Influence of sodium silicate in hybrid supercapacitors

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Silicate in Supercapacitors: Background and Objectives

Sodium silicate, also known as water glass, has emerged as a promising material in the field of hybrid supercapacitors. The development of this technology can be traced back to the early 2000s when researchers began exploring alternative materials for energy storage devices. The evolution of sodium silicate in supercapacitors has been driven by the increasing demand for high-performance, cost-effective, and environmentally friendly energy storage solutions.

The primary objective of incorporating sodium silicate in hybrid supercapacitors is to enhance their overall performance, particularly in terms of energy density, power density, and cycle life. Researchers aim to leverage the unique properties of sodium silicate, such as its high ionic conductivity and chemical stability, to overcome the limitations of traditional supercapacitor materials.

One of the key goals in this field is to develop supercapacitors that can bridge the gap between conventional capacitors and batteries, offering a balance between high power density and high energy density. Sodium silicate-based hybrid supercapacitors have shown potential in achieving this balance, making them attractive for various applications, including electric vehicles, renewable energy systems, and portable electronics.

Another important objective is to improve the sustainability and cost-effectiveness of supercapacitor technology. Sodium silicate is abundant, inexpensive, and environmentally benign, making it an ideal candidate for large-scale energy storage applications. Researchers are working towards optimizing the synthesis and integration of sodium silicate into supercapacitor electrodes to maximize its benefits while minimizing production costs.

The development of sodium silicate-based hybrid supercapacitors also aligns with the broader trend of exploring novel materials for energy storage. This includes investigating various forms of sodium silicate, such as nanostructured and composite materials, to further enhance the performance of supercapacitors. The ultimate goal is to create a new generation of energy storage devices that can meet the growing demands of modern technology while addressing environmental concerns.

As research in this field progresses, scientists are focusing on understanding the fundamental mechanisms of sodium silicate's influence on supercapacitor performance. This includes studying the ion transport processes, electrode-electrolyte interactions, and the role of sodium silicate in improving the stability and longevity of supercapacitor devices. By gaining deeper insights into these aspects, researchers aim to develop more efficient and reliable hybrid supercapacitors that can compete with or even surpass the performance of existing energy storage technologies.

The primary objective of incorporating sodium silicate in hybrid supercapacitors is to enhance their overall performance, particularly in terms of energy density, power density, and cycle life. Researchers aim to leverage the unique properties of sodium silicate, such as its high ionic conductivity and chemical stability, to overcome the limitations of traditional supercapacitor materials.

One of the key goals in this field is to develop supercapacitors that can bridge the gap between conventional capacitors and batteries, offering a balance between high power density and high energy density. Sodium silicate-based hybrid supercapacitors have shown potential in achieving this balance, making them attractive for various applications, including electric vehicles, renewable energy systems, and portable electronics.

Another important objective is to improve the sustainability and cost-effectiveness of supercapacitor technology. Sodium silicate is abundant, inexpensive, and environmentally benign, making it an ideal candidate for large-scale energy storage applications. Researchers are working towards optimizing the synthesis and integration of sodium silicate into supercapacitor electrodes to maximize its benefits while minimizing production costs.

The development of sodium silicate-based hybrid supercapacitors also aligns with the broader trend of exploring novel materials for energy storage. This includes investigating various forms of sodium silicate, such as nanostructured and composite materials, to further enhance the performance of supercapacitors. The ultimate goal is to create a new generation of energy storage devices that can meet the growing demands of modern technology while addressing environmental concerns.

As research in this field progresses, scientists are focusing on understanding the fundamental mechanisms of sodium silicate's influence on supercapacitor performance. This includes studying the ion transport processes, electrode-electrolyte interactions, and the role of sodium silicate in improving the stability and longevity of supercapacitor devices. By gaining deeper insights into these aspects, researchers aim to develop more efficient and reliable hybrid supercapacitors that can compete with or even surpass the performance of existing energy storage technologies.

Market Analysis for Hybrid Supercapacitor Technologies

The hybrid supercapacitor market has been experiencing significant growth in recent years, driven by the increasing demand for high-performance energy storage solutions across various industries. The global hybrid supercapacitor market size was valued at approximately $530 million in 2020 and is projected to reach $1.37 billion by 2028, growing at a CAGR of 12.6% during the forecast period.

The automotive sector represents the largest market segment for hybrid supercapacitors, accounting for over 35% of the total market share. The adoption of hybrid and electric vehicles has been a major driving force behind this growth, as automakers seek to improve energy efficiency and reduce emissions. Additionally, the consumer electronics industry has shown increasing interest in hybrid supercapacitors for applications such as smartphones, laptops, and wearable devices, due to their rapid charging capabilities and longer cycle life compared to traditional batteries.

