Utilizing sodium silicate in 3D bioprinting technologies

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Silicate in 3D Bioprinting: Background and Objectives

The utilization of sodium silicate in 3D bioprinting technologies represents a significant advancement in the field of tissue engineering and regenerative medicine. This innovative approach combines the versatility of 3D printing with the unique properties of sodium silicate to create biocompatible structures for various medical applications.

Sodium silicate, also known as water glass, has a long history of industrial use dating back to the 19th century. Its application in bioprinting, however, is a relatively recent development that has gained traction in the past decade. The evolution of this technology has been driven by the increasing demand for more effective and personalized medical treatments, particularly in the areas of organ transplantation and tissue repair.

The primary objective of incorporating sodium silicate into 3D bioprinting is to enhance the structural integrity and biocompatibility of printed constructs. Traditional bioinks often lack the necessary mechanical strength to maintain their shape during and after printing, especially for larger or more complex structures. Sodium silicate addresses this challenge by acting as a crosslinking agent, rapidly solidifying the printed material and providing improved structural support.

Furthermore, sodium silicate offers unique advantages in terms of biocompatibility and biodegradability. Its ability to form silica networks that mimic the extracellular matrix of natural tissues makes it an ideal candidate for creating scaffolds that support cell growth and tissue regeneration. This property aligns well with the broader goals of tissue engineering, which aims to create functional replacements for damaged or diseased tissues and organs.

The integration of sodium silicate into 3D bioprinting technologies also aims to expand the range of printable biomaterials. By modifying the rheological properties of bioinks, sodium silicate enables the printing of more diverse and complex tissue-like structures. This versatility opens up new possibilities for creating multi-material constructs that better replicate the heterogeneous nature of biological tissues.

As research in this field progresses, the objectives extend beyond mere structural improvements. Scientists and engineers are exploring the potential of sodium silicate-based bioinks to incorporate controlled release mechanisms for drugs or growth factors, further enhancing the functionality of printed tissues. Additionally, there is growing interest in leveraging the ion-exchange properties of sodium silicate to create smart materials that can respond to environmental stimuli, potentially leading to the development of adaptive tissue constructs.

The pursuit of these objectives is driven by the overarching goal of advancing personalized medicine. By enabling the creation of patient-specific tissue constructs, sodium silicate-enhanced 3D bioprinting has the potential to revolutionize treatments for a wide range of medical conditions, from burn injuries to organ failure. As such, this technology represents a convergence of materials science, bioengineering, and medical research, highlighting the interdisciplinary nature of modern biomedical innovation.

Sodium silicate, also known as water glass, has a long history of industrial use dating back to the 19th century. Its application in bioprinting, however, is a relatively recent development that has gained traction in the past decade. The evolution of this technology has been driven by the increasing demand for more effective and personalized medical treatments, particularly in the areas of organ transplantation and tissue repair.

The primary objective of incorporating sodium silicate into 3D bioprinting is to enhance the structural integrity and biocompatibility of printed constructs. Traditional bioinks often lack the necessary mechanical strength to maintain their shape during and after printing, especially for larger or more complex structures. Sodium silicate addresses this challenge by acting as a crosslinking agent, rapidly solidifying the printed material and providing improved structural support.

Furthermore, sodium silicate offers unique advantages in terms of biocompatibility and biodegradability. Its ability to form silica networks that mimic the extracellular matrix of natural tissues makes it an ideal candidate for creating scaffolds that support cell growth and tissue regeneration. This property aligns well with the broader goals of tissue engineering, which aims to create functional replacements for damaged or diseased tissues and organs.

The integration of sodium silicate into 3D bioprinting technologies also aims to expand the range of printable biomaterials. By modifying the rheological properties of bioinks, sodium silicate enables the printing of more diverse and complex tissue-like structures. This versatility opens up new possibilities for creating multi-material constructs that better replicate the heterogeneous nature of biological tissues.

As research in this field progresses, the objectives extend beyond mere structural improvements. Scientists and engineers are exploring the potential of sodium silicate-based bioinks to incorporate controlled release mechanisms for drugs or growth factors, further enhancing the functionality of printed tissues. Additionally, there is growing interest in leveraging the ion-exchange properties of sodium silicate to create smart materials that can respond to environmental stimuli, potentially leading to the development of adaptive tissue constructs.

