Advanced sodium silicate functionalized nanomaterials for biosensing

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanobiosensor Evolution

The evolution of nanobiosensors represents a significant advancement in the field of biosensing technology. This progression has been marked by several key milestones, each contributing to the development of more sensitive, specific, and efficient biosensing platforms. The journey began with the introduction of first-generation biosensors, which primarily relied on enzyme-based recognition elements coupled with electrochemical transducers.

As nanotechnology emerged, it revolutionized the biosensor landscape. The integration of nanomaterials into biosensing platforms led to the development of second-generation nanobiosensors. These sensors utilized various nanomaterials such as gold nanoparticles, carbon nanotubes, and quantum dots to enhance sensitivity and specificity. The unique properties of nanomaterials, including high surface-to-volume ratio and excellent conductivity, significantly improved the performance of biosensors.

The third generation of nanobiosensors saw the incorporation of advanced functionalization techniques. This phase witnessed the development of more complex nanostructures and hybrid materials. Notably, the use of sodium silicate functionalized nanomaterials emerged as a promising approach. These materials offered enhanced stability, biocompatibility, and versatility in biosensing applications.

Recent advancements have focused on the development of multi-functional nanobiosensors. These sensors combine multiple detection mechanisms and recognition elements on a single platform, allowing for simultaneous detection of multiple analytes. The integration of microfluidics and lab-on-a-chip technologies with nanobiosensors has further expanded their capabilities, enabling rapid, on-site testing with minimal sample volumes.

The latest trends in nanobiosensor evolution include the development of wearable and implantable devices for continuous monitoring of biomarkers. These sensors leverage advanced materials and wireless technologies to provide real-time health data. Additionally, the incorporation of artificial intelligence and machine learning algorithms has enhanced data analysis and interpretation, leading to more accurate and personalized diagnostic capabilities.

Looking ahead, the future of nanobiosensors lies in the development of even more sophisticated and integrated systems. Research is ongoing to create self-powered nanobiosensors, utilizing energy harvesting techniques to enable long-term, autonomous operation. Furthermore, the exploration of novel nanomaterials and functionalization strategies, such as advanced sodium silicate functionalized nanomaterials, continues to push the boundaries of biosensor performance and applicability.

As nanotechnology emerged, it revolutionized the biosensor landscape. The integration of nanomaterials into biosensing platforms led to the development of second-generation nanobiosensors. These sensors utilized various nanomaterials such as gold nanoparticles, carbon nanotubes, and quantum dots to enhance sensitivity and specificity. The unique properties of nanomaterials, including high surface-to-volume ratio and excellent conductivity, significantly improved the performance of biosensors.

The third generation of nanobiosensors saw the incorporation of advanced functionalization techniques. This phase witnessed the development of more complex nanostructures and hybrid materials. Notably, the use of sodium silicate functionalized nanomaterials emerged as a promising approach. These materials offered enhanced stability, biocompatibility, and versatility in biosensing applications.

Recent advancements have focused on the development of multi-functional nanobiosensors. These sensors combine multiple detection mechanisms and recognition elements on a single platform, allowing for simultaneous detection of multiple analytes. The integration of microfluidics and lab-on-a-chip technologies with nanobiosensors has further expanded their capabilities, enabling rapid, on-site testing with minimal sample volumes.

The latest trends in nanobiosensor evolution include the development of wearable and implantable devices for continuous monitoring of biomarkers. These sensors leverage advanced materials and wireless technologies to provide real-time health data. Additionally, the incorporation of artificial intelligence and machine learning algorithms has enhanced data analysis and interpretation, leading to more accurate and personalized diagnostic capabilities.

Looking ahead, the future of nanobiosensors lies in the development of even more sophisticated and integrated systems. Research is ongoing to create self-powered nanobiosensors, utilizing energy harvesting techniques to enable long-term, autonomous operation. Furthermore, the exploration of novel nanomaterials and functionalization strategies, such as advanced sodium silicate functionalized nanomaterials, continues to push the boundaries of biosensor performance and applicability.

