How isotonic solutions improve electrospinning polymer processes

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isotonic Solutions in Electrospinning: Background and Objectives

Electrospinning has emerged as a versatile and efficient technique for producing ultra-fine fibers with diameters ranging from nanometers to micrometers. This process has gained significant attention in various fields, including tissue engineering, drug delivery, and filtration, due to its ability to create highly porous structures with large surface areas. The incorporation of isotonic solutions in electrospinning polymer processes represents a promising avenue for enhancing the quality and functionality of the resulting fibers.

The concept of isotonic solutions in electrospinning stems from the need to maintain cellular viability and functionality when incorporating biological components into electrospun fibers. Isotonic solutions, which have the same osmotic pressure as the cellular environment, play a crucial role in preserving the integrity of cells and biomolecules during the electrospinning process. This approach has opened up new possibilities for creating bioactive scaffolds and drug-loaded fibers with improved efficacy and biocompatibility.

The primary objective of utilizing isotonic solutions in electrospinning is to overcome the limitations associated with conventional polymer solutions. Traditional electrospinning often employs organic solvents or aqueous solutions that may compromise the stability and activity of sensitive biological components. By introducing isotonic solutions, researchers aim to create a more favorable environment for cells and biomolecules, thereby expanding the range of materials that can be successfully electrospun.

As the field of electrospinning continues to evolve, the integration of isotonic solutions has become a focal point for addressing several key challenges. These include improving cell viability in tissue engineering scaffolds, enhancing the encapsulation efficiency of drugs and growth factors, and developing novel composite materials with unique properties. The use of isotonic solutions also aligns with the growing trend towards green and sustainable manufacturing processes, as it often allows for the reduction or elimination of harsh organic solvents.

The technological evolution in this area has been driven by interdisciplinary collaborations between materials scientists, bioengineers, and pharmaceutical researchers. Recent advancements have focused on optimizing the composition of isotonic solutions to achieve specific outcomes, such as controlled release profiles or enhanced cell adhesion. Additionally, efforts have been made to develop new electrospinning setups and protocols that can effectively handle isotonic solutions while maintaining the desired fiber morphology and properties.

Looking ahead, the integration of isotonic solutions in electrospinning polymer processes is expected to play a pivotal role in the development of next-generation biomaterials and drug delivery systems. This approach holds promise for creating more physiologically relevant tissue engineering scaffolds, improving the efficacy of wound healing materials, and enabling the production of advanced filtration membranes with enhanced performance characteristics. As research in this field progresses, it is anticipated that isotonic solution-based electrospinning will contribute significantly to addressing unmet needs in healthcare, environmental protection, and other critical areas.

The concept of isotonic solutions in electrospinning stems from the need to maintain cellular viability and functionality when incorporating biological components into electrospun fibers. Isotonic solutions, which have the same osmotic pressure as the cellular environment, play a crucial role in preserving the integrity of cells and biomolecules during the electrospinning process. This approach has opened up new possibilities for creating bioactive scaffolds and drug-loaded fibers with improved efficacy and biocompatibility.

The primary objective of utilizing isotonic solutions in electrospinning is to overcome the limitations associated with conventional polymer solutions. Traditional electrospinning often employs organic solvents or aqueous solutions that may compromise the stability and activity of sensitive biological components. By introducing isotonic solutions, researchers aim to create a more favorable environment for cells and biomolecules, thereby expanding the range of materials that can be successfully electrospun.

As the field of electrospinning continues to evolve, the integration of isotonic solutions has become a focal point for addressing several key challenges. These include improving cell viability in tissue engineering scaffolds, enhancing the encapsulation efficiency of drugs and growth factors, and developing novel composite materials with unique properties. The use of isotonic solutions also aligns with the growing trend towards green and sustainable manufacturing processes, as it often allows for the reduction or elimination of harsh organic solvents.

The technological evolution in this area has been driven by interdisciplinary collaborations between materials scientists, bioengineers, and pharmaceutical researchers. Recent advancements have focused on optimizing the composition of isotonic solutions to achieve specific outcomes, such as controlled release profiles or enhanced cell adhesion. Additionally, efforts have been made to develop new electrospinning setups and protocols that can effectively handle isotonic solutions while maintaining the desired fiber morphology and properties.

