Sodium silicate for microorganism encapsulation in biosensors

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biosensor Encapsulation Background and Objectives

Biosensors have emerged as powerful analytical tools in various fields, including healthcare, environmental monitoring, and food safety. The encapsulation of microorganisms within biosensors plays a crucial role in their functionality and performance. In recent years, sodium silicate has gained significant attention as a promising material for microorganism encapsulation in biosensors due to its unique properties and versatility.

The development of biosensors with encapsulated microorganisms dates back to the 1970s when researchers first explored the potential of immobilizing living cells for analytical purposes. Since then, the field has witnessed remarkable progress, driven by advancements in materials science, biotechnology, and nanotechnology. The evolution of encapsulation techniques has led to improved sensor stability, sensitivity, and longevity.

Sodium silicate, also known as water glass, has emerged as a particularly attractive option for microorganism encapsulation in biosensors. Its ability to form a porous, biocompatible matrix that allows for efficient diffusion of analytes while protecting the encapsulated microorganisms has made it a subject of intense research. The use of sodium silicate in biosensor applications aligns with the growing trend towards eco-friendly and sustainable materials in sensor development.

The primary objective of research on sodium silicate for microorganism encapsulation in biosensors is to optimize the encapsulation process and enhance the overall performance of biosensors. This includes improving the viability and metabolic activity of encapsulated microorganisms, increasing the sensitivity and selectivity of the biosensors, and extending their operational lifespan. Additionally, researchers aim to develop scalable and cost-effective methods for sodium silicate-based encapsulation to facilitate the widespread adoption of these biosensors in real-world applications.

Another key goal is to explore the versatility of sodium silicate in encapsulating various types of microorganisms, including bacteria, yeast, and algae, for different biosensing applications. This research aims to expand the range of detectable analytes and broaden the applicability of biosensors across diverse fields, from environmental monitoring to medical diagnostics.

Furthermore, the integration of sodium silicate-based encapsulation with other advanced technologies, such as microfluidics and nanomaterials, is being investigated to develop next-generation biosensors with enhanced capabilities. These efforts are driven by the increasing demand for rapid, sensitive, and portable biosensing platforms in various industries and research domains.

As the field of biosensors continues to evolve, the research on sodium silicate for microorganism encapsulation is expected to play a pivotal role in shaping the future of biosensor technology. The ongoing efforts in this area aim to address current limitations and unlock new possibilities for biosensor applications, ultimately contributing to advancements in environmental protection, healthcare, and industrial processes.

The development of biosensors with encapsulated microorganisms dates back to the 1970s when researchers first explored the potential of immobilizing living cells for analytical purposes. Since then, the field has witnessed remarkable progress, driven by advancements in materials science, biotechnology, and nanotechnology. The evolution of encapsulation techniques has led to improved sensor stability, sensitivity, and longevity.

Sodium silicate, also known as water glass, has emerged as a particularly attractive option for microorganism encapsulation in biosensors. Its ability to form a porous, biocompatible matrix that allows for efficient diffusion of analytes while protecting the encapsulated microorganisms has made it a subject of intense research. The use of sodium silicate in biosensor applications aligns with the growing trend towards eco-friendly and sustainable materials in sensor development.

The primary objective of research on sodium silicate for microorganism encapsulation in biosensors is to optimize the encapsulation process and enhance the overall performance of biosensors. This includes improving the viability and metabolic activity of encapsulated microorganisms, increasing the sensitivity and selectivity of the biosensors, and extending their operational lifespan. Additionally, researchers aim to develop scalable and cost-effective methods for sodium silicate-based encapsulation to facilitate the widespread adoption of these biosensors in real-world applications.

Another key goal is to explore the versatility of sodium silicate in encapsulating various types of microorganisms, including bacteria, yeast, and algae, for different biosensing applications. This research aims to expand the range of detectable analytes and broaden the applicability of biosensors across diverse fields, from environmental monitoring to medical diagnostics.

