Sodium silicate as a templating agent for hydrothermal processes

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Silicate Templating Background

Sodium silicate, also known as water glass or liquid glass, has emerged as a versatile templating agent in hydrothermal processes, playing a crucial role in the synthesis of various nanostructured materials. The use of sodium silicate as a template dates back to the early 1990s when researchers began exploring its potential in materials science and nanotechnology.

The fundamental principle behind sodium silicate templating lies in its ability to form silica-based structures that can guide the growth and assembly of other materials during hydrothermal reactions. This templating effect is primarily attributed to the unique chemical properties of sodium silicate, which can undergo controlled polymerization and depolymerization under different pH conditions and temperatures.

In hydrothermal processes, sodium silicate serves as a structure-directing agent, influencing the morphology, size, and arrangement of the synthesized materials. Its templating action is particularly effective in the formation of porous structures, hierarchical architectures, and hollow spheres. The versatility of sodium silicate as a templating agent stems from its ability to interact with various precursor materials and its responsiveness to different reaction parameters.

The evolution of sodium silicate templating techniques has been closely linked to advancements in materials characterization methods and the growing demand for tailored nanostructures in applications such as catalysis, energy storage, and environmental remediation. Researchers have progressively refined their understanding of the templating mechanisms, leading to more precise control over the resulting material properties.

One of the key advantages of using sodium silicate as a templating agent is its cost-effectiveness and environmental friendliness compared to many organic templates. This has made it an attractive option for large-scale synthesis and industrial applications. Additionally, the ease of removing the sodium silicate template through simple washing or etching processes has contributed to its widespread adoption in materials synthesis.

The research landscape surrounding sodium silicate templating has expanded significantly over the past two decades. Scientists have explored its application in synthesizing a wide range of materials, including zeolites, mesoporous silica, metal oxides, and composite structures. The templating approach has been successfully combined with other synthesis techniques, such as sol-gel processes and microwave-assisted methods, to create novel materials with enhanced properties.

As the field continues to evolve, researchers are focusing on developing more sophisticated templating strategies using sodium silicate. This includes the exploration of multi-step templating processes, the incorporation of functional additives, and the use of external fields to manipulate the templating effect. These advancements are paving the way for the creation of increasingly complex and functional nanostructured materials with tailored properties for specific applications.

The fundamental principle behind sodium silicate templating lies in its ability to form silica-based structures that can guide the growth and assembly of other materials during hydrothermal reactions. This templating effect is primarily attributed to the unique chemical properties of sodium silicate, which can undergo controlled polymerization and depolymerization under different pH conditions and temperatures.

In hydrothermal processes, sodium silicate serves as a structure-directing agent, influencing the morphology, size, and arrangement of the synthesized materials. Its templating action is particularly effective in the formation of porous structures, hierarchical architectures, and hollow spheres. The versatility of sodium silicate as a templating agent stems from its ability to interact with various precursor materials and its responsiveness to different reaction parameters.

The evolution of sodium silicate templating techniques has been closely linked to advancements in materials characterization methods and the growing demand for tailored nanostructures in applications such as catalysis, energy storage, and environmental remediation. Researchers have progressively refined their understanding of the templating mechanisms, leading to more precise control over the resulting material properties.

One of the key advantages of using sodium silicate as a templating agent is its cost-effectiveness and environmental friendliness compared to many organic templates. This has made it an attractive option for large-scale synthesis and industrial applications. Additionally, the ease of removing the sodium silicate template through simple washing or etching processes has contributed to its widespread adoption in materials synthesis.

The research landscape surrounding sodium silicate templating has expanded significantly over the past two decades. Scientists have explored its application in synthesizing a wide range of materials, including zeolites, mesoporous silica, metal oxides, and composite structures. The templating approach has been successfully combined with other synthesis techniques, such as sol-gel processes and microwave-assisted methods, to create novel materials with enhanced properties.

As the field continues to evolve, researchers are focusing on developing more sophisticated templating strategies using sodium silicate. This includes the exploration of multi-step templating processes, the incorporation of functional additives, and the use of external fields to manipulate the templating effect. These advancements are paving the way for the creation of increasingly complex and functional nanostructured materials with tailored properties for specific applications.

Market Analysis for Hydrothermal Processes

The hydrothermal process market has been experiencing significant growth in recent years, driven by increasing demand across various industries. This technology, which utilizes sodium silicate as a templating agent, has found applications in diverse sectors such as materials science, nanotechnology, and environmental remediation.

