Sodium silicate applications in refractory ceramic composites

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Silicate in Refractories: Background and Objectives

Sodium silicate, also known as water glass, has been a crucial component in the refractory industry for decades. Its applications in refractory ceramic composites have evolved significantly, driven by the increasing demands for high-performance materials in extreme environments. The historical development of sodium silicate in refractories can be traced back to the early 20th century when its binding properties were first recognized and utilized in the production of refractory bricks and mortars.

The primary objective of incorporating sodium silicate into refractory ceramic composites is to enhance their thermal stability, mechanical strength, and chemical resistance. As industries such as steel, glass, and cement production continue to push the boundaries of operational temperatures and corrosive environments, the need for advanced refractory materials has become more pressing. Sodium silicate plays a pivotal role in meeting these challenges by acting as a binder, densifier, and in some cases, a reactive component in the refractory matrix.

The evolution of sodium silicate applications in refractories has been marked by several key technological advancements. Initially used primarily as a cold-setting binder, its role has expanded to include hot-strength development, improved slag resistance, and enhanced thermal shock resistance. The modulation of silica-to-soda ratios in sodium silicate formulations has allowed for tailored properties, addressing specific refractory requirements across various industrial applications.

Recent trends in refractory technology have focused on the development of nano-engineered composites, where sodium silicate serves as a precursor for the in-situ formation of complex ceramic phases. This approach has opened new avenues for creating refractory materials with unprecedented combinations of properties, such as ultra-high temperature resistance coupled with excellent thermal shock behavior.

The ongoing research in this field aims to further optimize the interaction between sodium silicate and other refractory components, exploring novel synthesis routes and compositional designs. The ultimate goal is to develop next-generation refractory ceramic composites that can withstand even more extreme conditions while maintaining long-term stability and performance. As environmental concerns gain prominence, there is also a growing emphasis on developing eco-friendly refractory solutions, with sodium silicate being investigated for its potential in reducing the carbon footprint of refractory production processes.

The primary objective of incorporating sodium silicate into refractory ceramic composites is to enhance their thermal stability, mechanical strength, and chemical resistance. As industries such as steel, glass, and cement production continue to push the boundaries of operational temperatures and corrosive environments, the need for advanced refractory materials has become more pressing. Sodium silicate plays a pivotal role in meeting these challenges by acting as a binder, densifier, and in some cases, a reactive component in the refractory matrix.

The evolution of sodium silicate applications in refractories has been marked by several key technological advancements. Initially used primarily as a cold-setting binder, its role has expanded to include hot-strength development, improved slag resistance, and enhanced thermal shock resistance. The modulation of silica-to-soda ratios in sodium silicate formulations has allowed for tailored properties, addressing specific refractory requirements across various industrial applications.

Recent trends in refractory technology have focused on the development of nano-engineered composites, where sodium silicate serves as a precursor for the in-situ formation of complex ceramic phases. This approach has opened new avenues for creating refractory materials with unprecedented combinations of properties, such as ultra-high temperature resistance coupled with excellent thermal shock behavior.

The ongoing research in this field aims to further optimize the interaction between sodium silicate and other refractory components, exploring novel synthesis routes and compositional designs. The ultimate goal is to develop next-generation refractory ceramic composites that can withstand even more extreme conditions while maintaining long-term stability and performance. As environmental concerns gain prominence, there is also a growing emphasis on developing eco-friendly refractory solutions, with sodium silicate being investigated for its potential in reducing the carbon footprint of refractory production processes.

Market Analysis for Refractory Ceramic Composites

The refractory ceramic composites market has been experiencing steady growth, driven by increasing demand from various end-use industries such as steel, cement, glass, and petrochemicals. These materials play a crucial role in high-temperature applications, offering superior thermal resistance, mechanical strength, and chemical stability. The global market for refractory ceramic composites is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain robust over the next five years.

One of the key factors contributing to market growth is the rising demand for advanced materials in the steel industry, particularly in emerging economies. As these nations invest heavily in infrastructure development and industrial expansion, the need for high-performance refractory materials has surged. Additionally, the growing focus on energy efficiency and sustainability in industrial processes has led to increased adoption of refractory ceramic composites, which offer improved thermal insulation and longer service life compared to traditional materials.

