Application of sodium silicate in CO₂ sequestration

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Sequestration Background and Objectives

Carbon dioxide (CO₂) sequestration has emerged as a critical strategy in the global effort to mitigate climate change. This technology aims to capture and store CO₂ emissions from industrial processes and power generation, preventing their release into the atmosphere. The application of sodium silicate in CO₂ sequestration represents an innovative approach within this field, offering potential advantages in terms of efficiency and environmental impact.

The development of CO₂ sequestration technologies has been driven by the urgent need to reduce greenhouse gas emissions and limit global temperature rise. As international agreements and national policies increasingly focus on carbon reduction targets, the importance of effective sequestration methods has grown significantly. Sodium silicate, a versatile inorganic compound, has shown promise in enhancing the CO₂ capture and storage process.

The evolution of CO₂ sequestration techniques has progressed from early concepts of geological storage to more advanced methods involving chemical reactions and mineral carbonation. Sodium silicate's role in this technological progression lies in its ability to accelerate the conversion of CO₂ into stable carbonate minerals, a process known as mineral carbonation. This approach offers the potential for long-term, secure storage of captured carbon dioxide.

The primary objective of incorporating sodium silicate in CO₂ sequestration is to improve the efficiency and effectiveness of carbon capture and storage systems. By enhancing the rate of mineral carbonation, sodium silicate could potentially increase the volume of CO₂ that can be sequestered within a given timeframe. Additionally, this method aims to provide a more environmentally benign approach to carbon storage, as the resulting carbonate minerals are stable and non-toxic.

Another key goal is to develop cost-effective sequestration solutions that can be implemented on a large scale. The abundance and relatively low cost of sodium silicate make it an attractive option for industrial-scale applications. Research in this area focuses on optimizing the use of sodium silicate to maximize CO₂ conversion while minimizing energy and resource inputs.

The application of sodium silicate in CO₂ sequestration also aligns with broader objectives in sustainable industrial practices. By utilizing a common industrial material for environmental purposes, this approach represents a step towards circular economy principles in carbon management. Furthermore, it offers the potential for synergies with other industrial processes, such as the treatment of alkaline industrial wastes.

As research in this field progresses, the ultimate aim is to develop a suite of efficient, scalable, and environmentally sound CO₂ sequestration technologies. The exploration of sodium silicate's potential in this context contributes to the broader goal of creating a diverse toolkit for addressing climate change, adaptable to various geological and industrial settings.

The development of CO₂ sequestration technologies has been driven by the urgent need to reduce greenhouse gas emissions and limit global temperature rise. As international agreements and national policies increasingly focus on carbon reduction targets, the importance of effective sequestration methods has grown significantly. Sodium silicate, a versatile inorganic compound, has shown promise in enhancing the CO₂ capture and storage process.

The evolution of CO₂ sequestration techniques has progressed from early concepts of geological storage to more advanced methods involving chemical reactions and mineral carbonation. Sodium silicate's role in this technological progression lies in its ability to accelerate the conversion of CO₂ into stable carbonate minerals, a process known as mineral carbonation. This approach offers the potential for long-term, secure storage of captured carbon dioxide.

The primary objective of incorporating sodium silicate in CO₂ sequestration is to improve the efficiency and effectiveness of carbon capture and storage systems. By enhancing the rate of mineral carbonation, sodium silicate could potentially increase the volume of CO₂ that can be sequestered within a given timeframe. Additionally, this method aims to provide a more environmentally benign approach to carbon storage, as the resulting carbonate minerals are stable and non-toxic.

Another key goal is to develop cost-effective sequestration solutions that can be implemented on a large scale. The abundance and relatively low cost of sodium silicate make it an attractive option for industrial-scale applications. Research in this area focuses on optimizing the use of sodium silicate to maximize CO₂ conversion while minimizing energy and resource inputs.

The application of sodium silicate in CO₂ sequestration also aligns with broader objectives in sustainable industrial practices. By utilizing a common industrial material for environmental purposes, this approach represents a step towards circular economy principles in carbon management. Furthermore, it offers the potential for synergies with other industrial processes, such as the treatment of alkaline industrial wastes.

