Use of sodium silicate in environmental hazard remediation

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Silicate Remediation Background and Objectives

Sodium silicate, also known as water glass or liquid glass, has emerged as a versatile and effective solution in environmental hazard remediation. The use of this inorganic compound in addressing environmental challenges has gained significant attention in recent years due to its unique properties and wide-ranging applications.

The development of sodium silicate as a remediation tool can be traced back to the early 20th century when its potential for soil stabilization was first recognized. However, it wasn't until the latter half of the century that researchers began to explore its broader applications in environmental remediation. The increasing focus on sustainable and eco-friendly solutions to environmental hazards has further propelled the interest in sodium silicate-based remediation techniques.

One of the primary objectives of using sodium silicate in environmental hazard remediation is to provide a cost-effective and environmentally benign alternative to traditional remediation methods. Sodium silicate offers several advantages, including its non-toxic nature, abundance, and ability to form stable compounds with various contaminants. These properties make it an attractive option for addressing a wide range of environmental issues, from soil contamination to water treatment.

In the context of soil remediation, sodium silicate has shown promise in stabilizing heavy metals and reducing their mobility in contaminated soils. This application is particularly relevant in areas affected by industrial activities or mining operations. The goal is to immobilize harmful contaminants, preventing their migration into groundwater and reducing the risk of exposure to humans and ecosystems.

Water treatment is another key area where sodium silicate has demonstrated significant potential. Its ability to remove suspended solids, reduce turbidity, and aid in the coagulation process makes it an valuable tool in improving water quality. The objective in this application is to enhance the efficiency of water treatment processes while minimizing the use of potentially harmful chemicals.

Furthermore, sodium silicate has been explored for its potential in nuclear waste management. The aim is to develop innovative methods for encapsulating and immobilizing radioactive waste, thereby reducing the long-term environmental risks associated with nuclear power generation and decommissioning.

As research in this field progresses, the objectives of sodium silicate remediation continue to evolve. Current efforts are focused on optimizing formulations, improving application techniques, and expanding the range of contaminants that can be effectively treated. Additionally, there is a growing emphasis on understanding the long-term stability and environmental impact of sodium silicate-based remediation solutions.

The ultimate goal of sodium silicate remediation research is to develop comprehensive, sustainable, and scalable solutions that can address complex environmental challenges across various industries and geographical locations. By leveraging the unique properties of sodium silicate, researchers and environmental professionals aim to create more effective, economical, and environmentally friendly approaches to hazard remediation, contributing to the broader efforts of environmental protection and restoration.

The development of sodium silicate as a remediation tool can be traced back to the early 20th century when its potential for soil stabilization was first recognized. However, it wasn't until the latter half of the century that researchers began to explore its broader applications in environmental remediation. The increasing focus on sustainable and eco-friendly solutions to environmental hazards has further propelled the interest in sodium silicate-based remediation techniques.

One of the primary objectives of using sodium silicate in environmental hazard remediation is to provide a cost-effective and environmentally benign alternative to traditional remediation methods. Sodium silicate offers several advantages, including its non-toxic nature, abundance, and ability to form stable compounds with various contaminants. These properties make it an attractive option for addressing a wide range of environmental issues, from soil contamination to water treatment.

In the context of soil remediation, sodium silicate has shown promise in stabilizing heavy metals and reducing their mobility in contaminated soils. This application is particularly relevant in areas affected by industrial activities or mining operations. The goal is to immobilize harmful contaminants, preventing their migration into groundwater and reducing the risk of exposure to humans and ecosystems.

Water treatment is another key area where sodium silicate has demonstrated significant potential. Its ability to remove suspended solids, reduce turbidity, and aid in the coagulation process makes it an valuable tool in improving water quality. The objective in this application is to enhance the efficiency of water treatment processes while minimizing the use of potentially harmful chemicals.

