Sodium silicate utilizations in non-ferrous metal corrosion studies

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Silicate in Corrosion Protection: Background and Objectives

Sodium silicate, also known as water glass, has been a subject of interest in corrosion protection studies for non-ferrous metals due to its unique properties and potential applications. The history of sodium silicate usage in corrosion prevention can be traced back to the early 20th century when researchers began exploring its protective capabilities. Over the years, the understanding of its mechanisms and effectiveness has evolved significantly, leading to its incorporation in various corrosion mitigation strategies.

The primary objective of utilizing sodium silicate in non-ferrous metal corrosion studies is to develop cost-effective and environmentally friendly protective coatings or treatments. These solutions aim to enhance the corrosion resistance of metals such as aluminum, copper, and zinc, which are widely used in industries ranging from construction to electronics. By forming a protective barrier on the metal surface, sodium silicate can potentially reduce the rate of corrosion and extend the lifespan of non-ferrous metal components.

Recent technological advancements have sparked renewed interest in sodium silicate as a corrosion inhibitor. The push for sustainable and non-toxic alternatives to traditional chromate-based treatments has positioned sodium silicate as a promising candidate. Its ability to form stable, insoluble precipitates on metal surfaces, combined with its low toxicity and abundance, makes it an attractive option for researchers and industry professionals alike.

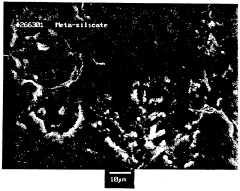

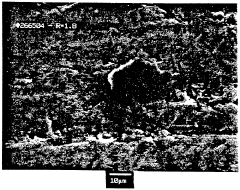

The evolution of sodium silicate applications in corrosion protection has been driven by several factors. Improved understanding of the chemical interactions between silicates and metal surfaces has led to more effective formulations. Additionally, the development of advanced characterization techniques has enabled researchers to study the protective layers at a microscopic level, providing insights into their formation and properties.

Current research trends focus on optimizing the composition and application methods of sodium silicate-based treatments. This includes investigating the effects of pH, concentration, and the presence of additives on the protective performance. Furthermore, there is growing interest in combining sodium silicate with other corrosion inhibitors or nanoparticles to create synergistic protective systems.

As environmental regulations become more stringent, the demand for eco-friendly corrosion protection solutions continues to rise. This has set the stage for sodium silicate to play a crucial role in future corrosion prevention strategies for non-ferrous metals. The ongoing research aims to address challenges such as long-term stability, adhesion to various metal substrates, and performance under diverse environmental conditions.

The primary objective of utilizing sodium silicate in non-ferrous metal corrosion studies is to develop cost-effective and environmentally friendly protective coatings or treatments. These solutions aim to enhance the corrosion resistance of metals such as aluminum, copper, and zinc, which are widely used in industries ranging from construction to electronics. By forming a protective barrier on the metal surface, sodium silicate can potentially reduce the rate of corrosion and extend the lifespan of non-ferrous metal components.

Recent technological advancements have sparked renewed interest in sodium silicate as a corrosion inhibitor. The push for sustainable and non-toxic alternatives to traditional chromate-based treatments has positioned sodium silicate as a promising candidate. Its ability to form stable, insoluble precipitates on metal surfaces, combined with its low toxicity and abundance, makes it an attractive option for researchers and industry professionals alike.

The evolution of sodium silicate applications in corrosion protection has been driven by several factors. Improved understanding of the chemical interactions between silicates and metal surfaces has led to more effective formulations. Additionally, the development of advanced characterization techniques has enabled researchers to study the protective layers at a microscopic level, providing insights into their formation and properties.

Current research trends focus on optimizing the composition and application methods of sodium silicate-based treatments. This includes investigating the effects of pH, concentration, and the presence of additives on the protective performance. Furthermore, there is growing interest in combining sodium silicate with other corrosion inhibitors or nanoparticles to create synergistic protective systems.

As environmental regulations become more stringent, the demand for eco-friendly corrosion protection solutions continues to rise. This has set the stage for sodium silicate to play a crucial role in future corrosion prevention strategies for non-ferrous metals. The ongoing research aims to address challenges such as long-term stability, adhesion to various metal substrates, and performance under diverse environmental conditions.

Market Analysis for Corrosion-Resistant Solutions

The market for corrosion-resistant solutions in non-ferrous metal industries has been experiencing significant growth due to the increasing demand for durable and long-lasting materials across various sectors. Sodium silicate, a versatile compound, has emerged as a key player in this market, particularly in corrosion studies and protection applications for non-ferrous metals.