The market for sodium silicate applications in refractory ceramic composites represents a significant segment within the broader refractory materials industry. Sodium silicate, also known as water glass, serves as a crucial binder and strengthening agent in the production of refractory ceramics. Its ability to enhance the thermal and mechanical properties of composites has made it an essential component in various high-temperature applications.

In recent years, there has been a notable shift towards the development of eco-friendly and energy-efficient refractory materials. This trend has further boosted the demand for sodium silicate-based composites, as they offer improved performance while reducing environmental impact. The construction industry, in particular, has shown increased interest in these materials for applications such as fire-resistant coatings and insulation.

Geographically, Asia-Pacific dominates the refractory ceramic composites market, with China and India being the major contributors. The rapid industrialization and urbanization in these countries have fueled the demand for refractory materials across various sectors. North America and Europe follow closely, driven by the need for advanced materials in aerospace, automotive, and energy industries.

Looking ahead, the market for sodium silicate applications in refractory ceramic composites is poised for further expansion. Ongoing research and development efforts are focused on enhancing the properties of these materials, such as improved thermal shock resistance and reduced porosity. As industries continue to push the boundaries of high-temperature processes, the demand for advanced refractory ceramic composites is expected to grow, presenting significant opportunities for market players and innovators in the field.

One of the key factors contributing to market growth is the rising demand for advanced materials in the steel industry, particularly in emerging economies. As these nations invest heavily in infrastructure development and industrial expansion, the need for high-performance refractory materials has surged. Additionally, the growing focus on energy efficiency and sustainability in industrial processes has led to increased adoption of refractory ceramic composites, which offer improved thermal insulation and longer service life compared to traditional materials.

The market for sodium silicate applications in refractory ceramic composites represents a significant segment within the broader refractory materials industry. Sodium silicate, also known as water glass, serves as a crucial binder and strengthening agent in the production of refractory ceramics. Its ability to enhance the thermal and mechanical properties of composites has made it an essential component in various high-temperature applications.

In recent years, there has been a notable shift towards the development of eco-friendly and energy-efficient refractory materials. This trend has further boosted the demand for sodium silicate-based composites, as they offer improved performance while reducing environmental impact. The construction industry, in particular, has shown increased interest in these materials for applications such as fire-resistant coatings and insulation.

Geographically, Asia-Pacific dominates the refractory ceramic composites market, with China and India being the major contributors. The rapid industrialization and urbanization in these countries have fueled the demand for refractory materials across various sectors. North America and Europe follow closely, driven by the need for advanced materials in aerospace, automotive, and energy industries.

Looking ahead, the market for sodium silicate applications in refractory ceramic composites is poised for further expansion. Ongoing research and development efforts are focused on enhancing the properties of these materials, such as improved thermal shock resistance and reduced porosity. As industries continue to push the boundaries of high-temperature processes, the demand for advanced refractory ceramic composites is expected to grow, presenting significant opportunities for market players and innovators in the field.

Current Challenges in Sodium Silicate Applications

Despite the widespread use of sodium silicate in refractory ceramic composites, several challenges persist in its application. One of the primary issues is the control of rheological properties during the manufacturing process. Sodium silicate solutions can exhibit complex flow behaviors, making it difficult to achieve consistent viscosity and workability in ceramic slurries. This variability can lead to inconsistencies in the final product's microstructure and performance.

Another significant challenge is the management of drying and curing processes. Sodium silicate-based composites are prone to cracking and shrinkage during these stages, which can compromise the structural integrity of the final product. The rate of water removal and the formation of silica networks need to be carefully controlled to minimize these defects, often requiring precise environmental conditions and extended curing times.

The high alkalinity of sodium silicate solutions presents corrosion risks to processing equipment and can affect the stability of other components in the composite mixture. This necessitates the use of specialized, corrosion-resistant materials in manufacturing facilities, increasing production costs. Additionally, the alkaline nature can interfere with certain additives or reinforcing materials, limiting formulation options.

Thermal stability is another area of concern, particularly in high-temperature applications. While sodium silicate contributes to the refractory properties of ceramic composites, it can undergo phase transformations at elevated temperatures, potentially leading to changes in volume and mechanical properties. This behavior can be especially problematic in applications requiring long-term exposure to extreme heat.