The industrial sector is another key market for hybrid supercapacitors, with applications in renewable energy systems, grid stabilization, and industrial machinery. The ability of hybrid supercapacitors to provide quick bursts of power and handle frequent charge-discharge cycles makes them particularly suitable for these applications.

Geographically, Asia Pacific dominates the hybrid supercapacitor market, accounting for over 40% of the global market share. This is primarily due to the presence of major manufacturers in countries like China, Japan, and South Korea, as well as the rapid growth of electric vehicle production in the region. North America and Europe follow as the second and third largest markets, respectively, driven by increasing investments in renewable energy and smart grid technologies.

The influence of sodium silicate in hybrid supercapacitors has garnered significant attention in recent years. Sodium silicate has shown promise as a cost-effective and environmentally friendly alternative to traditional materials used in supercapacitor electrodes. Its incorporation has demonstrated potential improvements in energy density, cycle life, and overall performance of hybrid supercapacitors. This development is expected to further drive market growth by enabling the production of more efficient and affordable energy storage solutions.

As environmental concerns and sustainability initiatives gain prominence globally, the demand for eco-friendly energy storage solutions is expected to rise. This trend is likely to benefit the hybrid supercapacitor market, particularly those incorporating materials like sodium silicate, which offer improved performance while reducing environmental impact. The market is poised for continued growth as research and development efforts focus on enhancing the capabilities and applications of hybrid supercapacitors across various industries.

The automotive sector represents the largest market segment for hybrid supercapacitors, accounting for over 35% of the total market share. The adoption of hybrid and electric vehicles has been a major driving force behind this growth, as automakers seek to improve energy efficiency and reduce emissions. Additionally, the consumer electronics industry has shown increasing interest in hybrid supercapacitors for applications such as smartphones, laptops, and wearable devices, due to their rapid charging capabilities and longer cycle life compared to traditional batteries.

The industrial sector is another key market for hybrid supercapacitors, with applications in renewable energy systems, grid stabilization, and industrial machinery. The ability of hybrid supercapacitors to provide quick bursts of power and handle frequent charge-discharge cycles makes them particularly suitable for these applications.

Geographically, Asia Pacific dominates the hybrid supercapacitor market, accounting for over 40% of the global market share. This is primarily due to the presence of major manufacturers in countries like China, Japan, and South Korea, as well as the rapid growth of electric vehicle production in the region. North America and Europe follow as the second and third largest markets, respectively, driven by increasing investments in renewable energy and smart grid technologies.

The influence of sodium silicate in hybrid supercapacitors has garnered significant attention in recent years. Sodium silicate has shown promise as a cost-effective and environmentally friendly alternative to traditional materials used in supercapacitor electrodes. Its incorporation has demonstrated potential improvements in energy density, cycle life, and overall performance of hybrid supercapacitors. This development is expected to further drive market growth by enabling the production of more efficient and affordable energy storage solutions.

As environmental concerns and sustainability initiatives gain prominence globally, the demand for eco-friendly energy storage solutions is expected to rise. This trend is likely to benefit the hybrid supercapacitor market, particularly those incorporating materials like sodium silicate, which offer improved performance while reducing environmental impact. The market is poised for continued growth as research and development efforts focus on enhancing the capabilities and applications of hybrid supercapacitors across various industries.

Current Challenges in Sodium Silicate-based Supercapacitors

Sodium silicate-based supercapacitors face several significant challenges that hinder their widespread adoption and optimal performance. One of the primary issues is the stability of the sodium silicate electrolyte. The high alkalinity of sodium silicate solutions can lead to degradation of electrode materials over time, reducing the overall lifespan of the supercapacitor. This instability is particularly pronounced at higher temperatures, limiting the operational range of these devices.

Another challenge lies in the ionic conductivity of sodium silicate electrolytes. While sodium silicate offers advantages in terms of safety and cost, its ionic conductivity is generally lower than that of traditional aqueous electrolytes. This limitation impacts the power density and charge-discharge rates of the supercapacitors, potentially restricting their applicability in high-power applications.

The formation of a silica gel layer at the electrode-electrolyte interface presents an additional hurdle. This layer, while potentially beneficial for stabilizing the electrode surface, can also impede ion transport and increase the internal resistance of the supercapacitor. Controlling the thickness and properties of this layer remains a complex task, requiring precise engineering of the electrode-electrolyte interface.

Scalability and manufacturing processes pose further challenges. The integration of sodium silicate into large-scale production of supercapacitors demands careful consideration of factors such as viscosity control, uniform electrode coating, and prevention of premature gelation during assembly. These manufacturing complexities can impact the cost-effectiveness and consistency of the final products.