Looking ahead, the integration of isotonic solutions in electrospinning polymer processes is expected to play a pivotal role in the development of next-generation biomaterials and drug delivery systems. This approach holds promise for creating more physiologically relevant tissue engineering scaffolds, improving the efficacy of wound healing materials, and enabling the production of advanced filtration membranes with enhanced performance characteristics. As research in this field progresses, it is anticipated that isotonic solution-based electrospinning will contribute significantly to addressing unmet needs in healthcare, environmental protection, and other critical areas.

Market Analysis for Advanced Electrospinning Techniques

The electrospinning polymer process market has experienced significant growth in recent years, driven by increasing demand for nanofibers in various industries. The global electrospinning market was valued at approximately $1.5 billion in 2020 and is projected to reach $3.2 billion by 2026, growing at a CAGR of around 12% during the forecast period.

The adoption of advanced electrospinning techniques, particularly those utilizing isotonic solutions, has been a key factor in market expansion. Isotonic solutions have shown remarkable potential in improving the electrospinning process, leading to enhanced fiber quality and production efficiency. This has attracted attention from both academic researchers and industrial players, fostering innovation and market growth.

Several industries are driving the demand for advanced electrospinning techniques. The healthcare sector, including tissue engineering and drug delivery systems, represents a significant market share. The use of isotonic solutions in electrospinning has enabled the production of biocompatible nanofibers with improved cellular interactions, opening new avenues for regenerative medicine and controlled drug release applications.

The filtration industry is another major consumer of electrospun nanofibers, with applications in air and water purification systems. The ability of isotonic solution-based electrospinning to produce uniform, high-quality fibers has led to increased adoption in this sector, as it allows for the development of more efficient filtration membranes.

Geographically, North America and Europe currently dominate the market for advanced electrospinning techniques, owing to their strong research infrastructure and established industrial base. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing investments in nanotechnology research and growing industrial applications in countries like China, Japan, and South Korea.

The market landscape is characterized by a mix of established players and innovative startups. Key companies are focusing on research and development to improve electrospinning processes and expand their product portfolios. Collaborations between academic institutions and industry partners are becoming more common, accelerating the commercialization of novel electrospinning technologies.

Despite the positive outlook, challenges remain in the widespread adoption of advanced electrospinning techniques. High initial investment costs and the need for specialized expertise can be barriers for smaller companies. However, ongoing research and development efforts are expected to address these challenges, potentially leading to more cost-effective and user-friendly electrospinning systems in the future.

The adoption of advanced electrospinning techniques, particularly those utilizing isotonic solutions, has been a key factor in market expansion. Isotonic solutions have shown remarkable potential in improving the electrospinning process, leading to enhanced fiber quality and production efficiency. This has attracted attention from both academic researchers and industrial players, fostering innovation and market growth.

Several industries are driving the demand for advanced electrospinning techniques. The healthcare sector, including tissue engineering and drug delivery systems, represents a significant market share. The use of isotonic solutions in electrospinning has enabled the production of biocompatible nanofibers with improved cellular interactions, opening new avenues for regenerative medicine and controlled drug release applications.

The filtration industry is another major consumer of electrospun nanofibers, with applications in air and water purification systems. The ability of isotonic solution-based electrospinning to produce uniform, high-quality fibers has led to increased adoption in this sector, as it allows for the development of more efficient filtration membranes.

Geographically, North America and Europe currently dominate the market for advanced electrospinning techniques, owing to their strong research infrastructure and established industrial base. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing investments in nanotechnology research and growing industrial applications in countries like China, Japan, and South Korea.

The market landscape is characterized by a mix of established players and innovative startups. Key companies are focusing on research and development to improve electrospinning processes and expand their product portfolios. Collaborations between academic institutions and industry partners are becoming more common, accelerating the commercialization of novel electrospinning technologies.

Despite the positive outlook, challenges remain in the widespread adoption of advanced electrospinning techniques. High initial investment costs and the need for specialized expertise can be barriers for smaller companies. However, ongoing research and development efforts are expected to address these challenges, potentially leading to more cost-effective and user-friendly electrospinning systems in the future.

Current Challenges in Polymer Electrospinning Processes

Polymer electrospinning processes face several significant challenges that hinder their widespread adoption and efficiency in various applications. One of the primary issues is the inconsistency in fiber diameter and morphology, which can greatly affect the final product's properties and performance. This variability often stems from fluctuations in solution viscosity, environmental conditions, and process parameters.

