Enhancing flax fiber properties with sodium silicate treatment

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flax Fiber Enhancement Goals

The enhancement of flax fiber properties through sodium silicate treatment represents a significant goal in the textile and composite industries. This technological advancement aims to improve the mechanical, physical, and chemical characteristics of flax fibers, thereby expanding their potential applications and market value.

One primary objective is to increase the tensile strength and modulus of flax fibers. By treating the fibers with sodium silicate, researchers seek to reinforce the fiber structure, leading to enhanced load-bearing capacity and improved resistance to deformation under stress. This improvement in mechanical properties is crucial for the fiber's performance in high-strength composite materials and technical textiles.

Another key goal is to enhance the fiber's moisture resistance and dimensional stability. Flax fibers are naturally hydrophilic, which can lead to swelling and degradation in humid environments. Sodium silicate treatment aims to create a protective barrier on the fiber surface, reducing water absorption and improving the fiber's stability in varying environmental conditions. This enhancement is particularly important for applications in outdoor and moisture-prone settings.

Improving the fiber's interfacial adhesion with various matrix materials is also a critical objective. Enhanced bonding between the flax fibers and polymer matrices in composites can lead to better stress transfer and overall mechanical performance of the final product. The sodium silicate treatment is expected to modify the fiber surface chemistry, promoting stronger interactions with matrix materials.

Researchers are also focusing on increasing the thermal stability of flax fibers through this treatment. By improving the fiber's resistance to degradation at elevated temperatures, the goal is to expand its use in applications that require higher processing temperatures or exposure to heat during service life.

Additionally, there is a strong emphasis on enhancing the fiber's durability and resistance to biological degradation. Sodium silicate treatment is being explored as a means to protect flax fibers from microbial attack and extend their lifespan, particularly in applications where long-term performance is crucial.

Finally, the treatment aims to improve the fiber's processability and compatibility with various manufacturing techniques. This includes enhancing the fiber's surface smoothness for better handling during textile production and improving its dispersibility in polymer matrices for composite manufacturing.

One primary objective is to increase the tensile strength and modulus of flax fibers. By treating the fibers with sodium silicate, researchers seek to reinforce the fiber structure, leading to enhanced load-bearing capacity and improved resistance to deformation under stress. This improvement in mechanical properties is crucial for the fiber's performance in high-strength composite materials and technical textiles.

Another key goal is to enhance the fiber's moisture resistance and dimensional stability. Flax fibers are naturally hydrophilic, which can lead to swelling and degradation in humid environments. Sodium silicate treatment aims to create a protective barrier on the fiber surface, reducing water absorption and improving the fiber's stability in varying environmental conditions. This enhancement is particularly important for applications in outdoor and moisture-prone settings.

Improving the fiber's interfacial adhesion with various matrix materials is also a critical objective. Enhanced bonding between the flax fibers and polymer matrices in composites can lead to better stress transfer and overall mechanical performance of the final product. The sodium silicate treatment is expected to modify the fiber surface chemistry, promoting stronger interactions with matrix materials.

Researchers are also focusing on increasing the thermal stability of flax fibers through this treatment. By improving the fiber's resistance to degradation at elevated temperatures, the goal is to expand its use in applications that require higher processing temperatures or exposure to heat during service life.

Additionally, there is a strong emphasis on enhancing the fiber's durability and resistance to biological degradation. Sodium silicate treatment is being explored as a means to protect flax fibers from microbial attack and extend their lifespan, particularly in applications where long-term performance is crucial.

Finally, the treatment aims to improve the fiber's processability and compatibility with various manufacturing techniques. This includes enhancing the fiber's surface smoothness for better handling during textile production and improving its dispersibility in polymer matrices for composite manufacturing.

Market Demand Analysis

The market demand for enhanced flax fiber properties through sodium silicate treatment has been steadily growing in recent years. This trend is driven by the increasing focus on sustainable and eco-friendly materials across various industries, particularly in textiles, composites, and construction.

In the textile industry, there is a rising demand for natural fibers with improved properties to compete with synthetic alternatives. Flax fibers treated with sodium silicate offer enhanced strength, durability, and moisture resistance, making them more attractive for high-performance apparel, home textiles, and technical textiles. The global natural fiber composites market, which includes flax fibers, is expected to grow significantly in the coming years, with a strong emphasis on improved fiber properties.