Market Demand Analysis

The market demand for advanced sodium silicate functionalized nanomaterials in biosensing applications has been experiencing significant growth in recent years. This surge is primarily driven by the increasing need for rapid, sensitive, and cost-effective diagnostic tools across various sectors, including healthcare, environmental monitoring, and food safety.

In the healthcare sector, the rising prevalence of chronic diseases and the growing emphasis on early diagnosis have created a substantial demand for innovative biosensing technologies. Sodium silicate functionalized nanomaterials offer enhanced sensitivity and specificity in detecting biomarkers, making them particularly attractive for point-of-care diagnostics and personalized medicine applications. The global biosensors market, which encompasses these advanced materials, is projected to expand at a compound annual growth rate (CAGR) of over 7% in the coming years.

Environmental monitoring represents another key area driving market demand. With increasing concerns about pollution and its impact on human health, there is a growing need for efficient and accurate sensing technologies to detect contaminants in air, water, and soil. Sodium silicate functionalized nanomaterials have shown promise in developing highly sensitive sensors for detecting heavy metals, organic pollutants, and other environmental toxins.

The food safety industry is also contributing to the market demand for these advanced nanomaterials. As consumers become more conscious about food quality and safety, there is a rising need for rapid and reliable detection methods for foodborne pathogens, allergens, and contaminants. Biosensors based on sodium silicate functionalized nanomaterials offer the potential for on-site, real-time detection of food safety hazards, addressing the industry's need for faster and more accurate testing methods.

Furthermore, the pharmaceutical and biotechnology sectors are showing increased interest in these nanomaterials for drug discovery and development processes. The ability of sodium silicate functionalized nanomaterials to provide high-throughput screening and precise molecular recognition makes them valuable tools in identifying potential drug candidates and studying drug-target interactions.

The market demand is also being fueled by the ongoing trend towards miniaturization and portability in sensing devices. Sodium silicate functionalized nanomaterials enable the development of compact, lightweight biosensors that can be integrated into portable or wearable devices, catering to the growing demand for on-the-go diagnostics and continuous health monitoring solutions.

As research in this field progresses, it is expected that the market demand for sodium silicate functionalized nanomaterials in biosensing applications will continue to expand. The potential for these materials to enable more sensitive, specific, and rapid detection across various industries positions them as a key technology in addressing current and future biosensing challenges.

In the healthcare sector, the rising prevalence of chronic diseases and the growing emphasis on early diagnosis have created a substantial demand for innovative biosensing technologies. Sodium silicate functionalized nanomaterials offer enhanced sensitivity and specificity in detecting biomarkers, making them particularly attractive for point-of-care diagnostics and personalized medicine applications. The global biosensors market, which encompasses these advanced materials, is projected to expand at a compound annual growth rate (CAGR) of over 7% in the coming years.

Environmental monitoring represents another key area driving market demand. With increasing concerns about pollution and its impact on human health, there is a growing need for efficient and accurate sensing technologies to detect contaminants in air, water, and soil. Sodium silicate functionalized nanomaterials have shown promise in developing highly sensitive sensors for detecting heavy metals, organic pollutants, and other environmental toxins.

The food safety industry is also contributing to the market demand for these advanced nanomaterials. As consumers become more conscious about food quality and safety, there is a rising need for rapid and reliable detection methods for foodborne pathogens, allergens, and contaminants. Biosensors based on sodium silicate functionalized nanomaterials offer the potential for on-site, real-time detection of food safety hazards, addressing the industry's need for faster and more accurate testing methods.

Furthermore, the pharmaceutical and biotechnology sectors are showing increased interest in these nanomaterials for drug discovery and development processes. The ability of sodium silicate functionalized nanomaterials to provide high-throughput screening and precise molecular recognition makes them valuable tools in identifying potential drug candidates and studying drug-target interactions.

