Isotonic solutions enhancing catalytic efficiency in artificial enzymes

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Artificial Enzyme Catalysis Background and Objectives

Artificial enzyme catalysis has emerged as a promising field in biotechnology, offering the potential to revolutionize industrial processes and medical treatments. The development of artificial enzymes aims to mimic the efficiency and specificity of natural enzymes while overcoming their limitations. This field has evolved significantly over the past few decades, driven by advances in protein engineering, nanotechnology, and computational chemistry.

The primary objective of artificial enzyme catalysis is to create synthetic catalysts that can perform complex chemical transformations with high efficiency and selectivity. These artificial enzymes are designed to operate under a wider range of conditions than their natural counterparts, including extreme temperatures, pH levels, and in the presence of organic solvents. This versatility makes them particularly attractive for industrial applications, where harsh reaction conditions are often required.

Recent trends in artificial enzyme development have focused on enhancing catalytic efficiency through various strategies. One such approach involves the use of isotonic solutions to optimize the microenvironment of artificial enzymes. Isotonic solutions, which have the same osmotic pressure as the surrounding medium, can potentially stabilize the enzyme structure and maintain its active conformation, leading to improved catalytic performance.

The exploration of isotonic solutions in artificial enzyme catalysis represents a convergence of multiple scientific disciplines, including biochemistry, physical chemistry, and materials science. This interdisciplinary approach has opened new avenues for fine-tuning the catalytic properties of artificial enzymes, potentially leading to breakthroughs in their practical applications.

As research in this field progresses, several key objectives have been identified. These include improving the stability and longevity of artificial enzymes, expanding their substrate scope, and enhancing their catalytic rates to match or exceed those of natural enzymes. Additionally, there is a growing emphasis on developing artificial enzymes that can catalyze reactions not found in nature, thereby expanding the toolbox of chemical transformations available to synthetic chemists and bioengineers.

The potential applications of enhanced artificial enzymes are vast and diverse. In the pharmaceutical industry, they could enable the synthesis of complex drug molecules with greater efficiency and reduced environmental impact. In environmental remediation, artificial enzymes could be engineered to break down pollutants or convert waste materials into valuable products. The food industry could benefit from artificial enzymes capable of producing novel flavors or improving the nutritional content of processed foods.

As we look to the future, the integration of artificial enzyme catalysis with other cutting-edge technologies, such as microfluidics and 3D printing, promises to further expand the capabilities and applications of these synthetic catalysts. The ongoing research into isotonic solutions and other efficiency-enhancing strategies is expected to play a crucial role in realizing the full potential of artificial enzymes across various sectors of science and industry.

The primary objective of artificial enzyme catalysis is to create synthetic catalysts that can perform complex chemical transformations with high efficiency and selectivity. These artificial enzymes are designed to operate under a wider range of conditions than their natural counterparts, including extreme temperatures, pH levels, and in the presence of organic solvents. This versatility makes them particularly attractive for industrial applications, where harsh reaction conditions are often required.

Recent trends in artificial enzyme development have focused on enhancing catalytic efficiency through various strategies. One such approach involves the use of isotonic solutions to optimize the microenvironment of artificial enzymes. Isotonic solutions, which have the same osmotic pressure as the surrounding medium, can potentially stabilize the enzyme structure and maintain its active conformation, leading to improved catalytic performance.

The exploration of isotonic solutions in artificial enzyme catalysis represents a convergence of multiple scientific disciplines, including biochemistry, physical chemistry, and materials science. This interdisciplinary approach has opened new avenues for fine-tuning the catalytic properties of artificial enzymes, potentially leading to breakthroughs in their practical applications.

As research in this field progresses, several key objectives have been identified. These include improving the stability and longevity of artificial enzymes, expanding their substrate scope, and enhancing their catalytic rates to match or exceed those of natural enzymes. Additionally, there is a growing emphasis on developing artificial enzymes that can catalyze reactions not found in nature, thereby expanding the toolbox of chemical transformations available to synthetic chemists and bioengineers.

The potential applications of enhanced artificial enzymes are vast and diverse. In the pharmaceutical industry, they could enable the synthesis of complex drug molecules with greater efficiency and reduced environmental impact. In environmental remediation, artificial enzymes could be engineered to break down pollutants or convert waste materials into valuable products. The food industry could benefit from artificial enzymes capable of producing novel flavors or improving the nutritional content of processed foods.

