additionally, there is a growing emphasis on green chemistry principles in the design of crystallization experiments, aiming to reduce the use of harmful chemicals and minimize waste production.

One of the primary environmental concerns associated with protein crystallization is the generation of chemical waste. The process typically involves the use of various buffers, salts, and precipitants, many of which are not easily biodegradable. When isotonic solutions are employed, the concentration of these chemicals may increase, potentially leading to a higher volume of waste that requires specialized disposal methods.

Water consumption is another critical environmental aspect of crystallization processes. Isotonic solutions often require precise control of solute concentrations, which may necessitate the use of purified water. The production and disposal of large volumes of purified water can strain local water resources and contribute to energy consumption through water treatment processes.

Energy usage is a significant factor in the environmental impact of crystallization processes. Maintaining precise temperature control, which is crucial for successful crystallization, requires continuous energy input. The use of isotonic solutions may necessitate even more stringent temperature regulation, potentially increasing energy demands and associated carbon emissions.

The materials used in crystallization experiments, including plastics for plates and disposable pipettes, contribute to solid waste generation. While efforts are being made to develop more sustainable lab plastics, the current reliance on single-use materials in many crystallization setups remains an environmental concern.

Scaling up protein crystallization processes for industrial applications can amplify these environmental impacts. Larger-scale operations may require more extensive use of chemicals, water, and energy, as well as generate greater volumes of waste. The environmental footprint of such operations can be substantial, particularly if not managed with sustainability in mind.

However, the use of isotonic solutions in protein crystallization can also offer some environmental benefits. By potentially improving the efficiency and success rate of crystallization experiments, isotonic solutions may reduce the need for repeated trials, thereby minimizing overall resource consumption and waste generation.

To mitigate the environmental impact of crystallization processes, researchers and industry professionals are exploring various strategies. These include the development of more environmentally friendly crystallization agents, implementation of recycling systems for buffers and precipitants, and the adoption of more energy-efficient equipment and processes. Additionally, there is a growing emphasis on green chemistry principles in the design of crystallization experiments, aiming to reduce the use of harmful chemicals and minimize waste production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!