The pursuit of these objectives is driven by the overarching goal of advancing personalized medicine. By enabling the creation of patient-specific tissue constructs, sodium silicate-enhanced 3D bioprinting has the potential to revolutionize treatments for a wide range of medical conditions, from burn injuries to organ failure. As such, this technology represents a convergence of materials science, bioengineering, and medical research, highlighting the interdisciplinary nature of modern biomedical innovation.

Market Analysis for Sodium Silicate-Based Bioinks

The market for sodium silicate-based bioinks in 3D bioprinting technologies is experiencing significant growth, driven by the increasing demand for advanced tissue engineering and regenerative medicine solutions. This market segment is part of the broader 3D bioprinting industry, which is projected to reach substantial value in the coming years. The adoption of sodium silicate-based bioinks is particularly notable in applications such as organ-on-a-chip models, drug screening platforms, and personalized medicine.

One of the key factors fueling market growth is the unique properties of sodium silicate as a bioink component. Its ability to form stable, porous structures that mimic natural extracellular matrices makes it highly attractive for tissue engineering applications. Additionally, the biocompatibility and biodegradability of sodium silicate-based bioinks align well with the requirements of biomedical research and potential clinical applications.

The market for these bioinks is segmented based on application areas, including but not limited to, bone tissue engineering, soft tissue regeneration, and drug delivery systems. Each of these segments shows promising growth potential, with bone tissue engineering currently leading in terms of market share due to the excellent osteogenic properties of sodium silicate-based materials.

Geographically, North America and Europe are the dominant markets for sodium silicate-based bioinks, primarily due to the presence of well-established research institutions and biotechnology companies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing investments in biomedical research and the rapid adoption of 3D bioprinting technologies in countries like China, Japan, and South Korea.

The competitive landscape of the sodium silicate-based bioink market is characterized by a mix of established 3D bioprinting companies and emerging startups specializing in biomaterials. These companies are actively engaged in research and development to enhance the properties of sodium silicate-based bioinks, such as improving printability, mechanical strength, and cell viability.

Despite the positive market outlook, there are challenges that need to be addressed. These include the need for standardization in bioink formulations, regulatory hurdles for clinical applications, and the high cost of 3D bioprinting equipment. Overcoming these challenges will be crucial for the widespread adoption of sodium silicate-based bioinks in both research and clinical settings.

In conclusion, the market for sodium silicate-based bioinks in 3D bioprinting technologies shows strong growth potential, driven by technological advancements and increasing applications in tissue engineering and regenerative medicine. As research continues to progress and regulatory pathways become clearer, this market segment is poised for significant expansion in the coming years.

One of the key factors fueling market growth is the unique properties of sodium silicate as a bioink component. Its ability to form stable, porous structures that mimic natural extracellular matrices makes it highly attractive for tissue engineering applications. Additionally, the biocompatibility and biodegradability of sodium silicate-based bioinks align well with the requirements of biomedical research and potential clinical applications.

The market for these bioinks is segmented based on application areas, including but not limited to, bone tissue engineering, soft tissue regeneration, and drug delivery systems. Each of these segments shows promising growth potential, with bone tissue engineering currently leading in terms of market share due to the excellent osteogenic properties of sodium silicate-based materials.

Geographically, North America and Europe are the dominant markets for sodium silicate-based bioinks, primarily due to the presence of well-established research institutions and biotechnology companies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing investments in biomedical research and the rapid adoption of 3D bioprinting technologies in countries like China, Japan, and South Korea.

The competitive landscape of the sodium silicate-based bioink market is characterized by a mix of established 3D bioprinting companies and emerging startups specializing in biomaterials. These companies are actively engaged in research and development to enhance the properties of sodium silicate-based bioinks, such as improving printability, mechanical strength, and cell viability.

Despite the positive market outlook, there are challenges that need to be addressed. These include the need for standardization in bioink formulations, regulatory hurdles for clinical applications, and the high cost of 3D bioprinting equipment. Overcoming these challenges will be crucial for the widespread adoption of sodium silicate-based bioinks in both research and clinical settings.