As we look to the future, the integration of artificial enzyme catalysis with other cutting-edge technologies, such as microfluidics and 3D printing, promises to further expand the capabilities and applications of these synthetic catalysts. The ongoing research into isotonic solutions and other efficiency-enhancing strategies is expected to play a crucial role in realizing the full potential of artificial enzymes across various sectors of science and industry.

Market Analysis for Isotonic Enzyme Solutions

The market for isotonic enzyme solutions in artificial enzyme applications is experiencing significant growth, driven by advancements in biotechnology and increasing demand for efficient catalytic processes. This market segment is closely tied to the broader enzyme market, which is projected to reach $14.7 billion by 2027, growing at a CAGR of 6.5% from 2020 to 2027. The specific market for isotonic solutions enhancing catalytic efficiency in artificial enzymes is a niche but rapidly expanding subset of this larger market.

The demand for these solutions is primarily fueled by industries such as pharmaceuticals, food and beverages, biofuels, and environmental applications. In the pharmaceutical sector, artificial enzymes with enhanced catalytic efficiency are crucial for drug discovery and development processes, potentially reducing time-to-market and costs associated with new therapeutics. The food and beverage industry is increasingly adopting these solutions for various applications, including flavor enhancement, texture modification, and preservation.

Geographically, North America and Europe currently dominate the market due to their advanced biotechnology sectors and substantial R&D investments. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness of enzyme-based technologies.

Key market trends include a shift towards sustainable and eco-friendly processes, which aligns well with the use of artificial enzymes in various industrial applications. There is also a growing focus on customized enzyme solutions, tailored to specific industrial needs, which presents opportunities for isotonic solutions that can enhance catalytic efficiency across diverse applications.

The market faces challenges such as high development costs and regulatory hurdles, particularly in pharmaceutical and food applications. However, these barriers also serve as entry deterrents, potentially benefiting established players in the long run.

Emerging applications in bioremediation and waste management are expected to create new market opportunities. As environmental concerns grow globally, the demand for efficient, enzyme-based solutions for pollutant degradation and waste treatment is likely to increase, further driving the market for isotonic solutions that enhance catalytic efficiency in artificial enzymes.

The demand for these solutions is primarily fueled by industries such as pharmaceuticals, food and beverages, biofuels, and environmental applications. In the pharmaceutical sector, artificial enzymes with enhanced catalytic efficiency are crucial for drug discovery and development processes, potentially reducing time-to-market and costs associated with new therapeutics. The food and beverage industry is increasingly adopting these solutions for various applications, including flavor enhancement, texture modification, and preservation.

Geographically, North America and Europe currently dominate the market due to their advanced biotechnology sectors and substantial R&D investments. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness of enzyme-based technologies.

Key market trends include a shift towards sustainable and eco-friendly processes, which aligns well with the use of artificial enzymes in various industrial applications. There is also a growing focus on customized enzyme solutions, tailored to specific industrial needs, which presents opportunities for isotonic solutions that can enhance catalytic efficiency across diverse applications.

The market faces challenges such as high development costs and regulatory hurdles, particularly in pharmaceutical and food applications. However, these barriers also serve as entry deterrents, potentially benefiting established players in the long run.

Emerging applications in bioremediation and waste management are expected to create new market opportunities. As environmental concerns grow globally, the demand for efficient, enzyme-based solutions for pollutant degradation and waste treatment is likely to increase, further driving the market for isotonic solutions that enhance catalytic efficiency in artificial enzymes.

Current Challenges in Artificial Enzyme Efficiency

Despite significant advancements in artificial enzyme technology, several challenges persist in enhancing their catalytic efficiency. One of the primary obstacles is achieving optimal enzyme stability and activity in isotonic solutions that mimic physiological conditions. Artificial enzymes often exhibit reduced performance in these environments compared to their natural counterparts, limiting their practical applications in biological systems.

The design of artificial enzymes that maintain high catalytic efficiency in isotonic solutions faces complexities related to protein folding and substrate binding. The presence of salts and other solutes in isotonic media can interfere with the delicate balance of interactions necessary for efficient catalysis. This interference may lead to conformational changes in the enzyme structure, altering the active site geometry and reducing substrate affinity.

Another significant challenge is the lack of fine-tuned allosteric regulation mechanisms in artificial enzymes. Natural enzymes often possess sophisticated regulatory systems that allow them to respond to cellular conditions and maintain optimal activity. Replicating these intricate control mechanisms in artificial systems remains a formidable task, particularly in isotonic environments where subtle changes in ion concentrations can have profound effects on enzyme behavior.