The global corrosion inhibitors market, which includes sodium silicate-based solutions, is projected to reach substantial value in the coming years. This growth is primarily driven by the expanding industrial infrastructure, rising awareness about the economic impact of corrosion, and stringent environmental regulations promoting the use of eco-friendly corrosion inhibitors.

In the non-ferrous metals sector, industries such as aerospace, automotive, construction, and electronics are major consumers of corrosion-resistant solutions. The aerospace industry, in particular, has shown a strong demand for advanced corrosion protection methods to ensure the longevity and safety of aircraft components. Similarly, the automotive sector's shift towards lightweight materials, including aluminum and magnesium alloys, has increased the need for effective corrosion inhibition techniques.

The construction industry also presents a significant market opportunity for sodium silicate-based corrosion-resistant solutions. With the growing use of non-ferrous metals in modern architecture and infrastructure projects, there is an increasing demand for protective coatings and treatments that can withstand harsh environmental conditions.

Geographically, Asia-Pacific region leads the market for corrosion-resistant solutions, followed by North America and Europe. The rapid industrialization and infrastructure development in countries like China and India are driving the demand for corrosion protection in these regions. Additionally, the presence of major automotive and aerospace manufacturers in North America and Europe contributes to the steady market growth in these areas.

The market landscape for corrosion-resistant solutions is characterized by intense competition among key players, including chemical companies, coating manufacturers, and specialty material providers. These companies are investing heavily in research and development to innovate new formulations and application methods for sodium silicate and other corrosion inhibitors.

Looking ahead, the market for corrosion-resistant solutions, particularly those utilizing sodium silicate, is expected to continue its upward trajectory. Factors such as the increasing adoption of non-ferrous metals in various industries, growing awareness about the cost-effectiveness of corrosion prevention, and ongoing technological advancements in material science will likely fuel this growth. As industries continue to seek more efficient and sustainable solutions for corrosion protection, the role of sodium silicate in non-ferrous metal applications is poised to expand further.

The global corrosion inhibitors market, which includes sodium silicate-based solutions, is projected to reach substantial value in the coming years. This growth is primarily driven by the expanding industrial infrastructure, rising awareness about the economic impact of corrosion, and stringent environmental regulations promoting the use of eco-friendly corrosion inhibitors.

In the non-ferrous metals sector, industries such as aerospace, automotive, construction, and electronics are major consumers of corrosion-resistant solutions. The aerospace industry, in particular, has shown a strong demand for advanced corrosion protection methods to ensure the longevity and safety of aircraft components. Similarly, the automotive sector's shift towards lightweight materials, including aluminum and magnesium alloys, has increased the need for effective corrosion inhibition techniques.

The construction industry also presents a significant market opportunity for sodium silicate-based corrosion-resistant solutions. With the growing use of non-ferrous metals in modern architecture and infrastructure projects, there is an increasing demand for protective coatings and treatments that can withstand harsh environmental conditions.

Geographically, Asia-Pacific region leads the market for corrosion-resistant solutions, followed by North America and Europe. The rapid industrialization and infrastructure development in countries like China and India are driving the demand for corrosion protection in these regions. Additionally, the presence of major automotive and aerospace manufacturers in North America and Europe contributes to the steady market growth in these areas.

The market landscape for corrosion-resistant solutions is characterized by intense competition among key players, including chemical companies, coating manufacturers, and specialty material providers. These companies are investing heavily in research and development to innovate new formulations and application methods for sodium silicate and other corrosion inhibitors.

Looking ahead, the market for corrosion-resistant solutions, particularly those utilizing sodium silicate, is expected to continue its upward trajectory. Factors such as the increasing adoption of non-ferrous metals in various industries, growing awareness about the cost-effectiveness of corrosion prevention, and ongoing technological advancements in material science will likely fuel this growth. As industries continue to seek more efficient and sustainable solutions for corrosion protection, the role of sodium silicate in non-ferrous metal applications is poised to expand further.

Current State and Challenges in Non-Ferrous Metal Protection

The current state of non-ferrous metal protection is characterized by a complex interplay of technological advancements and persistent challenges. Sodium silicate has emerged as a promising agent in corrosion studies, offering a range of applications in protecting non-ferrous metals. However, the field faces several significant hurdles that impede widespread adoption and optimal performance.