In conclusion, the market for sodium silicate-based bioinks in 3D bioprinting technologies shows strong growth potential, driven by technological advancements and increasing applications in tissue engineering and regenerative medicine. As research continues to progress and regulatory pathways become clearer, this market segment is poised for significant expansion in the coming years.

Current Challenges in Sodium Silicate Bioprinting

Despite the promising potential of sodium silicate in 3D bioprinting, several significant challenges currently hinder its widespread adoption and optimal utilization. These challenges span across material properties, processing techniques, and biological considerations.

One of the primary obstacles is controlling the gelation kinetics of sodium silicate during the printing process. The rapid solidification of sodium silicate upon exposure to carbon dioxide or acidic conditions can lead to premature gelation, clogging print nozzles and compromising print resolution. Conversely, insufficient gelation can result in poor structural integrity of the printed constructs.

The mechanical properties of sodium silicate-based bioinks present another challenge. While sodium silicate offers excellent printability, the resulting structures often lack the necessary strength and elasticity required for certain tissue engineering applications. Balancing the mechanical properties with biocompatibility and cell viability remains a complex task.

Biocompatibility issues also pose significant hurdles. Although sodium silicate is generally considered non-toxic, its alkaline nature can create unfavorable conditions for cell survival and proliferation. Mitigating the pH effects without compromising the material's printability is crucial for successful bioprinting applications.

The long-term stability of sodium silicate-based constructs in physiological conditions is another area of concern. The gradual dissolution of silicate structures in aqueous environments can lead to loss of structural integrity over time, limiting their use in long-term implantable devices or tissue scaffolds.

Achieving precise control over pore size and distribution within sodium silicate-based scaffolds remains challenging. The ability to create hierarchical porous structures is critical for promoting cell infiltration, vascularization, and nutrient diffusion in tissue engineering applications.

Furthermore, the integration of multiple cell types and bioactive molecules within sodium silicate bioinks presents difficulties. Ensuring uniform cell distribution, maintaining cell viability during the printing process, and providing a suitable microenvironment for cell differentiation and tissue formation are ongoing challenges.

Lastly, the scalability and reproducibility of sodium silicate bioprinting processes pose significant hurdles for industrial adoption. Developing standardized protocols and quality control measures for large-scale production of consistent, high-quality bioprinted constructs remains a critical challenge in the field.

Addressing these challenges will require interdisciplinary collaboration and innovative approaches, combining materials science, chemistry, biology, and engineering expertise to unlock the full potential of sodium silicate in 3D bioprinting technologies.

One of the primary obstacles is controlling the gelation kinetics of sodium silicate during the printing process. The rapid solidification of sodium silicate upon exposure to carbon dioxide or acidic conditions can lead to premature gelation, clogging print nozzles and compromising print resolution. Conversely, insufficient gelation can result in poor structural integrity of the printed constructs.

The mechanical properties of sodium silicate-based bioinks present another challenge. While sodium silicate offers excellent printability, the resulting structures often lack the necessary strength and elasticity required for certain tissue engineering applications. Balancing the mechanical properties with biocompatibility and cell viability remains a complex task.

Biocompatibility issues also pose significant hurdles. Although sodium silicate is generally considered non-toxic, its alkaline nature can create unfavorable conditions for cell survival and proliferation. Mitigating the pH effects without compromising the material's printability is crucial for successful bioprinting applications.

The long-term stability of sodium silicate-based constructs in physiological conditions is another area of concern. The gradual dissolution of silicate structures in aqueous environments can lead to loss of structural integrity over time, limiting their use in long-term implantable devices or tissue scaffolds.

Achieving precise control over pore size and distribution within sodium silicate-based scaffolds remains challenging. The ability to create hierarchical porous structures is critical for promoting cell infiltration, vascularization, and nutrient diffusion in tissue engineering applications.

Furthermore, the integration of multiple cell types and bioactive molecules within sodium silicate bioinks presents difficulties. Ensuring uniform cell distribution, maintaining cell viability during the printing process, and providing a suitable microenvironment for cell differentiation and tissue formation are ongoing challenges.