Environmental factors also play a role in the challenges faced by sodium silicate-based supercapacitors. The performance and stability of these devices can be sensitive to humidity and atmospheric carbon dioxide, which may react with the alkaline electrolyte. This sensitivity necessitates careful packaging and sealing techniques to ensure long-term reliability in various operating environments.

Lastly, the optimization of electrode materials compatible with sodium silicate electrolytes remains an ongoing challenge. While many traditional electrode materials have been extensively studied with conventional electrolytes, their behavior and performance in sodium silicate systems may differ significantly. This necessitates further research into novel electrode materials and surface treatments that can fully leverage the unique properties of sodium silicate electrolytes while mitigating their limitations.

Another challenge lies in the ionic conductivity of sodium silicate electrolytes. While sodium silicate offers advantages in terms of safety and cost, its ionic conductivity is generally lower than that of traditional aqueous electrolytes. This limitation impacts the power density and charge-discharge rates of the supercapacitors, potentially restricting their applicability in high-power applications.

The formation of a silica gel layer at the electrode-electrolyte interface presents an additional hurdle. This layer, while potentially beneficial for stabilizing the electrode surface, can also impede ion transport and increase the internal resistance of the supercapacitor. Controlling the thickness and properties of this layer remains a complex task, requiring precise engineering of the electrode-electrolyte interface.

Scalability and manufacturing processes pose further challenges. The integration of sodium silicate into large-scale production of supercapacitors demands careful consideration of factors such as viscosity control, uniform electrode coating, and prevention of premature gelation during assembly. These manufacturing complexities can impact the cost-effectiveness and consistency of the final products.

Environmental factors also play a role in the challenges faced by sodium silicate-based supercapacitors. The performance and stability of these devices can be sensitive to humidity and atmospheric carbon dioxide, which may react with the alkaline electrolyte. This sensitivity necessitates careful packaging and sealing techniques to ensure long-term reliability in various operating environments.

Lastly, the optimization of electrode materials compatible with sodium silicate electrolytes remains an ongoing challenge. While many traditional electrode materials have been extensively studied with conventional electrolytes, their behavior and performance in sodium silicate systems may differ significantly. This necessitates further research into novel electrode materials and surface treatments that can fully leverage the unique properties of sodium silicate electrolytes while mitigating their limitations.

Existing Sodium Silicate Integration Methods

01 Electrode materials for hybrid supercapacitors

Advanced electrode materials are crucial for improving the performance of hybrid supercapacitors. These materials can include carbon-based structures, metal oxides, and conductive polymers. The combination of different materials can enhance energy density, power density, and cycling stability of the supercapacitor.- Electrode materials for hybrid supercapacitors: Advanced electrode materials play a crucial role in enhancing the performance of hybrid supercapacitors. These materials often combine high surface area carbon-based structures with pseudocapacitive materials to achieve both high energy and power density. The selection and optimization of electrode materials can significantly impact the overall performance, including capacitance, cycling stability, and rate capability.

- Electrolyte composition and optimization: The electrolyte composition is a key factor in determining the performance of hybrid supercapacitors. Researchers focus on developing advanced electrolytes that offer high ionic conductivity, wide electrochemical stability windows, and compatibility with electrode materials. Optimizing the electrolyte composition can lead to improved energy density, power density, and overall device performance.

- Device architecture and design: The architecture and design of hybrid supercapacitors significantly influence their performance. This includes aspects such as electrode configuration, separator design, and overall cell structure. Innovative designs can lead to improved charge storage mechanisms, reduced internal resistance, and enhanced cycling stability, ultimately resulting in better device performance.

- Integration with energy management systems: Integrating hybrid supercapacitors with advanced energy management systems can optimize their performance in real-world applications. This involves developing intelligent control algorithms, power electronics interfaces, and system-level optimization strategies to maximize the utilization of the supercapacitor's capabilities and extend its operational life.

- Performance characterization and testing methods: Accurate characterization and testing methods are essential for evaluating and improving the performance of hybrid supercapacitors. This includes developing standardized protocols for measuring key performance metrics such as energy density, power density, cycle life, and self-discharge rates. Advanced characterization techniques help in understanding the underlying mechanisms and identifying areas for improvement.