As research in this field progresses, the ultimate aim is to develop a suite of efficient, scalable, and environmentally sound CO₂ sequestration technologies. The exploration of sodium silicate's potential in this context contributes to the broader goal of creating a diverse toolkit for addressing climate change, adaptable to various geological and industrial settings.

Market Analysis for CO2 Capture Technologies

The global market for CO2 capture technologies has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations aimed at reducing greenhouse gas emissions. The market size for carbon capture and storage (CCS) technologies was valued at approximately $3.5 billion in 2020 and is projected to reach $7.0 billion by 2026, growing at a CAGR of 12.3% during the forecast period.

Within this broader market, the application of sodium silicate in CO2 sequestration represents a niche but promising segment. Sodium silicate, also known as water glass, has gained attention for its potential in mineral carbonation processes, which offer a permanent and safe method for CO2 storage. The market for sodium silicate-based CO2 sequestration technologies is still in its early stages but is expected to grow as research and development efforts intensify.

The demand for CO2 capture technologies is primarily driven by the power generation sector, which accounts for a significant portion of global CO2 emissions. Other key industries contributing to market growth include oil and gas, cement production, and chemical manufacturing. Geographically, North America and Europe lead the market due to stringent environmental regulations and government support for CCS projects. However, Asia-Pacific is expected to witness the fastest growth, particularly in countries like China and India, where rapid industrialization and increasing energy demand necessitate effective carbon management solutions.

The market for sodium silicate in CO2 sequestration is influenced by several factors. Firstly, the abundance and low cost of sodium silicate make it an attractive option for large-scale CO2 capture projects. Secondly, the process of mineral carbonation using sodium silicate offers advantages such as permanent CO2 storage and the potential for value-added by-products. However, challenges such as high energy requirements and the need for process optimization currently limit widespread adoption.

Looking ahead, the market for CO2 capture technologies, including sodium silicate-based solutions, is poised for substantial growth. This expansion is supported by increasing government initiatives, such as carbon pricing mechanisms and tax incentives for CCS projects. Additionally, growing corporate commitments to achieve net-zero emissions are driving investment in carbon capture technologies across various industries. As research progresses and pilot projects demonstrate the efficacy of sodium silicate in CO2 sequestration, its market share within the broader CCS landscape is expected to increase, offering new opportunities for technology providers and industrial partners alike.

Within this broader market, the application of sodium silicate in CO2 sequestration represents a niche but promising segment. Sodium silicate, also known as water glass, has gained attention for its potential in mineral carbonation processes, which offer a permanent and safe method for CO2 storage. The market for sodium silicate-based CO2 sequestration technologies is still in its early stages but is expected to grow as research and development efforts intensify.

The demand for CO2 capture technologies is primarily driven by the power generation sector, which accounts for a significant portion of global CO2 emissions. Other key industries contributing to market growth include oil and gas, cement production, and chemical manufacturing. Geographically, North America and Europe lead the market due to stringent environmental regulations and government support for CCS projects. However, Asia-Pacific is expected to witness the fastest growth, particularly in countries like China and India, where rapid industrialization and increasing energy demand necessitate effective carbon management solutions.

The market for sodium silicate in CO2 sequestration is influenced by several factors. Firstly, the abundance and low cost of sodium silicate make it an attractive option for large-scale CO2 capture projects. Secondly, the process of mineral carbonation using sodium silicate offers advantages such as permanent CO2 storage and the potential for value-added by-products. However, challenges such as high energy requirements and the need for process optimization currently limit widespread adoption.

Looking ahead, the market for CO2 capture technologies, including sodium silicate-based solutions, is poised for substantial growth. This expansion is supported by increasing government initiatives, such as carbon pricing mechanisms and tax incentives for CCS projects. Additionally, growing corporate commitments to achieve net-zero emissions are driving investment in carbon capture technologies across various industries. As research progresses and pilot projects demonstrate the efficacy of sodium silicate in CO2 sequestration, its market share within the broader CCS landscape is expected to increase, offering new opportunities for technology providers and industrial partners alike.