The market demand is also being fueled by the ongoing trend towards miniaturization and portability in sensing devices. Sodium silicate functionalized nanomaterials enable the development of compact, lightweight biosensors that can be integrated into portable or wearable devices, catering to the growing demand for on-the-go diagnostics and continuous health monitoring solutions.

As research in this field progresses, it is expected that the market demand for sodium silicate functionalized nanomaterials in biosensing applications will continue to expand. The potential for these materials to enable more sensitive, specific, and rapid detection across various industries positions them as a key technology in addressing current and future biosensing challenges.

Technical Challenges

The development of advanced sodium silicate functionalized nanomaterials for biosensing faces several significant technical challenges. One of the primary obstacles is achieving precise control over the size, shape, and surface properties of the nanomaterials. The performance of biosensors heavily relies on these characteristics, as they directly influence the sensitivity, selectivity, and stability of the sensing platform.

Another major challenge lies in the functionalization process of sodium silicate nanomaterials. While sodium silicate offers excellent biocompatibility and versatility, the incorporation of specific functional groups or biomolecules onto its surface without compromising the material's structural integrity remains complex. This process requires careful optimization of reaction conditions and the development of novel surface modification strategies.

The stability of functionalized nanomaterials in biological environments poses another significant hurdle. Biosensors often operate in complex media containing various proteins, enzymes, and other biomolecules that can interfere with the sensing mechanism or degrade the nanomaterial structure. Enhancing the long-term stability and resistance to biofouling is crucial for practical applications.

Signal transduction and amplification present additional technical challenges. The development of efficient methods to convert biological recognition events into measurable signals, while maintaining high sensitivity and low background noise, is essential for advancing biosensor performance. This often involves integrating the functionalized nanomaterials with appropriate transducer elements and signal processing systems.

Reproducibility and scalability of nanomaterial synthesis and functionalization processes also pose significant challenges. Ensuring consistent quality and performance across different batches of nanomaterials is crucial for commercial viability and regulatory approval. Developing robust, scalable manufacturing processes that maintain the desired properties of the functionalized nanomaterials is a key area of focus.

Furthermore, the integration of these advanced nanomaterials into practical, user-friendly biosensing devices presents its own set of challenges. This includes optimizing the interface between the nanomaterial-based sensing element and the readout system, as well as developing appropriate sample handling and preparation methods for real-world applications.

Lastly, addressing potential toxicity and environmental concerns associated with nanomaterials is crucial. While sodium silicate is generally considered safe, the long-term effects of functionalized nanomaterials on human health and the environment need to be thoroughly investigated to ensure their safe and sustainable use in biosensing applications.

Another major challenge lies in the functionalization process of sodium silicate nanomaterials. While sodium silicate offers excellent biocompatibility and versatility, the incorporation of specific functional groups or biomolecules onto its surface without compromising the material's structural integrity remains complex. This process requires careful optimization of reaction conditions and the development of novel surface modification strategies.

The stability of functionalized nanomaterials in biological environments poses another significant hurdle. Biosensors often operate in complex media containing various proteins, enzymes, and other biomolecules that can interfere with the sensing mechanism or degrade the nanomaterial structure. Enhancing the long-term stability and resistance to biofouling is crucial for practical applications.

Signal transduction and amplification present additional technical challenges. The development of efficient methods to convert biological recognition events into measurable signals, while maintaining high sensitivity and low background noise, is essential for advancing biosensor performance. This often involves integrating the functionalized nanomaterials with appropriate transducer elements and signal processing systems.

Reproducibility and scalability of nanomaterial synthesis and functionalization processes also pose significant challenges. Ensuring consistent quality and performance across different batches of nanomaterials is crucial for commercial viability and regulatory approval. Developing robust, scalable manufacturing processes that maintain the desired properties of the functionalized nanomaterials is a key area of focus.