Another major challenge is the limited control over fiber orientation and alignment. While random fiber mats are suitable for some applications, many advanced uses require precisely aligned fibers. Achieving this level of control consistently across large-scale production remains difficult, particularly when dealing with complex three-dimensional structures.

The low throughput of traditional electrospinning setups presents a significant barrier to industrial-scale production. Single-nozzle systems typically produce only small quantities of fibers, making the process time-consuming and cost-ineffective for large-scale manufacturing. This limitation has spurred research into multi-nozzle and needleless electrospinning techniques, but these approaches introduce their own set of challenges related to uniformity and process control.

Solvent toxicity and environmental concerns also pose substantial challenges. Many polymers require the use of volatile organic compounds (VOCs) as solvents, which can be harmful to both workers and the environment. Finding eco-friendly alternatives that maintain the desired solution properties without compromising fiber quality is an ongoing area of research.

The instability of the electrospinning jet is another critical issue. Bending instabilities and whipping motions of the polymer jet can lead to defects in the fibers and non-uniform deposition. Controlling these instabilities, especially when scaling up the process, remains a significant technical hurdle.

Furthermore, the limited range of polymers suitable for electrospinning restricts the potential applications of this technology. Some high-performance polymers with desirable properties are challenging to electrospin due to their high molecular weight or poor solubility in common solvents. Expanding the range of spinnable materials is crucial for broadening the technique's applicability.

Lastly, the complexity of optimizing process parameters for new polymer-solvent systems presents a considerable challenge. The interplay between solution properties, environmental conditions, and equipment settings often requires extensive experimentation to achieve desired fiber characteristics. This time-consuming process can slow down innovation and product development in the field of electrospun materials.

Another major challenge is the limited control over fiber orientation and alignment. While random fiber mats are suitable for some applications, many advanced uses require precisely aligned fibers. Achieving this level of control consistently across large-scale production remains difficult, particularly when dealing with complex three-dimensional structures.

The low throughput of traditional electrospinning setups presents a significant barrier to industrial-scale production. Single-nozzle systems typically produce only small quantities of fibers, making the process time-consuming and cost-ineffective for large-scale manufacturing. This limitation has spurred research into multi-nozzle and needleless electrospinning techniques, but these approaches introduce their own set of challenges related to uniformity and process control.

Solvent toxicity and environmental concerns also pose substantial challenges. Many polymers require the use of volatile organic compounds (VOCs) as solvents, which can be harmful to both workers and the environment. Finding eco-friendly alternatives that maintain the desired solution properties without compromising fiber quality is an ongoing area of research.

The instability of the electrospinning jet is another critical issue. Bending instabilities and whipping motions of the polymer jet can lead to defects in the fibers and non-uniform deposition. Controlling these instabilities, especially when scaling up the process, remains a significant technical hurdle.

Furthermore, the limited range of polymers suitable for electrospinning restricts the potential applications of this technology. Some high-performance polymers with desirable properties are challenging to electrospin due to their high molecular weight or poor solubility in common solvents. Expanding the range of spinnable materials is crucial for broadening the technique's applicability.

Lastly, the complexity of optimizing process parameters for new polymer-solvent systems presents a considerable challenge. The interplay between solution properties, environmental conditions, and equipment settings often requires extensive experimentation to achieve desired fiber characteristics. This time-consuming process can slow down innovation and product development in the field of electrospun materials.

Isotonic Solutions: Current Implementation Methods

01 Electrospinning of isotonic polymer solutions

Electrospinning processes can be used to create fibers from isotonic polymer solutions. This technique involves applying an electric field to draw out thin fibers from a liquid polymer solution, resulting in nanoscale or microscale fibers. The use of isotonic solutions helps maintain osmotic balance, which can be beneficial for certain applications, particularly in biomedical fields.- Electrospinning of isotonic polymer solutions: Electrospinning processes can be used to create fibers from isotonic polymer solutions. This technique involves applying an electric field to draw out thin fibers from a liquid polymer solution, resulting in nanoscale or microscale fibers. The use of isotonic solutions helps maintain the osmotic balance during the process, which can be beneficial for certain applications, particularly in biomedical fields.

- Polymer selection for isotonic electrospinning: The choice of polymer is crucial in isotonic electrospinning processes. Polymers that can maintain isotonicity while still being suitable for electrospinning are selected. These may include natural polymers like collagen or synthetic polymers that are biocompatible and can be dissolved in isotonic solutions. The polymer selection affects the final properties of the electrospun fibers, including their mechanical strength and biological interactions.