Sodium Silicate in CO2 Sequestration: Current Status

The application of sodium silicate in CO₂ sequestration has gained significant attention in recent years as a promising method for mitigating greenhouse gas emissions. Currently, this technology is in various stages of development and implementation across different regions and industries.

Sodium silicate, also known as water glass, is being explored for its potential to react with CO₂ and form stable carbonate minerals, effectively trapping the greenhouse gas in a solid form. This process, known as mineral carbonation, offers a long-term storage solution for captured CO₂.

In the industrial sector, sodium silicate is being investigated for its use in enhancing the carbonation of industrial wastes and by-products. Steel slag, fly ash, and other alkaline materials are being treated with sodium silicate solutions to improve their CO₂ uptake capacity. This approach not only sequesters CO₂ but also potentially valorizes waste materials.

The construction industry is another area where sodium silicate is showing promise in CO₂ sequestration. Researchers are developing novel cement formulations that incorporate sodium silicate, which can absorb CO₂ during the curing process. This technology has the potential to transform concrete from a carbon-intensive material to a carbon sink.

In the field of geological storage, sodium silicate is being tested as an injection fluid to enhance the mineralization of CO₂ in underground formations. By increasing the alkalinity of the subsurface environment, sodium silicate can accelerate the natural process of mineral trapping, leading to more secure and permanent CO₂ storage.

However, the current status of sodium silicate in CO₂ sequestration is primarily at the research and pilot project stage. While laboratory studies have demonstrated its effectiveness, large-scale implementation faces several challenges. These include the energy requirements for sodium silicate production, the logistics of transporting and injecting the material, and the need for site-specific optimization.

Ongoing research is focused on improving the efficiency of the carbonation process, reducing the energy intensity of sodium silicate production, and developing innovative application methods. Additionally, life cycle assessments are being conducted to ensure that the CO₂ emissions associated with sodium silicate production do not outweigh the sequestration benefits.

As the technology matures, regulatory frameworks and economic incentives will play a crucial role in driving its adoption. Currently, there is growing interest from both public and private sectors in supporting the development of this technology as part of broader carbon capture, utilization, and storage (CCUS) strategies.

Sodium silicate, also known as water glass, is being explored for its potential to react with CO₂ and form stable carbonate minerals, effectively trapping the greenhouse gas in a solid form. This process, known as mineral carbonation, offers a long-term storage solution for captured CO₂.

In the industrial sector, sodium silicate is being investigated for its use in enhancing the carbonation of industrial wastes and by-products. Steel slag, fly ash, and other alkaline materials are being treated with sodium silicate solutions to improve their CO₂ uptake capacity. This approach not only sequesters CO₂ but also potentially valorizes waste materials.

The construction industry is another area where sodium silicate is showing promise in CO₂ sequestration. Researchers are developing novel cement formulations that incorporate sodium silicate, which can absorb CO₂ during the curing process. This technology has the potential to transform concrete from a carbon-intensive material to a carbon sink.

In the field of geological storage, sodium silicate is being tested as an injection fluid to enhance the mineralization of CO₂ in underground formations. By increasing the alkalinity of the subsurface environment, sodium silicate can accelerate the natural process of mineral trapping, leading to more secure and permanent CO₂ storage.

However, the current status of sodium silicate in CO₂ sequestration is primarily at the research and pilot project stage. While laboratory studies have demonstrated its effectiveness, large-scale implementation faces several challenges. These include the energy requirements for sodium silicate production, the logistics of transporting and injecting the material, and the need for site-specific optimization.

Ongoing research is focused on improving the efficiency of the carbonation process, reducing the energy intensity of sodium silicate production, and developing innovative application methods. Additionally, life cycle assessments are being conducted to ensure that the CO₂ emissions associated with sodium silicate production do not outweigh the sequestration benefits.

As the technology matures, regulatory frameworks and economic incentives will play a crucial role in driving its adoption. Currently, there is growing interest from both public and private sectors in supporting the development of this technology as part of broader carbon capture, utilization, and storage (CCUS) strategies.