The automotive sector has shown increasing interest in natural fiber composites, including those made with enhanced flax fibers. As automakers strive to reduce vehicle weight and improve fuel efficiency, the demand for lightweight, strong, and environmentally friendly materials continues to rise. Sodium silicate-treated flax fibers offer a promising solution to meet these requirements.

In the construction industry, there is a growing trend towards sustainable building materials. Enhanced flax fibers can be used in various applications, such as insulation, reinforcement in concrete and plaster, and as a component in bio-based composites. The improved properties achieved through sodium silicate treatment make flax fibers more suitable for these demanding applications.

The packaging industry is another sector showing increased demand for enhanced natural fibers. As consumers and regulators push for more sustainable packaging solutions, treated flax fibers offer an attractive alternative to traditional materials. The improved strength and moisture resistance of sodium silicate-treated flax fibers make them suitable for various packaging applications.

Market analysis indicates that regions with strong agricultural sectors and a focus on sustainability, such as Europe and North America, are likely to be key markets for enhanced flax fiber products. Additionally, emerging economies with growing manufacturing sectors are expected to contribute significantly to the demand for these improved natural fibers.

The potential market size for enhanced flax fiber products is substantial, considering the diverse range of applications across multiple industries. As research and development in this area continue to advance, it is anticipated that new applications and markets will emerge, further driving demand for sodium silicate-treated flax fibers.

In the textile industry, there is a rising demand for natural fibers with improved properties to compete with synthetic alternatives. Flax fibers treated with sodium silicate offer enhanced strength, durability, and moisture resistance, making them more attractive for high-performance apparel, home textiles, and technical textiles. The global natural fiber composites market, which includes flax fibers, is expected to grow significantly in the coming years, with a strong emphasis on improved fiber properties.

The automotive sector has shown increasing interest in natural fiber composites, including those made with enhanced flax fibers. As automakers strive to reduce vehicle weight and improve fuel efficiency, the demand for lightweight, strong, and environmentally friendly materials continues to rise. Sodium silicate-treated flax fibers offer a promising solution to meet these requirements.

In the construction industry, there is a growing trend towards sustainable building materials. Enhanced flax fibers can be used in various applications, such as insulation, reinforcement in concrete and plaster, and as a component in bio-based composites. The improved properties achieved through sodium silicate treatment make flax fibers more suitable for these demanding applications.

The packaging industry is another sector showing increased demand for enhanced natural fibers. As consumers and regulators push for more sustainable packaging solutions, treated flax fibers offer an attractive alternative to traditional materials. The improved strength and moisture resistance of sodium silicate-treated flax fibers make them suitable for various packaging applications.

Market analysis indicates that regions with strong agricultural sectors and a focus on sustainability, such as Europe and North America, are likely to be key markets for enhanced flax fiber products. Additionally, emerging economies with growing manufacturing sectors are expected to contribute significantly to the demand for these improved natural fibers.

The potential market size for enhanced flax fiber products is substantial, considering the diverse range of applications across multiple industries. As research and development in this area continue to advance, it is anticipated that new applications and markets will emerge, further driving demand for sodium silicate-treated flax fibers.

Current Challenges

The enhancement of flax fiber properties through sodium silicate treatment faces several significant challenges that need to be addressed for widespread adoption and optimal results. One of the primary obstacles is achieving consistent and uniform treatment across all fibers. The heterogeneous nature of natural fibers, including variations in diameter, surface characteristics, and chemical composition, makes it difficult to ensure that the sodium silicate solution penetrates and coats each fiber evenly. This inconsistency can lead to variable improvements in fiber properties, potentially compromising the overall performance of the treated fibers.

Another challenge lies in optimizing the concentration and application method of the sodium silicate solution. Too high a concentration may lead to excessive silica deposition, resulting in brittle fibers, while too low a concentration may not provide sufficient reinforcement. Finding the right balance is crucial for maximizing the benefits of the treatment without compromising the inherent flexibility and strength of the flax fibers.

The environmental impact of the sodium silicate treatment process is also a concern. While sodium silicate itself is generally considered environmentally friendly, the treatment process may involve the use of additional chemicals or energy-intensive steps. Developing eco-friendly and sustainable treatment methods that minimize water usage, reduce chemical waste, and lower energy consumption is essential for the long-term viability of this technology.