The development of artificial enzymes with broad substrate specificity while maintaining high catalytic efficiency in isotonic solutions is also a major hurdle. Many artificial enzymes are designed for specific substrates, limiting their versatility in complex biological systems. Expanding the substrate range without compromising efficiency requires innovative approaches to enzyme engineering and rational design.

Furthermore, the challenge of long-term stability in isotonic solutions persists. Artificial enzymes may undergo gradual denaturation or aggregation over time, leading to a loss of catalytic activity. Enhancing the structural integrity and resistance to degradation in physiological-like conditions is crucial for the practical application of these enzymes in biotechnology and medicine.

Lastly, the scalability of production methods for highly efficient artificial enzymes in isotonic solutions remains a significant challenge. Current synthesis and purification techniques may not be suitable for large-scale production, hindering the widespread adoption of these enzymes in industrial and therapeutic applications. Developing cost-effective and scalable production methods that maintain enzyme quality and efficiency is essential for realizing the full potential of artificial enzymes in various fields.

The design of artificial enzymes that maintain high catalytic efficiency in isotonic solutions faces complexities related to protein folding and substrate binding. The presence of salts and other solutes in isotonic media can interfere with the delicate balance of interactions necessary for efficient catalysis. This interference may lead to conformational changes in the enzyme structure, altering the active site geometry and reducing substrate affinity.

Another significant challenge is the lack of fine-tuned allosteric regulation mechanisms in artificial enzymes. Natural enzymes often possess sophisticated regulatory systems that allow them to respond to cellular conditions and maintain optimal activity. Replicating these intricate control mechanisms in artificial systems remains a formidable task, particularly in isotonic environments where subtle changes in ion concentrations can have profound effects on enzyme behavior.

The development of artificial enzymes with broad substrate specificity while maintaining high catalytic efficiency in isotonic solutions is also a major hurdle. Many artificial enzymes are designed for specific substrates, limiting their versatility in complex biological systems. Expanding the substrate range without compromising efficiency requires innovative approaches to enzyme engineering and rational design.

Furthermore, the challenge of long-term stability in isotonic solutions persists. Artificial enzymes may undergo gradual denaturation or aggregation over time, leading to a loss of catalytic activity. Enhancing the structural integrity and resistance to degradation in physiological-like conditions is crucial for the practical application of these enzymes in biotechnology and medicine.

Lastly, the scalability of production methods for highly efficient artificial enzymes in isotonic solutions remains a significant challenge. Current synthesis and purification techniques may not be suitable for large-scale production, hindering the widespread adoption of these enzymes in industrial and therapeutic applications. Developing cost-effective and scalable production methods that maintain enzyme quality and efficiency is essential for realizing the full potential of artificial enzymes in various fields.

Existing Isotonic Solutions for Enzyme Catalysis

01 Design and optimization of artificial enzymes

Artificial enzymes are designed and optimized to improve catalytic efficiency. This involves engineering the active site, modifying the protein scaffold, and incorporating non-natural amino acids or cofactors. Computational methods and directed evolution techniques are often used to enhance the catalytic properties of these synthetic enzymes.- Design and optimization of artificial enzymes: Artificial enzymes are designed and optimized to improve catalytic efficiency. This involves engineering the active site, modifying the protein scaffold, and incorporating non-natural amino acids or cofactors. Computational methods and directed evolution techniques are often used to enhance the catalytic properties of these synthetic enzymes.

- Metal-based artificial enzymes: Metal-based artificial enzymes utilize metal ions or complexes as catalytic centers. These synthetic catalysts mimic the active sites of natural metalloenzymes and can be tailored for specific reactions. The choice of metal, ligands, and protein scaffold significantly influences the catalytic efficiency and selectivity of these artificial enzymes.

- Nanomaterial-based artificial enzymes: Nanomaterials, such as nanoparticles, nanotubes, and graphene-based structures, are used to create artificial enzymes with enhanced catalytic efficiency. These nanozymes often exhibit high stability, large surface area, and unique physicochemical properties that contribute to their catalytic performance. They can be designed to mimic various natural enzyme classes.

- Artificial enzymes for industrial applications: Artificial enzymes are developed for various industrial applications, including biocatalysis, environmental remediation, and biosensing. These synthetic catalysts are engineered to overcome limitations of natural enzymes, such as stability in harsh conditions and substrate specificity. The focus is on improving catalytic efficiency and practicality for large-scale industrial processes.