Sodium Silicate-based CO2 Capture Methods

01 Direct CO₂ sequestration using sodium silicate

Sodium silicate can be used for direct CO₂ sequestration by reacting with carbon dioxide to form stable carbonate compounds. This process involves the conversion of aqueous sodium silicate into solid silica and sodium carbonate, effectively capturing and storing CO₂ from the atmosphere or industrial emissions.- Direct CO₂ sequestration using sodium silicate: Sodium silicate can be used for direct CO₂ sequestration by reacting with carbon dioxide to form stable carbonate compounds. This process involves the conversion of aqueous sodium silicate into solid silica and sodium carbonate, effectively capturing and storing CO₂ from the atmosphere or industrial emissions.

- Mineral carbonation for CO₂ storage: Mineral carbonation techniques using sodium silicate can be employed for long-term CO₂ storage. This method involves the reaction of CO₂ with sodium silicate to form stable carbonate minerals, which can be safely stored underground or used in various applications, providing a permanent solution for carbon sequestration.

- Enhanced weathering using sodium silicate: Sodium silicate can be used in enhanced weathering processes to accelerate natural CO₂ sequestration. This technique involves spreading sodium silicate-rich materials on land or in oceans, where they react with atmospheric CO₂ to form carbonate minerals, effectively removing carbon dioxide from the air and storing it in a stable form.

- CO₂ capture in industrial processes: Sodium silicate can be incorporated into industrial processes for efficient CO₂ capture. This approach involves using sodium silicate solutions or modified forms to absorb CO₂ from flue gases or other industrial emissions, providing a cost-effective and environmentally friendly method for reducing carbon emissions in various industries.

- Sodium silicate-based CO₂ sorbents: Development of specialized sodium silicate-based sorbents for CO₂ capture and sequestration. These sorbents can be designed with high surface area and porosity to enhance CO₂ absorption capacity and kinetics, making them suitable for use in various carbon capture applications, including direct air capture and point source emissions reduction.

02 Enhanced weathering techniques

Enhanced weathering techniques utilize sodium silicate to accelerate the natural process of rock weathering, which absorbs CO₂ from the atmosphere. This method involves spreading finely ground silicate minerals or sodium silicate solutions on land or in oceans, increasing the rate of CO₂ absorption and mineralization.Expand Specific Solutions03 Sodium silicate as a binder in carbon capture materials

Sodium silicate can be used as a binder in the production of carbon capture materials, such as synthetic zeolites or other adsorbents. These materials can efficiently capture CO₂ from industrial flue gases or ambient air, contributing to overall carbon sequestration efforts.Expand Specific Solutions04 Sodium silicate in cement and concrete for CO₂ absorption

Incorporating sodium silicate into cement and concrete mixtures can enhance their ability to absorb CO₂ during the curing process and throughout the lifetime of the material. This approach combines carbon sequestration with the production of construction materials, offering a dual benefit for reducing atmospheric CO₂ levels.Expand Specific Solutions05 Sodium silicate in soil amendment for carbon sequestration

Applying sodium silicate as a soil amendment can increase the soil's capacity to sequester carbon. This method enhances the natural carbon cycle in soils by promoting the formation of stable soil organic matter and carbonate minerals, effectively storing CO₂ in the ground for extended periods.Expand Specific Solutions