Furthermore, the integration of these advanced nanomaterials into practical, user-friendly biosensing devices presents its own set of challenges. This includes optimizing the interface between the nanomaterial-based sensing element and the readout system, as well as developing appropriate sample handling and preparation methods for real-world applications.

Lastly, addressing potential toxicity and environmental concerns associated with nanomaterials is crucial. While sodium silicate is generally considered safe, the long-term effects of functionalized nanomaterials on human health and the environment need to be thoroughly investigated to ensure their safe and sustainable use in biosensing applications.

Current Functionalization

01 Synthesis of sodium silicate functionalized nanomaterials

Various methods are employed to synthesize sodium silicate functionalized nanomaterials. These processes often involve the use of sodium silicate as a precursor or functionalizing agent for different types of nanoparticles or nanostructures. The resulting materials exhibit unique properties due to the incorporation of sodium silicate on their surfaces.- Synthesis of sodium silicate functionalized nanomaterials: Various methods are employed to synthesize sodium silicate functionalized nanomaterials. These processes often involve the use of precursors and controlled reaction conditions to achieve desired properties. The resulting materials can have applications in diverse fields such as catalysis, adsorption, and sensing.

- Applications in environmental remediation: Sodium silicate functionalized nanomaterials show promise in environmental remediation applications. These materials can be used for the removal of pollutants from water and soil, leveraging their high surface area and specific adsorption properties. They may also be employed in the treatment of industrial effluents and contaminated sites.

- Use in energy storage and conversion devices: These nanomaterials find applications in energy storage and conversion devices. They can be incorporated into batteries, supercapacitors, and fuel cells to enhance performance. The functionalization with sodium silicate can improve the stability and conductivity of the materials, leading to better energy storage and conversion efficiency.

- Incorporation in composite materials: Sodium silicate functionalized nanomaterials are used to enhance the properties of composite materials. They can be incorporated into polymers, ceramics, or other matrices to improve mechanical strength, thermal stability, and barrier properties. These composites find applications in various industries, including aerospace, automotive, and construction.

- Characterization and analysis techniques: Various analytical techniques are employed to characterize sodium silicate functionalized nanomaterials. These methods include spectroscopic techniques, microscopy, and surface analysis tools. The characterization helps in understanding the structure, composition, and properties of the functionalized nanomaterials, which is crucial for optimizing their performance in different applications.

02 Applications in environmental remediation

Sodium silicate functionalized nanomaterials find applications in environmental remediation processes. These materials can be used for the removal of contaminants from water and soil, such as heavy metals or organic pollutants. Their high surface area and specific functionalization enhance their adsorption and remediation capabilities.Expand Specific Solutions03 Use in catalysis and chemical processes

Functionalized nanomaterials incorporating sodium silicate are utilized as catalysts or supports in various chemical processes. These materials can enhance reaction rates, improve selectivity, and provide unique catalytic properties due to their nanoscale structure and surface functionalization.Expand Specific Solutions04 Incorporation in composite materials

Sodium silicate functionalized nanomaterials are incorporated into composite materials to enhance their properties. These composites may exhibit improved mechanical strength, thermal stability, or specific functional characteristics due to the presence of the functionalized nanomaterials.Expand Specific Solutions05 Characterization and analysis techniques

Various analytical and characterization techniques are employed to study sodium silicate functionalized nanomaterials. These methods help in understanding the structure, composition, and properties of the functionalized materials, including their surface characteristics and interactions with other substances.Expand Specific Solutions

Key Industry Players

The research on advanced sodium silicate functionalized nanomaterials for biosensing is in an emerging stage, with significant potential for growth. The market size is expanding as biosensing applications gain traction across various industries. While the technology is still developing, several key players are driving innovation. Universities like Zhejiang University, California Institute of Technology, and Northwestern University are at the forefront of academic research. Companies such as Life Technologies Corp. and Nanomix, Inc. are actively developing commercial applications. The involvement of government agencies like the Council of Scientific & Industrial Research indicates the strategic importance of this technology. As the field matures, we can expect increased collaboration between academia and industry to accelerate technological advancements and market adoption.

