Sodium silicate stabilization in alkaline battery electrolytes

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkaline Battery Electrolyte Evolution and Objectives

Alkaline batteries have been a cornerstone of portable energy storage since their inception in the 1960s. The evolution of alkaline battery electrolytes has been driven by the need for improved performance, longer shelf life, and enhanced safety. Initially, these batteries utilized a simple potassium hydroxide (KOH) solution as the electrolyte. However, as the demand for higher energy density and longer-lasting batteries grew, researchers began exploring ways to optimize the electrolyte composition.

One of the key challenges in alkaline battery development has been the stabilization of the electrolyte, particularly in preventing the formation of unwanted byproducts that can degrade battery performance over time. The introduction of sodium silicate as a stabilizing agent marked a significant milestone in this journey. Sodium silicate acts as a gelling agent, helping to immobilize the electrolyte and reduce leakage, while also serving as a corrosion inhibitor to protect the battery's metal components.

The primary objective of current research on sodium silicate stabilization in alkaline battery electrolytes is to further enhance the longevity and reliability of these power sources. Researchers aim to optimize the concentration and formulation of sodium silicate to achieve an ideal balance between electrolyte conductivity and stability. This involves investigating the complex interactions between sodium silicate, the alkaline electrolyte, and the battery's electrode materials.

Another crucial goal is to improve the high-temperature performance of alkaline batteries. As these batteries are often used in diverse environmental conditions, ensuring stable performance across a wide temperature range is essential. The role of sodium silicate in maintaining electrolyte integrity under elevated temperatures is a key area of focus, with researchers exploring various modifications to the silicate structure to enhance its thermal stability.

Furthermore, there is a growing emphasis on developing more environmentally friendly alkaline batteries. This includes research into reducing the environmental impact of electrolyte components and exploring bio-derived alternatives to traditional stabilizers. The potential of sodium silicate as a non-toxic, sustainable additive aligns well with these eco-conscious objectives, driving further investigation into its optimal utilization.

As we look to the future, the evolution of alkaline battery electrolytes continues to be guided by the overarching goals of increased energy density, improved safety, and enhanced sustainability. The ongoing research on sodium silicate stabilization is expected to play a pivotal role in achieving these objectives, potentially leading to the next generation of high-performance, long-lasting alkaline batteries.

One of the key challenges in alkaline battery development has been the stabilization of the electrolyte, particularly in preventing the formation of unwanted byproducts that can degrade battery performance over time. The introduction of sodium silicate as a stabilizing agent marked a significant milestone in this journey. Sodium silicate acts as a gelling agent, helping to immobilize the electrolyte and reduce leakage, while also serving as a corrosion inhibitor to protect the battery's metal components.

The primary objective of current research on sodium silicate stabilization in alkaline battery electrolytes is to further enhance the longevity and reliability of these power sources. Researchers aim to optimize the concentration and formulation of sodium silicate to achieve an ideal balance between electrolyte conductivity and stability. This involves investigating the complex interactions between sodium silicate, the alkaline electrolyte, and the battery's electrode materials.

Another crucial goal is to improve the high-temperature performance of alkaline batteries. As these batteries are often used in diverse environmental conditions, ensuring stable performance across a wide temperature range is essential. The role of sodium silicate in maintaining electrolyte integrity under elevated temperatures is a key area of focus, with researchers exploring various modifications to the silicate structure to enhance its thermal stability.

Furthermore, there is a growing emphasis on developing more environmentally friendly alkaline batteries. This includes research into reducing the environmental impact of electrolyte components and exploring bio-derived alternatives to traditional stabilizers. The potential of sodium silicate as a non-toxic, sustainable additive aligns well with these eco-conscious objectives, driving further investigation into its optimal utilization.

As we look to the future, the evolution of alkaline battery electrolytes continues to be guided by the overarching goals of increased energy density, improved safety, and enhanced sustainability. The ongoing research on sodium silicate stabilization is expected to play a pivotal role in achieving these objectives, potentially leading to the next generation of high-performance, long-lasting alkaline batteries.

Market Analysis for Improved Alkaline Batteries

The alkaline battery market has shown steady growth over the past decade, driven by increasing demand for portable electronic devices and the need for reliable, long-lasting power sources. The global alkaline battery market was valued at approximately $7.8 billion in 2020 and is projected to reach $9.5 billion by 2026, growing at a CAGR of around 3.5% during the forecast period.