Scalability presents another significant hurdle. While sodium silicate treatment may be effective on a laboratory scale, translating this process to industrial-scale production poses several challenges. These include designing efficient treatment systems that can handle large volumes of fibers, ensuring uniform treatment in bulk processing, and developing cost-effective methods for solution recovery and recycling to minimize waste and reduce operational costs.

The durability and long-term stability of the treated fibers are also areas of concern. It is crucial to ensure that the improvements in fiber properties, such as increased tensile strength and moisture resistance, are maintained over time and under various environmental conditions. This includes resistance to degradation from UV exposure, temperature fluctuations, and repeated mechanical stress.

Furthermore, the compatibility of sodium silicate-treated flax fibers with different matrix materials in composite applications needs to be thoroughly investigated. The surface modifications resulting from the treatment may affect the fiber-matrix interface, potentially impacting the overall performance of the composite materials. Optimizing the treatment process to enhance fiber-matrix adhesion without compromising other desirable properties is a complex challenge that requires extensive research and testing.

Lastly, the economic viability of sodium silicate treatment for flax fibers remains a significant consideration. The additional processing step and materials cost must be justified by the improvements in fiber properties and the resulting enhancement in final product performance. Striking a balance between cost-effectiveness and performance enhancement is crucial for the widespread adoption of this technology in various industries.

Another challenge lies in optimizing the concentration and application method of the sodium silicate solution. Too high a concentration may lead to excessive silica deposition, resulting in brittle fibers, while too low a concentration may not provide sufficient reinforcement. Finding the right balance is crucial for maximizing the benefits of the treatment without compromising the inherent flexibility and strength of the flax fibers.

The environmental impact of the sodium silicate treatment process is also a concern. While sodium silicate itself is generally considered environmentally friendly, the treatment process may involve the use of additional chemicals or energy-intensive steps. Developing eco-friendly and sustainable treatment methods that minimize water usage, reduce chemical waste, and lower energy consumption is essential for the long-term viability of this technology.

Scalability presents another significant hurdle. While sodium silicate treatment may be effective on a laboratory scale, translating this process to industrial-scale production poses several challenges. These include designing efficient treatment systems that can handle large volumes of fibers, ensuring uniform treatment in bulk processing, and developing cost-effective methods for solution recovery and recycling to minimize waste and reduce operational costs.

The durability and long-term stability of the treated fibers are also areas of concern. It is crucial to ensure that the improvements in fiber properties, such as increased tensile strength and moisture resistance, are maintained over time and under various environmental conditions. This includes resistance to degradation from UV exposure, temperature fluctuations, and repeated mechanical stress.

Furthermore, the compatibility of sodium silicate-treated flax fibers with different matrix materials in composite applications needs to be thoroughly investigated. The surface modifications resulting from the treatment may affect the fiber-matrix interface, potentially impacting the overall performance of the composite materials. Optimizing the treatment process to enhance fiber-matrix adhesion without compromising other desirable properties is a complex challenge that requires extensive research and testing.

Lastly, the economic viability of sodium silicate treatment for flax fibers remains a significant consideration. The additional processing step and materials cost must be justified by the improvements in fiber properties and the resulting enhancement in final product performance. Striking a balance between cost-effectiveness and performance enhancement is crucial for the widespread adoption of this technology in various industries.

Sodium Silicate Solutions

01 Mechanical properties of flax fibers

Flax fibers exhibit excellent mechanical properties, including high tensile strength and modulus. These properties make them suitable for use in various applications, particularly as reinforcement in composite materials. The mechanical characteristics of flax fibers can be further enhanced through various treatment processes.- Mechanical properties of flax fibers: Flax fibers exhibit excellent mechanical properties, including high tensile strength and modulus. These properties make them suitable for use in various applications, particularly as reinforcements in composite materials. The mechanical characteristics of flax fibers can be further enhanced through various treatment processes.

- Chemical composition and structure of flax fibers: Flax fibers are primarily composed of cellulose, hemicellulose, and lignin. The unique chemical composition and structural arrangement of these components contribute to the fiber's properties. Understanding the chemical structure is crucial for developing effective treatment methods and optimizing fiber performance in various applications.

- Surface modification of flax fibers: Various surface modification techniques can be applied to flax fibers to improve their properties. These methods include chemical treatments, plasma treatments, and coating processes. Surface modifications can enhance the fiber's compatibility with matrix materials in composites, improve moisture resistance, and alter surface roughness for better adhesion.