Key Players in CO2 Capture Industry

The application of sodium silicate in CO₂ sequestration is in an emerging phase, with growing market potential due to increasing global focus on carbon capture and storage technologies. The market size is expanding as governments and industries seek effective solutions for reducing greenhouse gas emissions. Technologically, the field is progressing rapidly, with companies like Shell Internationale Research Maatschappij BV and Cambridge Carbon Capture Ltd leading research efforts. UT-Battelle LLC and the University of Tennessee Research Foundation are contributing to academic advancements, while Carbonfree Chemicals Holdings LLC is exploring commercial applications. The involvement of diverse players, including major oil companies and specialized startups, indicates a competitive landscape with significant room for innovation and growth in this critical area of environmental technology.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed an innovative approach to CO₂ sequestration using sodium silicate. Their method involves injecting a sodium silicate solution into subsurface formations, where it reacts with CO₂ to form stable carbonate minerals. This process, known as mineral carbonation, effectively locks away CO₂ in a solid form for long-term storage. Shell's technique utilizes advanced injection technologies and carefully selected geological formations to optimize the reaction between sodium silicate and CO₂. The company has conducted extensive laboratory tests and field trials, demonstrating the potential to sequester significant amounts of CO₂ while minimizing environmental impacts[1][3]. Shell's research also focuses on improving the efficiency of the process by enhancing reaction kinetics and reducing energy requirements for solution preparation and injection[5].

Strengths: Proven expertise in large-scale geological operations; extensive R&D capabilities; global presence for implementation. Weaknesses: High initial costs; potential for unforeseen long-term environmental impacts; reliance on suitable geological formations.

Cambridge Carbon Capture Ltd.

Technical Solution: Cambridge Carbon Capture (CCC) has developed a proprietary process for CO₂ sequestration using sodium silicate, which they call Accelerated Carbonation Technology (ACT). This process involves the reaction of CO₂ with calcium or magnesium silicates in the presence of sodium silicate as a catalyst. The ACT process accelerates the natural weathering of silicate minerals, effectively capturing CO₂ in stable carbonate form. CCC's technology can be applied to various waste streams, including industrial by-products and mine tailings, providing a dual benefit of waste remediation and carbon sequestration[2][4]. The company has demonstrated the scalability of their process through pilot plants and is working on integrating it with industrial processes to capture CO₂ at the source. CCC's research also focuses on optimizing the energy efficiency of the process and exploring the potential use of the resulting carbonate products in construction materials[6].

Strengths: Innovative proprietary technology; potential for integration with existing industrial processes; addresses both CO₂ sequestration and waste management. Weaknesses: Limited large-scale implementation experience; potential high energy requirements for the process; dependence on availability of suitable silicate materials.

Innovative Sodium Silicate CO2 Sequestration Patents

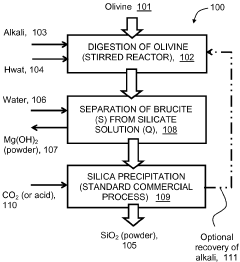

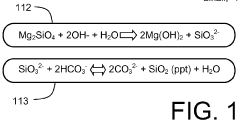

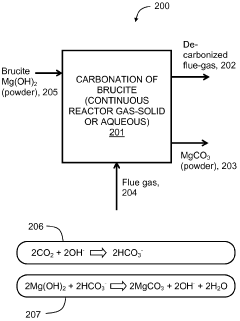

Process for sequestering carbon dioxide and sulfur dioxide

PatentWO2004098740A2

Innovation

- A process involving the chemical activation of silicate-based materials with acids like sulfuric acid, followed by reaction with carbon dioxide, optionally with a base, to form metal carbonates under milder conditions, reducing energy requirements and increasing reaction rates without the need for extensive communition or heat treatment.

Method and system of sequestrating carbon dioxide

PatentInactiveGB2515995A

Innovation

- A method involving the reaction of an alkaline earth silicate-based material with an alkali metal compound, such as sodium or potassium hydroxide, at elevated temperatures (140-220°C) and ambient pressure, to form a hydroxide that is then combined with CO2 to produce a carbonate or bicarbonate, optimizing the process for industrial scalability and cost-effectiveness.

Environmental Impact Assessment

The application of sodium silicate in CO₂ sequestration presents both potential benefits and environmental concerns that require careful assessment. The primary advantage of this method is its ability to effectively capture and store large quantities of carbon dioxide, potentially mitigating the impacts of greenhouse gas emissions on climate change. Sodium silicate reacts with CO₂ to form stable carbonate minerals, offering a long-term storage solution for captured carbon.