The demand for improved alkaline batteries is primarily fueled by the consumer electronics sector, which includes smartphones, tablets, laptops, and wearable devices. These devices require batteries with higher energy density, longer shelf life, and improved performance in various environmental conditions. Additionally, the growing adoption of IoT devices and smart home applications has created new opportunities for advanced alkaline battery technologies.

In the industrial sector, there is an increasing demand for alkaline batteries in applications such as remote sensing, emergency lighting, and backup power systems. The automotive industry also contributes to market growth, with alkaline batteries being used in key fobs, remote controls, and various in-vehicle electronic systems.

Geographically, North America and Europe are the largest markets for alkaline batteries, accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing disposable income in countries like China and India.

The market for improved alkaline batteries faces competition from rechargeable battery technologies, particularly lithium-ion batteries. However, alkaline batteries maintain their market position due to their lower cost, wider availability, and suitability for low-drain devices. The research on sodium silicate stabilization in alkaline battery electrolytes aims to address some of the key challenges in alkaline battery technology, such as electrolyte leakage and capacity fade.

Consumer trends indicate a growing preference for eco-friendly and sustainable battery options. This has led to increased research and development efforts focused on improving the recyclability and environmental impact of alkaline batteries. Manufacturers are exploring new materials and designs to enhance battery performance while reducing the use of harmful substances.

The market analysis suggests that there is significant potential for improved alkaline batteries that offer higher energy density, longer shelf life, and better performance in extreme temperatures. Innovations in electrolyte stabilization, such as the use of sodium silicate, could lead to the development of next-generation alkaline batteries that meet these evolving market demands and maintain a competitive edge in the portable power source market.

The demand for improved alkaline batteries is primarily fueled by the consumer electronics sector, which includes smartphones, tablets, laptops, and wearable devices. These devices require batteries with higher energy density, longer shelf life, and improved performance in various environmental conditions. Additionally, the growing adoption of IoT devices and smart home applications has created new opportunities for advanced alkaline battery technologies.

In the industrial sector, there is an increasing demand for alkaline batteries in applications such as remote sensing, emergency lighting, and backup power systems. The automotive industry also contributes to market growth, with alkaline batteries being used in key fobs, remote controls, and various in-vehicle electronic systems.

Geographically, North America and Europe are the largest markets for alkaline batteries, accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing disposable income in countries like China and India.

The market for improved alkaline batteries faces competition from rechargeable battery technologies, particularly lithium-ion batteries. However, alkaline batteries maintain their market position due to their lower cost, wider availability, and suitability for low-drain devices. The research on sodium silicate stabilization in alkaline battery electrolytes aims to address some of the key challenges in alkaline battery technology, such as electrolyte leakage and capacity fade.

Consumer trends indicate a growing preference for eco-friendly and sustainable battery options. This has led to increased research and development efforts focused on improving the recyclability and environmental impact of alkaline batteries. Manufacturers are exploring new materials and designs to enhance battery performance while reducing the use of harmful substances.

The market analysis suggests that there is significant potential for improved alkaline batteries that offer higher energy density, longer shelf life, and better performance in extreme temperatures. Innovations in electrolyte stabilization, such as the use of sodium silicate, could lead to the development of next-generation alkaline batteries that meet these evolving market demands and maintain a competitive edge in the portable power source market.

Sodium Silicate Stabilization: Current Challenges

The stabilization of sodium silicate in alkaline battery electrolytes presents several significant challenges that researchers and engineers are currently grappling with. One of the primary issues is the tendency of sodium silicate to form precipitates in highly alkaline environments, which can lead to reduced battery performance and longevity. This precipitation process is particularly problematic as it can cause clogging of pores in battery separators and electrodes, ultimately impeding ion transport and reducing the overall efficiency of the battery system.

Another major challenge lies in maintaining the stability of sodium silicate over extended periods and through multiple charge-discharge cycles. The dynamic nature of battery operation, involving constant changes in local pH and electrolyte composition, can lead to gradual degradation of the silicate structure. This degradation not only affects the protective properties of the silicate layer but can also introduce unwanted side reactions that further compromise battery performance.