Furthermore, sodium silicate has been explored for its potential in nuclear waste management. The aim is to develop innovative methods for encapsulating and immobilizing radioactive waste, thereby reducing the long-term environmental risks associated with nuclear power generation and decommissioning.

As research in this field progresses, the objectives of sodium silicate remediation continue to evolve. Current efforts are focused on optimizing formulations, improving application techniques, and expanding the range of contaminants that can be effectively treated. Additionally, there is a growing emphasis on understanding the long-term stability and environmental impact of sodium silicate-based remediation solutions.

The ultimate goal of sodium silicate remediation research is to develop comprehensive, sustainable, and scalable solutions that can address complex environmental challenges across various industries and geographical locations. By leveraging the unique properties of sodium silicate, researchers and environmental professionals aim to create more effective, economical, and environmentally friendly approaches to hazard remediation, contributing to the broader efforts of environmental protection and restoration.

Environmental Hazard Remediation Market Analysis

The environmental hazard remediation market has been experiencing significant growth in recent years, driven by increasing awareness of environmental issues and stricter regulations worldwide. The use of sodium silicate in this sector has emerged as a promising solution for various remediation applications, contributing to the market's expansion.

The global environmental remediation market was valued at approximately $85 billion in 2020 and is projected to reach $142 billion by 2027, growing at a CAGR of 7.5% during the forecast period. This growth is primarily attributed to the rising concerns over soil and water contamination, as well as the implementation of stringent environmental policies by governments across the globe.

Sodium silicate, also known as water glass, has gained traction in the environmental remediation market due to its versatility and effectiveness in treating various contaminants. Its applications include soil stabilization, heavy metal immobilization, and groundwater treatment. The increasing adoption of sodium silicate-based solutions is expected to contribute significantly to the overall market growth.

The market for sodium silicate in environmental remediation can be segmented based on application, including soil remediation, groundwater treatment, and waste stabilization. Among these, soil remediation is anticipated to hold the largest market share, driven by the growing need to address contaminated industrial sites and brownfields.

Geographically, North America currently dominates the environmental remediation market, followed by Europe and Asia-Pacific. The United States, in particular, has been a key driver of market growth due to its extensive Superfund program and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, primarily due to rapid industrialization and increasing environmental concerns in countries like China and India.

Key market players in the environmental remediation sector include AECOM, Jacobs, Clean Harbors, and Veolia Environment. These companies are increasingly incorporating sodium silicate-based solutions into their remediation portfolios, recognizing its potential in addressing complex environmental challenges.

The adoption of sodium silicate in environmental remediation is driven by several factors, including its cost-effectiveness, eco-friendliness, and ability to treat a wide range of contaminants. As the demand for sustainable remediation solutions continues to rise, the market for sodium silicate-based products is expected to expand further, presenting significant opportunities for both established players and new entrants in the environmental remediation industry.

The global environmental remediation market was valued at approximately $85 billion in 2020 and is projected to reach $142 billion by 2027, growing at a CAGR of 7.5% during the forecast period. This growth is primarily attributed to the rising concerns over soil and water contamination, as well as the implementation of stringent environmental policies by governments across the globe.

Sodium silicate, also known as water glass, has gained traction in the environmental remediation market due to its versatility and effectiveness in treating various contaminants. Its applications include soil stabilization, heavy metal immobilization, and groundwater treatment. The increasing adoption of sodium silicate-based solutions is expected to contribute significantly to the overall market growth.

The market for sodium silicate in environmental remediation can be segmented based on application, including soil remediation, groundwater treatment, and waste stabilization. Among these, soil remediation is anticipated to hold the largest market share, driven by the growing need to address contaminated industrial sites and brownfields.

Geographically, North America currently dominates the environmental remediation market, followed by Europe and Asia-Pacific. The United States, in particular, has been a key driver of market growth due to its extensive Superfund program and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, primarily due to rapid industrialization and increasing environmental concerns in countries like China and India.