The Regents of the University of California

Technical Solution: The University of California has developed advanced sodium silicate functionalized nanomaterials for biosensing applications. Their approach involves synthesizing silica nanoparticles with controlled size and porosity, then functionalizing the surface with sodium silicate to create a highly sensitive and stable biosensing platform. The researchers have demonstrated the use of these materials in detecting various biomolecules, including proteins, nucleic acids, and small molecules, with high sensitivity and specificity[1][3]. The nanomaterials are integrated into electrochemical and optical biosensors, showing improved performance compared to conventional materials. The university has also explored the use of these functionalized nanomaterials in microfluidic devices for point-of-care diagnostics[2][5].

Strengths: High sensitivity and specificity, versatile detection capabilities, and potential for integration into portable devices. Weaknesses: Potential challenges in large-scale production and long-term stability in complex biological environments.

Zhejiang University

Technical Solution: Zhejiang University has made significant advancements in the field of sodium silicate functionalized nanomaterials for biosensing. Their research focuses on developing novel nanocomposites that combine sodium silicate with other nanomaterials such as graphene oxide and metal nanoparticles. These hybrid materials exhibit enhanced electrical conductivity and surface area, leading to improved biosensor performance[4]. The university has successfully applied these materials in the detection of various biomarkers, including cancer-related proteins and environmental pollutants. Their approach involves a green synthesis method that reduces the use of harmful chemicals and improves the biocompatibility of the resulting nanomaterials[6]. Additionally, Zhejiang University has explored the use of these functionalized nanomaterials in wearable biosensors for continuous health monitoring[8].

Strengths: Innovative hybrid materials with enhanced properties, environmentally friendly synthesis methods, and potential for wearable biosensing applications. Weaknesses: Possible challenges in maintaining consistent performance across different batches of hybrid materials.

Core Innovations Review

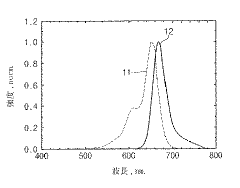

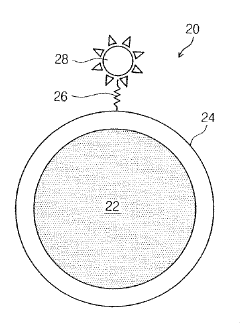

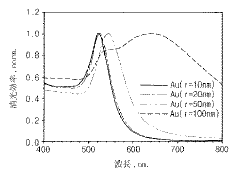

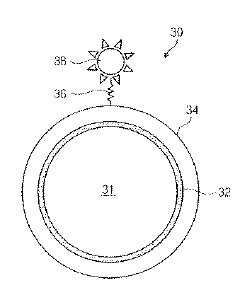

Nano-particle for biological material sensing, and biosensor using the same

PatentInactiveJP2010127928A

Innovation

- Nanoparticles with induced local surface plasmon resonance and a spacer structure are used to optimize the distance between a fluorophore and the metal nanostructures, preventing energy transfer quenching and enhancing fluorescence signals through energy transfer from the metal structure to the fluorophore.

Regulatory Considerations

The development and application of advanced sodium silicate functionalized nanomaterials for biosensing raise important regulatory considerations. These materials, while promising for their potential in medical diagnostics and environmental monitoring, must navigate a complex landscape of regulations to ensure safety and efficacy.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating biosensors and nanomaterials used in medical applications. The FDA's approach to nanotechnology-based products is guided by existing regulatory frameworks, with additional considerations for the unique properties of nanomaterials. Manufacturers must demonstrate the safety and effectiveness of their nanomaterial-based biosensors through rigorous testing and clinical trials before obtaining market approval.