The interaction between sodium silicate and other battery components poses additional complications. For instance, the presence of silicate can potentially alter the surface chemistry of electrodes, affecting their catalytic properties and charge transfer characteristics. Moreover, the formation of complex silicate species in the electrolyte can influence the overall ionic conductivity and transport properties of the system, necessitating a delicate balance between stabilization and maintaining optimal electrolyte performance.

Researchers are also confronted with the challenge of achieving uniform and controlled deposition of sodium silicate within the battery structure. Uneven distribution can lead to localized areas of excessive silicate concentration, potentially causing increased internal resistance and reduced capacity. Conversely, insufficient coverage may fail to provide adequate protection against corrosion and other degradation mechanisms.

The long-term stability of sodium silicate under various operating conditions remains a concern. Factors such as temperature fluctuations, mechanical stress, and exposure to contaminants can all impact the integrity of the silicate layer. Developing formulations that can withstand these diverse environmental challenges while maintaining their protective properties is a key area of ongoing research.

Furthermore, the scalability and cost-effectiveness of sodium silicate stabilization techniques present additional hurdles. As the battery industry moves towards larger-scale applications, such as grid storage and electric vehicles, the need for economically viable and easily implementable stabilization methods becomes increasingly critical. Balancing the benefits of silicate stabilization with the associated costs and manufacturing complexities is a significant consideration in the development of commercial battery systems.

Another major challenge lies in maintaining the stability of sodium silicate over extended periods and through multiple charge-discharge cycles. The dynamic nature of battery operation, involving constant changes in local pH and electrolyte composition, can lead to gradual degradation of the silicate structure. This degradation not only affects the protective properties of the silicate layer but can also introduce unwanted side reactions that further compromise battery performance.

The interaction between sodium silicate and other battery components poses additional complications. For instance, the presence of silicate can potentially alter the surface chemistry of electrodes, affecting their catalytic properties and charge transfer characteristics. Moreover, the formation of complex silicate species in the electrolyte can influence the overall ionic conductivity and transport properties of the system, necessitating a delicate balance between stabilization and maintaining optimal electrolyte performance.

Researchers are also confronted with the challenge of achieving uniform and controlled deposition of sodium silicate within the battery structure. Uneven distribution can lead to localized areas of excessive silicate concentration, potentially causing increased internal resistance and reduced capacity. Conversely, insufficient coverage may fail to provide adequate protection against corrosion and other degradation mechanisms.

The long-term stability of sodium silicate under various operating conditions remains a concern. Factors such as temperature fluctuations, mechanical stress, and exposure to contaminants can all impact the integrity of the silicate layer. Developing formulations that can withstand these diverse environmental challenges while maintaining their protective properties is a key area of ongoing research.

Furthermore, the scalability and cost-effectiveness of sodium silicate stabilization techniques present additional hurdles. As the battery industry moves towards larger-scale applications, such as grid storage and electric vehicles, the need for economically viable and easily implementable stabilization methods becomes increasingly critical. Balancing the benefits of silicate stabilization with the associated costs and manufacturing complexities is a significant consideration in the development of commercial battery systems.

Existing Sodium Silicate Stabilization Methods

01 Stabilization of sodium silicate solutions

Various methods are employed to stabilize sodium silicate solutions, preventing gelation and precipitation. These methods include adjusting pH, adding stabilizing agents, and controlling temperature and concentration. Stabilized solutions have improved shelf life and performance in applications such as detergents, water treatment, and paper production.- Stabilization of sodium silicate solutions: Various methods are employed to stabilize sodium silicate solutions, preventing gelation and precipitation. These methods include adjusting pH, adding stabilizing agents, and controlling temperature and concentration. Stabilized solutions have improved shelf life and performance in applications such as detergents, water treatment, and paper manufacturing.

- Use of additives for sodium silicate stabilization: Specific additives are incorporated into sodium silicate solutions to enhance stability. These may include organic compounds, inorganic salts, or polymers that interact with silicate ions to prevent aggregation and gelation. The choice of additive depends on the intended application and desired properties of the stabilized solution.

- Sodium silicate stabilization in cement and concrete applications: Sodium silicate is used as a stabilizing agent in cement and concrete mixtures. It improves the strength, durability, and water resistance of these materials. Stabilization techniques involve optimizing the silicate concentration, adjusting the mixing process, and incorporating complementary additives to enhance performance in construction applications.