In the materials science sector, hydrothermal processes are extensively used for the synthesis of advanced materials, including zeolites, metal oxides, and nanostructured materials. The global market for these materials is projected to expand substantially, with a particular focus on zeolites due to their wide-ranging applications in catalysis, adsorption, and ion exchange processes.

The nanotechnology industry has also embraced hydrothermal processes for the production of nanoparticles and nanostructures. This sector's growth is fueled by the increasing demand for nanomaterials in electronics, healthcare, and energy applications. The use of sodium silicate as a templating agent in these processes has proven to be particularly effective in controlling the morphology and properties of the resulting nanostructures.

Environmental remediation represents another significant market for hydrothermal processes. The technology is being increasingly adopted for the treatment of industrial wastewater, soil decontamination, and the recovery of valuable resources from waste streams. The global focus on sustainability and circular economy principles is expected to further drive the demand for hydrothermal processes in this sector.

The energy industry is also a key market for hydrothermal processes, particularly in geothermal energy production and the conversion of biomass to biofuels. The use of sodium silicate as a templating agent in these applications has shown promise in improving efficiency and reducing costs.

Geographically, the market for hydrothermal processes is well-established in North America and Europe, with these regions accounting for a significant share of the global market. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, environmental concerns, and government initiatives to promote clean technologies.

The market is characterized by the presence of both large multinational corporations and specialized small to medium-sized enterprises. Key players in the market are investing heavily in research and development to improve process efficiency, reduce costs, and expand the range of applications for hydrothermal processes.

In conclusion, the market for hydrothermal processes, particularly those utilizing sodium silicate as a templating agent, is poised for substantial growth across multiple industries. The technology's versatility, coupled with increasing demand for advanced materials and sustainable solutions, is expected to drive market expansion in the coming years.

In the materials science sector, hydrothermal processes are extensively used for the synthesis of advanced materials, including zeolites, metal oxides, and nanostructured materials. The global market for these materials is projected to expand substantially, with a particular focus on zeolites due to their wide-ranging applications in catalysis, adsorption, and ion exchange processes.

The nanotechnology industry has also embraced hydrothermal processes for the production of nanoparticles and nanostructures. This sector's growth is fueled by the increasing demand for nanomaterials in electronics, healthcare, and energy applications. The use of sodium silicate as a templating agent in these processes has proven to be particularly effective in controlling the morphology and properties of the resulting nanostructures.

Environmental remediation represents another significant market for hydrothermal processes. The technology is being increasingly adopted for the treatment of industrial wastewater, soil decontamination, and the recovery of valuable resources from waste streams. The global focus on sustainability and circular economy principles is expected to further drive the demand for hydrothermal processes in this sector.

The energy industry is also a key market for hydrothermal processes, particularly in geothermal energy production and the conversion of biomass to biofuels. The use of sodium silicate as a templating agent in these applications has shown promise in improving efficiency and reducing costs.

Geographically, the market for hydrothermal processes is well-established in North America and Europe, with these regions accounting for a significant share of the global market. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, environmental concerns, and government initiatives to promote clean technologies.

The market is characterized by the presence of both large multinational corporations and specialized small to medium-sized enterprises. Key players in the market are investing heavily in research and development to improve process efficiency, reduce costs, and expand the range of applications for hydrothermal processes.

In conclusion, the market for hydrothermal processes, particularly those utilizing sodium silicate as a templating agent, is poised for substantial growth across multiple industries. The technology's versatility, coupled with increasing demand for advanced materials and sustainable solutions, is expected to drive market expansion in the coming years.

Current Challenges in Templating Agents

Despite the widespread use of sodium silicate as a templating agent in hydrothermal processes, several challenges persist in its application. One of the primary issues is the difficulty in precisely controlling the morphology and size of the resulting structures. The templating process is highly sensitive to various factors, including pH, temperature, and concentration ratios, making it challenging to achieve consistent and reproducible results across different batches.

Another significant challenge lies in the removal of the sodium silicate template after the synthesis process. The strong interactions between the silicate species and the target material often lead to incomplete removal, which can affect the purity and performance of the final product. This is particularly problematic in applications requiring high-purity materials, such as catalysis or advanced electronics.