Environmental and health considerations also pose challenges. The production and use of sodium silicate can generate alkaline waste streams, requiring careful management and disposal. Moreover, the dust generated during the handling of dried sodium silicate-based materials can be a respiratory hazard, necessitating stringent safety measures in manufacturing and application processes.

Lastly, achieving consistent quality across batches remains a persistent issue. Variations in raw material sources, processing conditions, and environmental factors can all contribute to fluctuations in the final product's properties. This variability makes it challenging to meet the stringent performance requirements of advanced refractory applications, particularly in industries such as aerospace, metallurgy, and high-temperature industrial processes.

Another significant challenge is the management of drying and curing processes. Sodium silicate-based composites are prone to cracking and shrinkage during these stages, which can compromise the structural integrity of the final product. The rate of water removal and the formation of silica networks need to be carefully controlled to minimize these defects, often requiring precise environmental conditions and extended curing times.

The high alkalinity of sodium silicate solutions presents corrosion risks to processing equipment and can affect the stability of other components in the composite mixture. This necessitates the use of specialized, corrosion-resistant materials in manufacturing facilities, increasing production costs. Additionally, the alkaline nature can interfere with certain additives or reinforcing materials, limiting formulation options.

Thermal stability is another area of concern, particularly in high-temperature applications. While sodium silicate contributes to the refractory properties of ceramic composites, it can undergo phase transformations at elevated temperatures, potentially leading to changes in volume and mechanical properties. This behavior can be especially problematic in applications requiring long-term exposure to extreme heat.

Environmental and health considerations also pose challenges. The production and use of sodium silicate can generate alkaline waste streams, requiring careful management and disposal. Moreover, the dust generated during the handling of dried sodium silicate-based materials can be a respiratory hazard, necessitating stringent safety measures in manufacturing and application processes.

Lastly, achieving consistent quality across batches remains a persistent issue. Variations in raw material sources, processing conditions, and environmental factors can all contribute to fluctuations in the final product's properties. This variability makes it challenging to meet the stringent performance requirements of advanced refractory applications, particularly in industries such as aerospace, metallurgy, and high-temperature industrial processes.

Existing Sodium Silicate-Based Refractory Solutions

01 Use in detergent compositions

Sodium silicate is commonly used in detergent compositions due to its alkaline properties and ability to soften water. It acts as a builder, helping to remove dirt and stains by suspending them in the wash water. Additionally, it provides corrosion protection for washing machines and helps prevent redeposition of soil onto fabrics.- Use in detergent compositions: Sodium silicate is commonly used in detergent compositions as a builder and alkalinity source. It helps to soften water, remove dirt and stains, and protect washing machines from corrosion. The inclusion of sodium silicate in detergent formulations can enhance cleaning performance and provide stability to the product.

- Application in cement and concrete: Sodium silicate is utilized in the production of cement and concrete materials. It acts as a binder, improves strength, and enhances durability. When added to cement mixtures, it can accelerate setting time, increase resistance to chemical attack, and reduce permeability of the final product.

- Role in water treatment: Sodium silicate plays a significant role in water treatment processes. It is used as a coagulant aid, helping to remove suspended particles and impurities from water. Additionally, it can be employed to control corrosion in water distribution systems by forming a protective layer on metal surfaces.

- Use in fire-resistant coatings: Sodium silicate is an important component in the formulation of fire-resistant coatings. When exposed to high temperatures, it forms a protective barrier that insulates the underlying material. This property makes it valuable in the production of fire-resistant paints, sealants, and other protective coatings for various surfaces and structures.

- Application in paper and pulp industry: In the paper and pulp industry, sodium silicate serves multiple purposes. It is used as a sizing agent to improve paper strength and water resistance. Additionally, it aids in the de-inking process during paper recycling and can be employed as a retention aid in papermaking to enhance filler retention and drainage.