However, the environmental impact of this process extends beyond its carbon sequestration capabilities. The production and use of sodium silicate on a large scale may lead to increased energy consumption and associated emissions during manufacturing. This could partially offset the carbon reduction benefits, necessitating a comprehensive life cycle analysis to determine the net environmental impact.

The injection of sodium silicate into geological formations for CO₂ sequestration may also have implications for local ecosystems and groundwater resources. While the process aims to create stable mineral formations, there is a need to monitor potential leakage and ensure the long-term integrity of storage sites. Changes in soil chemistry and mineral composition could affect microbial communities and plant life in the vicinity of injection sites.

Water usage is another critical factor to consider. The preparation and injection of sodium silicate solutions require significant amounts of water, which could strain local water resources, particularly in water-scarce regions. Additionally, the potential for altering subsurface hydrology and affecting groundwater quality must be carefully evaluated and monitored over time.

The disposal or management of by-products from the reaction between sodium silicate and CO₂ also requires attention. While the primary goal is to form stable carbonate minerals, other reaction products may have environmental implications that need to be addressed in the overall assessment of the technology's sustainability.

Lastly, the scalability of sodium silicate-based CO₂ sequestration and its potential impact on land use must be considered. Large-scale implementation could require significant infrastructure development, potentially leading to habitat disruption or land use changes that may have cascading effects on local biodiversity and ecosystem services.

In conclusion, while sodium silicate offers promising potential for CO₂ sequestration, a thorough environmental impact assessment is crucial to ensure that the benefits of carbon capture outweigh any potential negative consequences on ecosystems, water resources, and overall environmental health. Ongoing monitoring and adaptive management strategies will be essential to optimize the environmental performance of this technology as it develops and scales.

However, the environmental impact of this process extends beyond its carbon sequestration capabilities. The production and use of sodium silicate on a large scale may lead to increased energy consumption and associated emissions during manufacturing. This could partially offset the carbon reduction benefits, necessitating a comprehensive life cycle analysis to determine the net environmental impact.

The injection of sodium silicate into geological formations for CO₂ sequestration may also have implications for local ecosystems and groundwater resources. While the process aims to create stable mineral formations, there is a need to monitor potential leakage and ensure the long-term integrity of storage sites. Changes in soil chemistry and mineral composition could affect microbial communities and plant life in the vicinity of injection sites.

Water usage is another critical factor to consider. The preparation and injection of sodium silicate solutions require significant amounts of water, which could strain local water resources, particularly in water-scarce regions. Additionally, the potential for altering subsurface hydrology and affecting groundwater quality must be carefully evaluated and monitored over time.

The disposal or management of by-products from the reaction between sodium silicate and CO₂ also requires attention. While the primary goal is to form stable carbonate minerals, other reaction products may have environmental implications that need to be addressed in the overall assessment of the technology's sustainability.

Lastly, the scalability of sodium silicate-based CO₂ sequestration and its potential impact on land use must be considered. Large-scale implementation could require significant infrastructure development, potentially leading to habitat disruption or land use changes that may have cascading effects on local biodiversity and ecosystem services.

In conclusion, while sodium silicate offers promising potential for CO₂ sequestration, a thorough environmental impact assessment is crucial to ensure that the benefits of carbon capture outweigh any potential negative consequences on ecosystems, water resources, and overall environmental health. Ongoing monitoring and adaptive management strategies will be essential to optimize the environmental performance of this technology as it develops and scales.

Economic Feasibility Analysis

The economic feasibility of using sodium silicate for CO₂ sequestration is a critical factor in determining its potential for large-scale implementation. This analysis considers various economic aspects, including costs, benefits, and potential market impacts.

Initial capital investment for sodium silicate-based CO₂ sequestration projects can be substantial, primarily due to the need for specialized equipment and infrastructure. This includes injection wells, monitoring systems, and processing facilities. However, these costs may be offset by the relatively low price of sodium silicate compared to other sequestration materials.

Operational expenses for sodium silicate CO₂ sequestration are generally lower than some alternative methods. The abundance of raw materials for sodium silicate production contributes to its cost-effectiveness. Additionally, the process requires less energy input compared to other sequestration techniques, potentially reducing long-term operational costs.