Key market players in the environmental remediation sector include AECOM, Jacobs, Clean Harbors, and Veolia Environment. These companies are increasingly incorporating sodium silicate-based solutions into their remediation portfolios, recognizing its potential in addressing complex environmental challenges.

The adoption of sodium silicate in environmental remediation is driven by several factors, including its cost-effectiveness, eco-friendliness, and ability to treat a wide range of contaminants. As the demand for sustainable remediation solutions continues to rise, the market for sodium silicate-based products is expected to expand further, presenting significant opportunities for both established players and new entrants in the environmental remediation industry.

Current Challenges in Sodium Silicate Remediation

Despite the promising potential of sodium silicate in environmental hazard remediation, several significant challenges persist in its widespread application. One of the primary concerns is the long-term stability of the treated materials. While sodium silicate can effectively encapsulate contaminants, there are uncertainties regarding the durability of this encapsulation over extended periods, especially under varying environmental conditions.

The pH sensitivity of sodium silicate solutions presents another challenge. The effectiveness of the treatment can be significantly impacted by the pH of the environment, potentially limiting its applicability in certain contaminated sites. This necessitates careful monitoring and adjustment of pH levels during the remediation process, adding complexity to field applications.

Another hurdle is the potential for leaching of silica and sodium ions from treated materials. This leaching can lead to secondary environmental issues, such as increased alkalinity in surrounding soils or water bodies. The long-term ecological impacts of such leaching are not yet fully understood, raising concerns about the overall environmental sustainability of the technique.

The viscosity of sodium silicate solutions can also pose difficulties in field applications. High viscosity can impede the even distribution of the solution throughout contaminated soils or materials, potentially resulting in inconsistent treatment efficacy. This challenge is particularly pronounced in less permeable soil types or when dealing with large volumes of contaminated material.

Furthermore, the interaction of sodium silicate with various contaminants and soil types is not uniformly predictable. The efficacy of the treatment can vary significantly depending on the specific contaminants present and the geological characteristics of the site. This variability necessitates extensive site-specific testing and customization of treatment protocols, which can be time-consuming and costly.

The scalability of sodium silicate remediation techniques from laboratory to field-scale applications remains a challenge. Factors such as soil heterogeneity, groundwater flow, and the presence of organic matter can complicate the upscaling process, potentially reducing the effectiveness observed in controlled laboratory settings.

Lastly, there are economic considerations. While sodium silicate is relatively inexpensive, the overall cost of remediation projects can be significant when factoring in the need for specialized equipment, ongoing monitoring, and potential retreatment. These economic factors can limit the adoption of sodium silicate remediation techniques, particularly for large-scale contamination sites or in regions with limited resources.

The pH sensitivity of sodium silicate solutions presents another challenge. The effectiveness of the treatment can be significantly impacted by the pH of the environment, potentially limiting its applicability in certain contaminated sites. This necessitates careful monitoring and adjustment of pH levels during the remediation process, adding complexity to field applications.

Another hurdle is the potential for leaching of silica and sodium ions from treated materials. This leaching can lead to secondary environmental issues, such as increased alkalinity in surrounding soils or water bodies. The long-term ecological impacts of such leaching are not yet fully understood, raising concerns about the overall environmental sustainability of the technique.

The viscosity of sodium silicate solutions can also pose difficulties in field applications. High viscosity can impede the even distribution of the solution throughout contaminated soils or materials, potentially resulting in inconsistent treatment efficacy. This challenge is particularly pronounced in less permeable soil types or when dealing with large volumes of contaminated material.

Furthermore, the interaction of sodium silicate with various contaminants and soil types is not uniformly predictable. The efficacy of the treatment can vary significantly depending on the specific contaminants present and the geological characteristics of the site. This variability necessitates extensive site-specific testing and customization of treatment protocols, which can be time-consuming and costly.