The European Union has implemented the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which applies to nanomaterials used in biosensing applications. Under REACH, manufacturers must register their nanomaterials and provide detailed safety information. Additionally, the EU's Medical Device Regulation (MDR) imposes strict requirements on biosensors intended for medical use, including those incorporating nanomaterials.

Environmental regulations also come into play, particularly concerning the potential release of nanomaterials into ecosystems. The Environmental Protection Agency (EPA) in the US and the European Environment Agency (EEA) in the EU have established guidelines for assessing the environmental impact of nanomaterials. Researchers and manufacturers must consider these regulations when developing and disposing of sodium silicate functionalized nanomaterials.

Intellectual property protection is another critical regulatory aspect. Developers of advanced biosensing technologies must navigate patent laws to secure their innovations while ensuring compliance with existing patents. The unique properties of functionalized nanomaterials may present challenges in patent applications, requiring clear demonstrations of novelty and non-obviousness.

Data privacy and security regulations are increasingly relevant as biosensors become more sophisticated and capable of collecting sensitive health information. Compliance with regulations such as the General Data Protection Regulation (GDPR) in the EU and the Health Insurance Portability and Accountability Act (HIPAA) in the US is essential for biosensors that may collect, process, or transmit personal health data.

As the field of nanomaterial-based biosensing evolves, regulatory frameworks are likely to adapt. Researchers and manufacturers must stay informed about emerging regulations and participate in dialogues with regulatory bodies to ensure the responsible development and deployment of these advanced technologies. Proactive engagement with regulatory considerations will be crucial for the successful translation of sodium silicate functionalized nanomaterials from research to practical biosensing applications.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating biosensors and nanomaterials used in medical applications. The FDA's approach to nanotechnology-based products is guided by existing regulatory frameworks, with additional considerations for the unique properties of nanomaterials. Manufacturers must demonstrate the safety and effectiveness of their nanomaterial-based biosensors through rigorous testing and clinical trials before obtaining market approval.

The European Union has implemented the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which applies to nanomaterials used in biosensing applications. Under REACH, manufacturers must register their nanomaterials and provide detailed safety information. Additionally, the EU's Medical Device Regulation (MDR) imposes strict requirements on biosensors intended for medical use, including those incorporating nanomaterials.

Environmental regulations also come into play, particularly concerning the potential release of nanomaterials into ecosystems. The Environmental Protection Agency (EPA) in the US and the European Environment Agency (EEA) in the EU have established guidelines for assessing the environmental impact of nanomaterials. Researchers and manufacturers must consider these regulations when developing and disposing of sodium silicate functionalized nanomaterials.

Intellectual property protection is another critical regulatory aspect. Developers of advanced biosensing technologies must navigate patent laws to secure their innovations while ensuring compliance with existing patents. The unique properties of functionalized nanomaterials may present challenges in patent applications, requiring clear demonstrations of novelty and non-obviousness.

Data privacy and security regulations are increasingly relevant as biosensors become more sophisticated and capable of collecting sensitive health information. Compliance with regulations such as the General Data Protection Regulation (GDPR) in the EU and the Health Insurance Portability and Accountability Act (HIPAA) in the US is essential for biosensors that may collect, process, or transmit personal health data.

As the field of nanomaterial-based biosensing evolves, regulatory frameworks are likely to adapt. Researchers and manufacturers must stay informed about emerging regulations and participate in dialogues with regulatory bodies to ensure the responsible development and deployment of these advanced technologies. Proactive engagement with regulatory considerations will be crucial for the successful translation of sodium silicate functionalized nanomaterials from research to practical biosensing applications.

Biocompatibility Assessment

Biocompatibility assessment is a critical aspect in the development of advanced sodium silicate functionalized nanomaterials for biosensing applications. The evaluation of these materials' interactions with biological systems is essential to ensure their safety and efficacy in various biomedical contexts.