Lastly, the scalability and reproducibility of sodium silicate bioprinting processes pose significant hurdles for industrial adoption. Developing standardized protocols and quality control measures for large-scale production of consistent, high-quality bioprinted constructs remains a critical challenge in the field.

Addressing these challenges will require interdisciplinary collaboration and innovative approaches, combining materials science, chemistry, biology, and engineering expertise to unlock the full potential of sodium silicate in 3D bioprinting technologies.

Existing Sodium Silicate Bioink Formulations

01 Use in detergent compositions

Sodium silicate is commonly used in detergent compositions due to its alkaline properties and ability to soften water. It helps to improve the cleaning efficiency of detergents by preventing the redeposition of soil onto fabrics and providing corrosion protection for washing machines.- Use in detergent compositions: Sodium silicate is commonly used in detergent compositions as a builder and alkalinity source. It helps to soften water, remove dirt and stains, and protect washing machines from corrosion. The inclusion of sodium silicate in detergent formulations can improve cleaning performance and stability of the product.

- Application in cement and concrete: Sodium silicate is utilized in the production of cement and concrete materials. It acts as a binder, sealant, and hardening agent, improving the strength and durability of concrete structures. The addition of sodium silicate can enhance the setting time, water resistance, and overall performance of cement-based products.

- Use in fire-resistant coatings: Sodium silicate is employed in the formulation of fire-resistant coatings and materials. When exposed to high temperatures, it forms a protective barrier that helps prevent the spread of fire and protects underlying surfaces. This property makes it valuable in various fire protection applications for buildings and industrial equipment.

- Application in water treatment: Sodium silicate is used in water treatment processes for various purposes. It can act as a coagulant aid, helping to remove suspended particles and impurities from water. Additionally, it can be used to control corrosion in water distribution systems and industrial cooling systems by forming a protective film on metal surfaces.

- Use in catalysts and adsorbents: Sodium silicate serves as a precursor in the synthesis of various catalysts and adsorbents. It can be used to produce zeolites, silica gels, and other porous materials with high surface areas. These materials find applications in catalysis, gas separation, and purification processes across different industries.

02 Application in cement and concrete

Sodium silicate is utilized in the production of cement and concrete materials. It acts as a binder, improving the strength and durability of concrete structures. Additionally, it can be used as a sealant to reduce water penetration and enhance the overall performance of cement-based products.Expand Specific Solutions03 Role in water treatment

Sodium silicate plays a significant role in water treatment processes. It is used as a coagulant aid to remove suspended particles and impurities from water. It also helps in controlling corrosion in water distribution systems by forming a protective layer on metal surfaces.Expand Specific Solutions04 Use in fire-resistant materials

Sodium silicate is employed in the production of fire-resistant materials due to its ability to form a protective barrier when exposed to high temperatures. It is used in the manufacture of fire-resistant coatings, insulation materials, and intumescent paints to enhance the fire resistance of various structures and products.Expand Specific Solutions05 Application in paper and pulp industry

Sodium silicate finds applications in the paper and pulp industry. It is used as a sizing agent to improve the strength and printability of paper. Additionally, it serves as a deinking agent in paper recycling processes, helping to remove ink from recycled paper fibers.Expand Specific Solutions

Key Players in Sodium Silicate Bioprinting Industry

The utilization of sodium silicate in 3D bioprinting technologies is an emerging field in the early stages of development, with a growing market potential driven by advancements in tissue engineering and regenerative medicine. The global 3D bioprinting market is expanding rapidly, expected to reach several billion dollars by 2025. While the technology is still maturing, several key players are making significant strides. Universities like Rice University and King Abdullah University of Science & Technology are conducting cutting-edge research, while companies such as BICO Group AB and Impossible Objects LLC are developing commercial applications. Research institutions like Fraunhofer-Gesellschaft and Agency for Science, Technology & Research are also contributing to technological advancements, indicating a collaborative ecosystem driving innovation in this field.