Furthermore, the integration of sodium silicate-based encapsulation with other advanced technologies, such as microfluidics and nanomaterials, is being investigated to develop next-generation biosensors with enhanced capabilities. These efforts are driven by the increasing demand for rapid, sensitive, and portable biosensing platforms in various industries and research domains.

As the field of biosensors continues to evolve, the research on sodium silicate for microorganism encapsulation is expected to play a pivotal role in shaping the future of biosensor technology. The ongoing efforts in this area aim to address current limitations and unlock new possibilities for biosensor applications, ultimately contributing to advancements in environmental protection, healthcare, and industrial processes.

Market Analysis for Microorganism-based Biosensors

The market for microorganism-based biosensors has been experiencing significant growth in recent years, driven by increasing demand for rapid, sensitive, and cost-effective detection methods across various industries. These biosensors, which utilize microorganisms as the biological recognition element, offer unique advantages in terms of specificity, sensitivity, and adaptability to different environmental conditions.

In the healthcare sector, microorganism-based biosensors are gaining traction for applications such as disease diagnosis, drug discovery, and monitoring of patient health. The global healthcare biosensors market is expected to grow substantially, with microorganism-based sensors playing a crucial role in this expansion. The food and beverage industry is another key market, where these biosensors are used for detecting pathogens, toxins, and contaminants in food products, ensuring food safety and quality control.

Environmental monitoring represents a rapidly growing application area for microorganism-based biosensors. These devices are increasingly used for detecting pollutants in water, soil, and air, as well as for monitoring ecological systems. The rising concern over environmental pollution and the need for real-time monitoring solutions are driving the demand in this sector.

The agriculture industry is also adopting microorganism-based biosensors for soil analysis, crop disease detection, and precision farming applications. This trend is expected to continue as the agriculture sector moves towards more sustainable and efficient practices.

In terms of geographical distribution, North America and Europe currently lead the market for microorganism-based biosensors, owing to advanced research infrastructure and stringent regulatory standards in these regions. However, the Asia-Pacific region is anticipated to witness the fastest growth, driven by increasing investments in biotechnology research, rising environmental concerns, and growing adoption of biosensors in various industries.

The market is characterized by intense competition and rapid technological advancements. Key players are focusing on developing more sensitive, reliable, and user-friendly biosensor systems. The integration of nanotechnology and microfluidics with microorganism-based biosensors is opening up new possibilities and expanding the application scope of these devices.

Despite the promising outlook, challenges such as the need for standardization, concerns about long-term stability of microorganisms, and the complexity of data interpretation remain. Addressing these challenges will be crucial for the widespread adoption of microorganism-based biosensors across different industries.

In the healthcare sector, microorganism-based biosensors are gaining traction for applications such as disease diagnosis, drug discovery, and monitoring of patient health. The global healthcare biosensors market is expected to grow substantially, with microorganism-based sensors playing a crucial role in this expansion. The food and beverage industry is another key market, where these biosensors are used for detecting pathogens, toxins, and contaminants in food products, ensuring food safety and quality control.

Environmental monitoring represents a rapidly growing application area for microorganism-based biosensors. These devices are increasingly used for detecting pollutants in water, soil, and air, as well as for monitoring ecological systems. The rising concern over environmental pollution and the need for real-time monitoring solutions are driving the demand in this sector.

The agriculture industry is also adopting microorganism-based biosensors for soil analysis, crop disease detection, and precision farming applications. This trend is expected to continue as the agriculture sector moves towards more sustainable and efficient practices.

In terms of geographical distribution, North America and Europe currently lead the market for microorganism-based biosensors, owing to advanced research infrastructure and stringent regulatory standards in these regions. However, the Asia-Pacific region is anticipated to witness the fastest growth, driven by increasing investments in biotechnology research, rising environmental concerns, and growing adoption of biosensors in various industries.

The market is characterized by intense competition and rapid technological advancements. Key players are focusing on developing more sensitive, reliable, and user-friendly biosensor systems. The integration of nanotechnology and microfluidics with microorganism-based biosensors is opening up new possibilities and expanding the application scope of these devices.