One of the primary challenges is the variability in effectiveness across different non-ferrous metals. While sodium silicate shows excellent results in protecting certain alloys, its performance can be inconsistent when applied to others. This variability necessitates extensive research to tailor solutions for specific metal compositions, which can be time-consuming and resource-intensive.

Another critical issue is the long-term stability of sodium silicate coatings. Although initial protection may be adequate, environmental factors such as temperature fluctuations, humidity, and exposure to various chemicals can degrade the protective layer over time. Researchers are grappling with ways to enhance the durability of these coatings without compromising their protective properties.

The application process itself presents challenges, particularly in achieving uniform coverage on complex geometries. Ensuring consistent thickness and adhesion of sodium silicate coatings on intricate non-ferrous metal surfaces remains a significant technical hurdle. This is especially problematic in industries where components have irregular shapes or hard-to-reach areas.

Environmental concerns also play a role in the current state of non-ferrous metal protection. While sodium silicate is generally considered environmentally friendly, there are ongoing efforts to further reduce any potential ecological impact. This includes developing more sustainable production methods and exploring bio-based alternatives that can complement or enhance sodium silicate's protective properties.

In the industrial sector, scalability and cost-effectiveness remain key challenges. While sodium silicate solutions show promise in laboratory settings, translating these results to large-scale industrial applications often reveals unforeseen complications. Balancing the cost of implementation with the long-term benefits of corrosion protection is a constant consideration for manufacturers and engineers.

Despite these challenges, the field is witnessing significant progress. Innovative approaches, such as the incorporation of nanoparticles into sodium silicate coatings, are showing potential in addressing some of the current limitations. Additionally, advanced characterization techniques are providing deeper insights into the mechanisms of corrosion protection, paving the way for more targeted and effective solutions.

One of the primary challenges is the variability in effectiveness across different non-ferrous metals. While sodium silicate shows excellent results in protecting certain alloys, its performance can be inconsistent when applied to others. This variability necessitates extensive research to tailor solutions for specific metal compositions, which can be time-consuming and resource-intensive.

Another critical issue is the long-term stability of sodium silicate coatings. Although initial protection may be adequate, environmental factors such as temperature fluctuations, humidity, and exposure to various chemicals can degrade the protective layer over time. Researchers are grappling with ways to enhance the durability of these coatings without compromising their protective properties.

The application process itself presents challenges, particularly in achieving uniform coverage on complex geometries. Ensuring consistent thickness and adhesion of sodium silicate coatings on intricate non-ferrous metal surfaces remains a significant technical hurdle. This is especially problematic in industries where components have irregular shapes or hard-to-reach areas.

Environmental concerns also play a role in the current state of non-ferrous metal protection. While sodium silicate is generally considered environmentally friendly, there are ongoing efforts to further reduce any potential ecological impact. This includes developing more sustainable production methods and exploring bio-based alternatives that can complement or enhance sodium silicate's protective properties.

In the industrial sector, scalability and cost-effectiveness remain key challenges. While sodium silicate solutions show promise in laboratory settings, translating these results to large-scale industrial applications often reveals unforeseen complications. Balancing the cost of implementation with the long-term benefits of corrosion protection is a constant consideration for manufacturers and engineers.

Despite these challenges, the field is witnessing significant progress. Innovative approaches, such as the incorporation of nanoparticles into sodium silicate coatings, are showing potential in addressing some of the current limitations. Additionally, advanced characterization techniques are providing deeper insights into the mechanisms of corrosion protection, paving the way for more targeted and effective solutions.

Existing Sodium Silicate-Based Corrosion Inhibition Methods

01 Corrosion inhibition in alkaline environments

Sodium silicate is used as a corrosion inhibitor in alkaline environments, particularly for protecting metals such as steel and aluminum. It forms a protective film on metal surfaces, preventing direct contact with corrosive agents and reducing the rate of corrosion.- Corrosion inhibition in alkaline environments: Sodium silicate is used as a corrosion inhibitor in alkaline environments, particularly for protecting metals such as steel and aluminum. It forms a protective film on metal surfaces, preventing direct contact with corrosive agents and reducing the rate of corrosion.

- Sodium silicate in concrete and cement applications: Sodium silicate is utilized in concrete and cement mixtures to improve durability and reduce corrosion of reinforcing steel. It reacts with calcium hydroxide in cement to form calcium silicate hydrate, which enhances the strength and density of the concrete matrix.