William Marsh Rice University

Technical Solution: William Marsh Rice University has pioneered a groundbreaking approach to utilizing sodium silicate in 3D bioprinting technologies. Their research team has developed a novel bioink formulation that incorporates sodium silicate as a key component, enhancing the printability and structural integrity of the resulting constructs[1]. The university's method involves a two-step crosslinking process, where sodium silicate is first used to create a pre-gel state, followed by secondary crosslinking with calcium ions[2]. This approach allows for the creation of complex, hierarchical structures with improved mechanical properties and cell viability[3]. Rice University researchers have also explored the use of sodium silicate as a sacrificial material in bioprinting, enabling the fabrication of intricate vascular networks within tissue constructs[4]. Their technology has shown promising results in various tissue engineering applications, including bone and cartilage regeneration[5].

Strengths: Innovative two-step crosslinking process, ability to create complex hierarchical structures, and potential for vascularized tissue constructs. Weaknesses: Limited scalability and potential challenges in long-term stability of printed constructs.

The Shenzhen Institutes of Advanced Technology

Technical Solution: The Shenzhen Institutes of Advanced Technology has developed an innovative approach to utilizing sodium silicate in 3D bioprinting technologies. Their method involves the integration of sodium silicate into a multi-component bioink system, which allows for the creation of highly structured and mechanically robust tissue constructs[1]. The institute's researchers have engineered a unique crosslinking mechanism that combines sodium silicate with other biocompatible materials, such as alginate and gelatin methacrylate, to form a stable and printable hydrogel matrix[2]. This technology enables the fabrication of complex 3D structures with controlled porosity and mechanical properties, suitable for various tissue engineering applications[3]. The institute has also developed a specialized bioprinting platform that incorporates in-situ mixing and precise deposition of sodium silicate-containing bioinks, allowing for the creation of gradient structures and spatially controlled material properties[4].

Strengths: Multi-component bioink system, controlled porosity and mechanical properties, and ability to create gradient structures. Weaknesses: Potential challenges in maintaining cell viability during the crosslinking process and limited long-term stability of printed constructs.

Innovative Sodium Silicate Bioprinting Techniques

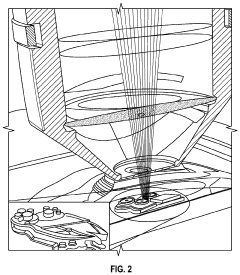

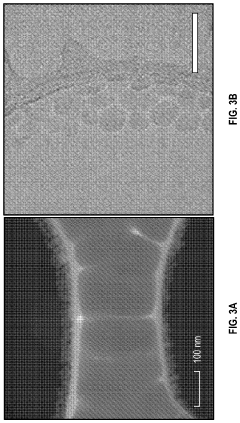

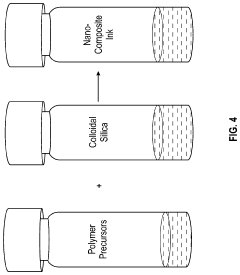

3D printed silica with nanoscale resolution

PatentPendingUS20230203326A1

Innovation

- A method involving the preparation of a nanocomposite ink with colloidal silica nanoparticles, photopolymer precursors, a photoinitiator, and a photoinhibitor, followed by two-photon polymerization and pyrolysis/sintering to create 3D inorganic nanostructures with controlled crystallinity and doping, enabling sub-200 nm resolution and high thermal tolerance.

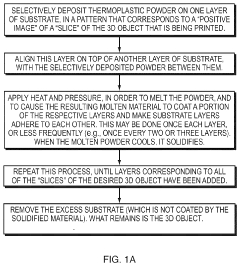

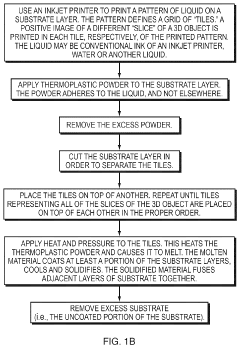

Three-dimensional printed composites using substrates with sodium silicate binder

PatentInactiveUS20230339174A1

Innovation

- The use of engineered powders such as emulsion aggregation and chemically-produced toner powders, which offer improved control over particle size, morphology, and surface energy, and the adoption of sodium silicate as a binder that does not burn at high temperatures, allowing for the production of 3D objects with enhanced properties and broader material selection.

