Sodium silicate as an adhesive in advanced manufacturing

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Silicate Adhesive Background and Objectives

Sodium silicate, also known as water glass, has a long history of use as an adhesive dating back to the 19th century. Its unique properties, including high bonding strength, fire resistance, and eco-friendliness, have made it a subject of renewed interest in advanced manufacturing. The evolution of sodium silicate as an adhesive has been driven by the increasing demand for sustainable and high-performance bonding solutions in various industries.

The primary objective of researching sodium silicate as an adhesive in advanced manufacturing is to explore its potential as a versatile and environmentally friendly alternative to traditional adhesives. This research aims to address the growing need for adhesives that can meet the stringent requirements of modern manufacturing processes while minimizing environmental impact. By investigating sodium silicate's adhesive properties, researchers seek to develop innovative applications that can enhance production efficiency, reduce costs, and improve product quality across multiple sectors.

One of the key trends driving the interest in sodium silicate adhesives is the global shift towards sustainable manufacturing practices. As industries face increasing pressure to reduce their carbon footprint and adopt eco-friendly materials, sodium silicate presents an attractive option due to its non-toxic nature and biodegradability. This aligns with the broader technological trend of developing green chemistry solutions for industrial applications.

The research into sodium silicate adhesives also aims to overcome some of the limitations associated with traditional adhesives, such as volatile organic compound (VOC) emissions and limited temperature resistance. By focusing on sodium silicate, researchers hope to develop adhesive formulations that can withstand extreme conditions while maintaining strong bonding properties. This is particularly relevant in advanced manufacturing sectors such as aerospace, automotive, and electronics, where materials are often subjected to harsh environments.

Furthermore, the study of sodium silicate as an adhesive in advanced manufacturing is expected to contribute to the development of multi-functional materials. The unique chemical structure of sodium silicate allows for the possibility of incorporating additional functionalities, such as fire retardancy or electrical conductivity, into the adhesive matrix. This opens up new avenues for creating smart materials that can serve multiple purposes within a single product, potentially revolutionizing manufacturing processes and product designs.

The primary objective of researching sodium silicate as an adhesive in advanced manufacturing is to explore its potential as a versatile and environmentally friendly alternative to traditional adhesives. This research aims to address the growing need for adhesives that can meet the stringent requirements of modern manufacturing processes while minimizing environmental impact. By investigating sodium silicate's adhesive properties, researchers seek to develop innovative applications that can enhance production efficiency, reduce costs, and improve product quality across multiple sectors.

One of the key trends driving the interest in sodium silicate adhesives is the global shift towards sustainable manufacturing practices. As industries face increasing pressure to reduce their carbon footprint and adopt eco-friendly materials, sodium silicate presents an attractive option due to its non-toxic nature and biodegradability. This aligns with the broader technological trend of developing green chemistry solutions for industrial applications.

The research into sodium silicate adhesives also aims to overcome some of the limitations associated with traditional adhesives, such as volatile organic compound (VOC) emissions and limited temperature resistance. By focusing on sodium silicate, researchers hope to develop adhesive formulations that can withstand extreme conditions while maintaining strong bonding properties. This is particularly relevant in advanced manufacturing sectors such as aerospace, automotive, and electronics, where materials are often subjected to harsh environments.

Furthermore, the study of sodium silicate as an adhesive in advanced manufacturing is expected to contribute to the development of multi-functional materials. The unique chemical structure of sodium silicate allows for the possibility of incorporating additional functionalities, such as fire retardancy or electrical conductivity, into the adhesive matrix. This opens up new avenues for creating smart materials that can serve multiple purposes within a single product, potentially revolutionizing manufacturing processes and product designs.

Market Analysis for Advanced Manufacturing Adhesives

The advanced manufacturing adhesives market has been experiencing significant growth in recent years, driven by the increasing demand for high-performance bonding solutions across various industries. This market segment is characterized by its focus on innovative adhesive technologies that can meet the stringent requirements of modern manufacturing processes, including high strength, durability, and resistance to extreme conditions.

Sodium silicate, also known as water glass, has emerged as a promising adhesive material in advanced manufacturing applications. Its unique properties, such as excellent thermal stability, fire resistance, and eco-friendliness, have attracted considerable attention from manufacturers and researchers alike. The market for sodium silicate adhesives is expected to grow steadily, particularly in sectors such as automotive, aerospace, and electronics manufacturing.