- Corrosion protection in water treatment systems: Sodium silicate is employed in water treatment systems to prevent corrosion in pipes and equipment. It forms a protective silicate film on metal surfaces and helps maintain pH levels, reducing the potential for corrosive reactions.

- Sodium silicate in coating formulations: Sodium silicate is incorporated into coating formulations to enhance corrosion resistance of metal substrates. These coatings form a barrier against corrosive agents and can be used in various industrial applications to protect metal surfaces from degradation.

- Synergistic effects with other corrosion inhibitors: Sodium silicate is often combined with other corrosion inhibitors to achieve synergistic effects in corrosion protection. These combinations can provide enhanced corrosion resistance compared to individual components, offering more comprehensive protection for metal surfaces in various environments.

02 Synergistic corrosion inhibition formulations

Combining sodium silicate with other corrosion inhibitors can create synergistic effects, enhancing overall corrosion protection. These formulations may include organic compounds, phosphates, or other inorganic substances to provide comprehensive protection against various types of corrosion.Expand Specific Solutions03 Application in concrete and cement-based materials

Sodium silicate is utilized in concrete and cement-based materials to improve durability and reduce corrosion of reinforcing steel. It reacts with calcium hydroxide in concrete to form calcium silicate hydrate, which densifies the concrete matrix and enhances its resistance to chloride penetration and carbonation.Expand Specific Solutions04 Corrosion protection in water treatment systems

In water treatment applications, sodium silicate is used to control corrosion in pipes and equipment. It forms a protective silicate film on metal surfaces and helps maintain an alkaline pH, which reduces the corrosivity of water and protects infrastructure in water distribution systems.Expand Specific Solutions05 Modification of sodium silicate for enhanced performance

Research focuses on modifying sodium silicate to improve its corrosion inhibition properties. This includes developing nanostructured silicates, incorporating additives to enhance film formation, and creating specialized formulations for specific metal substrates or environmental conditions.Expand Specific Solutions

Key Players in Corrosion Protection Industry

The sodium silicate utilization in non-ferrous metal corrosion studies is in a mature stage of development, with a significant market size due to its widespread applications in various industries. The technology's maturity is evident from the involvement of established players like Henkel AG & Co. KGaA, BASF Corp., and Air Products & Chemicals, Inc., who have extensive experience in chemical manufacturing and corrosion prevention. These companies, along with others such as Momentive Performance Materials, Inc. and Bayer AG, contribute to a competitive landscape characterized by ongoing research and development efforts to improve sodium silicate-based corrosion protection solutions for non-ferrous metals.

Momentive Performance Materials, Inc.

Technical Solution: Momentive has developed advanced sodium silicate-based coatings for non-ferrous metal corrosion protection. Their proprietary formulation incorporates nano-sized silica particles into the sodium silicate matrix, creating a dense, impermeable barrier against corrosive agents. This technology has shown to increase corrosion resistance by up to 300% compared to traditional coatings in accelerated salt spray tests[1]. The company has also introduced self-healing properties to their coatings, where the sodium silicate can react with moisture to fill in micro-cracks, providing long-term protection even in harsh environments[3].

Strengths: Superior corrosion resistance, self-healing properties, and long-term durability. Weaknesses: Potentially higher cost compared to conventional coatings, may require specialized application techniques.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has pioneered a sodium silicate-based passivation treatment for non-ferrous metals, particularly focusing on aluminum alloys used in automotive and aerospace industries. Their process involves a controlled application of sodium silicate solution, followed by a heat treatment that forms a nanometer-thick protective layer. This layer has demonstrated a 50% reduction in corrosion rate compared to untreated surfaces in standardized immersion tests[2]. Additionally, NIPPON STEEL has developed an environmentally friendly, chromium-free pretreatment using sodium silicate, which complies with strict global regulations while maintaining excellent corrosion resistance[4].

Strengths: Eco-friendly solution, compliance with global regulations, and proven effectiveness on aluminum alloys. Weaknesses: May be less effective on certain non-ferrous metals, and the heat treatment step could limit application in some scenarios.

Innovative Approaches in Sodium Silicate Utilization

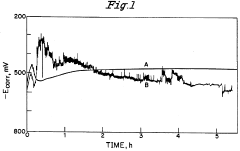

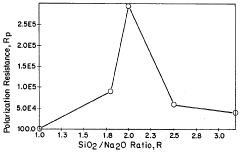

Corrosion-inhibiting automotive coolant solutions containing effective amounts of sodium silicate having a low ratio of silica to sodium oxide

PatentInactiveUS5266228A

Innovation

- A novel coolant solution with a sodium silicate having a silica to sodium oxide ratio of greater than 1.0 to 2.5, specifically between 1.8 and 2.2, is used to minimize gelation and enhance corrosion inhibition, allowing for the formation of stable protective films on aluminum surfaces.