- Solvent systems for isotonic electrospinning: Developing appropriate solvent systems is essential for isotonic electrospinning. The solvents must dissolve the chosen polymers while maintaining an isotonic environment. This often involves using a combination of solvents or adding salts to adjust the osmolarity. The solvent system affects the viscosity and conductivity of the solution, which in turn influences the electrospinning process and fiber formation.

- Process parameters for isotonic electrospinning: Optimizing process parameters is crucial for successful isotonic electrospinning. These parameters include the applied voltage, flow rate, distance between the needle and collector, and environmental conditions such as temperature and humidity. For isotonic solutions, special attention may be needed to prevent changes in osmolarity during the process, which could affect fiber formation and properties.

- Applications of isotonic electrospun fibers: Isotonic electrospun fibers have various applications, particularly in the biomedical field. They can be used for tissue engineering scaffolds, drug delivery systems, and wound dressings. The isotonic nature of these fibers makes them compatible with biological systems, potentially improving cell adhesion and proliferation. Other applications may include filtration membranes or sensors that require an isotonic environment for optimal performance.

02 Polymer selection for isotonic electrospinning

The choice of polymer is crucial in isotonic electrospinning processes. Polymers that can maintain isotonicity while still being suitable for electrospinning are selected. These may include natural polymers like collagen or synthetic polymers that are biocompatible and can be formulated into isotonic solutions. The polymer selection affects the final fiber properties and their potential applications.Expand Specific Solutions03 Additives for isotonic electrospinning solutions

Various additives can be incorporated into the polymer solutions to enhance the electrospinning process or modify the properties of the resulting fibers. These may include salts to maintain isotonicity, surfactants to improve solution properties, or bioactive compounds for specific applications. The careful selection and balance of these additives is crucial for successful isotonic electrospinning.Expand Specific Solutions04 Process parameters for isotonic electrospinning

Optimizing process parameters is essential for successful isotonic electrospinning. These parameters include applied voltage, solution flow rate, distance between the needle and collector, and environmental conditions such as temperature and humidity. Careful control of these factors is necessary to produce consistent, high-quality fibers while maintaining the isotonic nature of the solution.Expand Specific Solutions05 Applications of isotonic electrospun fibers

Fibers produced from isotonic polymer solutions through electrospinning have various potential applications, particularly in biomedical fields. These may include wound dressings, tissue engineering scaffolds, drug delivery systems, and biosensors. The isotonic nature of the fibers can promote better compatibility with biological systems and enhance their performance in these applications.Expand Specific Solutions

Key Players in Electrospinning Industry

The market for isotonic solutions in electrospinning polymer processes is in a growth phase, driven by increasing demand for advanced materials in various industries. The global electrospinning market is expected to expand significantly, with a projected CAGR of over 10% in the coming years. While the technology is maturing, there is still room for innovation and improvement in solution formulations and process optimization. Key players in this field include academic institutions like Donghua University and Philipps University of Marburg, as well as major chemical companies such as BASF Corp., Bayer AG, and ExxonMobil Chemical Patents, Inc. These organizations are actively researching and developing new isotonic solutions to enhance electrospinning processes, focusing on improving fiber quality, productivity, and application-specific properties.

Donghua University

Technical Solution: Donghua University has developed an innovative approach to improve electrospinning polymer processes using isotonic solutions. Their method involves incorporating carefully selected salts into the polymer solution to create an isotonic environment. This approach enhances the stability of the electrospinning jet by balancing osmotic pressures, resulting in more uniform fiber formation[1]. The university's research has shown that isotonic solutions can significantly reduce bead formation and improve fiber alignment in the electrospinning process[2]. They have also explored the use of biocompatible salts to create isotonic environments suitable for tissue engineering applications, demonstrating improved cell adhesion and proliferation on the resulting nanofiber scaffolds[3].

Strengths: Enhanced fiber uniformity, reduced bead formation, and improved cell compatibility for biomedical applications. Weaknesses: May require careful optimization of salt concentrations for different polymer systems, potentially increasing process complexity.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed a proprietary isotonic solution technology for electrospinning processes, focusing on improving the production of high-performance polymer fibers. Their approach involves creating a carefully balanced electrolyte solution that matches the osmotic pressure of the polymer solution. This isotonic environment helps to stabilize the Taylor cone during electrospinning, resulting in more consistent fiber formation and improved mechanical properties[4]. Dow's technology also incorporates surfactants and viscosity modifiers to further enhance the electrospinning process, allowing for the production of ultra-fine fibers with diameters as small as 50 nanometers[5]. The company has successfully applied this technology to a range of polymer systems, including polyethylene, polypropylene, and specialty elastomers, demonstrating its versatility in various industrial applications[6].