Despite the promising outlook, challenges such as the need for standardization, concerns about long-term stability of microorganisms, and the complexity of data interpretation remain. Addressing these challenges will be crucial for the widespread adoption of microorganism-based biosensors across different industries.

Sodium Silicate Encapsulation: Current Status and Challenges

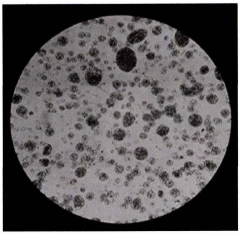

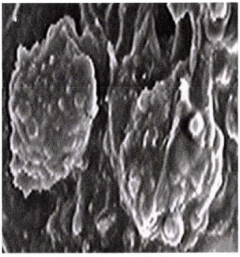

Sodium silicate encapsulation for microorganisms in biosensors has emerged as a promising technique in recent years. However, the current status of this technology reveals both significant advancements and persistent challenges. The primary advantage of sodium silicate lies in its biocompatibility and ability to form porous structures, which allow for efficient nutrient diffusion and metabolite exchange while protecting encapsulated microorganisms.

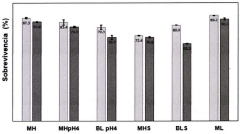

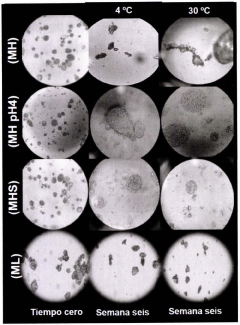

One of the main challenges in sodium silicate encapsulation is achieving precise control over the pore size and distribution. This is crucial for maintaining cell viability and optimizing biosensor performance. Researchers have made progress in this area by manipulating factors such as pH, temperature, and silicate concentration during the encapsulation process. However, further refinement is needed to ensure consistent and reproducible results across different microbial species and biosensor applications.

Another significant challenge is the long-term stability of sodium silicate matrices. While these structures provide initial protection for encapsulated microorganisms, they can degrade over time, potentially compromising biosensor functionality. This degradation is particularly problematic in harsh environments or when exposed to certain chemicals. Efforts to enhance the durability of sodium silicate matrices have included the incorporation of additional polymers or cross-linking agents, but finding the right balance between stability and permeability remains an ongoing challenge.

The integration of sodium silicate-encapsulated microorganisms with electronic components in biosensors presents another set of challenges. Ensuring efficient signal transduction from the biological component to the electronic interface while maintaining the integrity of the encapsulation matrix is a complex task. Researchers are exploring various approaches, such as the use of conductive additives or the development of hybrid organic-inorganic matrices, to address this issue.

Furthermore, the scalability of sodium silicate encapsulation techniques for large-scale biosensor production is an area that requires additional research. Current methods often involve batch processes that can be time-consuming and difficult to standardize. Developing continuous or semi-continuous encapsulation processes that maintain the quality and uniformity of the final product is a key challenge for industrial applications.

Despite these challenges, recent advancements in nanotechnology and materials science have opened up new possibilities for improving sodium silicate encapsulation. For instance, the incorporation of nanoparticles or the use of templating agents to create more defined pore structures shows promise in enhancing both the stability and functionality of encapsulated microorganisms. Additionally, the development of multi-layered encapsulation systems, where sodium silicate is combined with other materials, offers potential solutions to some of the current limitations.

One of the main challenges in sodium silicate encapsulation is achieving precise control over the pore size and distribution. This is crucial for maintaining cell viability and optimizing biosensor performance. Researchers have made progress in this area by manipulating factors such as pH, temperature, and silicate concentration during the encapsulation process. However, further refinement is needed to ensure consistent and reproducible results across different microbial species and biosensor applications.