The stability of sodium silicate solutions under hydrothermal conditions also presents a challenge. At elevated temperatures and pressures, the silicate species can undergo complex transformations, leading to unexpected changes in the templating behavior. This instability can result in the formation of undesired phases or structures, compromising the quality of the synthesized materials.

Furthermore, the environmental impact of using sodium silicate as a templating agent is a growing concern. The disposal of waste solutions containing silicates can contribute to water pollution and soil alkalinization. Developing more eco-friendly alternatives or improving the recyclability of sodium silicate solutions remains a significant challenge in the field.

The scalability of sodium silicate-based templating processes is another hurdle that researchers face. While successful at laboratory scales, translating these processes to industrial production levels often encounters difficulties in maintaining uniform templating effects and product quality. This scaling issue limits the commercial viability of many promising materials synthesized using this approach.

Lastly, the limited versatility of sodium silicate as a templating agent poses challenges in creating complex, multi-functional materials. As research moves towards more sophisticated nanostructures and hybrid materials, there is a growing need for templating agents that can offer greater flexibility in terms of structure direction and compositional control. Overcoming these limitations to expand the range of materials that can be synthesized using sodium silicate templates remains an active area of research in the field of hydrothermal synthesis.

Another significant challenge lies in the removal of the sodium silicate template after the synthesis process. The strong interactions between the silicate species and the target material often lead to incomplete removal, which can affect the purity and performance of the final product. This is particularly problematic in applications requiring high-purity materials, such as catalysis or advanced electronics.

The stability of sodium silicate solutions under hydrothermal conditions also presents a challenge. At elevated temperatures and pressures, the silicate species can undergo complex transformations, leading to unexpected changes in the templating behavior. This instability can result in the formation of undesired phases or structures, compromising the quality of the synthesized materials.

Furthermore, the environmental impact of using sodium silicate as a templating agent is a growing concern. The disposal of waste solutions containing silicates can contribute to water pollution and soil alkalinization. Developing more eco-friendly alternatives or improving the recyclability of sodium silicate solutions remains a significant challenge in the field.

The scalability of sodium silicate-based templating processes is another hurdle that researchers face. While successful at laboratory scales, translating these processes to industrial production levels often encounters difficulties in maintaining uniform templating effects and product quality. This scaling issue limits the commercial viability of many promising materials synthesized using this approach.

Lastly, the limited versatility of sodium silicate as a templating agent poses challenges in creating complex, multi-functional materials. As research moves towards more sophisticated nanostructures and hybrid materials, there is a growing need for templating agents that can offer greater flexibility in terms of structure direction and compositional control. Overcoming these limitations to expand the range of materials that can be synthesized using sodium silicate templates remains an active area of research in the field of hydrothermal synthesis.

Existing Sodium Silicate Solutions

01 Use of sodium silicate in detergent compositions

Sodium silicate is commonly used in detergent compositions as a builder and corrosion inhibitor. It helps to soften water, enhance cleaning performance, and protect washing machine parts from corrosion. The alkaline nature of sodium silicate also contributes to the overall cleaning efficiency of the detergent.- Use in detergent compositions: Sodium silicate is commonly used in detergent compositions due to its ability to provide alkalinity, act as a builder, and protect against corrosion. It can improve the cleaning efficiency of detergents and help in the removal of various types of stains.

- Application in cement and concrete: Sodium silicate is utilized in the production of cement and concrete materials. It can act as a binder, improve the strength and durability of concrete, and enhance its resistance to chemical attacks. It is also used in the production of refractory materials.

- Role in water treatment: Sodium silicate is employed in water treatment processes for various purposes. It can be used as a coagulant aid, helping to remove suspended particles from water. It also helps in controlling corrosion in water distribution systems and can be used to remove heavy metals from wastewater.

- Use in fire-resistant materials: Sodium silicate is an important component in the production of fire-resistant materials. It can be used to create intumescent coatings that provide fire protection for various substrates. When exposed to high temperatures, it forms a protective barrier that insulates the underlying material.

- Application in soil stabilization: Sodium silicate is used in soil stabilization techniques. It can be injected into soil to improve its strength and reduce permeability. This application is particularly useful in construction projects, where it helps to stabilize foundations and prevent soil erosion.