The scalability of sodium silicate remediation techniques from laboratory to field-scale applications remains a challenge. Factors such as soil heterogeneity, groundwater flow, and the presence of organic matter can complicate the upscaling process, potentially reducing the effectiveness observed in controlled laboratory settings.

Lastly, there are economic considerations. While sodium silicate is relatively inexpensive, the overall cost of remediation projects can be significant when factoring in the need for specialized equipment, ongoing monitoring, and potential retreatment. These economic factors can limit the adoption of sodium silicate remediation techniques, particularly for large-scale contamination sites or in regions with limited resources.

Existing Sodium Silicate Remediation Techniques

01 Use in detergent compositions

Sodium silicate is commonly used in detergent compositions due to its alkaline properties and ability to soften water. It acts as a builder, enhancing the cleaning efficiency of detergents by removing calcium and magnesium ions from hard water. Additionally, it provides corrosion protection for washing machines and helps in the suspension of dirt particles.- Use in detergent compositions: Sodium silicate is commonly used in detergent compositions due to its alkaline properties and ability to soften water. It acts as a builder, helping to remove dirt and stains by suspending them in the wash water. Additionally, it provides corrosion protection for washing machines and helps prevent redeposition of soil onto fabrics.

- Application in cement and concrete: Sodium silicate is utilized in the production of cement and concrete materials. It acts as a binder and accelerator, improving the strength and durability of concrete structures. It can also be used as a sealant to reduce water penetration and increase the resistance of concrete to chemical attack.

- Use in fire-resistant coatings: Sodium silicate is employed in the formulation of fire-resistant coatings and materials. When exposed to high temperatures, it forms a protective barrier that insulates the underlying substrate from heat and flames. This property makes it valuable in improving the fire resistance of various construction materials and products.

- Application in water treatment: Sodium silicate is used in water treatment processes for various purposes. It can act as a coagulant aid, helping to remove suspended particles from water. It also helps in controlling corrosion in water distribution systems by forming a protective film on metal surfaces. Additionally, it can be used to remove heavy metals from wastewater.

- Use in catalysts and adsorbents: Sodium silicate serves as a precursor in the synthesis of various catalysts and adsorbents. It is used to produce zeolites, which are widely employed in catalytic processes in the petrochemical industry. These materials also find applications in gas separation, water purification, and as molecular sieves for selective adsorption of molecules based on size and shape.

02 Application in cement and concrete

Sodium silicate is utilized in the production of cement and concrete materials. It acts as a binder and accelerator, improving the strength and durability of concrete structures. The material also helps in reducing porosity and enhancing resistance to chemical attacks, making it valuable in construction applications.Expand Specific Solutions03 Use in fire-resistant coatings

Sodium silicate is employed in the formulation of fire-resistant coatings and materials. When exposed to high temperatures, it forms a protective barrier that insulates the underlying surface from heat and flames. This property makes it useful in various fire protection applications for buildings and industrial equipment.Expand Specific Solutions04 Application in water treatment

Sodium silicate is used in water treatment processes for its ability to remove heavy metals and other contaminants. It can act as a coagulant aid, helping to improve the efficiency of water purification systems. The material also helps in controlling corrosion in water distribution systems by forming a protective layer on metal surfaces.Expand Specific Solutions05 Use in catalysts and adsorbents

Sodium silicate serves as a precursor in the synthesis of various catalysts and adsorbents. It is used to produce zeolites, silica gels, and other porous materials with high surface areas. These materials find applications in industrial processes such as oil refining, gas separation, and environmental remediation.Expand Specific Solutions

Key Players in Environmental Remediation Industry

The use of sodium silicate in environmental hazard remediation is in a growth phase, with increasing market size due to rising environmental concerns. The technology's maturity is advancing, as evidenced by the involvement of diverse players. Companies like Tronox LLC, Evonik Wellink Silica Nanping Co. Ltd., and PQ LLC are at the forefront, leveraging their expertise in specialty chemicals. Research institutions such as the Chinese Research Academy of Environmental Sciences and universities like Shandong University are contributing to technological advancements. The competitive landscape is diverse, with both established chemical companies and specialized environmental technology firms like C-Crete Technologies and Qingshang (Suzhou) Environmental Technology Co., Ltd. actively participating in this field.