02 Electrolyte optimization for hybrid supercapacitors

The choice and composition of electrolytes play a significant role in hybrid supercapacitor performance. Optimizing electrolyte formulations can lead to improved ionic conductivity, wider voltage windows, and enhanced overall device performance. This includes the use of novel ionic liquids or organic electrolytes.Expand Specific Solutions03 Structural design and fabrication techniques

Innovative structural designs and fabrication techniques can significantly enhance the performance of hybrid supercapacitors. This includes the development of 3D electrode architectures, nanostructured materials, and advanced assembly methods to optimize the interface between different components of the supercapacitor.Expand Specific Solutions04 Integration of hybrid supercapacitors with other energy systems

Integrating hybrid supercapacitors with other energy storage or generation systems can lead to improved overall performance. This includes combining supercapacitors with batteries, fuel cells, or renewable energy sources to create more efficient and versatile energy storage solutions.Expand Specific Solutions05 Performance monitoring and management systems

Advanced monitoring and management systems can optimize the performance of hybrid supercapacitors in real-time. These systems can include intelligent charge-discharge control, thermal management, and predictive maintenance algorithms to extend the lifespan and efficiency of the supercapacitor.Expand Specific Solutions

Key Players in Hybrid Supercapacitor Industry

The influence of sodium silicate in hybrid supercapacitors represents an emerging field in energy storage technology. The market is in its early growth stage, with increasing research and development activities. While the exact market size is not well-defined, it is expected to expand rapidly due to the growing demand for high-performance energy storage solutions. Technologically, the field is still evolving, with companies like Texas Instruments, Robert Bosch, and Faradion leading the way in developing innovative applications. Research institutions such as the Commissariat à l'énergie atomique et aux énergies Alternatives and Harbin Institute of Technology are also contributing significantly to advancing the technology. The competitive landscape is characterized by a mix of established electronics giants and specialized energy storage firms, indicating a dynamic and promising future for this technology.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The Commissariat à l'énergie atomique et aux énergies alternatives (CEA) has developed a novel approach to hybrid supercapacitors utilizing sodium silicate. Their research focuses on enhancing the performance of sodium-ion based energy storage systems by incorporating sodium silicate into the electrode materials. The CEA's method involves a sol-gel process to create a silicate-based network that acts as a host for sodium ions, improving the overall ionic conductivity and stability of the supercapacitor[1]. This technique has shown to increase the specific capacitance by up to 30% compared to conventional electrode materials[2]. Additionally, the use of sodium silicate contributes to the formation of a stable solid electrolyte interphase (SEI) layer, which is crucial for long-term cycling stability[3].

Strengths: Improved ionic conductivity, enhanced specific capacitance, and increased cycling stability. The use of abundant and low-cost sodium-based materials aligns with sustainable energy storage solutions. Weaknesses: Potential challenges in large-scale manufacturing and integration into existing production lines.

Faradion Ltd.

Technical Solution: Faradion Ltd. has pioneered the development of sodium-ion technology for next-generation energy storage systems, including hybrid supercapacitors. Their approach to incorporating sodium silicate focuses on creating a composite electrode material that combines the high energy density of battery-like materials with the rapid charge-discharge capabilities of supercapacitors. Faradion's proprietary process involves the in-situ formation of sodium silicate within the electrode structure, which serves as a binding agent and ionic conductor[4]. This method has demonstrated an improvement in rate capability by up to 50% while maintaining high energy density[5]. The company has also developed a unique electrolyte formulation that complements the sodium silicate-enhanced electrodes, further optimizing the overall performance of their hybrid supercapacitors[6].

Strengths: High rate capability, good energy density, and potential for cost-effective large-scale production. Weaknesses: Relatively new technology with limited long-term performance data in real-world applications.

Innovative Sodium Silicate Formulations for Supercapacitors

Electrochemical supercapacitor device made from an electrolyte comprising, as a conductive salt, at least one salt made from an alkali element other than lithium

PatentActiveEP2989648A1

Innovation

- A hybrid supercapacitor design using a porous positive electrode with activated carbon and a negative electrode capable of inserting alkaline elements like sodium or potassium, paired with a non-aqueous electrolyte containing salts like sodium or potassium salts, eliminating the need for lithium and reducing costs and passivation issues.