02 Application in cement and concrete production

Sodium silicate is utilized in the production of cement and concrete as an accelerator and strengthening agent. It can improve the setting time, increase early strength, and enhance the overall durability of concrete structures. Additionally, it can be used as a sealant for concrete surfaces to improve water resistance.Expand Specific Solutions03 Role in water treatment and purification

Sodium silicate plays a significant role in water treatment processes. It acts as a coagulant aid, helping to remove suspended particles and impurities from water. It can also be used to adjust pH levels and control corrosion in water distribution systems, making it valuable in both industrial and municipal water treatment applications.Expand Specific Solutions04 Use in fireproofing and flame-retardant coatings

Sodium silicate is employed in the development of fireproofing materials and flame-retardant coatings. When exposed to high temperatures, it forms a protective barrier that helps prevent the spread of fire. This property makes it useful in various applications, including building materials, textiles, and industrial coatings.Expand Specific Solutions05 Application in paper and pulp industry

In the paper and pulp industry, sodium silicate serves multiple purposes. It is used as a sizing agent to improve paper strength and water resistance. Additionally, it acts as a de-inking agent in paper recycling processes, helping to remove ink from recycled paper fibers. Sodium silicate also contributes to the bleaching and brightening of paper products.Expand Specific Solutions

Key Players in Templating Technology

The research on sodium silicate as a templating agent for hydrothermal processes is in a developing stage, with growing market potential due to its applications in materials science and nanotechnology. The global market for advanced materials using such processes is expanding, driven by demand in sectors like electronics and energy storage. Technologically, the field is progressing rapidly, with companies like Henkel AG & Co. KGaA, China Petroleum & Chemical Corp., and Tronox LLC leading in research and development. These firms are investing in innovative applications of sodium silicate templating, aiming to enhance material properties and production efficiency. The technology's maturity varies across different applications, with some areas nearing commercialization while others remain in early research phases.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an advanced hydrothermal process using sodium silicate as a templating agent for the synthesis of hierarchical zeolites. Their approach involves precise control of the sodium silicate concentration and pH to create a dual-templating effect[1]. This method produces zeolites with both micropores and mesopores, enhancing catalytic performance in oil refining processes. Sinopec's research has shown that these hierarchical zeolites can increase gasoline yield by up to 5% compared to conventional zeolites[2]. The company has also explored the use of sodium silicate in the hydrothermal synthesis of other materials, such as metal-organic frameworks (MOFs), for applications in gas separation and storage[3].

Strengths: Improved catalytic efficiency, increased product yield, and versatility in material synthesis. Weaknesses: Potential scalability issues and higher production costs compared to traditional zeolite synthesis methods.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering at the Chinese Academy of Sciences has conducted extensive research on using sodium silicate as a templating agent in hydrothermal processes. Their innovative approach involves combining sodium silicate with organic structure-directing agents to create hierarchically structured materials[1]. This method has been successfully applied to the synthesis of mesoporous silica, aluminosilicates, and metal oxides. The institute has developed a novel "soft-hard" templating strategy, where sodium silicate acts as the "soft" template, allowing for precise control over pore size distribution and morphology[2]. Their research has demonstrated that materials synthesized using this method exhibit enhanced surface area (up to 1200 m²/g) and improved mass transfer properties, making them ideal for catalysis and adsorption applications[3].

Strengths: High degree of control over material properties, versatility in synthesizing various porous materials. Weaknesses: Complex synthesis process may be challenging to scale up for industrial production.

Innovations in Silicate Templating

Process for hydrothermal production of sodium silicate solutions

PatentInactiveUS5000933A

Innovation

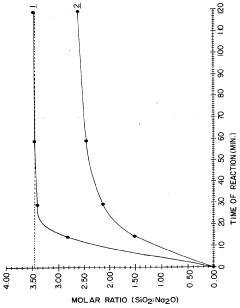

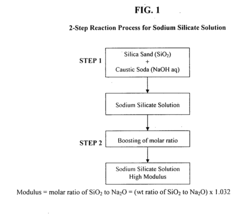

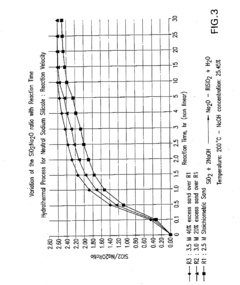

- A process involving the reaction of heat-treated crystalline silica, preferably in its cristobalite form, with an aqueous sodium hydroxide solution under hydrothermal conditions in a pressure reactor, allowing for the production of sodium silicate solutions with SiO2:Na2O molar ratios exceeding 2.9:1, utilizing a silica source heated to at least 1100°C and reacting it with a sodium hydroxide solution at temperatures between 150°C to 300°C.