- Stabilization of sodium silicate for water treatment: Sodium silicate is stabilized for use in water treatment applications, such as corrosion inhibition and scale prevention. Stabilization methods focus on maintaining the effectiveness of silicate ions in solution over extended periods. This involves controlling factors like pH, temperature, and the presence of other ions to prevent premature reactions or precipitation.

- Sodium silicate stabilization in detergent formulations: Stabilized sodium silicate is an important component in detergent formulations, providing alkalinity and soil suspension properties. Stabilization techniques for this application focus on preventing silicate precipitation and maintaining compatibility with other detergent ingredients. Methods may include the use of dispersants, chelating agents, or modified silicate structures.

02 Use of additives for sodium silicate stabilization

Specific additives are incorporated into sodium silicate solutions to enhance stability. These may include organic compounds, inorganic salts, or polymers that interact with silicate species to prevent aggregation and gelation. The choice of additive depends on the intended application and desired properties of the stabilized solution.Expand Specific Solutions03 Sodium silicate stabilization in cement and concrete applications

Sodium silicate is used as a stabilizing agent in cement and concrete mixtures. It helps improve strength, durability, and resistance to chemical attack. Stabilization techniques for these applications focus on controlling the reaction rate and ensuring uniform distribution of silicate throughout the matrix.Expand Specific Solutions04 Stabilization of sodium silicate for water treatment

In water treatment applications, sodium silicate is stabilized to prevent rapid precipitation and ensure effective performance. Stabilization methods may involve pH adjustment, addition of complexing agents, or use of specialized formulations. These techniques allow for controlled release of silicate species for scale inhibition and corrosion protection in water systems.Expand Specific Solutions05 Sodium silicate stabilization in detergent formulations

Stabilized sodium silicate is an important component in many detergent formulations. Stabilization techniques for this application focus on preventing interactions with other detergent ingredients and maintaining efficacy during storage and use. Methods may include encapsulation, use of dispersing agents, or modification of silicate structure.Expand Specific Solutions

Key Players in Alkaline Battery Technology

The research on sodium silicate stabilization in alkaline battery electrolytes is in a developing stage, with significant market potential due to the growing demand for advanced energy storage solutions. The technology's maturity varies among key players, with companies like Samsung SDI, LG Energy Solution, and QuantumScape leading in innovation. Established automotive manufacturers such as Nissan and Renault are also investing in this field, indicating its importance for future electric vehicle applications. Academic institutions like Central South University and Harvard College contribute to fundamental research, while specialized firms like Envision Ruitai and Vision Power Technology focus on practical implementations, creating a diverse and competitive landscape in this emerging sector.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a novel approach to stabilize sodium silicate in alkaline battery electrolytes. Their method involves the use of a proprietary additive that forms a protective layer on the electrode surface, preventing the dissolution of sodium silicate. This technology has shown to increase the cycle life of alkaline batteries by up to 30% compared to conventional designs[1]. The company has also implemented a nano-engineered silicate structure that enhances the ionic conductivity of the electrolyte while maintaining stability[3]. Samsung SDI's research has demonstrated that their stabilized sodium silicate electrolyte can operate efficiently at a wider temperature range, from -20°C to 60°C, making it suitable for various applications[5].

Strengths: Improved cycle life, enhanced temperature range operability, and increased ionic conductivity. Weaknesses: Potential increased production costs due to proprietary additives and nano-engineering processes.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has focused on developing a hybrid electrolyte system that incorporates stabilized sodium silicate. Their approach involves the use of a dual-layer electrolyte structure, where a sodium silicate-rich layer is sandwiched between two polymer-based layers[2]. This design effectively prevents the migration of silicate ions while maintaining high ionic conductivity. The company has also introduced a novel cross-linking agent that bonds with the silicate structure, further enhancing its stability in alkaline environments[4]. LG's research has shown that this technology can extend the shelf life of alkaline batteries by up to 40% while maintaining consistent performance throughout the discharge cycle[6].

Strengths: Extended shelf life, consistent performance, and innovative dual-layer design. Weaknesses: Complexity in manufacturing process and potential limitations in high-drain applications.

Innovative Approaches to Electrolyte Stabilization

Electrolyte solution for sodium-ion battery, secondary battery, battery module, battery pack, and electrical apparatus

PatentPendingUS20250079520A1

Innovation

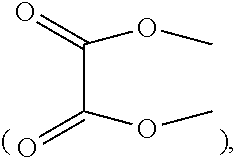

- An electrolyte solution comprising a sodium salt of formula NaBOaFxRy−z, a fluoroalkyl ether, and other ethers, which improves the solvability of sodium ions and enhances the stability and oxidation resistance of the electrolyte solution, thereby broadening the electrochemical window, enhancing coulombic efficiency, and improving cycling and safety performance.