One of the key drivers for the adoption of sodium silicate adhesives is the growing emphasis on sustainable and environmentally friendly manufacturing practices. As industries face increasing pressure to reduce their carbon footprint and minimize the use of hazardous materials, sodium silicate offers a viable alternative to traditional petroleum-based adhesives. This trend is likely to continue, further boosting the market potential for sodium silicate adhesives in advanced manufacturing.

The automotive industry represents a significant market opportunity for sodium silicate adhesives. With the shift towards lightweight materials and electric vehicles, there is a growing need for adhesives that can bond dissimilar materials effectively while maintaining structural integrity. Sodium silicate adhesives have shown promise in this area, particularly in applications such as battery assembly and composite bonding.

In the aerospace sector, sodium silicate adhesives are gaining traction due to their ability to withstand high temperatures and provide excellent fire resistance. These properties make them suitable for use in aircraft interiors, engine components, and other critical applications where safety and performance are paramount. As the aerospace industry continues to innovate and develop new materials, the demand for advanced adhesives like sodium silicate is expected to increase.

The electronics manufacturing industry is another key market for sodium silicate adhesives. With the ongoing miniaturization of electronic devices and the need for improved thermal management, sodium silicate-based adhesives offer potential solutions for bonding and sealing applications in this sector. Their ability to form strong, heat-resistant bonds makes them particularly attractive for use in high-performance electronic components and assemblies.

Despite the promising outlook, challenges remain in the widespread adoption of sodium silicate adhesives in advanced manufacturing. These include the need for improved curing processes, enhanced mechanical properties, and better compatibility with a wider range of substrates. Ongoing research and development efforts are focused on addressing these challenges and expanding the application range of sodium silicate adhesives in advanced manufacturing processes.

Sodium silicate, also known as water glass, has emerged as a promising adhesive material in advanced manufacturing applications. Its unique properties, such as excellent thermal stability, fire resistance, and eco-friendliness, have attracted considerable attention from manufacturers and researchers alike. The market for sodium silicate adhesives is expected to grow steadily, particularly in sectors such as automotive, aerospace, and electronics manufacturing.

One of the key drivers for the adoption of sodium silicate adhesives is the growing emphasis on sustainable and environmentally friendly manufacturing practices. As industries face increasing pressure to reduce their carbon footprint and minimize the use of hazardous materials, sodium silicate offers a viable alternative to traditional petroleum-based adhesives. This trend is likely to continue, further boosting the market potential for sodium silicate adhesives in advanced manufacturing.

The automotive industry represents a significant market opportunity for sodium silicate adhesives. With the shift towards lightweight materials and electric vehicles, there is a growing need for adhesives that can bond dissimilar materials effectively while maintaining structural integrity. Sodium silicate adhesives have shown promise in this area, particularly in applications such as battery assembly and composite bonding.

In the aerospace sector, sodium silicate adhesives are gaining traction due to their ability to withstand high temperatures and provide excellent fire resistance. These properties make them suitable for use in aircraft interiors, engine components, and other critical applications where safety and performance are paramount. As the aerospace industry continues to innovate and develop new materials, the demand for advanced adhesives like sodium silicate is expected to increase.

The electronics manufacturing industry is another key market for sodium silicate adhesives. With the ongoing miniaturization of electronic devices and the need for improved thermal management, sodium silicate-based adhesives offer potential solutions for bonding and sealing applications in this sector. Their ability to form strong, heat-resistant bonds makes them particularly attractive for use in high-performance electronic components and assemblies.

Despite the promising outlook, challenges remain in the widespread adoption of sodium silicate adhesives in advanced manufacturing. These include the need for improved curing processes, enhanced mechanical properties, and better compatibility with a wider range of substrates. Ongoing research and development efforts are focused on addressing these challenges and expanding the application range of sodium silicate adhesives in advanced manufacturing processes.

Current Challenges in Sodium Silicate Adhesive Technology

Despite the long history and widespread use of sodium silicate as an adhesive, several challenges persist in its application within advanced manufacturing contexts. One of the primary issues is the limited strength of sodium silicate bonds compared to modern synthetic adhesives. This weakness becomes particularly apparent in high-stress applications or environments with significant temperature fluctuations, where the bond may fail prematurely.

Another significant challenge is the relatively slow curing time of sodium silicate adhesives. In advanced manufacturing processes where rapid assembly and production speeds are crucial, the extended setting time can lead to bottlenecks and reduced efficiency. This limitation often necessitates the use of heat or other catalysts to accelerate curing, which can complicate manufacturing processes and increase energy consumption.