Process for hydrothermal production of sodium silicate solutions and precipitated silicas

PatentActiveUS20090022646A1

Innovation

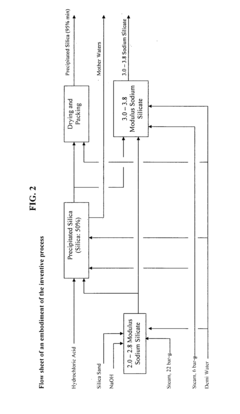

- The process involves recovering silica sand scrubs from titanium dioxide manufacturing, subjecting them to shear washing and sieving to remove TiO2 impurities, followed by hydrothermal reaction with caustic soda to produce intermediate sodium silicate solutions, which are then boosted to high modulus through acidification and precipitation of amorphous silica, utilizing by-products like hydrochloric acid for efficient and environmentally friendly production.

Environmental Impact Assessment

The use of sodium silicate as a templating agent in hydrothermal processes has significant environmental implications that warrant careful consideration. This assessment focuses on the potential impacts of this technology on various environmental aspects.

Firstly, the production of sodium silicate itself involves energy-intensive processes, typically requiring high temperatures and pressures. This energy consumption contributes to greenhouse gas emissions and carbon footprint. However, when used as a templating agent, sodium silicate can potentially lead to more efficient hydrothermal processes, which may offset some of the initial environmental costs.

Water usage is another critical factor to consider. Hydrothermal processes inherently involve substantial water consumption. The introduction of sodium silicate as a templating agent may alter water requirements, potentially leading to more efficient use of water resources. This could be particularly beneficial in water-scarce regions where industrial water use is a concern.

The disposal of waste products from hydrothermal processes using sodium silicate templates requires attention. These wastes may contain residual sodium silicate and other byproducts, which could impact soil and water quality if not properly managed. Proper treatment and disposal methods must be implemented to mitigate potential contamination risks.

On a positive note, the use of sodium silicate as a templating agent can lead to the production of materials with enhanced properties and performance. This may result in more durable and efficient end products, potentially reducing the need for frequent replacements and thereby decreasing overall resource consumption and waste generation in the long term.

The impact on local ecosystems should also be evaluated. The release of sodium silicate or its byproducts into aquatic environments could potentially alter pH levels and affect aquatic life. Careful monitoring and control of effluents from hydrothermal processes are essential to protect local biodiversity.

Furthermore, the use of sodium silicate in hydrothermal processes may influence air quality. While the process itself may not directly emit significant air pollutants, the production and transportation of sodium silicate and other raw materials could contribute to air pollution. This indirect impact should be factored into comprehensive environmental assessments.

Lastly, the potential for recycling and circular economy practices should be explored. Developing methods to recover and reuse sodium silicate from hydrothermal processes could significantly reduce the environmental footprint of this technology, aligning with sustainable development goals and promoting resource efficiency.

Firstly, the production of sodium silicate itself involves energy-intensive processes, typically requiring high temperatures and pressures. This energy consumption contributes to greenhouse gas emissions and carbon footprint. However, when used as a templating agent, sodium silicate can potentially lead to more efficient hydrothermal processes, which may offset some of the initial environmental costs.

Water usage is another critical factor to consider. Hydrothermal processes inherently involve substantial water consumption. The introduction of sodium silicate as a templating agent may alter water requirements, potentially leading to more efficient use of water resources. This could be particularly beneficial in water-scarce regions where industrial water use is a concern.

The disposal of waste products from hydrothermal processes using sodium silicate templates requires attention. These wastes may contain residual sodium silicate and other byproducts, which could impact soil and water quality if not properly managed. Proper treatment and disposal methods must be implemented to mitigate potential contamination risks.

On a positive note, the use of sodium silicate as a templating agent can lead to the production of materials with enhanced properties and performance. This may result in more durable and efficient end products, potentially reducing the need for frequent replacements and thereby decreasing overall resource consumption and waste generation in the long term.

The impact on local ecosystems should also be evaluated. The release of sodium silicate or its byproducts into aquatic environments could potentially alter pH levels and affect aquatic life. Careful monitoring and control of effluents from hydrothermal processes are essential to protect local biodiversity.