Strengths: Versatile application across multiple polymer systems, production of ultra-fine fibers, and improved mechanical properties. Weaknesses: May require specialized equipment and careful process control, potentially increasing production costs.

Core Innovations in Isotonic Electrospinning

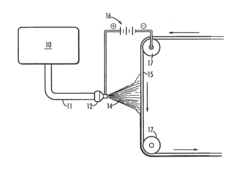

Electrospinning of PTFE

PatentActiveUS20150183940A1

Innovation

- A process that increases the viscosity of PTFE dispersions to at least 50,000 cP by incorporating a fiberizing polymer like polyethylene oxide, allowing for electrostatic spinning into high-viscosity PTFE mats with improved properties, using an electrostatic spinning apparatus with a charge source and target to collect the charged dispersion and subsequent heating to remove the solvent and polymer, forming a PTFE mat with enhanced mechanical integrity.

Polymer solutions in ionic liquids with improved thermal and rheological stability

PatentActiveEP2460843A1

Innovation

- The addition of small amounts of inorganic transition metal salts, such as Cu, Co, Ni, Mn, Zn, or Ag cations, to polymer solutions in ionic liquids forms complexes that enhance thermal and rheological stability, allowing for consistent spinning conditions and reduced degradation, even at lower temperatures.

Environmental Impact of Isotonic Electrospinning

The environmental impact of isotonic electrospinning is a crucial aspect to consider in the development and application of this polymer processing technique. Isotonic solutions used in electrospinning have shown potential to improve the overall process efficiency and product quality, but their environmental implications must be carefully evaluated.

One of the primary environmental benefits of isotonic electrospinning is the reduction in solvent usage. Traditional electrospinning often requires large volumes of organic solvents, which can be harmful to the environment and human health. Isotonic solutions, being water-based, significantly reduce the need for these volatile organic compounds, leading to decreased air pollution and lower risks of environmental contamination.

Furthermore, the use of isotonic solutions can enhance the biodegradability of the resulting nanofibers. Many polymers used in electrospinning are not readily biodegradable, contributing to long-term environmental pollution. However, the incorporation of isotonic components can potentially accelerate the breakdown of these fibers in natural environments, reducing their ecological footprint.

The energy efficiency of isotonic electrospinning processes is another important environmental consideration. Compared to conventional electrospinning, isotonic solutions often require lower voltages and can be processed at room temperature. This reduction in energy consumption translates to lower greenhouse gas emissions associated with the manufacturing process.

However, it is essential to consider the potential negative impacts of isotonic electrospinning as well. The production and disposal of isotonic solutions may introduce new environmental challenges. For instance, the increased use of salts and other solutes in these solutions could lead to water pollution if not properly managed. Additionally, the long-term effects of nano-scale fibers produced through this method on ecosystems and wildlife are not yet fully understood and require further investigation.

The scalability of isotonic electrospinning also has environmental implications. As the technology moves towards industrial-scale production, the volume of materials used and waste generated will increase significantly. This scaling up necessitates the development of robust waste management and recycling strategies to mitigate potential environmental harm.

In conclusion, while isotonic electrospinning offers several environmental advantages over traditional methods, a comprehensive life cycle assessment is necessary to fully understand its ecological impact. Future research should focus on optimizing the environmental performance of this technology, exploring biodegradable polymer options, and developing closed-loop systems for material recovery and reuse.

One of the primary environmental benefits of isotonic electrospinning is the reduction in solvent usage. Traditional electrospinning often requires large volumes of organic solvents, which can be harmful to the environment and human health. Isotonic solutions, being water-based, significantly reduce the need for these volatile organic compounds, leading to decreased air pollution and lower risks of environmental contamination.

Furthermore, the use of isotonic solutions can enhance the biodegradability of the resulting nanofibers. Many polymers used in electrospinning are not readily biodegradable, contributing to long-term environmental pollution. However, the incorporation of isotonic components can potentially accelerate the breakdown of these fibers in natural environments, reducing their ecological footprint.