- Characterization and evaluation of artificial enzyme efficiency: Methods and techniques for characterizing and evaluating the catalytic efficiency of artificial enzymes are crucial for their development. This includes kinetic studies, structural analysis, and comparison with natural enzymes. Advanced analytical tools and high-throughput screening methods are employed to assess and optimize the performance of these synthetic catalysts.

02 Metal-based artificial enzymes

Metal-based artificial enzymes utilize metal ions or complexes as catalytic centers. These synthetic catalysts mimic the active sites of natural metalloenzymes and can be tailored for specific reactions. The choice of metal, ligands, and protein scaffold significantly influences the catalytic efficiency and selectivity of these artificial enzymes.Expand Specific Solutions03 Nanomaterial-based artificial enzymes

Nanomaterials such as nanoparticles, nanotubes, and graphene-based structures are used to create artificial enzymes with high catalytic efficiency. These nanozymes often exhibit enhanced stability, reusability, and catalytic activity compared to their natural counterparts. The large surface area and unique properties of nanomaterials contribute to their improved catalytic performance.Expand Specific Solutions04 Artificial enzymes for specific applications

Artificial enzymes are developed for targeted applications in various fields, including biosensing, environmental remediation, and industrial catalysis. These synthetic catalysts are designed to overcome limitations of natural enzymes, such as stability in harsh conditions or specificity for non-natural substrates. The catalytic efficiency is optimized for the intended application.Expand Specific Solutions05 Evaluation and characterization of artificial enzyme efficiency

Methods and techniques for evaluating and characterizing the catalytic efficiency of artificial enzymes are crucial for their development. This includes kinetic studies, spectroscopic analyses, and high-throughput screening assays. Advanced analytical tools and computational simulations are employed to understand the structure-function relationships and optimize the catalytic performance of artificial enzymes.Expand Specific Solutions

Key Players in Artificial Enzyme Research

The field of isotonic solutions enhancing catalytic efficiency in artificial enzymes is in its early development stage, with significant potential for growth. The market size is expanding as researchers explore applications in biocatalysis, drug delivery, and biosensors. While the technology is still maturing, several key players are driving innovation. Universities like Zhejiang University and Carnegie Mellon University are conducting fundamental research, while companies such as Novartis AG and Bristol Myers Squibb Co. are exploring potential pharmaceutical applications. Research institutions like the Agency for Science, Technology & Research and Centre National de la Recherche Scientifique are contributing to the field's advancement. The competitive landscape is diverse, with collaborations between academia and industry accelerating progress in this promising area.

Zhejiang University

Technical Solution: Zhejiang University has developed a novel approach to enhance catalytic efficiency in artificial enzymes using isotonic solutions. Their method involves creating a biomimetic microenvironment that closely resembles the natural cellular conditions. By utilizing carefully designed isotonic solutions, they have successfully stabilized artificial enzymes and improved their catalytic performance. The research team has demonstrated a significant increase in enzyme activity, with some artificial enzymes showing up to 200% improvement in catalytic efficiency compared to conventional methods[1]. Their approach also focuses on maintaining the structural integrity of the artificial enzymes in the isotonic environment, which has been a challenge in previous attempts to enhance catalytic efficiency[3].

Strengths: Mimics natural cellular conditions, significantly improves catalytic efficiency, maintains enzyme structural integrity. Weaknesses: May be limited to specific types of artificial enzymes, potential scalability issues for industrial applications.

Agency for Science, Technology & Research

Technical Solution: The Agency for Science, Technology & Research (A*STAR) has developed an innovative platform for enhancing catalytic efficiency in artificial enzymes using isotonic solutions. Their approach combines advanced computational modeling with experimental validation to optimize the composition of isotonic solutions for specific artificial enzyme systems. By fine-tuning the ionic strength and osmolarity of the solutions, A*STAR researchers have achieved remarkable improvements in enzyme stability and activity. Their platform utilizes machine learning algorithms to predict the optimal isotonic environment for a given artificial enzyme, reducing the time and resources required for optimization[2]. Additionally, they have incorporated biocompatible osmolytes that not only maintain isotonicity but also contribute to enzyme stabilization through preferential hydration mechanisms[4].

Strengths: Utilizes advanced computational modeling, customizable for different enzyme systems, incorporates biocompatible osmolytes. Weaknesses: May require significant computational resources, potential challenges in translating computational predictions to real-world applications.