02 Application in cement and concrete

Sodium silicate is utilized in the production of cement and concrete materials. It can act as a hardening accelerator, improving the strength and durability of concrete. It also helps in reducing porosity and enhancing resistance to chemical attack, making it valuable in construction applications.Expand Specific Solutions03 Use in fire-resistant coatings

Sodium silicate is employed in the formulation of fire-resistant coatings and materials. When exposed to high temperatures, it forms a protective barrier that helps prevent the spread of fire. This property makes it useful in various applications, including building materials and industrial coatings.Expand Specific Solutions04 Application in water treatment

Sodium silicate is used in water treatment processes for its ability to remove heavy metals and other contaminants. It can act as a coagulant aid, helping to improve the efficiency of water purification systems. Additionally, it can be used to adjust pH levels and control corrosion in water distribution systems.Expand Specific Solutions05 Use in catalysts and adsorbents

Sodium silicate serves as a precursor in the synthesis of various catalysts and adsorbents. It can be used to produce zeolites, silica gels, and other porous materials with high surface areas. These materials find applications in industrial processes, such as petroleum refining, gas separation, and environmental remediation.Expand Specific Solutions

Key Players in Refractory Ceramic Industry

The sodium silicate applications in refractory ceramic composites market is in a growth phase, driven by increasing demand in industries such as metallurgy, petrochemicals, and power generation. The global market size is estimated to be in the hundreds of millions of dollars, with steady growth projected. Technologically, the field is moderately mature but continues to evolve, with companies like Saint-Gobain Ceramics & Plastics, Johnson Matthey, and Shinagawa Refractories leading innovation. These firms, along with others like IBIDEN and RTX Corp., are investing in R&D to improve performance and sustainability of refractory ceramic composites, indicating a competitive and dynamic market landscape.

Saint-Gobain Ceramics & Plastics, Inc.

Technical Solution: Saint-Gobain has developed advanced sodium silicate-based refractory ceramic composites for high-temperature applications. Their technology involves incorporating sodium silicate as a binder and strengthening agent in ceramic matrix composites. The process includes precise control of sodium silicate concentration and curing conditions to optimize mechanical properties and thermal resistance. Saint-Gobain's composites demonstrate enhanced crack resistance and improved thermal shock resistance compared to traditional refractories[1][3]. The company has also implemented a novel sol-gel process to create nanostructured sodium silicate coatings on ceramic fibers, further enhancing the composite's performance in extreme environments[2].

Strengths: Excellent thermal shock resistance, improved mechanical properties, and enhanced durability in high-temperature applications. Weaknesses: Potential for alkali attack in certain environments, and higher production costs compared to conventional refractories.

Refractory Intellectual Property GmbH & Co. KG

Technical Solution: Refractory Intellectual Property has pioneered a unique approach to sodium silicate applications in refractory ceramic composites. Their technology focuses on creating a gradient structure within the composite, where sodium silicate concentration varies throughout the material thickness. This gradient structure allows for optimized thermal expansion behavior and improved resistance to thermal cycling[4]. The company has also developed a proprietary curing process that involves controlled humidity and temperature cycles, resulting in a more uniform microstructure and enhanced bonding between the ceramic matrix and reinforcing fibers[5]. Additionally, they have introduced nano-sized sodium silicate particles into the composite, which has shown to significantly improve the material's resistance to slag penetration in steel industry applications[6].

Strengths: Excellent thermal cycling resistance, improved slag penetration resistance, and tailored thermal expansion properties. Weaknesses: Complex manufacturing process and potential limitations in very high alkaline environments.

Innovative Sodium Silicate Formulations for Refractories

Refractory composite material and process for its fabrication

PatentInactiveEP0341150A1

Innovation

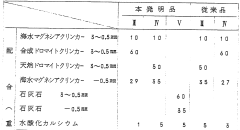

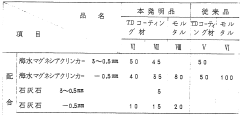

- A refractory composite material with a honeycomb structure is developed using a hardened foam of a mineral binder, specifically sodium silicate, combined with mineral fillers, which undergoes volume expansion during dehydration to achieve precise molding without re-machining, while maintaining low density and cost-effectiveness.

Basic refractory composition

PatentWO1987005288A1

Innovation

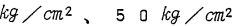

- A salt-based refractory composition using modified sodium silicate from acid clay, combined with aggregates like magnesia, dolomite, and calcium oxide, which reacts to form high-strength compounds at high temperatures, eliminating harmful components like phosphorus, sulfur, and fluorine.