The energy efficiency of isotonic electrospinning processes is another important environmental consideration. Compared to conventional electrospinning, isotonic solutions often require lower voltages and can be processed at room temperature. This reduction in energy consumption translates to lower greenhouse gas emissions associated with the manufacturing process.

However, it is essential to consider the potential negative impacts of isotonic electrospinning as well. The production and disposal of isotonic solutions may introduce new environmental challenges. For instance, the increased use of salts and other solutes in these solutions could lead to water pollution if not properly managed. Additionally, the long-term effects of nano-scale fibers produced through this method on ecosystems and wildlife are not yet fully understood and require further investigation.

The scalability of isotonic electrospinning also has environmental implications. As the technology moves towards industrial-scale production, the volume of materials used and waste generated will increase significantly. This scaling up necessitates the development of robust waste management and recycling strategies to mitigate potential environmental harm.

In conclusion, while isotonic electrospinning offers several environmental advantages over traditional methods, a comprehensive life cycle assessment is necessary to fully understand its ecological impact. Future research should focus on optimizing the environmental performance of this technology, exploring biodegradable polymer options, and developing closed-loop systems for material recovery and reuse.

Scalability and Industrial Applications

The scalability and industrial applications of isotonic solutions in electrospinning polymer processes represent a significant area of interest for manufacturers and researchers alike. As the demand for high-quality nanofibers continues to grow across various sectors, the ability to scale up production while maintaining consistent fiber quality becomes paramount.

Isotonic solutions have demonstrated remarkable potential in enhancing the scalability of electrospinning processes. By maintaining a constant osmotic pressure throughout the polymer solution, these solutions enable more stable jet formation and reduce the likelihood of fiber defects during large-scale production. This stability is particularly crucial when transitioning from laboratory-scale experiments to industrial-scale manufacturing.

In industrial settings, the use of isotonic solutions has shown promise in improving process efficiency and product consistency. Manufacturers have reported increased throughput rates and reduced material waste when incorporating isotonic additives into their electrospinning formulations. This not only translates to cost savings but also allows for more efficient use of resources in large-scale operations.

The application of isotonic solution-enhanced electrospinning has found traction in several industries. In the biomedical field, the production of uniform, defect-free nanofiber scaffolds for tissue engineering and drug delivery systems has been significantly improved. The textile industry has also benefited from this technology, with the ability to produce high-performance fabrics with enhanced properties at industrial scales.

Furthermore, the use of isotonic solutions in electrospinning has opened up new possibilities for the production of advanced filtration materials. The improved control over fiber diameter and porosity has led to the development of more efficient air and water filtration systems, capable of meeting the demanding requirements of industrial and environmental applications.

As the technology continues to mature, researchers are exploring ways to further optimize isotonic solution formulations for specific polymer systems and end-use applications. This tailored approach is expected to unlock even greater potential for scalability and industrial adoption across a wider range of sectors, including energy storage, sensors, and protective coatings.

Isotonic solutions have demonstrated remarkable potential in enhancing the scalability of electrospinning processes. By maintaining a constant osmotic pressure throughout the polymer solution, these solutions enable more stable jet formation and reduce the likelihood of fiber defects during large-scale production. This stability is particularly crucial when transitioning from laboratory-scale experiments to industrial-scale manufacturing.

In industrial settings, the use of isotonic solutions has shown promise in improving process efficiency and product consistency. Manufacturers have reported increased throughput rates and reduced material waste when incorporating isotonic additives into their electrospinning formulations. This not only translates to cost savings but also allows for more efficient use of resources in large-scale operations.

The application of isotonic solution-enhanced electrospinning has found traction in several industries. In the biomedical field, the production of uniform, defect-free nanofiber scaffolds for tissue engineering and drug delivery systems has been significantly improved. The textile industry has also benefited from this technology, with the ability to produce high-performance fabrics with enhanced properties at industrial scales.

Furthermore, the use of isotonic solutions in electrospinning has opened up new possibilities for the production of advanced filtration materials. The improved control over fiber diameter and porosity has led to the development of more efficient air and water filtration systems, capable of meeting the demanding requirements of industrial and environmental applications.

As the technology continues to mature, researchers are exploring ways to further optimize isotonic solution formulations for specific polymer systems and end-use applications. This tailored approach is expected to unlock even greater potential for scalability and industrial adoption across a wider range of sectors, including energy storage, sensors, and protective coatings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!