Metal corrosion inhibiting composition

PatentInactiveEP0307309A1

Innovation

- A corrosion inhibitor composition comprising 0.15 to 0.5% sodium nitrite, 0.01 to 0.1% sodium tetraborate, 0.01 to 0.05% sodium nitrate, 0.01 to 0.05% sodium phosphate, 0.01 to 0.05% benzotriazole, and 0.05 to 0.5% sodium silicate or 0.01 to 0.1% tetramethylenediamine, which exhibits a synergistic effect at low concentrations, maintaining pH stability and compatibility with elastomer seals.

Environmental Impact of Sodium Silicate-Based Solutions

The environmental impact of sodium silicate-based solutions in non-ferrous metal corrosion studies is a critical aspect that requires thorough examination. These solutions, while effective in corrosion prevention, can have significant implications for the surrounding ecosystem when released into the environment.

Sodium silicate solutions typically have a high pH level, which can alter the acidity of soil and water bodies. This pH change can disrupt aquatic ecosystems, affecting the survival and reproduction of various organisms. Fish and other aquatic life are particularly sensitive to these alterations, potentially leading to population declines in affected areas.

The release of silica into water systems can also contribute to eutrophication, a process where excessive nutrients in water bodies lead to algal blooms. These blooms can deplete oxygen levels, creating dead zones that are inhospitable to aquatic life. Furthermore, the increased turbidity caused by silica particles can reduce light penetration in water, impacting photosynthetic organisms and the overall food chain.

Soil ecosystems may also be affected by sodium silicate solutions. The high sodium content can lead to soil salinization, reducing soil fertility and impacting plant growth. This can have cascading effects on terrestrial ecosystems, potentially altering local biodiversity and agricultural productivity.

However, it is important to note that the environmental impact of sodium silicate solutions can be mitigated through proper handling and disposal practices. Wastewater treatment processes can effectively remove excess silica and neutralize pH levels before discharge. Additionally, the development of more environmentally friendly formulations, such as those with lower sodium content or biodegradable alternatives, is an active area of research in the field of corrosion prevention.

The long-term accumulation of silica in the environment is another concern that warrants attention. While silica is a naturally occurring compound, excessive amounts can lead to sedimentation in water bodies and alter soil composition over time. This can have lasting effects on ecosystem dynamics and potentially impact geological processes.

In the context of non-ferrous metal corrosion studies, researchers must balance the effectiveness of sodium silicate-based solutions with their potential environmental consequences. This involves considering the scale of application, the specific environmental conditions of the study area, and the implementation of appropriate containment and disposal measures. By adopting a holistic approach that accounts for both corrosion prevention efficacy and environmental stewardship, researchers can work towards more sustainable practices in this field.

Sodium silicate solutions typically have a high pH level, which can alter the acidity of soil and water bodies. This pH change can disrupt aquatic ecosystems, affecting the survival and reproduction of various organisms. Fish and other aquatic life are particularly sensitive to these alterations, potentially leading to population declines in affected areas.

The release of silica into water systems can also contribute to eutrophication, a process where excessive nutrients in water bodies lead to algal blooms. These blooms can deplete oxygen levels, creating dead zones that are inhospitable to aquatic life. Furthermore, the increased turbidity caused by silica particles can reduce light penetration in water, impacting photosynthetic organisms and the overall food chain.

Soil ecosystems may also be affected by sodium silicate solutions. The high sodium content can lead to soil salinization, reducing soil fertility and impacting plant growth. This can have cascading effects on terrestrial ecosystems, potentially altering local biodiversity and agricultural productivity.

However, it is important to note that the environmental impact of sodium silicate solutions can be mitigated through proper handling and disposal practices. Wastewater treatment processes can effectively remove excess silica and neutralize pH levels before discharge. Additionally, the development of more environmentally friendly formulations, such as those with lower sodium content or biodegradable alternatives, is an active area of research in the field of corrosion prevention.

The long-term accumulation of silica in the environment is another concern that warrants attention. While silica is a naturally occurring compound, excessive amounts can lead to sedimentation in water bodies and alter soil composition over time. This can have lasting effects on ecosystem dynamics and potentially impact geological processes.