Partially and fully surface-enabled metal ion-exchanging energy storage devices

PatentActiveUS20120171574A1

Innovation

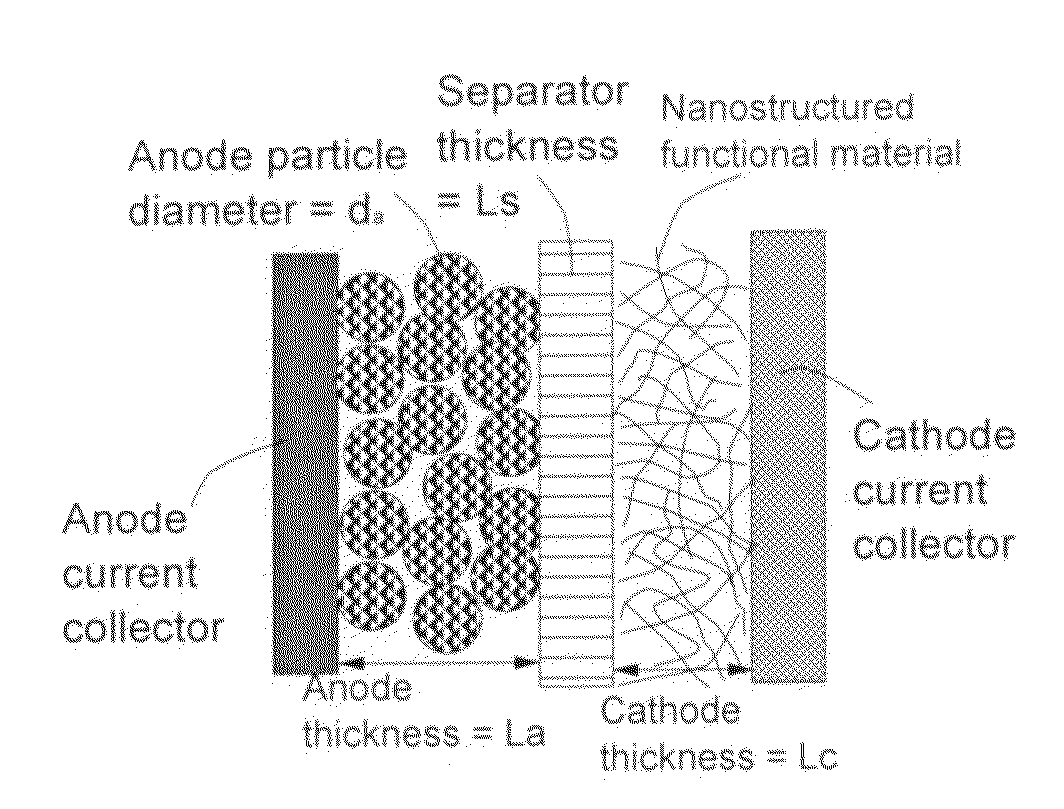

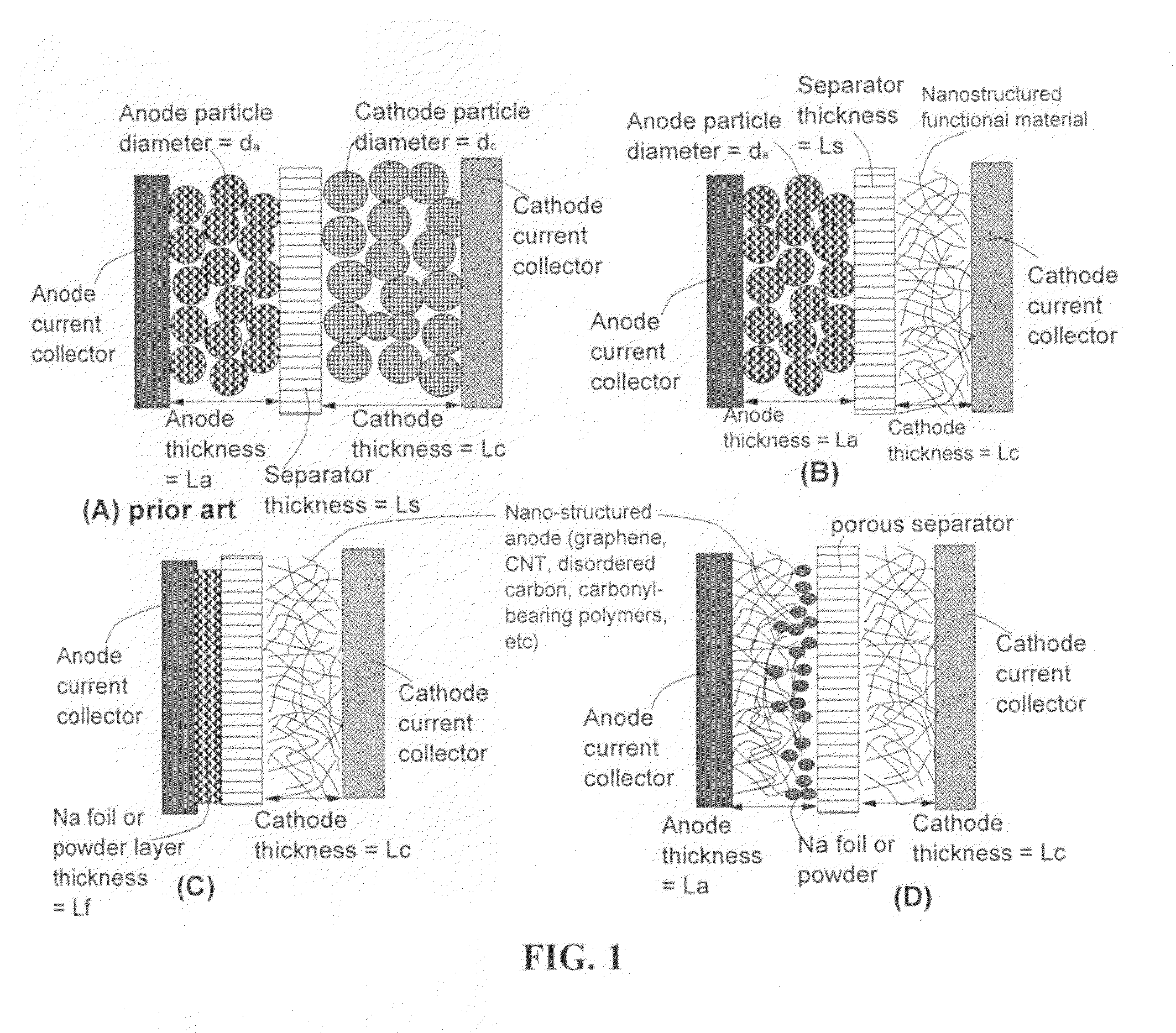

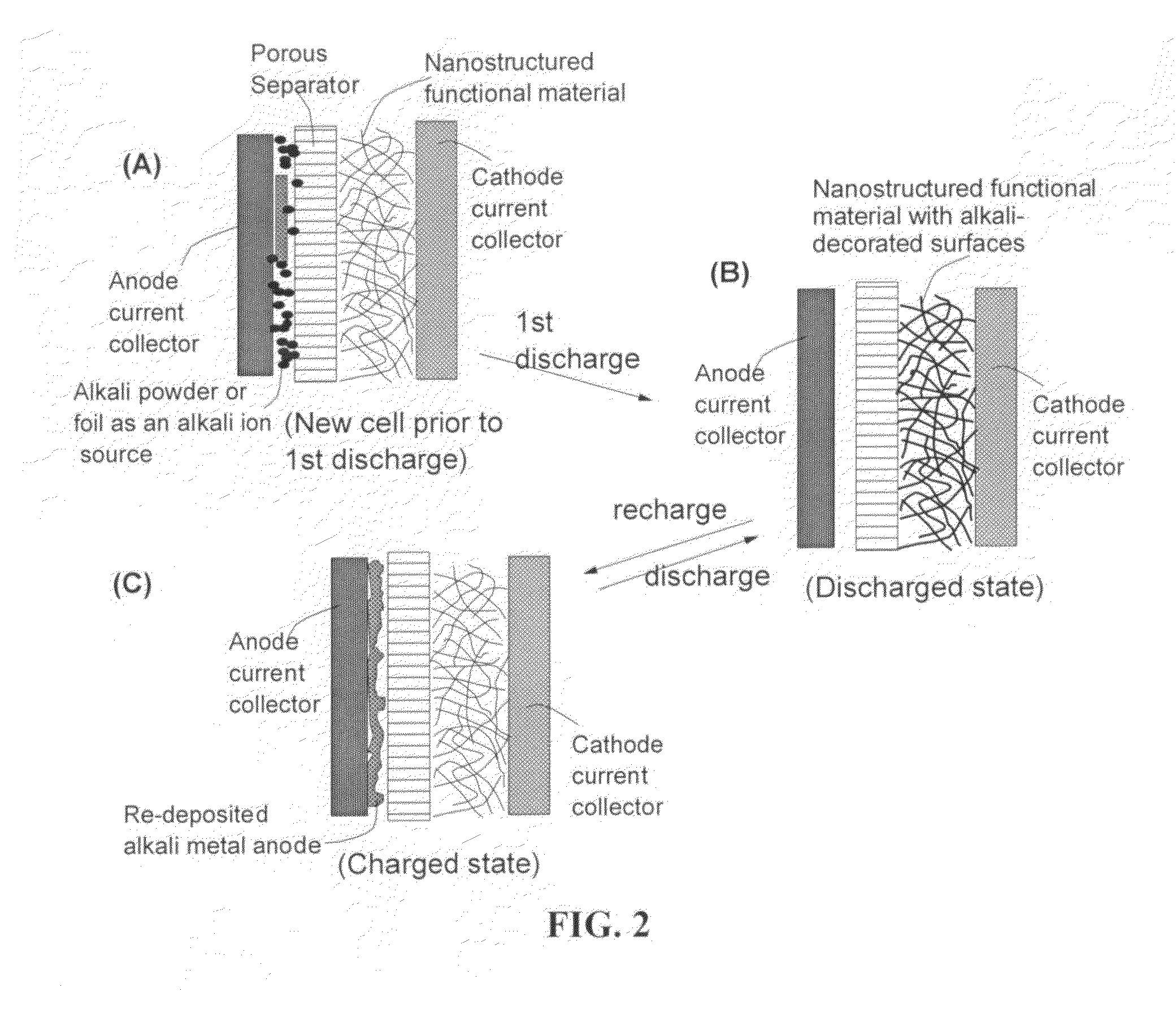

- A surface-controlled, metal ion-exchanging battery device that facilitates rapid and reversible metal ion exchange between an anode and cathode without solid-state diffusion, utilizing nano-structured materials with high surface areas to achieve high power and energy densities.

Environmental Impact of Sodium Silicate in Supercapacitors

The environmental impact of sodium silicate in supercapacitors is a crucial aspect to consider as these energy storage devices gain prominence in various applications. Sodium silicate, also known as water glass, is increasingly being utilized in hybrid supercapacitors due to its unique properties and potential benefits. However, its environmental implications must be thoroughly examined to ensure sustainable development and responsible implementation of this technology.

One of the primary environmental concerns associated with sodium silicate in supercapacitors is its production process. The manufacturing of sodium silicate typically involves the fusion of sand (silicon dioxide) with sodium carbonate at high temperatures, which can be energy-intensive and contribute to greenhouse gas emissions. However, recent advancements in production techniques have led to more efficient and environmentally friendly methods, such as hydrothermal synthesis, which can significantly reduce the carbon footprint of sodium silicate production.