The sensitivity of sodium silicate adhesives to moisture presents another hurdle in their widespread adoption. In humid environments or applications exposed to water, the bond strength can deteriorate over time, leading to potential product failures. This hygroscopic nature also complicates storage and handling of the adhesive, requiring careful environmental control to maintain its efficacy.

Furthermore, the alkaline nature of sodium silicate adhesives poses compatibility issues with certain substrates, particularly those sensitive to high pH levels. This limitation restricts its use in some advanced materials and composites, where chemical interactions between the adhesive and substrate could compromise the integrity of the final product.

The brittleness of cured sodium silicate adhesives is another area of concern. In applications requiring flexibility or subjected to vibrations, the rigid nature of the bond can lead to cracking or complete failure. This characteristic limits its use in dynamic or flexible assemblies, which are increasingly common in advanced manufacturing.

Lastly, the environmental impact of sodium silicate production and disposal remains a challenge. While the adhesive itself is inorganic and generally considered environmentally friendly, the energy-intensive manufacturing process and the potential for releasing alkaline substances during disposal or recycling raise sustainability concerns. As industries increasingly prioritize eco-friendly materials and processes, addressing these environmental aspects becomes crucial for the continued relevance of sodium silicate adhesives in advanced manufacturing.

Another significant challenge is the relatively slow curing time of sodium silicate adhesives. In advanced manufacturing processes where rapid assembly and production speeds are crucial, the extended setting time can lead to bottlenecks and reduced efficiency. This limitation often necessitates the use of heat or other catalysts to accelerate curing, which can complicate manufacturing processes and increase energy consumption.

The sensitivity of sodium silicate adhesives to moisture presents another hurdle in their widespread adoption. In humid environments or applications exposed to water, the bond strength can deteriorate over time, leading to potential product failures. This hygroscopic nature also complicates storage and handling of the adhesive, requiring careful environmental control to maintain its efficacy.

Furthermore, the alkaline nature of sodium silicate adhesives poses compatibility issues with certain substrates, particularly those sensitive to high pH levels. This limitation restricts its use in some advanced materials and composites, where chemical interactions between the adhesive and substrate could compromise the integrity of the final product.

The brittleness of cured sodium silicate adhesives is another area of concern. In applications requiring flexibility or subjected to vibrations, the rigid nature of the bond can lead to cracking or complete failure. This characteristic limits its use in dynamic or flexible assemblies, which are increasingly common in advanced manufacturing.

Lastly, the environmental impact of sodium silicate production and disposal remains a challenge. While the adhesive itself is inorganic and generally considered environmentally friendly, the energy-intensive manufacturing process and the potential for releasing alkaline substances during disposal or recycling raise sustainability concerns. As industries increasingly prioritize eco-friendly materials and processes, addressing these environmental aspects becomes crucial for the continued relevance of sodium silicate adhesives in advanced manufacturing.

Existing Sodium Silicate Adhesive Formulations

01 Adhesive properties of sodium silicate in construction materials

Sodium silicate exhibits strong adhesive properties, making it suitable for use in various construction materials. It can be used as a binder in cement and concrete mixtures, enhancing the strength and durability of these materials. The adhesive nature of sodium silicate also makes it effective in bonding aggregates and other components in construction applications.- Composition of sodium silicate adhesives: Sodium silicate adhesives are typically composed of sodium silicate solutions with varying ratios of silica to sodium oxide. These adhesives may also include additives such as fillers, stabilizers, and curing agents to enhance their properties and performance.

- Bonding strength and durability: Sodium silicate adhesives exhibit strong bonding properties, particularly for porous materials like paper, wood, and ceramics. The adhesive strength can be further improved by optimizing the silica-to-sodium oxide ratio and incorporating reinforcing agents. These adhesives also demonstrate good durability and resistance to environmental factors.

- Water resistance and curing mechanisms: While sodium silicate adhesives are water-soluble initially, they can be formulated to achieve water resistance after curing. Various curing mechanisms, such as heat treatment, chemical reactions, or the addition of specific compounds, can be employed to enhance water resistance and overall adhesive performance.

- Application methods and viscosity control: Sodium silicate adhesives can be applied through various methods, including spraying, brushing, or roller coating. The viscosity of the adhesive can be adjusted by controlling the solids content or adding thickening agents, allowing for optimal application in different industrial processes.

- Environmental and safety considerations: Sodium silicate adhesives are generally considered environmentally friendly due to their inorganic nature and low toxicity. They are non-flammable and do not emit volatile organic compounds (VOCs). However, proper handling and safety precautions should be observed due to their alkaline nature.