In the context of non-ferrous metal corrosion studies, researchers must balance the effectiveness of sodium silicate-based solutions with their potential environmental consequences. This involves considering the scale of application, the specific environmental conditions of the study area, and the implementation of appropriate containment and disposal measures. By adopting a holistic approach that accounts for both corrosion prevention efficacy and environmental stewardship, researchers can work towards more sustainable practices in this field.

Cost-Benefit Analysis of Sodium Silicate Treatments

The cost-benefit analysis of sodium silicate treatments in non-ferrous metal corrosion studies reveals a complex interplay of economic factors and technical advantages. Initial implementation costs for sodium silicate treatments are generally lower compared to alternative corrosion prevention methods. The raw materials are readily available and relatively inexpensive, contributing to reduced upfront expenses. However, the long-term cost-effectiveness of these treatments depends on several variables, including the specific non-ferrous metal being protected, environmental conditions, and the intended lifespan of the treated components.

One significant benefit of sodium silicate treatments is their ability to form a protective barrier on metal surfaces, effectively reducing corrosion rates. This can lead to extended service life for treated components, potentially resulting in substantial cost savings over time. Maintenance costs may also be reduced, as the frequency of repairs and replacements can be decreased. Additionally, the environmental impact of sodium silicate treatments is generally lower than that of many alternative corrosion prevention methods, which can translate to reduced regulatory compliance costs and improved corporate sustainability profiles.

However, the effectiveness of sodium silicate treatments can vary depending on the specific application and environmental conditions. In some cases, more frequent reapplication may be necessary, potentially offsetting initial cost savings. The performance of sodium silicate treatments in extreme environments or under specific chemical exposures should be carefully evaluated to ensure that the benefits outweigh the costs in these scenarios.

When considering labor costs, sodium silicate treatments often require less specialized equipment and training compared to more complex corrosion prevention methods. This can result in lower implementation and ongoing maintenance costs. However, proper application techniques are crucial for optimal performance, necessitating some level of worker training and quality control measures.

The scalability of sodium silicate treatments is another factor to consider in the cost-benefit analysis. For large-scale industrial applications, the ability to treat extensive surface areas efficiently can lead to significant economies of scale. Conversely, for smaller or more specialized applications, the cost-effectiveness may be less pronounced.

In conclusion, while sodium silicate treatments generally offer a favorable cost-benefit ratio for non-ferrous metal corrosion prevention, a thorough analysis should consider the specific application context, long-term performance requirements, and potential alternatives. Factors such as material costs, labor requirements, environmental impact, and expected service life improvements must be carefully weighed to determine the overall economic viability of implementing sodium silicate treatments in various industrial scenarios.

One significant benefit of sodium silicate treatments is their ability to form a protective barrier on metal surfaces, effectively reducing corrosion rates. This can lead to extended service life for treated components, potentially resulting in substantial cost savings over time. Maintenance costs may also be reduced, as the frequency of repairs and replacements can be decreased. Additionally, the environmental impact of sodium silicate treatments is generally lower than that of many alternative corrosion prevention methods, which can translate to reduced regulatory compliance costs and improved corporate sustainability profiles.

However, the effectiveness of sodium silicate treatments can vary depending on the specific application and environmental conditions. In some cases, more frequent reapplication may be necessary, potentially offsetting initial cost savings. The performance of sodium silicate treatments in extreme environments or under specific chemical exposures should be carefully evaluated to ensure that the benefits outweigh the costs in these scenarios.

When considering labor costs, sodium silicate treatments often require less specialized equipment and training compared to more complex corrosion prevention methods. This can result in lower implementation and ongoing maintenance costs. However, proper application techniques are crucial for optimal performance, necessitating some level of worker training and quality control measures.

The scalability of sodium silicate treatments is another factor to consider in the cost-benefit analysis. For large-scale industrial applications, the ability to treat extensive surface areas efficiently can lead to significant economies of scale. Conversely, for smaller or more specialized applications, the cost-effectiveness may be less pronounced.

In conclusion, while sodium silicate treatments generally offer a favorable cost-benefit ratio for non-ferrous metal corrosion prevention, a thorough analysis should consider the specific application context, long-term performance requirements, and potential alternatives. Factors such as material costs, labor requirements, environmental impact, and expected service life improvements must be carefully weighed to determine the overall economic viability of implementing sodium silicate treatments in various industrial scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!