Furthermore, the use of sodium silicate in hydrothermal processes may influence air quality. While the process itself may not directly emit significant air pollutants, the production and transportation of sodium silicate and other raw materials could contribute to air pollution. This indirect impact should be factored into comprehensive environmental assessments.

Lastly, the potential for recycling and circular economy practices should be explored. Developing methods to recover and reuse sodium silicate from hydrothermal processes could significantly reduce the environmental footprint of this technology, aligning with sustainable development goals and promoting resource efficiency.

Scalability and Industrial Applications

The scalability and industrial applications of sodium silicate as a templating agent in hydrothermal processes are of significant importance for large-scale production and commercial viability. The use of sodium silicate in these processes has shown promising results in laboratory settings, but transitioning to industrial-scale operations presents both opportunities and challenges.

One of the key advantages of sodium silicate as a templating agent is its cost-effectiveness and abundance. This makes it an attractive option for large-scale production, as it can potentially reduce overall manufacturing costs. Additionally, sodium silicate's versatility in creating various porous structures and its ability to control particle size and morphology make it adaptable to different industrial requirements.

In terms of scalability, the hydrothermal process using sodium silicate can be scaled up through the use of larger reactors and continuous flow systems. This allows for increased production capacity while maintaining consistent product quality. However, careful consideration must be given to factors such as temperature and pressure control, mixing efficiency, and reaction kinetics when scaling up the process.

Industrial applications of sodium silicate-templated materials produced through hydrothermal processes span across various sectors. In the field of catalysis, these materials can be used as supports for catalysts in petrochemical processes, environmental remediation, and fine chemical synthesis. The controlled porosity and high surface area of these materials make them excellent candidates for enhancing catalytic performance.

Another promising application is in the field of energy storage and conversion. Sodium silicate-templated materials can be used to create electrodes for batteries and supercapacitors, potentially improving energy density and charge-discharge cycles. In the realm of environmental technology, these materials show potential for water purification and gas separation applications due to their tunable pore structures.

The construction industry is also exploring the use of sodium silicate-templated materials for developing lightweight, high-strength concrete and insulation materials. These applications leverage the material's unique structural properties to enhance building performance and energy efficiency.

Despite the numerous potential applications, challenges remain in scaling up and implementing these processes in industrial settings. Issues such as maintaining uniform product quality, optimizing reaction conditions for large-scale production, and addressing potential environmental concerns related to waste management need to be carefully addressed. Furthermore, the development of standardized production protocols and quality control measures will be crucial for widespread industrial adoption.

One of the key advantages of sodium silicate as a templating agent is its cost-effectiveness and abundance. This makes it an attractive option for large-scale production, as it can potentially reduce overall manufacturing costs. Additionally, sodium silicate's versatility in creating various porous structures and its ability to control particle size and morphology make it adaptable to different industrial requirements.

In terms of scalability, the hydrothermal process using sodium silicate can be scaled up through the use of larger reactors and continuous flow systems. This allows for increased production capacity while maintaining consistent product quality. However, careful consideration must be given to factors such as temperature and pressure control, mixing efficiency, and reaction kinetics when scaling up the process.

Industrial applications of sodium silicate-templated materials produced through hydrothermal processes span across various sectors. In the field of catalysis, these materials can be used as supports for catalysts in petrochemical processes, environmental remediation, and fine chemical synthesis. The controlled porosity and high surface area of these materials make them excellent candidates for enhancing catalytic performance.

Another promising application is in the field of energy storage and conversion. Sodium silicate-templated materials can be used to create electrodes for batteries and supercapacitors, potentially improving energy density and charge-discharge cycles. In the realm of environmental technology, these materials show potential for water purification and gas separation applications due to their tunable pore structures.

The construction industry is also exploring the use of sodium silicate-templated materials for developing lightweight, high-strength concrete and insulation materials. These applications leverage the material's unique structural properties to enhance building performance and energy efficiency.

Despite the numerous potential applications, challenges remain in scaling up and implementing these processes in industrial settings. Issues such as maintaining uniform product quality, optimizing reaction conditions for large-scale production, and addressing potential environmental concerns related to waste management need to be carefully addressed. Furthermore, the development of standardized production protocols and quality control measures will be crucial for widespread industrial adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!