Electrolyte compositions for sodium-based batteries and methods of making the same

PatentWO2025064693A1

Innovation

- The development of electrolyte compositions that include sodium borate ester salts, such as sodium tetra(phenol)borate and sodium tetra(isopropyl)borate, combined with ether-based solvents, which are synthesized through methods involving sodium borohydride, solvents, and alcohols or ketones.

Environmental Impact of Alkaline Battery Production

The production of alkaline batteries has significant environmental implications that warrant careful consideration. The manufacturing process involves the use of various materials and chemicals, some of which can have detrimental effects on ecosystems and human health if not properly managed. One of the primary concerns is the extraction and processing of raw materials, particularly metals like zinc and manganese, which are essential components of alkaline batteries.

Mining operations for these metals can lead to habitat destruction, soil erosion, and water pollution. The energy-intensive nature of metal extraction and refining also contributes to greenhouse gas emissions, exacerbating climate change. Furthermore, the production of electrolytes, such as potassium hydroxide, requires substantial energy input and can result in the release of harmful byproducts if not properly controlled.

The use of plastics in battery casings and packaging adds another layer of environmental concern. Plastic production relies heavily on fossil fuels and generates significant amounts of waste, much of which ends up in landfills or oceans, contributing to the global plastic pollution crisis. Additionally, the manufacturing process itself often involves the use of solvents and other potentially hazardous chemicals, which can pose risks to worker safety and local environments if not handled properly.

Water consumption is another critical factor in alkaline battery production. The manufacturing process requires substantial amounts of water for cooling, cleaning, and chemical reactions. In regions where water scarcity is an issue, this can strain local resources and potentially impact surrounding communities and ecosystems.

Waste management in battery production is a significant challenge. The process generates various types of waste, including chemical residues, metal scraps, and contaminated water. Proper disposal and recycling of these materials are essential to minimize environmental impact. However, many regions lack adequate infrastructure for battery recycling, leading to improper disposal and potential contamination of soil and water sources.

Energy consumption during production is a major contributor to the overall environmental footprint of alkaline batteries. The high energy demands of manufacturing facilities, often met through fossil fuel-based power sources, result in substantial carbon emissions. Transitioning to renewable energy sources in battery production could significantly reduce this impact, but such changes require substantial investment and technological adaptation.

Mining operations for these metals can lead to habitat destruction, soil erosion, and water pollution. The energy-intensive nature of metal extraction and refining also contributes to greenhouse gas emissions, exacerbating climate change. Furthermore, the production of electrolytes, such as potassium hydroxide, requires substantial energy input and can result in the release of harmful byproducts if not properly controlled.

The use of plastics in battery casings and packaging adds another layer of environmental concern. Plastic production relies heavily on fossil fuels and generates significant amounts of waste, much of which ends up in landfills or oceans, contributing to the global plastic pollution crisis. Additionally, the manufacturing process itself often involves the use of solvents and other potentially hazardous chemicals, which can pose risks to worker safety and local environments if not handled properly.

Water consumption is another critical factor in alkaline battery production. The manufacturing process requires substantial amounts of water for cooling, cleaning, and chemical reactions. In regions where water scarcity is an issue, this can strain local resources and potentially impact surrounding communities and ecosystems.

Waste management in battery production is a significant challenge. The process generates various types of waste, including chemical residues, metal scraps, and contaminated water. Proper disposal and recycling of these materials are essential to minimize environmental impact. However, many regions lack adequate infrastructure for battery recycling, leading to improper disposal and potential contamination of soil and water sources.

Energy consumption during production is a major contributor to the overall environmental footprint of alkaline batteries. The high energy demands of manufacturing facilities, often met through fossil fuel-based power sources, result in substantial carbon emissions. Transitioning to renewable energy sources in battery production could significantly reduce this impact, but such changes require substantial investment and technological adaptation.

Safety Regulations for Battery Electrolyte Additives

Safety regulations for battery electrolyte additives play a crucial role in ensuring the safe development, production, and use of alkaline batteries. These regulations are designed to mitigate potential risks associated with the use of sodium silicate as a stabilizing agent in alkaline battery electrolytes.