02 Sodium silicate as a binder in refractory materials

Sodium silicate is utilized as a binder in refractory materials due to its excellent adhesive properties at high temperatures. It helps to bond refractory particles together, creating a strong and heat-resistant structure. This application is particularly useful in industries requiring materials that can withstand extreme heat, such as furnace linings and foundry molds.Expand Specific Solutions03 Use of sodium silicate in paper and cardboard production

The adhesive properties of sodium silicate are beneficial in the paper and cardboard industry. It is used as a binder and sizing agent, improving the strength and water resistance of paper products. Sodium silicate can also enhance the bonding between paper fibers, resulting in improved paper quality and durability.Expand Specific Solutions04 Sodium silicate as an adhesive in wood products

Sodium silicate's adhesive properties make it suitable for use in wood products and furniture manufacturing. It can be used as a binder in particleboard and fiberboard production, as well as an adhesive for wood veneers. The water-resistant nature of sodium silicate-based adhesives contributes to the durability of wood products.Expand Specific Solutions05 Modification of sodium silicate for improved adhesive properties

Research has been conducted on modifying sodium silicate to enhance its adhesive properties for specific applications. This includes the addition of various additives, chemical modifications, and the development of composite materials incorporating sodium silicate. These modifications aim to improve bonding strength, water resistance, and compatibility with different substrates.Expand Specific Solutions

Key Players in Sodium Silicate Adhesive Industry

The research on sodium silicate as an adhesive in advanced manufacturing is in a growth phase, with increasing market size and technological advancements. The global market for sodium silicate adhesives is expanding due to their eco-friendly nature and versatile applications. Companies like Henkel AG & Co. KGaA, BASF Corp., and Wanhua Chemical Group Co., Ltd. are at the forefront of developing innovative sodium silicate-based adhesive solutions. The technology is maturing, with ongoing research focused on improving performance and expanding applications. However, challenges remain in optimizing properties for specific advanced manufacturing processes, indicating room for further development and market growth.

Henkel AG & Co. KGaA

Technical Solution: Henkel has made significant advancements in sodium silicate adhesive technology for advanced manufacturing. Their research has led to the development of hybrid sodium silicate adhesives that combine the benefits of inorganic and organic components. These hybrids offer improved flexibility and impact resistance while maintaining the high-temperature resistance of traditional sodium silicates[5]. Henkel has also pioneered the use of sodium silicate in 3D printing applications, creating specialized formulations that can be used as binders in additive manufacturing processes[6].

Strengths: Improved flexibility and impact resistance, versatility in application methods including 3D printing. Weaknesses: May have limited shelf life, requires careful storage to prevent premature curing.

Evonik Operations GmbH

Technical Solution: Evonik has developed advanced sodium silicate-based adhesives for use in manufacturing processes. Their technology focuses on creating customized formulations with improved bonding strength and durability. Evonik's sodium silicate adhesives incorporate nanoparticle additives to enhance adhesion and water resistance[1]. The company has also developed a spray-drying process to produce sodium silicate powders with controlled particle size distribution, allowing for more precise application in advanced manufacturing[3].

Strengths: Customizable formulations, enhanced bonding properties, improved water resistance. Weaknesses: May be more expensive than traditional adhesives, requires specialized application equipment.

Innovative Sodium Silicate Adhesive Patents

Aqueous sodium silicate adhesive

PatentInactiveGB2301598A

Innovation

- A mixture of aqueous sodium silicate solution with a reactive amino-functional silicone emulsion, silane, and zinc oxide, along with powder additives like hydrated magnesium and silica frits, is used to enhance adhesion, mechanical properties, and water resistance, while inhibiting burning and smoke production.

Adhesive composition (and variant embodiments thereof)

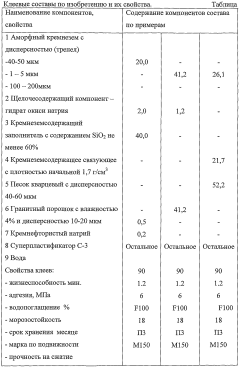

PatentWO2010140920A1

Innovation

- Development of adhesive compositions using amorphous silica as a binder with specific ratios of silica-containing fillers, alkali-containing components, and superplasticizers, which enhance water, acid, and alkali resistance, and improve strength properties, allowing for broader industrial applications.