- Thermal and fire-resistant properties of flax fibers: Flax fibers possess inherent thermal stability and can be further treated to enhance their fire-resistant properties. These characteristics make flax fibers suitable for applications requiring heat resistance or flame retardancy. Various methods can be employed to improve the thermal and fire-resistant properties of flax fibers.

- Biodegradability and environmental aspects of flax fibers: Flax fibers are biodegradable and environmentally friendly, making them an attractive alternative to synthetic fibers in various applications. Their renewable nature and low environmental impact contribute to their growing popularity in sustainable product development. The biodegradability of flax fibers can be controlled or enhanced through specific treatments.

02 Chemical composition and structure of flax fibers

Flax fibers are primarily composed of cellulose, hemicellulose, and lignin. The unique chemical composition and structural arrangement of these components contribute to the fiber's properties. Understanding the chemical structure is crucial for developing effective treatment methods and optimizing fiber performance in various applications.Expand Specific Solutions03 Surface modification of flax fibers

Various surface modification techniques can be applied to flax fibers to improve their properties and compatibility with different matrices. These modifications can enhance the fiber's adhesion, moisture resistance, and overall performance in composite materials. Common methods include chemical treatments, plasma treatments, and coating processes.Expand Specific Solutions04 Thermal and fire-resistant properties of flax fibers

Flax fibers possess inherent thermal stability and fire-resistant properties. These characteristics can be further enhanced through various treatments and additives. The thermal properties of flax fibers make them suitable for applications requiring heat resistance and fire retardancy.Expand Specific Solutions05 Environmental and sustainability aspects of flax fibers

Flax fibers are known for their eco-friendly nature and sustainability. They are biodegradable, renewable, and require less energy to produce compared to synthetic fibers. The use of flax fibers in various applications contributes to reducing environmental impact and promoting sustainable material solutions.Expand Specific Solutions

Key Industry Players

The market for enhancing flax fiber properties with sodium silicate treatment is in an early development stage, characterized by ongoing research and limited commercial applications. The global flax fiber market, valued at approximately $300 million in 2020, is expected to grow steadily due to increasing demand for sustainable materials. Technologically, the sodium silicate treatment process is still evolving, with research institutions like Centre National de la Recherche Scientifique and universities such as Taiyuan University of Technology and Donghua University leading the way. Companies like Lenzing AG and Kingdom Holdings Ltd. are exploring potential industrial applications, but the technology's maturity remains low, requiring further development and optimization for large-scale implementation.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed an innovative sodium silicate treatment for flax fibers, focusing on improving their mechanical and physical properties. The process involves immersing flax fibers in a sodium silicate solution, followed by a controlled drying and curing process. This treatment results in the formation of a silica-rich layer on the fiber surface, enhancing its interfacial adhesion with polymer matrices. The treated fibers exhibit improved tensile strength, up to 20% higher than untreated fibers [1], and enhanced moisture resistance. Additionally, the treatment reduces the hydrophilic nature of flax fibers, making them more compatible with hydrophobic polymer matrices commonly used in composites [3].

Strengths: Significantly improves mechanical properties and moisture resistance of flax fibers. Enhances compatibility with polymer matrices. Weaknesses: May require additional processing steps, potentially increasing production costs.

Taiyuan University of Technology

Technical Solution: Taiyuan University of Technology has developed a modified sodium silicate treatment for flax fibers, focusing on optimizing the treatment conditions for enhanced fiber properties. Their approach involves a two-step process: first, an alkali pre-treatment to remove impurities and increase fiber reactivity, followed by a sodium silicate treatment under controlled pH and temperature conditions. This method has shown to improve the fiber's tensile strength by up to 25% and reduce water absorption by 30% compared to untreated fibers [2]. The research team has also investigated the use of silane coupling agents in combination with sodium silicate to further enhance the fiber-matrix interface in composite materials [4].

Strengths: Comprehensive approach combining alkali pre-treatment with sodium silicate treatment. Significant improvements in mechanical properties and moisture resistance. Weaknesses: Two-step process may increase production time and complexity.