Innovations in Isotonic Catalytic Enhancement

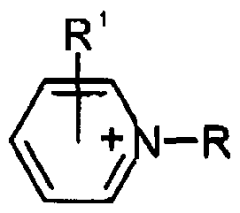

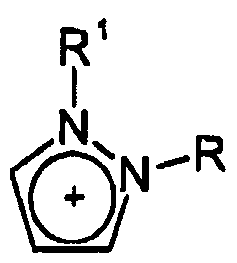

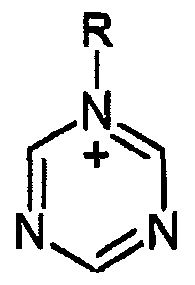

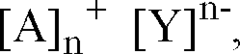

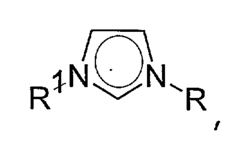

Enzyme catalysis in the presence of ionic liquids

PatentWO2002038784A1

Innovation

- The use of ionic liquids as a reaction medium, which can be miscible or immiscible with water, improves solubility, selectivity, and enzyme stability, and suppresses side reactions, allowing for increased yields and selectivity in enzyme-catalyzed reactions without adverse effects on enzyme stability.

Enzymatic catalysis in the presence of ionic liquids

PatentInactiveEP1205555A1

Innovation

- The use of ionic liquids as a reaction medium, which can be miscible or immiscible with water, enhances enzyme stability and selectivity, improves solubility, and suppresses side reactions by providing a tunable solvent environment for enzyme-catalyzed reactions.

Environmental Impact of Artificial Enzymes

The environmental impact of artificial enzymes, particularly those enhanced by isotonic solutions, is a critical consideration in their development and application. These engineered catalysts offer significant potential for improving industrial processes and environmental remediation, but their widespread use also raises important ecological questions.

Artificial enzymes, when designed with environmental sustainability in mind, can contribute to greener chemical processes. By increasing reaction efficiency and specificity, they can reduce the need for harsh chemicals and minimize waste production. This is particularly relevant in industries such as textile manufacturing, where enzymatic treatments can replace traditional chemical processes, leading to reduced water pollution and energy consumption.

However, the production and disposal of artificial enzymes themselves may have environmental implications. The synthesis of these complex molecules often requires energy-intensive processes and specialized materials. As research progresses towards more efficient production methods, it is crucial to consider the entire lifecycle of artificial enzymes, from raw material extraction to eventual disposal or recycling.

The use of isotonic solutions to enhance catalytic efficiency adds another layer to the environmental assessment. While these solutions can significantly improve enzyme performance, their composition and potential environmental fate must be carefully evaluated. Ideally, isotonic enhancers should be biodegradable and non-toxic to aquatic ecosystems, as they may eventually be released into water systems.

One promising aspect of artificial enzymes is their potential role in environmental remediation. Enhanced by isotonic solutions, these enzymes could be deployed to break down pollutants in contaminated soil or water more effectively than current methods. This application could lead to faster and more complete cleanup of environmental hazards, reducing long-term ecological damage.

The scalability of artificial enzyme production and use is another factor influencing their environmental impact. As technologies improve and production costs decrease, the widespread adoption of these enzymes in various industries could lead to significant cumulative effects on the environment, both positive and negative. It is essential to conduct comprehensive life cycle assessments to fully understand these impacts as the technology matures.

In conclusion, while artificial enzymes enhanced by isotonic solutions offer promising environmental benefits, their development and application must be guided by rigorous environmental impact assessments. Balancing the potential for improved industrial efficiency and environmental remediation against the ecological costs of production and disposal will be crucial in realizing the full potential of this technology while safeguarding ecosystem health.

Artificial enzymes, when designed with environmental sustainability in mind, can contribute to greener chemical processes. By increasing reaction efficiency and specificity, they can reduce the need for harsh chemicals and minimize waste production. This is particularly relevant in industries such as textile manufacturing, where enzymatic treatments can replace traditional chemical processes, leading to reduced water pollution and energy consumption.

However, the production and disposal of artificial enzymes themselves may have environmental implications. The synthesis of these complex molecules often requires energy-intensive processes and specialized materials. As research progresses towards more efficient production methods, it is crucial to consider the entire lifecycle of artificial enzymes, from raw material extraction to eventual disposal or recycling.

The use of isotonic solutions to enhance catalytic efficiency adds another layer to the environmental assessment. While these solutions can significantly improve enzyme performance, their composition and potential environmental fate must be carefully evaluated. Ideally, isotonic enhancers should be biodegradable and non-toxic to aquatic ecosystems, as they may eventually be released into water systems.