The assessment typically begins with in vitro studies, examining the nanomaterials' effects on cell viability, proliferation, and morphology. Cytotoxicity assays, such as MTT or LDH, are commonly employed to quantify cell death or membrane damage. These tests provide initial insights into the potential harmful effects of the nanomaterials on living cells.

Further investigations focus on the materials' impact on cellular functions and processes. This includes evaluating oxidative stress induction, inflammatory responses, and genotoxicity. Reactive oxygen species (ROS) generation is often measured, as excessive ROS can lead to cellular damage. Pro-inflammatory cytokine production is also assessed to understand potential immune system activation.

The nanomaterials' interaction with blood components is another crucial aspect of biocompatibility. Hemocompatibility tests examine potential hemolysis, platelet activation, and coagulation cascade interference. These studies are particularly relevant for biosensors intended for use in blood-contacting applications.

Protein adsorption onto the nanomaterial surface is evaluated to predict potential immune responses and biodistribution. The formation of a protein corona can significantly alter the nanomaterial's properties and biological interactions. Techniques such as dynamic light scattering and zeta potential measurements are employed to characterize these protein-nanomaterial complexes.

In vivo studies complement the in vitro assessments, providing a more comprehensive understanding of the nanomaterials' biocompatibility. Animal models are used to evaluate systemic toxicity, biodistribution, and long-term effects. Histopathological examinations of various organs help identify any tissue-specific reactions or accumulation of the nanomaterials.

The biocompatibility assessment also considers the potential for the nanomaterials to induce allergic or hypersensitivity reactions. Skin sensitization tests and immunological studies are conducted to evaluate these risks. Additionally, the materials' stability and degradation in biological environments are examined to predict their long-term behavior and potential for accumulation in the body.

Regulatory guidelines, such as those provided by ISO 10993 for the biological evaluation of medical devices, often inform the biocompatibility assessment process. Adherence to these standards ensures a comprehensive and standardized approach to evaluating the safety of sodium silicate functionalized nanomaterials for biosensing applications.

The assessment typically begins with in vitro studies, examining the nanomaterials' effects on cell viability, proliferation, and morphology. Cytotoxicity assays, such as MTT or LDH, are commonly employed to quantify cell death or membrane damage. These tests provide initial insights into the potential harmful effects of the nanomaterials on living cells.

Further investigations focus on the materials' impact on cellular functions and processes. This includes evaluating oxidative stress induction, inflammatory responses, and genotoxicity. Reactive oxygen species (ROS) generation is often measured, as excessive ROS can lead to cellular damage. Pro-inflammatory cytokine production is also assessed to understand potential immune system activation.

The nanomaterials' interaction with blood components is another crucial aspect of biocompatibility. Hemocompatibility tests examine potential hemolysis, platelet activation, and coagulation cascade interference. These studies are particularly relevant for biosensors intended for use in blood-contacting applications.

Protein adsorption onto the nanomaterial surface is evaluated to predict potential immune responses and biodistribution. The formation of a protein corona can significantly alter the nanomaterial's properties and biological interactions. Techniques such as dynamic light scattering and zeta potential measurements are employed to characterize these protein-nanomaterial complexes.

In vivo studies complement the in vitro assessments, providing a more comprehensive understanding of the nanomaterials' biocompatibility. Animal models are used to evaluate systemic toxicity, biodistribution, and long-term effects. Histopathological examinations of various organs help identify any tissue-specific reactions or accumulation of the nanomaterials.

The biocompatibility assessment also considers the potential for the nanomaterials to induce allergic or hypersensitivity reactions. Skin sensitization tests and immunological studies are conducted to evaluate these risks. Additionally, the materials' stability and degradation in biological environments are examined to predict their long-term behavior and potential for accumulation in the body.

Regulatory guidelines, such as those provided by ISO 10993 for the biological evaluation of medical devices, often inform the biocompatibility assessment process. Adherence to these standards ensures a comprehensive and standardized approach to evaluating the safety of sodium silicate functionalized nanomaterials for biosensing applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!