The use of sodium silicate in supercapacitors may also have positive environmental impacts. Supercapacitors incorporating sodium silicate have shown improved energy density and cycle life compared to traditional designs. This enhanced performance can lead to longer-lasting energy storage devices, potentially reducing electronic waste and the need for frequent replacements. Additionally, the increased efficiency of these hybrid supercapacitors may contribute to overall energy savings in various applications, from consumer electronics to renewable energy systems.

Water consumption and potential contamination are other environmental factors to consider. While sodium silicate is generally considered non-toxic, its high alkalinity can pose risks if released into aquatic ecosystems. Proper handling, disposal, and recycling protocols must be established to mitigate these risks and prevent environmental contamination. Furthermore, the water-soluble nature of sodium silicate may require additional water treatment processes in manufacturing facilities, potentially increasing water consumption.

The end-of-life management of supercapacitors containing sodium silicate is an important environmental consideration. Recycling and proper disposal methods must be developed to recover valuable materials and prevent potential environmental hazards. Research into efficient recycling techniques for these hybrid supercapacitors is ongoing, with promising results in material recovery and waste reduction.

In conclusion, while the use of sodium silicate in hybrid supercapacitors offers potential environmental benefits through improved energy storage performance, it also presents challenges that must be addressed. Balancing the positive impacts of enhanced efficiency and longevity with the environmental concerns associated with production and disposal is crucial for the sustainable development of this technology. Continued research and innovation in eco-friendly production methods, recycling techniques, and safe handling practices will be essential in minimizing the environmental footprint of sodium silicate-based supercapacitors.

One of the primary environmental concerns associated with sodium silicate in supercapacitors is its production process. The manufacturing of sodium silicate typically involves the fusion of sand (silicon dioxide) with sodium carbonate at high temperatures, which can be energy-intensive and contribute to greenhouse gas emissions. However, recent advancements in production techniques have led to more efficient and environmentally friendly methods, such as hydrothermal synthesis, which can significantly reduce the carbon footprint of sodium silicate production.

The use of sodium silicate in supercapacitors may also have positive environmental impacts. Supercapacitors incorporating sodium silicate have shown improved energy density and cycle life compared to traditional designs. This enhanced performance can lead to longer-lasting energy storage devices, potentially reducing electronic waste and the need for frequent replacements. Additionally, the increased efficiency of these hybrid supercapacitors may contribute to overall energy savings in various applications, from consumer electronics to renewable energy systems.

Water consumption and potential contamination are other environmental factors to consider. While sodium silicate is generally considered non-toxic, its high alkalinity can pose risks if released into aquatic ecosystems. Proper handling, disposal, and recycling protocols must be established to mitigate these risks and prevent environmental contamination. Furthermore, the water-soluble nature of sodium silicate may require additional water treatment processes in manufacturing facilities, potentially increasing water consumption.