Another significant challenge is the long-term stability of sodium silicate matrices. While these structures provide initial protection for encapsulated microorganisms, they can degrade over time, potentially compromising biosensor functionality. This degradation is particularly problematic in harsh environments or when exposed to certain chemicals. Efforts to enhance the durability of sodium silicate matrices have included the incorporation of additional polymers or cross-linking agents, but finding the right balance between stability and permeability remains an ongoing challenge.

The integration of sodium silicate-encapsulated microorganisms with electronic components in biosensors presents another set of challenges. Ensuring efficient signal transduction from the biological component to the electronic interface while maintaining the integrity of the encapsulation matrix is a complex task. Researchers are exploring various approaches, such as the use of conductive additives or the development of hybrid organic-inorganic matrices, to address this issue.

Furthermore, the scalability of sodium silicate encapsulation techniques for large-scale biosensor production is an area that requires additional research. Current methods often involve batch processes that can be time-consuming and difficult to standardize. Developing continuous or semi-continuous encapsulation processes that maintain the quality and uniformity of the final product is a key challenge for industrial applications.

Despite these challenges, recent advancements in nanotechnology and materials science have opened up new possibilities for improving sodium silicate encapsulation. For instance, the incorporation of nanoparticles or the use of templating agents to create more defined pore structures shows promise in enhancing both the stability and functionality of encapsulated microorganisms. Additionally, the development of multi-layered encapsulation systems, where sodium silicate is combined with other materials, offers potential solutions to some of the current limitations.

Existing Sodium Silicate Encapsulation Methods

01 Encapsulation methods for sodium silicate

Various methods are used to encapsulate sodium silicate, including spray drying, emulsion techniques, and sol-gel processes. These methods aim to protect the sodium silicate from premature reaction and control its release in specific applications.- Encapsulation methods for sodium silicate: Various methods are used to encapsulate sodium silicate, including spray drying, emulsion techniques, and sol-gel processes. These methods aim to protect the sodium silicate from premature reaction and control its release in specific applications. Encapsulation can improve the stability and handling properties of sodium silicate.

- Applications of encapsulated sodium silicate: Encapsulated sodium silicate finds applications in diverse fields such as detergents, water treatment, construction materials, and fire retardants. The controlled release of sodium silicate in these applications enhances performance and extends the shelf life of products. Encapsulation allows for better dispersion and targeted delivery of sodium silicate.

- Coating materials for sodium silicate encapsulation: Various coating materials are used to encapsulate sodium silicate, including polymers, waxes, and inorganic materials. These coatings provide a protective barrier that prevents premature reaction of sodium silicate with the environment. The choice of coating material depends on the specific application and desired release properties.

- Controlled release mechanisms of encapsulated sodium silicate: Encapsulated sodium silicate can be designed for controlled release through various mechanisms, such as pH-triggered release, temperature-sensitive coatings, or mechanical rupture. These mechanisms allow for the targeted release of sodium silicate in specific conditions or environments, enhancing its effectiveness in various applications.

- Optimization of sodium silicate encapsulation process: Research focuses on optimizing the encapsulation process for sodium silicate to improve efficiency, reduce costs, and enhance product quality. This includes studying parameters such as particle size, coating thickness, and encapsulation efficiency. Advanced techniques like microfluidics and nanoencapsulation are being explored to further improve the encapsulation of sodium silicate.

02 Applications of encapsulated sodium silicate

Encapsulated sodium silicate finds applications in diverse fields such as detergents, water treatment, construction materials, and fire retardants. The encapsulation allows for controlled release and improved stability in various product formulations.Expand Specific Solutions03 Coating materials for sodium silicate encapsulation

Different coating materials are used to encapsulate sodium silicate, including polymers, waxes, and inorganic materials. The choice of coating material depends on the desired release properties and the intended application of the encapsulated product.Expand Specific Solutions04 Controlled release mechanisms of encapsulated sodium silicate

Various mechanisms are employed to control the release of encapsulated sodium silicate, such as pH-triggered release, temperature-sensitive coatings, and mechanical rupture. These mechanisms allow for targeted release in specific environments or conditions.Expand Specific Solutions05 Stability and shelf life of encapsulated sodium silicate