Core Innovations

Method for preparing flax fiber-based multi-scale cellulose nanofibers

PatentWO2022095102A1

Innovation

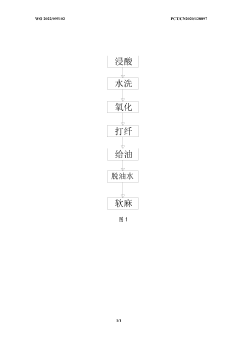

- 采用基于亚麻纤维的多尺度纤维素纳米纤维制备方法,包括浸酸、水洗、氧化、打纤、给油、脱油水和软麻,通过在水中加入碳酸钠、硅酸钠、尿素和渗透剂,进行氧化和给油处理,减少化学药品用量,提高纤维强度和细度。

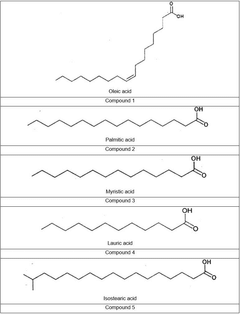

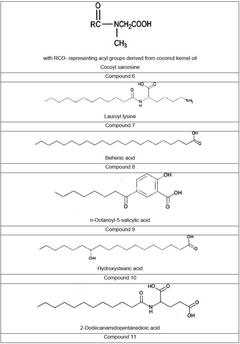

Process for treating keratin fibres using a composition comprising at least two different particular fatty acids and at least one modified polysaccharide

PatentWO2025003162A1

Innovation

- A process involving a composition comprising at least two different fatty acids and one modified polysaccharide is applied to keratin fibers, improving softness, disentangling, smoothness, and humidity resistance without using silicone-based materials.

Environmental Impact

The sodium silicate treatment of flax fibers presents both environmental benefits and potential concerns that warrant careful consideration. On the positive side, this treatment enhances the properties of flax fibers, potentially increasing their durability and performance in various applications. This improvement could lead to a reduced need for synthetic fibers, which often have a higher environmental footprint in terms of production energy and non-biodegradability.

Furthermore, the use of sodium silicate, a relatively benign and abundant compound, aligns with principles of green chemistry. It is non-toxic and does not produce harmful by-products during the treatment process. The treatment can be carried out at moderate temperatures, reducing energy consumption compared to more intensive fiber modification methods.

However, the environmental impact of sodium silicate production must be taken into account. The manufacturing process involves high-temperature fusion of sand and sodium carbonate, which can be energy-intensive. Additionally, the extraction and processing of raw materials for sodium silicate production may have localized environmental impacts, such as habitat disruption and water usage.

The disposal of treated flax fibers at the end of their lifecycle is another important consideration. While untreated flax fibers are fully biodegradable, the sodium silicate treatment may alter this property. Research is needed to determine if the treated fibers maintain their biodegradability or if they require special end-of-life management.

Water usage in the treatment process is a potential environmental concern. The application of sodium silicate typically involves aqueous solutions, and the subsequent washing and drying of fibers can consume significant amounts of water. Implementing water recycling systems and optimizing the treatment process could help mitigate this impact.

Lastly, the potential for improved flax fiber properties could lead to increased cultivation of flax plants. While flax is generally considered an environmentally friendly crop due to its low input requirements, large-scale expansion of flax farming could have implications for land use and biodiversity. Sustainable agricultural practices would need to be employed to ensure that increased flax production does not negatively impact ecosystems or compete with food crops for arable land.

Furthermore, the use of sodium silicate, a relatively benign and abundant compound, aligns with principles of green chemistry. It is non-toxic and does not produce harmful by-products during the treatment process. The treatment can be carried out at moderate temperatures, reducing energy consumption compared to more intensive fiber modification methods.

However, the environmental impact of sodium silicate production must be taken into account. The manufacturing process involves high-temperature fusion of sand and sodium carbonate, which can be energy-intensive. Additionally, the extraction and processing of raw materials for sodium silicate production may have localized environmental impacts, such as habitat disruption and water usage.

The disposal of treated flax fibers at the end of their lifecycle is another important consideration. While untreated flax fibers are fully biodegradable, the sodium silicate treatment may alter this property. Research is needed to determine if the treated fibers maintain their biodegradability or if they require special end-of-life management.

Water usage in the treatment process is a potential environmental concern. The application of sodium silicate typically involves aqueous solutions, and the subsequent washing and drying of fibers can consume significant amounts of water. Implementing water recycling systems and optimizing the treatment process could help mitigate this impact.