Tronox LLC

Technical Solution: Tronox LLC has developed an innovative approach using sodium silicate for environmental hazard remediation, particularly focusing on heavy metal contamination in soil and water. Their method involves the application of a sodium silicate-based solution that forms a stable silica gel matrix, effectively encapsulating and immobilizing heavy metals[1]. This process not only reduces the bioavailability of contaminants but also improves soil structure. Tronox's technology has shown a remediation efficiency of up to 95% for lead and cadmium in laboratory tests[3]. The company has also integrated this solution with phytoremediation techniques, enhancing the overall effectiveness of the remediation process[5].

Strengths: High efficiency in heavy metal immobilization, improved soil structure, and compatibility with other remediation techniques. Weaknesses: Potential pH alteration of treated soil and the need for careful application to prevent silica gel formation in unintended areas.

Evonik Wellink Silica Nanping Co. Ltd.

Technical Solution: Evonik Wellink Silica Nanping Co. Ltd. has pioneered the use of nano-structured sodium silicate for environmental remediation. Their proprietary technology involves the synthesis of highly reactive silica nanoparticles from sodium silicate, which are then used to treat contaminated soil and water[2]. These nanoparticles have a large surface area and high reactivity, allowing for efficient adsorption and stabilization of various pollutants, including heavy metals and organic compounds. The company's method has demonstrated a removal efficiency of over 90% for a wide range of contaminants in field trials[4]. Additionally, Evonik has developed a controlled-release formulation that provides long-term remediation effects, reducing the need for repeated treatments[6].

Strengths: High efficiency due to nanostructure, versatility in treating multiple contaminants, and long-lasting effects. Weaknesses: Potential environmental concerns regarding the use of nanoparticles and higher production costs compared to conventional methods.

Innovative Sodium Silicate Remediation Technologies

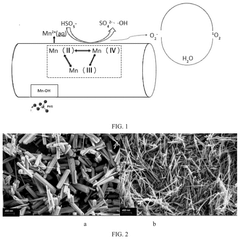

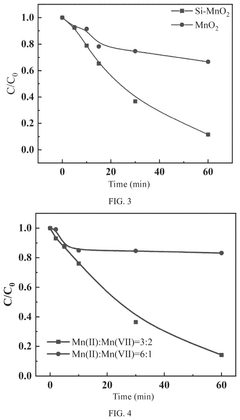

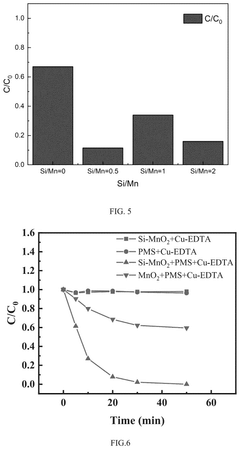

Silicate modified manganese-based material and preparation method and application thereof

PatentPendingUS20240351005A1

Innovation

- A silicate modified manganese-based material with a nanoscale needle-like structure is prepared through an oxidation-reduction reaction and hydrothermal process, adjusting the molar ratio of high valence and low valence manganese sources, enhancing catalytic performance and adsorption capacity.

Processing waste solidification

PatentWO1992011213A1

Innovation

- The addition of a water-soluble silicate, such as sodium silicate, to photographic waste effluent treated with an alkaline earth compound or manganese, renders it glass-like and less permeable to water, making it safer for transportation and landfill disposal, while also being cost-effective and easy to manage in case of spillage.