Encapsulation techniques are developed to improve the stability and shelf life of sodium silicate products. This includes protection from moisture, prevention of agglomeration, and maintaining the reactivity of the encapsulated material over extended periods.Expand Specific Solutions

Key Players in Biosensor and Encapsulation Technologies

The research on sodium silicate for microorganism encapsulation in biosensors is in an emerging stage, with growing market potential due to increasing applications in healthcare, environmental monitoring, and biotechnology. The global biosensor market is expanding rapidly, expected to reach significant value in the coming years. Technologically, the field is advancing, but still requires further development for widespread commercial adoption. Companies like Abbott Point of Care, Koninklijke Philips NV, and Fujitsu Ltd. are investing in biosensor technologies, while research institutions such as the Institute of Electronics Chinese Academy of Sciences and the Agency for Science, Technology & Research are contributing to fundamental advancements in this area.

Institute of Electronics Chinese Academy of Sciences

Technical Solution: The Institute of Electronics Chinese Academy of Sciences has developed a novel biosensor platform utilizing sodium silicate for microorganism encapsulation. Their approach involves creating a porous silica matrix through sol-gel processing of sodium silicate, which provides a biocompatible environment for immobilizing microorganisms. The encapsulated microorganisms retain their metabolic activity and can interact with target analytes, generating measurable signals. This method enhances the stability and longevity of the biosensor, allowing for extended use in various environmental and clinical applications[1][3].

Strengths: Improved stability and longevity of encapsulated microorganisms, biocompatibility, and versatility for various applications. Weaknesses: Potential diffusion limitations and reduced sensitivity compared to free-cell systems.

The Regents of the University of California

Technical Solution: The University of California has conducted extensive research on sodium silicate-based microorganism encapsulation for biosensor applications. Their approach focuses on optimizing the sol-gel process to create tailored silica matrices that provide an ideal microenvironment for specific microbial strains. The university has developed methods to control pore size distribution and surface chemistry of the silica matrix, allowing for improved diffusion of analytes and enhanced signal generation. Their research has led to the development of highly sensitive biosensors for detecting pathogens and environmental contaminants[9][10].

Strengths: Tailored microenvironments for specific microorganisms, improved analyte diffusion, and high sensitivity. Weaknesses: Potential limitations in long-term stability and challenges in scaling up production for commercial applications.

Innovations in Sodium Silicate for Biosensor Applications

Method for microencapsulation of probiotic bacteria using sodium alginate and extrusion.

PatentActiveMX2020014178A

Innovation

- A combination of extrusion and ionic gelation using calcium alginate to form microcapsules with sizes between 15 to 116 microns, achieving encapsulation efficiencies greater than 85% and maintaining probiotic viability for at least 6 weeks, suitable for use in food, pharmaceutical, and cosmetic products.

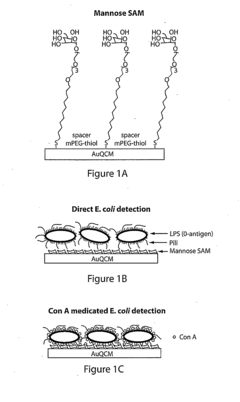

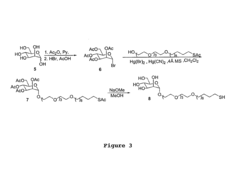

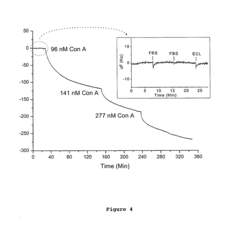

Microorganism detection and analysis using carbohydrate and lectin recognition

PatentActiveUS20140073515A1

Innovation

- A method involving a solid substrate with a covalently bound saccharide moiety and an unbound lectin, such as Concanavalin A, is used to bind microorganisms, enhancing attachment and detection through Quartz Crystal Microbalance (QCM) or Surface Plasmon Resonance (SPR) devices, reducing non-specific binding and improving sensitivity and specificity.