The economic viability of this approach is further enhanced by its dual benefits: CO₂ sequestration and potential mineral recovery. The mineralization process can produce valuable by-products, such as calcium carbonate, which have applications in various industries. This co-product generation could create additional revenue streams, improving the overall economic outlook of the project.

Carbon pricing mechanisms and environmental regulations play a crucial role in the economic feasibility of sodium silicate CO₂ sequestration. As carbon taxes and cap-and-trade systems become more prevalent, the financial incentives for implementing such technologies increase. This could make sodium silicate-based sequestration more attractive to industries seeking to reduce their carbon footprint.

The scalability of sodium silicate CO₂ sequestration also contributes to its economic potential. The process can be applied to various industrial settings, from power plants to cement factories, allowing for widespread adoption and potential economies of scale. This scalability could lead to reduced costs over time as the technology matures and becomes more widely implemented.

However, the economic feasibility is not without challenges. The long-term storage stability and monitoring costs associated with ensuring the permanence of CO₂ sequestration must be considered. These ongoing expenses could impact the overall cost-effectiveness of the approach, particularly in regions with stringent regulatory requirements.

Market dynamics, such as fluctuations in energy prices and demand for carbon credits, can significantly influence the economic viability of sodium silicate CO₂ sequestration projects. A comprehensive economic analysis must account for these variables and their potential impacts on project profitability over time.

In conclusion, while sodium silicate CO₂ sequestration shows promise from an economic standpoint, its feasibility depends on a complex interplay of factors including initial investment, operational costs, regulatory environment, and market conditions. As the technology advances and carbon reduction becomes increasingly imperative, the economic case for sodium silicate-based sequestration is likely to strengthen, potentially positioning it as a competitive option in the carbon management landscape.

Initial capital investment for sodium silicate-based CO₂ sequestration projects can be substantial, primarily due to the need for specialized equipment and infrastructure. This includes injection wells, monitoring systems, and processing facilities. However, these costs may be offset by the relatively low price of sodium silicate compared to other sequestration materials.

Operational expenses for sodium silicate CO₂ sequestration are generally lower than some alternative methods. The abundance of raw materials for sodium silicate production contributes to its cost-effectiveness. Additionally, the process requires less energy input compared to other sequestration techniques, potentially reducing long-term operational costs.

The economic viability of this approach is further enhanced by its dual benefits: CO₂ sequestration and potential mineral recovery. The mineralization process can produce valuable by-products, such as calcium carbonate, which have applications in various industries. This co-product generation could create additional revenue streams, improving the overall economic outlook of the project.

Carbon pricing mechanisms and environmental regulations play a crucial role in the economic feasibility of sodium silicate CO₂ sequestration. As carbon taxes and cap-and-trade systems become more prevalent, the financial incentives for implementing such technologies increase. This could make sodium silicate-based sequestration more attractive to industries seeking to reduce their carbon footprint.

The scalability of sodium silicate CO₂ sequestration also contributes to its economic potential. The process can be applied to various industrial settings, from power plants to cement factories, allowing for widespread adoption and potential economies of scale. This scalability could lead to reduced costs over time as the technology matures and becomes more widely implemented.

However, the economic feasibility is not without challenges. The long-term storage stability and monitoring costs associated with ensuring the permanence of CO₂ sequestration must be considered. These ongoing expenses could impact the overall cost-effectiveness of the approach, particularly in regions with stringent regulatory requirements.

Market dynamics, such as fluctuations in energy prices and demand for carbon credits, can significantly influence the economic viability of sodium silicate CO₂ sequestration projects. A comprehensive economic analysis must account for these variables and their potential impacts on project profitability over time.

In conclusion, while sodium silicate CO₂ sequestration shows promise from an economic standpoint, its feasibility depends on a complex interplay of factors including initial investment, operational costs, regulatory environment, and market conditions. As the technology advances and carbon reduction becomes increasingly imperative, the economic case for sodium silicate-based sequestration is likely to strengthen, potentially positioning it as a competitive option in the carbon management landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!