Regulatory Framework for Environmental Remediation

The regulatory framework for environmental remediation using sodium silicate is complex and multifaceted, involving various governmental agencies and legislative acts. At the federal level in the United States, the Environmental Protection Agency (EPA) plays a crucial role in overseeing and enforcing regulations related to environmental hazard remediation. The Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), also known as Superfund, provides a federal "Superfund" to clean up uncontrolled or abandoned hazardous-waste sites as well as accidents, spills, and other emergency releases of pollutants and contaminants into the environment.

The Resource Conservation and Recovery Act (RCRA) is another key piece of legislation that governs the disposal of solid and hazardous waste. It sets standards for the treatment, storage, and disposal of hazardous waste, including those that may be addressed using sodium silicate remediation techniques. The Clean Water Act and Safe Drinking Water Act also come into play when considering the use of sodium silicate in environmental remediation, particularly in cases involving groundwater contamination.

At the state level, regulations can vary significantly, with some states imposing stricter standards than federal requirements. Many states have their own environmental protection agencies that work in conjunction with the EPA to enforce regulations and oversee remediation efforts. These state-level agencies often have the authority to issue permits, conduct inspections, and enforce compliance with both state and federal environmental laws.

Internationally, the use of sodium silicate in environmental remediation must comply with various treaties and agreements. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, for instance, sets global standards for the management of hazardous wastes. The Stockholm Convention on Persistent Organic Pollutants also influences remediation practices, particularly when dealing with certain types of contaminants.

Regulatory compliance in this field requires careful consideration of technical standards and guidelines. Organizations such as ASTM International provide standardized testing methods and specifications that are often referenced in regulatory frameworks. These standards help ensure consistency and reliability in the application of sodium silicate and other remediation technologies.

As environmental concerns continue to evolve, regulatory frameworks are likely to adapt. Emerging contaminants and new scientific understanding of environmental impacts may lead to changes in how sodium silicate and other remediation techniques are regulated. Stakeholders in the field must stay informed about these developments to ensure ongoing compliance and effectiveness in environmental hazard remediation efforts.

The Resource Conservation and Recovery Act (RCRA) is another key piece of legislation that governs the disposal of solid and hazardous waste. It sets standards for the treatment, storage, and disposal of hazardous waste, including those that may be addressed using sodium silicate remediation techniques. The Clean Water Act and Safe Drinking Water Act also come into play when considering the use of sodium silicate in environmental remediation, particularly in cases involving groundwater contamination.

At the state level, regulations can vary significantly, with some states imposing stricter standards than federal requirements. Many states have their own environmental protection agencies that work in conjunction with the EPA to enforce regulations and oversee remediation efforts. These state-level agencies often have the authority to issue permits, conduct inspections, and enforce compliance with both state and federal environmental laws.

Internationally, the use of sodium silicate in environmental remediation must comply with various treaties and agreements. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, for instance, sets global standards for the management of hazardous wastes. The Stockholm Convention on Persistent Organic Pollutants also influences remediation practices, particularly when dealing with certain types of contaminants.

Regulatory compliance in this field requires careful consideration of technical standards and guidelines. Organizations such as ASTM International provide standardized testing methods and specifications that are often referenced in regulatory frameworks. These standards help ensure consistency and reliability in the application of sodium silicate and other remediation technologies.

As environmental concerns continue to evolve, regulatory frameworks are likely to adapt. Emerging contaminants and new scientific understanding of environmental impacts may lead to changes in how sodium silicate and other remediation techniques are regulated. Stakeholders in the field must stay informed about these developments to ensure ongoing compliance and effectiveness in environmental hazard remediation efforts.

Sustainability Aspects of Sodium Silicate Remediation

The sustainability aspects of sodium silicate remediation are crucial considerations in environmental hazard management. Sodium silicate, a versatile and eco-friendly compound, offers significant advantages in terms of environmental sustainability when used for remediation purposes.