Biocompatibility and Safety Considerations

Biocompatibility and safety considerations are paramount in the development of biosensors utilizing sodium silicate for microorganism encapsulation. The interaction between the encapsulation matrix and the biological components must be carefully evaluated to ensure the viability and functionality of the encapsulated microorganisms while maintaining the integrity of the biosensor system.

Sodium silicate, when used as an encapsulation material, forms a porous silica gel matrix that can provide a suitable microenvironment for microorganisms. However, the biocompatibility of this matrix must be thoroughly assessed. The pH of the sodium silicate solution and the resulting gel can significantly impact the survival and metabolic activity of the encapsulated microorganisms. Optimization of the silicate concentration and gelation conditions is crucial to create a hospitable environment that supports microbial growth and maintains their sensing capabilities.

The potential toxicity of sodium silicate and its degradation products must be carefully evaluated, particularly in applications where the biosensor may come into contact with living tissues or environmental systems. While silica is generally considered biologically inert, the presence of residual sodium ions and the potential for silica nanoparticle formation during the sol-gel process may pose safety concerns. Long-term stability studies are essential to assess the potential leaching of silica or other components from the encapsulation matrix.

Furthermore, the permeability of the sodium silicate matrix plays a critical role in the performance and safety of the biosensor. The matrix must allow for sufficient diffusion of analytes and metabolites to maintain the viability of the encapsulated microorganisms while preventing their release into the surrounding environment. This balance is crucial for both the functionality of the biosensor and the prevention of unintended environmental contamination.

Immunogenicity is another important consideration, especially for in vivo applications. The encapsulation matrix should not elicit an adverse immune response when in contact with biological systems. Surface modifications of the silica matrix may be necessary to reduce protein adsorption and minimize immune recognition, thereby improving the overall biocompatibility of the biosensor.

Lastly, the sterilization and storage of sodium silicate-based biosensors present unique challenges. The encapsulation process and any subsequent treatments must ensure the elimination of potential pathogens without compromising the viability of the sensing microorganisms or the structural integrity of the silica matrix. Appropriate storage conditions must be established to maintain the stability and functionality of the encapsulated microorganisms over extended periods.

Sodium silicate, when used as an encapsulation material, forms a porous silica gel matrix that can provide a suitable microenvironment for microorganisms. However, the biocompatibility of this matrix must be thoroughly assessed. The pH of the sodium silicate solution and the resulting gel can significantly impact the survival and metabolic activity of the encapsulated microorganisms. Optimization of the silicate concentration and gelation conditions is crucial to create a hospitable environment that supports microbial growth and maintains their sensing capabilities.

The potential toxicity of sodium silicate and its degradation products must be carefully evaluated, particularly in applications where the biosensor may come into contact with living tissues or environmental systems. While silica is generally considered biologically inert, the presence of residual sodium ions and the potential for silica nanoparticle formation during the sol-gel process may pose safety concerns. Long-term stability studies are essential to assess the potential leaching of silica or other components from the encapsulation matrix.

Furthermore, the permeability of the sodium silicate matrix plays a critical role in the performance and safety of the biosensor. The matrix must allow for sufficient diffusion of analytes and metabolites to maintain the viability of the encapsulated microorganisms while preventing their release into the surrounding environment. This balance is crucial for both the functionality of the biosensor and the prevention of unintended environmental contamination.

Immunogenicity is another important consideration, especially for in vivo applications. The encapsulation matrix should not elicit an adverse immune response when in contact with biological systems. Surface modifications of the silica matrix may be necessary to reduce protein adsorption and minimize immune recognition, thereby improving the overall biocompatibility of the biosensor.

Lastly, the sterilization and storage of sodium silicate-based biosensors present unique challenges. The encapsulation process and any subsequent treatments must ensure the elimination of potential pathogens without compromising the viability of the sensing microorganisms or the structural integrity of the silica matrix. Appropriate storage conditions must be established to maintain the stability and functionality of the encapsulated microorganisms over extended periods.