Regulatory Framework for Bioprinted Medical Products

The regulatory framework for bioprinted medical products utilizing sodium silicate in 3D bioprinting technologies is a complex and evolving landscape. As this innovative field continues to advance, regulatory bodies worldwide are working to establish guidelines that ensure the safety and efficacy of these novel products while fostering innovation.

In the United States, the Food and Drug Administration (FDA) has taken a lead role in developing regulatory approaches for 3D-bioprinted products. The FDA has issued guidance documents that outline the agency's current thinking on the regulatory considerations for additive manufactured medical devices, which include bioprinted products. These guidelines address issues such as design and manufacturing considerations, device testing, and quality system requirements.

The European Medicines Agency (EMA) and the European Commission have also been actively engaged in developing regulatory frameworks for advanced therapy medicinal products (ATMPs), which encompass many bioprinted products. The EU's regulatory approach emphasizes risk-based assessment and considers factors such as the intended use, manufacturing process, and biological characteristics of the bioprinted products.

Regulatory bodies are particularly focused on addressing the unique challenges posed by bioprinted products containing sodium silicate. These challenges include ensuring the long-term stability and biocompatibility of the printed constructs, assessing the potential for silica-induced toxicity, and evaluating the degradation profiles of sodium silicate-based scaffolds in vivo.

Key regulatory considerations for bioprinted medical products using sodium silicate include:

1. Manufacturing process validation: Demonstrating consistency and reproducibility in the bioprinting process, including the incorporation of sodium silicate.

2. Material characterization: Providing comprehensive data on the physical, chemical, and biological properties of the sodium silicate-based bioinks and resulting constructs.

3. Biocompatibility testing: Conducting extensive in vitro and in vivo studies to assess the safety and potential toxicity of sodium silicate in bioprinted products.

4. Stability and degradation studies: Evaluating the long-term stability of bioprinted constructs and characterizing the degradation profile of sodium silicate-based materials in physiological conditions.

5. Clinical evidence: Generating robust clinical data to support the safety and efficacy of bioprinted medical products containing sodium silicate.

As the field of 3D bioprinting with sodium silicate continues to evolve, regulatory frameworks are likely to adapt and become more refined. Collaboration between regulatory agencies, researchers, and industry stakeholders will be crucial in developing appropriate guidelines that balance innovation with patient safety.

In the United States, the Food and Drug Administration (FDA) has taken a lead role in developing regulatory approaches for 3D-bioprinted products. The FDA has issued guidance documents that outline the agency's current thinking on the regulatory considerations for additive manufactured medical devices, which include bioprinted products. These guidelines address issues such as design and manufacturing considerations, device testing, and quality system requirements.

The European Medicines Agency (EMA) and the European Commission have also been actively engaged in developing regulatory frameworks for advanced therapy medicinal products (ATMPs), which encompass many bioprinted products. The EU's regulatory approach emphasizes risk-based assessment and considers factors such as the intended use, manufacturing process, and biological characteristics of the bioprinted products.

Regulatory bodies are particularly focused on addressing the unique challenges posed by bioprinted products containing sodium silicate. These challenges include ensuring the long-term stability and biocompatibility of the printed constructs, assessing the potential for silica-induced toxicity, and evaluating the degradation profiles of sodium silicate-based scaffolds in vivo.

Key regulatory considerations for bioprinted medical products using sodium silicate include:

1. Manufacturing process validation: Demonstrating consistency and reproducibility in the bioprinting process, including the incorporation of sodium silicate.

2. Material characterization: Providing comprehensive data on the physical, chemical, and biological properties of the sodium silicate-based bioinks and resulting constructs.

3. Biocompatibility testing: Conducting extensive in vitro and in vivo studies to assess the safety and potential toxicity of sodium silicate in bioprinted products.

4. Stability and degradation studies: Evaluating the long-term stability of bioprinted constructs and characterizing the degradation profile of sodium silicate-based materials in physiological conditions.

5. Clinical evidence: Generating robust clinical data to support the safety and efficacy of bioprinted medical products containing sodium silicate.