One of the primary sustainability benefits of sodium silicate remediation is its low environmental impact. Unlike many chemical treatments, sodium silicate is non-toxic and does not introduce harmful substances into the ecosystem. This characteristic ensures that the remediation process itself does not create additional environmental hazards, aligning with the principles of sustainable environmental management.

The production of sodium silicate is relatively energy-efficient compared to other remediation materials. It is manufactured from abundant natural resources, primarily sand and soda ash, which are widely available and have a lower environmental footprint in terms of extraction and processing. This aspect contributes to the overall sustainability of the remediation process by reducing the carbon footprint associated with material production.

In terms of long-term environmental effects, sodium silicate remediation demonstrates favorable outcomes. Once applied, it forms stable silicate structures that integrate with the surrounding soil or groundwater matrix. This integration enhances the durability of the remediation solution, reducing the need for frequent reapplications and minimizing ongoing environmental disturbances.

The versatility of sodium silicate in addressing various environmental hazards also contributes to its sustainability profile. It can be used for soil stabilization, heavy metal immobilization, and groundwater contamination treatment. This multi-functionality means that a single compound can address multiple environmental issues, potentially reducing the overall resource consumption and complexity of remediation projects.

Furthermore, sodium silicate remediation often supports natural attenuation processes. By altering the pH and chemical composition of contaminated areas, it can create conditions that favor the growth of beneficial microorganisms. These microorganisms can further break down contaminants, leading to a more comprehensive and sustainable cleanup process.

The recyclability and reusability of sodium silicate in certain applications add another layer to its sustainability credentials. In some cases, treated materials can be repurposed or safely disposed of without additional environmental concerns, contributing to circular economy principles in environmental management.

However, it is important to note that the sustainability of sodium silicate remediation also depends on proper application techniques and site-specific considerations. Overuse or misapplication can lead to soil alkalinity issues or affect local ecosystems. Therefore, careful planning and monitoring are essential to maximize the sustainability benefits while minimizing potential negative impacts.

One of the primary sustainability benefits of sodium silicate remediation is its low environmental impact. Unlike many chemical treatments, sodium silicate is non-toxic and does not introduce harmful substances into the ecosystem. This characteristic ensures that the remediation process itself does not create additional environmental hazards, aligning with the principles of sustainable environmental management.

The production of sodium silicate is relatively energy-efficient compared to other remediation materials. It is manufactured from abundant natural resources, primarily sand and soda ash, which are widely available and have a lower environmental footprint in terms of extraction and processing. This aspect contributes to the overall sustainability of the remediation process by reducing the carbon footprint associated with material production.

In terms of long-term environmental effects, sodium silicate remediation demonstrates favorable outcomes. Once applied, it forms stable silicate structures that integrate with the surrounding soil or groundwater matrix. This integration enhances the durability of the remediation solution, reducing the need for frequent reapplications and minimizing ongoing environmental disturbances.

The versatility of sodium silicate in addressing various environmental hazards also contributes to its sustainability profile. It can be used for soil stabilization, heavy metal immobilization, and groundwater contamination treatment. This multi-functionality means that a single compound can address multiple environmental issues, potentially reducing the overall resource consumption and complexity of remediation projects.

Furthermore, sodium silicate remediation often supports natural attenuation processes. By altering the pH and chemical composition of contaminated areas, it can create conditions that favor the growth of beneficial microorganisms. These microorganisms can further break down contaminants, leading to a more comprehensive and sustainable cleanup process.

The recyclability and reusability of sodium silicate in certain applications add another layer to its sustainability credentials. In some cases, treated materials can be repurposed or safely disposed of without additional environmental concerns, contributing to circular economy principles in environmental management.

However, it is important to note that the sustainability of sodium silicate remediation also depends on proper application techniques and site-specific considerations. Overuse or misapplication can lead to soil alkalinity issues or affect local ecosystems. Therefore, careful planning and monitoring are essential to maximize the sustainability benefits while minimizing potential negative impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!