Environmental Impact of Sodium Silicate-based Biosensors

The environmental impact of sodium silicate-based biosensors is a crucial consideration in their development and deployment. These biosensors, which utilize microorganism encapsulation techniques, offer significant advantages in terms of sensitivity and specificity for various applications. However, their potential effects on ecosystems and human health must be carefully evaluated.

Sodium silicate, the primary component in these biosensors, is generally considered to have low toxicity. Its biodegradability and non-accumulative nature in living organisms contribute to its relatively benign environmental profile. When released into aquatic environments, sodium silicate tends to dissolve and dissociate into silica and sodium ions, which are naturally occurring elements in water bodies.

Despite its low toxicity, the increased use of sodium silicate-based biosensors may lead to localized changes in water chemistry. Elevated levels of silica can potentially alter the growth patterns of certain aquatic organisms, particularly diatoms and other silica-dependent species. This could result in shifts in local ecosystem dynamics, although the extent of such impacts would depend on the scale of biosensor deployment and environmental conditions.

The encapsulated microorganisms within these biosensors present another environmental consideration. While the silicate matrix is designed to contain these organisms, there is a potential risk of release into the environment. This could occur through degradation of the sensor or improper disposal. The ecological consequences of introducing non-native or genetically modified microorganisms into natural habitats must be thoroughly assessed and mitigated.

From a lifecycle perspective, the production and disposal of sodium silicate-based biosensors also warrant attention. The manufacturing process of sodium silicate involves energy-intensive steps and may contribute to carbon emissions. End-of-life management of these biosensors is crucial to prevent accumulation in landfills or uncontrolled release into the environment.

To address these environmental concerns, research efforts are focusing on developing more sustainable production methods for sodium silicate and improving the biodegradability of the biosensor materials. Additionally, protocols for safe handling, use, and disposal of these biosensors are being established to minimize their environmental footprint.

In conclusion, while sodium silicate-based biosensors offer promising applications, their environmental impact must be carefully managed. Ongoing research and regulatory frameworks aim to ensure that the benefits of these technologies are realized without compromising environmental integrity.

Sodium silicate, the primary component in these biosensors, is generally considered to have low toxicity. Its biodegradability and non-accumulative nature in living organisms contribute to its relatively benign environmental profile. When released into aquatic environments, sodium silicate tends to dissolve and dissociate into silica and sodium ions, which are naturally occurring elements in water bodies.

Despite its low toxicity, the increased use of sodium silicate-based biosensors may lead to localized changes in water chemistry. Elevated levels of silica can potentially alter the growth patterns of certain aquatic organisms, particularly diatoms and other silica-dependent species. This could result in shifts in local ecosystem dynamics, although the extent of such impacts would depend on the scale of biosensor deployment and environmental conditions.

The encapsulated microorganisms within these biosensors present another environmental consideration. While the silicate matrix is designed to contain these organisms, there is a potential risk of release into the environment. This could occur through degradation of the sensor or improper disposal. The ecological consequences of introducing non-native or genetically modified microorganisms into natural habitats must be thoroughly assessed and mitigated.

From a lifecycle perspective, the production and disposal of sodium silicate-based biosensors also warrant attention. The manufacturing process of sodium silicate involves energy-intensive steps and may contribute to carbon emissions. End-of-life management of these biosensors is crucial to prevent accumulation in landfills or uncontrolled release into the environment.

To address these environmental concerns, research efforts are focusing on developing more sustainable production methods for sodium silicate and improving the biodegradability of the biosensor materials. Additionally, protocols for safe handling, use, and disposal of these biosensors are being established to minimize their environmental footprint.

In conclusion, while sodium silicate-based biosensors offer promising applications, their environmental impact must be carefully managed. Ongoing research and regulatory frameworks aim to ensure that the benefits of these technologies are realized without compromising environmental integrity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!