Environmental Impact of Sodium Silicate in Refractories

The environmental impact of sodium silicate in refractories is a crucial consideration for the sustainable development of the refractory ceramic composites industry. Sodium silicate, while offering numerous benefits in refractory applications, also presents potential environmental challenges that must be carefully managed.

One of the primary environmental concerns associated with sodium silicate in refractories is its contribution to air pollution. During the manufacturing process and high-temperature applications, sodium silicate can release volatile compounds, including sodium oxide vapors. These emissions can contribute to air quality issues and potentially impact local ecosystems if not properly controlled.

Water pollution is another significant environmental aspect to consider. Sodium silicate is highly soluble in water, and improper disposal or leaching from refractory materials can lead to increased sodium levels in water bodies. This can adversely affect aquatic ecosystems and potentially contaminate groundwater resources, necessitating careful waste management practices.

The production of sodium silicate itself has environmental implications. The process typically involves high-temperature fusion of sand and soda ash, which requires substantial energy input and results in carbon dioxide emissions. As the refractory industry strives for sustainability, addressing the carbon footprint associated with sodium silicate production becomes increasingly important.

Landfill disposal of refractory materials containing sodium silicate also presents environmental challenges. The high alkalinity of sodium silicate can affect soil pH levels and potentially impact surrounding vegetation. Furthermore, the leaching of sodium and silica compounds from disposed refractories can alter local soil and water chemistry.

However, it is important to note that sodium silicate also offers some environmental benefits in refractory applications. Its use can enhance the durability and lifespan of refractory materials, potentially reducing the frequency of replacements and associated waste generation. Additionally, sodium silicate can improve the energy efficiency of certain refractory systems, indirectly contributing to reduced energy consumption and emissions in industrial processes.

To mitigate the environmental impact of sodium silicate in refractories, several strategies can be employed. These include optimizing manufacturing processes to minimize emissions, implementing effective waste management and recycling programs, and exploring alternative, more environmentally friendly binder systems. Research into novel formulations that reduce the required sodium silicate content while maintaining performance characteristics is also a promising avenue for environmental improvement.

One of the primary environmental concerns associated with sodium silicate in refractories is its contribution to air pollution. During the manufacturing process and high-temperature applications, sodium silicate can release volatile compounds, including sodium oxide vapors. These emissions can contribute to air quality issues and potentially impact local ecosystems if not properly controlled.

Water pollution is another significant environmental aspect to consider. Sodium silicate is highly soluble in water, and improper disposal or leaching from refractory materials can lead to increased sodium levels in water bodies. This can adversely affect aquatic ecosystems and potentially contaminate groundwater resources, necessitating careful waste management practices.

The production of sodium silicate itself has environmental implications. The process typically involves high-temperature fusion of sand and soda ash, which requires substantial energy input and results in carbon dioxide emissions. As the refractory industry strives for sustainability, addressing the carbon footprint associated with sodium silicate production becomes increasingly important.

Landfill disposal of refractory materials containing sodium silicate also presents environmental challenges. The high alkalinity of sodium silicate can affect soil pH levels and potentially impact surrounding vegetation. Furthermore, the leaching of sodium and silica compounds from disposed refractories can alter local soil and water chemistry.

However, it is important to note that sodium silicate also offers some environmental benefits in refractory applications. Its use can enhance the durability and lifespan of refractory materials, potentially reducing the frequency of replacements and associated waste generation. Additionally, sodium silicate can improve the energy efficiency of certain refractory systems, indirectly contributing to reduced energy consumption and emissions in industrial processes.

To mitigate the environmental impact of sodium silicate in refractories, several strategies can be employed. These include optimizing manufacturing processes to minimize emissions, implementing effective waste management and recycling programs, and exploring alternative, more environmentally friendly binder systems. Research into novel formulations that reduce the required sodium silicate content while maintaining performance characteristics is also a promising avenue for environmental improvement.