Lastly, the potential for improved flax fiber properties could lead to increased cultivation of flax plants. While flax is generally considered an environmentally friendly crop due to its low input requirements, large-scale expansion of flax farming could have implications for land use and biodiversity. Sustainable agricultural practices would need to be employed to ensure that increased flax production does not negatively impact ecosystems or compete with food crops for arable land.

Regulatory Considerations

The regulatory landscape surrounding the sodium silicate treatment of flax fibers is complex and multifaceted, requiring careful consideration of various aspects. Environmental regulations play a significant role, as the process involves chemical treatments that may have ecological implications. Manufacturers must adhere to strict guidelines regarding the disposal of waste products and the management of chemical runoff to prevent water and soil contamination. Additionally, air quality regulations may apply due to potential emissions during the treatment process.

Worker safety regulations are another crucial aspect to consider. The use of sodium silicate and other chemicals in the treatment process necessitates compliance with occupational health and safety standards. This includes providing appropriate personal protective equipment, implementing safety protocols, and ensuring proper ventilation in treatment facilities. Regular safety training and health monitoring of workers may also be required to meet regulatory standards.

Product safety regulations are equally important, particularly for flax fibers intended for use in consumer goods. Treated fibers must meet specific safety standards, especially if they are to be used in textiles that come into direct contact with skin. This may involve testing for chemical residues and ensuring that the treated fibers do not pose any health risks to end-users.

Labeling and certification requirements must also be considered. Depending on the intended use of the treated flax fibers, manufacturers may need to obtain specific certifications or include particular information on product labels. This could include details about the treatment process, potential allergens, or environmental impact.

International trade regulations add another layer of complexity, especially for companies operating in global markets. Different countries may have varying standards and requirements for treated natural fibers, necessitating compliance with multiple regulatory frameworks. This may include adherence to import/export regulations, tariffs, and specific product standards in target markets.

Sustainability certifications, while not always mandatory, are becoming increasingly important in the textile industry. Manufacturers using sodium silicate treatment for flax fibers may need to consider obtaining certifications that demonstrate their commitment to sustainable practices. This could involve documenting the environmental impact of the treatment process and demonstrating efforts to minimize resource consumption and waste generation.

As regulations continue to evolve, staying informed about changes in regulatory requirements is crucial. This may involve ongoing consultation with legal experts, participation in industry associations, and regular review of regulatory updates from relevant authorities. Proactive engagement with regulatory bodies can help manufacturers anticipate and adapt to new requirements, ensuring long-term compliance and market access for their treated flax fiber products.

Worker safety regulations are another crucial aspect to consider. The use of sodium silicate and other chemicals in the treatment process necessitates compliance with occupational health and safety standards. This includes providing appropriate personal protective equipment, implementing safety protocols, and ensuring proper ventilation in treatment facilities. Regular safety training and health monitoring of workers may also be required to meet regulatory standards.

Product safety regulations are equally important, particularly for flax fibers intended for use in consumer goods. Treated fibers must meet specific safety standards, especially if they are to be used in textiles that come into direct contact with skin. This may involve testing for chemical residues and ensuring that the treated fibers do not pose any health risks to end-users.

Labeling and certification requirements must also be considered. Depending on the intended use of the treated flax fibers, manufacturers may need to obtain specific certifications or include particular information on product labels. This could include details about the treatment process, potential allergens, or environmental impact.

International trade regulations add another layer of complexity, especially for companies operating in global markets. Different countries may have varying standards and requirements for treated natural fibers, necessitating compliance with multiple regulatory frameworks. This may include adherence to import/export regulations, tariffs, and specific product standards in target markets.

Sustainability certifications, while not always mandatory, are becoming increasingly important in the textile industry. Manufacturers using sodium silicate treatment for flax fibers may need to consider obtaining certifications that demonstrate their commitment to sustainable practices. This could involve documenting the environmental impact of the treatment process and demonstrating efforts to minimize resource consumption and waste generation.

As regulations continue to evolve, staying informed about changes in regulatory requirements is crucial. This may involve ongoing consultation with legal experts, participation in industry associations, and regular review of regulatory updates from relevant authorities. Proactive engagement with regulatory bodies can help manufacturers anticipate and adapt to new requirements, ensuring long-term compliance and market access for their treated flax fiber products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!