Environmental Impact of Sodium Silicate Adhesives

The environmental impact of sodium silicate adhesives in advanced manufacturing is a crucial consideration for sustainable industrial practices. These adhesives, while effective in many applications, have both positive and negative effects on the environment throughout their lifecycle.

Sodium silicate adhesives offer several environmental benefits. They are derived from abundant natural materials, primarily sand and soda ash, which reduces the reliance on petrochemical-based resources. The production process of sodium silicate is relatively energy-efficient compared to many synthetic adhesives, contributing to a lower carbon footprint. Additionally, these adhesives are non-toxic, non-flammable, and do not emit volatile organic compounds (VOCs) during application or curing, making them safer for both workers and the environment.

However, the environmental impact of sodium silicate adhesives is not entirely benign. The mining of raw materials, particularly silica sand, can lead to habitat disruption and landscape alterations. The extraction process may also contribute to air and water pollution if not properly managed. Furthermore, the production of sodium silicate involves high-temperature processes, which consume significant energy and contribute to greenhouse gas emissions.

In terms of waste management, sodium silicate adhesives present both challenges and opportunities. On the positive side, these adhesives are water-soluble, which facilitates easier cleaning of equipment and reduces the need for harsh chemical solvents. However, this solubility can also lead to increased water consumption during the manufacturing process and potential contamination of wastewater streams if not properly treated.

The end-of-life considerations for products bonded with sodium silicate adhesives are generally favorable. Unlike many synthetic adhesives, sodium silicate does not persist in the environment for extended periods. It eventually breaks down into harmless components, primarily silica and sodium compounds, which are naturally occurring in the environment. This biodegradability reduces the long-term environmental impact of disposed products.

In advanced manufacturing, the use of sodium silicate adhesives can contribute to the development of more recyclable and environmentally friendly products. Their ability to create strong bonds that can be easily broken down under specific conditions (such as high pH environments) facilitates the separation of materials at the end of a product's life, enhancing recyclability and reducing waste.

However, the alkaline nature of sodium silicate adhesives requires careful handling and disposal practices. Improper disposal can lead to localized pH changes in soil or water bodies, potentially affecting ecosystems. Manufacturers must implement proper waste management protocols to mitigate these risks.

As industries strive for more sustainable practices, ongoing research is focused on further improving the environmental profile of sodium silicate adhesives. This includes exploring ways to reduce energy consumption in production, developing more efficient application methods to minimize waste, and investigating the potential for incorporating recycled materials into the adhesive formulation.

Sodium silicate adhesives offer several environmental benefits. They are derived from abundant natural materials, primarily sand and soda ash, which reduces the reliance on petrochemical-based resources. The production process of sodium silicate is relatively energy-efficient compared to many synthetic adhesives, contributing to a lower carbon footprint. Additionally, these adhesives are non-toxic, non-flammable, and do not emit volatile organic compounds (VOCs) during application or curing, making them safer for both workers and the environment.

However, the environmental impact of sodium silicate adhesives is not entirely benign. The mining of raw materials, particularly silica sand, can lead to habitat disruption and landscape alterations. The extraction process may also contribute to air and water pollution if not properly managed. Furthermore, the production of sodium silicate involves high-temperature processes, which consume significant energy and contribute to greenhouse gas emissions.

In terms of waste management, sodium silicate adhesives present both challenges and opportunities. On the positive side, these adhesives are water-soluble, which facilitates easier cleaning of equipment and reduces the need for harsh chemical solvents. However, this solubility can also lead to increased water consumption during the manufacturing process and potential contamination of wastewater streams if not properly treated.

The end-of-life considerations for products bonded with sodium silicate adhesives are generally favorable. Unlike many synthetic adhesives, sodium silicate does not persist in the environment for extended periods. It eventually breaks down into harmless components, primarily silica and sodium compounds, which are naturally occurring in the environment. This biodegradability reduces the long-term environmental impact of disposed products.

In advanced manufacturing, the use of sodium silicate adhesives can contribute to the development of more recyclable and environmentally friendly products. Their ability to create strong bonds that can be easily broken down under specific conditions (such as high pH environments) facilitates the separation of materials at the end of a product's life, enhancing recyclability and reducing waste.

However, the alkaline nature of sodium silicate adhesives requires careful handling and disposal practices. Improper disposal can lead to localized pH changes in soil or water bodies, potentially affecting ecosystems. Manufacturers must implement proper waste management protocols to mitigate these risks.

As industries strive for more sustainable practices, ongoing research is focused on further improving the environmental profile of sodium silicate adhesives. This includes exploring ways to reduce energy consumption in production, developing more efficient application methods to minimize waste, and investigating the potential for incorporating recycled materials into the adhesive formulation.