As the field of 3D bioprinting with sodium silicate continues to evolve, regulatory frameworks are likely to adapt and become more refined. Collaboration between regulatory agencies, researchers, and industry stakeholders will be crucial in developing appropriate guidelines that balance innovation with patient safety.

Biocompatibility and Safety Considerations

The utilization of sodium silicate in 3D bioprinting technologies necessitates a thorough examination of biocompatibility and safety considerations. Sodium silicate, also known as water glass, has been widely used in various industrial applications due to its adhesive and sealant properties. However, its integration into bioprinting processes requires careful evaluation of its interactions with living cells and tissues.

One of the primary concerns when using sodium silicate in bioprinting is its potential cytotoxicity. Studies have shown that high concentrations of sodium silicate can be harmful to cells, potentially causing membrane damage and disrupting cellular functions. Therefore, determining the optimal concentration range that balances the material's structural properties with cellular viability is crucial for successful bioprinting applications.

The pH-altering effects of sodium silicate also warrant consideration. When dissolved in water, sodium silicate creates an alkaline environment, which may not be suitable for all cell types. Researchers must carefully control and adjust the pH levels to ensure a physiologically appropriate environment for the printed cells and tissues.

Another important aspect is the long-term stability and degradation profile of sodium silicate-based bioinks. The ideal bioprinting material should provide initial structural support while gradually degrading to allow for tissue regeneration and integration. Understanding the degradation kinetics of sodium silicate in physiological conditions is essential for predicting its behavior in vivo and ensuring proper tissue development.

The potential for immune responses to sodium silicate-based constructs must also be evaluated. While silica-based materials are generally considered biocompatible, the specific formulation and processing methods used in bioprinting may alter their immunogenicity. Comprehensive in vitro and in vivo studies are necessary to assess any potential inflammatory or allergic reactions.

Furthermore, the mechanical properties of sodium silicate-based bioinks and their impact on cell behavior require thorough investigation. The stiffness and elasticity of the printed constructs can significantly influence cell adhesion, proliferation, and differentiation. Optimizing these properties to mimic the native tissue environment is crucial for promoting proper cell function and tissue development.

Lastly, the potential for sodium silicate to interact with other components of the bioink formulation must be considered. These interactions may affect the overall biocompatibility and functionality of the printed constructs. Extensive testing of various bioink compositions and their effects on cell viability and function is essential for developing safe and effective 3D bioprinting technologies utilizing sodium silicate.

One of the primary concerns when using sodium silicate in bioprinting is its potential cytotoxicity. Studies have shown that high concentrations of sodium silicate can be harmful to cells, potentially causing membrane damage and disrupting cellular functions. Therefore, determining the optimal concentration range that balances the material's structural properties with cellular viability is crucial for successful bioprinting applications.

The pH-altering effects of sodium silicate also warrant consideration. When dissolved in water, sodium silicate creates an alkaline environment, which may not be suitable for all cell types. Researchers must carefully control and adjust the pH levels to ensure a physiologically appropriate environment for the printed cells and tissues.

Another important aspect is the long-term stability and degradation profile of sodium silicate-based bioinks. The ideal bioprinting material should provide initial structural support while gradually degrading to allow for tissue regeneration and integration. Understanding the degradation kinetics of sodium silicate in physiological conditions is essential for predicting its behavior in vivo and ensuring proper tissue development.

The potential for immune responses to sodium silicate-based constructs must also be evaluated. While silica-based materials are generally considered biocompatible, the specific formulation and processing methods used in bioprinting may alter their immunogenicity. Comprehensive in vitro and in vivo studies are necessary to assess any potential inflammatory or allergic reactions.

Furthermore, the mechanical properties of sodium silicate-based bioinks and their impact on cell behavior require thorough investigation. The stiffness and elasticity of the printed constructs can significantly influence cell adhesion, proliferation, and differentiation. Optimizing these properties to mimic the native tissue environment is crucial for promoting proper cell function and tissue development.

Lastly, the potential for sodium silicate to interact with other components of the bioink formulation must be considered. These interactions may affect the overall biocompatibility and functionality of the printed constructs. Extensive testing of various bioink compositions and their effects on cell viability and function is essential for developing safe and effective 3D bioprinting technologies utilizing sodium silicate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!