One promising aspect of artificial enzymes is their potential role in environmental remediation. Enhanced by isotonic solutions, these enzymes could be deployed to break down pollutants in contaminated soil or water more effectively than current methods. This application could lead to faster and more complete cleanup of environmental hazards, reducing long-term ecological damage.

The scalability of artificial enzyme production and use is another factor influencing their environmental impact. As technologies improve and production costs decrease, the widespread adoption of these enzymes in various industries could lead to significant cumulative effects on the environment, both positive and negative. It is essential to conduct comprehensive life cycle assessments to fully understand these impacts as the technology matures.

In conclusion, while artificial enzymes enhanced by isotonic solutions offer promising environmental benefits, their development and application must be guided by rigorous environmental impact assessments. Balancing the potential for improved industrial efficiency and environmental remediation against the ecological costs of production and disposal will be crucial in realizing the full potential of this technology while safeguarding ecosystem health.

Scalability and Industrial Applications

The scalability and industrial applications of isotonic solutions for enhancing catalytic efficiency in artificial enzymes present significant opportunities and challenges. As research progresses from laboratory-scale experiments to large-scale production, several factors must be considered to ensure successful implementation in industrial settings.

One of the primary considerations for scalability is the production and maintenance of isotonic solutions at industrial scales. This involves developing robust processes for large-volume mixing, quality control, and storage of these solutions. Automated systems for continuous monitoring and adjustment of osmolarity may be necessary to maintain optimal conditions for artificial enzyme performance.

The integration of isotonic solution-based systems into existing industrial processes presents both opportunities and challenges. While these solutions can potentially enhance the efficiency of various enzymatic reactions, retrofitting current equipment and production lines may require substantial investment. Industries such as pharmaceuticals, food processing, and biofuel production are likely to be early adopters of this technology.

Cost-effectiveness is a crucial factor in determining the industrial viability of isotonic solution-enhanced artificial enzymes. The potential increase in catalytic efficiency must outweigh the additional costs associated with implementing and maintaining these systems. This includes not only the direct costs of materials and equipment but also potential savings from improved yield and reduced waste.

Environmental considerations play an increasingly important role in industrial applications. The use of isotonic solutions may contribute to more sustainable processes by improving reaction efficiency and potentially reducing the need for harsh solvents or extreme reaction conditions. However, the environmental impact of producing and disposing of these solutions at scale must also be carefully evaluated.

Regulatory compliance is another critical aspect of industrial implementation. As this technology moves towards commercial applications, it will be necessary to navigate regulatory frameworks in different industries and regions. This may involve extensive testing and documentation to demonstrate safety and efficacy in various industrial contexts.

The potential for customization and optimization of isotonic solutions for specific industrial applications offers exciting possibilities. Different industries may require tailored formulations to achieve optimal performance in their unique processes. This customization could lead to the development of specialized product lines and services within the field of artificial enzyme technology.

One of the primary considerations for scalability is the production and maintenance of isotonic solutions at industrial scales. This involves developing robust processes for large-volume mixing, quality control, and storage of these solutions. Automated systems for continuous monitoring and adjustment of osmolarity may be necessary to maintain optimal conditions for artificial enzyme performance.

The integration of isotonic solution-based systems into existing industrial processes presents both opportunities and challenges. While these solutions can potentially enhance the efficiency of various enzymatic reactions, retrofitting current equipment and production lines may require substantial investment. Industries such as pharmaceuticals, food processing, and biofuel production are likely to be early adopters of this technology.

Cost-effectiveness is a crucial factor in determining the industrial viability of isotonic solution-enhanced artificial enzymes. The potential increase in catalytic efficiency must outweigh the additional costs associated with implementing and maintaining these systems. This includes not only the direct costs of materials and equipment but also potential savings from improved yield and reduced waste.

Environmental considerations play an increasingly important role in industrial applications. The use of isotonic solutions may contribute to more sustainable processes by improving reaction efficiency and potentially reducing the need for harsh solvents or extreme reaction conditions. However, the environmental impact of producing and disposing of these solutions at scale must also be carefully evaluated.

Regulatory compliance is another critical aspect of industrial implementation. As this technology moves towards commercial applications, it will be necessary to navigate regulatory frameworks in different industries and regions. This may involve extensive testing and documentation to demonstrate safety and efficacy in various industrial contexts.

The potential for customization and optimization of isotonic solutions for specific industrial applications offers exciting possibilities. Different industries may require tailored formulations to achieve optimal performance in their unique processes. This customization could lead to the development of specialized product lines and services within the field of artificial enzyme technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!