The primary focus of safety regulations in this context is to establish guidelines for the proper handling, storage, and disposal of sodium silicate and other electrolyte additives. These regulations typically require manufacturers to conduct thorough risk assessments and implement appropriate safety measures throughout the production process.

One key aspect of safety regulations is the requirement for comprehensive material safety data sheets (MSDS) for all electrolyte additives, including sodium silicate. These documents provide detailed information on the chemical properties, potential hazards, and recommended handling procedures for each substance used in battery production.

Regulations also mandate the use of appropriate personal protective equipment (PPE) for workers involved in the handling and processing of electrolyte additives. This may include protective clothing, gloves, and eye protection to minimize the risk of exposure to potentially harmful substances.

Environmental considerations are another important aspect of safety regulations for battery electrolyte additives. Manufacturers are required to implement proper waste management and disposal procedures to prevent environmental contamination. This includes guidelines for the safe disposal of unused or expired electrolyte additives and the proper treatment of any waste products generated during the production process.

Safety regulations also address the potential risks associated with the transportation of battery electrolyte additives. Specific guidelines are in place for the packaging, labeling, and shipping of these materials to ensure safe handling during transit and minimize the risk of accidents or spills.

In the context of sodium silicate stabilization in alkaline battery electrolytes, safety regulations may also focus on the potential chemical interactions between sodium silicate and other components of the battery. This includes requirements for compatibility testing and the establishment of safe concentration limits for sodium silicate in the electrolyte solution.

Regulatory bodies often require manufacturers to conduct extensive testing and provide documentation demonstrating the safety and efficacy of their electrolyte formulations. This may include long-term stability tests, performance evaluations under various conditions, and assessments of potential failure modes.

Compliance with these safety regulations is typically monitored through regular inspections and audits of manufacturing facilities. Companies are required to maintain detailed records of their safety procedures, testing results, and any incidents or near-misses related to the use of electrolyte additives.

As research in sodium silicate stabilization progresses, safety regulations are likely to evolve to address new findings and potential risks. This may include updates to handling procedures, revised concentration limits, or new testing requirements to ensure the continued safe use of this technology in alkaline battery production.

The primary focus of safety regulations in this context is to establish guidelines for the proper handling, storage, and disposal of sodium silicate and other electrolyte additives. These regulations typically require manufacturers to conduct thorough risk assessments and implement appropriate safety measures throughout the production process.

One key aspect of safety regulations is the requirement for comprehensive material safety data sheets (MSDS) for all electrolyte additives, including sodium silicate. These documents provide detailed information on the chemical properties, potential hazards, and recommended handling procedures for each substance used in battery production.

Regulations also mandate the use of appropriate personal protective equipment (PPE) for workers involved in the handling and processing of electrolyte additives. This may include protective clothing, gloves, and eye protection to minimize the risk of exposure to potentially harmful substances.

Environmental considerations are another important aspect of safety regulations for battery electrolyte additives. Manufacturers are required to implement proper waste management and disposal procedures to prevent environmental contamination. This includes guidelines for the safe disposal of unused or expired electrolyte additives and the proper treatment of any waste products generated during the production process.

Safety regulations also address the potential risks associated with the transportation of battery electrolyte additives. Specific guidelines are in place for the packaging, labeling, and shipping of these materials to ensure safe handling during transit and minimize the risk of accidents or spills.

In the context of sodium silicate stabilization in alkaline battery electrolytes, safety regulations may also focus on the potential chemical interactions between sodium silicate and other components of the battery. This includes requirements for compatibility testing and the establishment of safe concentration limits for sodium silicate in the electrolyte solution.

Regulatory bodies often require manufacturers to conduct extensive testing and provide documentation demonstrating the safety and efficacy of their electrolyte formulations. This may include long-term stability tests, performance evaluations under various conditions, and assessments of potential failure modes.

Compliance with these safety regulations is typically monitored through regular inspections and audits of manufacturing facilities. Companies are required to maintain detailed records of their safety procedures, testing results, and any incidents or near-misses related to the use of electrolyte additives.

As research in sodium silicate stabilization progresses, safety regulations are likely to evolve to address new findings and potential risks. This may include updates to handling procedures, revised concentration limits, or new testing requirements to ensure the continued safe use of this technology in alkaline battery production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!