Regulatory Framework for Industrial Adhesives

The regulatory framework for industrial adhesives plays a crucial role in ensuring the safe and responsible use of sodium silicate as an adhesive in advanced manufacturing. Governments and regulatory bodies worldwide have established guidelines and standards to govern the production, distribution, and application of industrial adhesives, including sodium silicate-based products.

In the United States, the Occupational Safety and Health Administration (OSHA) sets forth regulations for the handling and use of industrial adhesives in manufacturing environments. These regulations cover aspects such as proper storage, handling procedures, and personal protective equipment requirements for workers exposed to sodium silicate adhesives. Additionally, the Environmental Protection Agency (EPA) regulates the environmental impact of industrial adhesives, including waste disposal and emissions control.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to sodium silicate and other industrial adhesives. REACH requires manufacturers and importers to assess and manage the risks associated with these substances, ensuring their safe use throughout the supply chain. The Classification, Labeling, and Packaging (CLP) Regulation further mandates the proper labeling and packaging of adhesives to communicate potential hazards effectively.

In Asia, countries like China and Japan have their own regulatory frameworks for industrial adhesives. China's Ministry of Ecology and Environment oversees the environmental aspects of adhesive production and use, while the State Administration for Market Regulation enforces quality and safety standards. Japan's Chemical Substances Control Law regulates the manufacture, import, and use of chemical substances, including those used in industrial adhesives.

International standards organizations, such as the International Organization for Standardization (ISO), have developed specific standards for adhesives used in advanced manufacturing. These standards address performance requirements, testing methods, and quality control measures for various types of industrial adhesives, including sodium silicate-based products.

Regulatory compliance in the use of sodium silicate as an adhesive also extends to specific industry sectors. For instance, in the automotive industry, adhesives must meet stringent safety and performance standards set by organizations like the Society of Automotive Engineers (SAE). Similarly, the aerospace industry has its own set of regulations and standards governed by entities such as the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA).

As advanced manufacturing techniques continue to evolve, regulatory frameworks are adapting to address new challenges and opportunities. This includes the development of regulations for emerging technologies such as 3D printing and nanotechnology, which may incorporate sodium silicate-based adhesives in novel applications. Manufacturers and researchers working with sodium silicate adhesives must stay informed about these evolving regulations to ensure compliance and maintain the safety and efficacy of their products in advanced manufacturing processes.

In the United States, the Occupational Safety and Health Administration (OSHA) sets forth regulations for the handling and use of industrial adhesives in manufacturing environments. These regulations cover aspects such as proper storage, handling procedures, and personal protective equipment requirements for workers exposed to sodium silicate adhesives. Additionally, the Environmental Protection Agency (EPA) regulates the environmental impact of industrial adhesives, including waste disposal and emissions control.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to sodium silicate and other industrial adhesives. REACH requires manufacturers and importers to assess and manage the risks associated with these substances, ensuring their safe use throughout the supply chain. The Classification, Labeling, and Packaging (CLP) Regulation further mandates the proper labeling and packaging of adhesives to communicate potential hazards effectively.

In Asia, countries like China and Japan have their own regulatory frameworks for industrial adhesives. China's Ministry of Ecology and Environment oversees the environmental aspects of adhesive production and use, while the State Administration for Market Regulation enforces quality and safety standards. Japan's Chemical Substances Control Law regulates the manufacture, import, and use of chemical substances, including those used in industrial adhesives.

International standards organizations, such as the International Organization for Standardization (ISO), have developed specific standards for adhesives used in advanced manufacturing. These standards address performance requirements, testing methods, and quality control measures for various types of industrial adhesives, including sodium silicate-based products.

Regulatory compliance in the use of sodium silicate as an adhesive also extends to specific industry sectors. For instance, in the automotive industry, adhesives must meet stringent safety and performance standards set by organizations like the Society of Automotive Engineers (SAE). Similarly, the aerospace industry has its own set of regulations and standards governed by entities such as the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA).

As advanced manufacturing techniques continue to evolve, regulatory frameworks are adapting to address new challenges and opportunities. This includes the development of regulations for emerging technologies such as 3D printing and nanotechnology, which may incorporate sodium silicate-based adhesives in novel applications. Manufacturers and researchers working with sodium silicate adhesives must stay informed about these evolving regulations to ensure compliance and maintain the safety and efficacy of their products in advanced manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!