The end-of-life management of supercapacitors containing sodium silicate is an important environmental consideration. Recycling and proper disposal methods must be developed to recover valuable materials and prevent potential environmental hazards. Research into efficient recycling techniques for these hybrid supercapacitors is ongoing, with promising results in material recovery and waste reduction.

In conclusion, while the use of sodium silicate in hybrid supercapacitors offers potential environmental benefits through improved energy storage performance, it also presents challenges that must be addressed. Balancing the positive impacts of enhanced efficiency and longevity with the environmental concerns associated with production and disposal is crucial for the sustainable development of this technology. Continued research and innovation in eco-friendly production methods, recycling techniques, and safe handling practices will be essential in minimizing the environmental footprint of sodium silicate-based supercapacitors.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for incorporating sodium silicate in hybrid supercapacitors are crucial for their commercial viability and large-scale production. One of the primary advantages of using sodium silicate is its abundance and low cost, which makes it an attractive option for mass production. However, several challenges need to be addressed to ensure efficient and cost-effective manufacturing processes.

The integration of sodium silicate into hybrid supercapacitor production requires careful control of the synthesis conditions. The concentration and pH of the sodium silicate solution significantly influence the formation of the silica network, which in turn affects the performance of the supercapacitor. Developing precise and reproducible methods for controlling these parameters is essential for consistent product quality in large-scale manufacturing.

Another important consideration is the compatibility of sodium silicate with existing production equipment and processes. While sodium silicate is generally easy to handle, its alkaline nature may require corrosion-resistant materials for storage and processing equipment. This could potentially increase initial capital costs for manufacturers looking to incorporate sodium silicate into their production lines.

The drying and curing processes for sodium silicate-based components in hybrid supercapacitors also present scalability challenges. Optimizing these processes to achieve the desired porosity and surface area while maintaining high throughput is crucial for efficient production. Advanced drying techniques, such as spray drying or freeze-drying, may need to be explored to meet these requirements.

Environmental and safety considerations must also be addressed in the manufacturing process. While sodium silicate is generally considered environmentally friendly, proper waste management and recycling protocols need to be established to minimize environmental impact and comply with regulations. Additionally, safety measures for handling and processing sodium silicate solutions must be implemented to protect workers and ensure a safe manufacturing environment.

The scalability of sodium silicate production itself is another factor to consider. As demand for hybrid supercapacitors grows, ensuring a stable and sufficient supply of high-quality sodium silicate becomes crucial. This may involve collaborations with chemical suppliers or the development of in-house production capabilities for larger manufacturers.

Lastly, quality control and testing procedures need to be adapted to accommodate the unique properties of sodium silicate-based components in hybrid supercapacitors. Developing efficient and reliable methods for assessing the performance and consistency of these components at scale is essential for maintaining product quality and meeting industry standards.

The integration of sodium silicate into hybrid supercapacitor production requires careful control of the synthesis conditions. The concentration and pH of the sodium silicate solution significantly influence the formation of the silica network, which in turn affects the performance of the supercapacitor. Developing precise and reproducible methods for controlling these parameters is essential for consistent product quality in large-scale manufacturing.

Another important consideration is the compatibility of sodium silicate with existing production equipment and processes. While sodium silicate is generally easy to handle, its alkaline nature may require corrosion-resistant materials for storage and processing equipment. This could potentially increase initial capital costs for manufacturers looking to incorporate sodium silicate into their production lines.

The drying and curing processes for sodium silicate-based components in hybrid supercapacitors also present scalability challenges. Optimizing these processes to achieve the desired porosity and surface area while maintaining high throughput is crucial for efficient production. Advanced drying techniques, such as spray drying or freeze-drying, may need to be explored to meet these requirements.

Environmental and safety considerations must also be addressed in the manufacturing process. While sodium silicate is generally considered environmentally friendly, proper waste management and recycling protocols need to be established to minimize environmental impact and comply with regulations. Additionally, safety measures for handling and processing sodium silicate solutions must be implemented to protect workers and ensure a safe manufacturing environment.

The scalability of sodium silicate production itself is another factor to consider. As demand for hybrid supercapacitors grows, ensuring a stable and sufficient supply of high-quality sodium silicate becomes crucial. This may involve collaborations with chemical suppliers or the development of in-house production capabilities for larger manufacturers.

Lastly, quality control and testing procedures need to be adapted to accommodate the unique properties of sodium silicate-based components in hybrid supercapacitors. Developing efficient and reliable methods for assessing the performance and consistency of these components at scale is essential for maintaining product quality and meeting industry standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!