Thermal Performance Evaluation Methods

Thermal performance evaluation methods for sodium silicate applications in refractory ceramic composites are crucial for assessing their effectiveness and suitability in high-temperature environments. These methods typically involve a combination of laboratory testing and field trials to determine the thermal properties and behavior of the composites under various conditions.

One of the primary evaluation techniques is thermal conductivity measurement. This is often conducted using the hot wire method or laser flash analysis. The hot wire method involves embedding a thin wire in the sample and measuring the temperature rise over time when a constant electric current is applied. Laser flash analysis, on the other hand, uses a short laser pulse to heat one side of a thin sample while measuring the temperature rise on the opposite side.

Thermal expansion testing is another critical aspect of performance evaluation. Dilatometry is commonly employed to measure the dimensional changes of the composite as a function of temperature. This information is vital for predicting the behavior of the material during heating and cooling cycles, which is essential for preventing thermal shock and ensuring structural integrity.

High-temperature mechanical testing is also an integral part of the evaluation process. This includes compressive strength tests, flexural strength tests, and creep resistance measurements at elevated temperatures. These tests help determine the ability of the sodium silicate-based refractory ceramic composites to maintain their structural integrity under thermal and mechanical stresses.

Thermal cycling tests are performed to assess the material's resistance to thermal shock and fatigue. Samples are subjected to repeated heating and cooling cycles, simulating the conditions they would experience in industrial applications. The number of cycles a material can withstand before failure provides valuable information about its durability and longevity.

Microstructural analysis is often conducted in conjunction with thermal performance tests. Techniques such as scanning electron microscopy (SEM) and X-ray diffraction (XRD) are used to examine the material's structure before and after thermal exposure. This analysis helps in understanding the mechanisms of thermal resistance and identifying any phase changes or degradation that may occur during high-temperature service.

Thermal gravimetric analysis (TGA) is employed to study the weight changes of the composite as a function of temperature. This technique provides insights into the material's thermal stability, decomposition behavior, and potential chemical reactions that may occur at elevated temperatures.

Finally, simulated service testing is often conducted to evaluate the performance of sodium silicate-based refractory ceramic composites under conditions that closely resemble their intended application. This may involve exposure to specific industrial atmospheres, corrosive environments, or thermal gradients that the material is likely to encounter in real-world scenarios.

One of the primary evaluation techniques is thermal conductivity measurement. This is often conducted using the hot wire method or laser flash analysis. The hot wire method involves embedding a thin wire in the sample and measuring the temperature rise over time when a constant electric current is applied. Laser flash analysis, on the other hand, uses a short laser pulse to heat one side of a thin sample while measuring the temperature rise on the opposite side.

Thermal expansion testing is another critical aspect of performance evaluation. Dilatometry is commonly employed to measure the dimensional changes of the composite as a function of temperature. This information is vital for predicting the behavior of the material during heating and cooling cycles, which is essential for preventing thermal shock and ensuring structural integrity.

High-temperature mechanical testing is also an integral part of the evaluation process. This includes compressive strength tests, flexural strength tests, and creep resistance measurements at elevated temperatures. These tests help determine the ability of the sodium silicate-based refractory ceramic composites to maintain their structural integrity under thermal and mechanical stresses.

Thermal cycling tests are performed to assess the material's resistance to thermal shock and fatigue. Samples are subjected to repeated heating and cooling cycles, simulating the conditions they would experience in industrial applications. The number of cycles a material can withstand before failure provides valuable information about its durability and longevity.

Microstructural analysis is often conducted in conjunction with thermal performance tests. Techniques such as scanning electron microscopy (SEM) and X-ray diffraction (XRD) are used to examine the material's structure before and after thermal exposure. This analysis helps in understanding the mechanisms of thermal resistance and identifying any phase changes or degradation that may occur during high-temperature service.

Thermal gravimetric analysis (TGA) is employed to study the weight changes of the composite as a function of temperature. This technique provides insights into the material's thermal stability, decomposition behavior, and potential chemical reactions that may occur at elevated temperatures.

Finally, simulated service testing is often conducted to evaluate the performance of sodium silicate-based refractory ceramic composites under conditions that closely resemble their intended application. This may involve exposure to specific industrial atmospheres, corrosive environments, or thermal gradients that the material is likely to encounter in real-world scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!