Role of sodium silicate in nanoscale sensors

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Silicate in Nanosensors: Background and Objectives

Sodium silicate, a versatile inorganic compound, has emerged as a crucial component in the development of nanoscale sensors. The evolution of this technology can be traced back to the early 2000s when researchers began exploring the potential of silicon-based materials in sensing applications. As nanotechnology advanced, the unique properties of sodium silicate at the nanoscale became increasingly apparent, leading to its integration into various sensor designs.

The primary objective of incorporating sodium silicate into nanoscale sensors is to enhance their sensitivity, selectivity, and stability. Sodium silicate's ability to form stable, porous structures at the nanoscale makes it an ideal candidate for sensor fabrication. These porous structures provide a high surface area-to-volume ratio, which is essential for improving sensor performance by increasing the number of active sites for target molecule interactions.

Over the past decade, the field has witnessed significant advancements in the synthesis and application of sodium silicate-based nanosensors. Researchers have developed novel methods to control the morphology and porosity of sodium silicate nanostructures, tailoring them for specific sensing applications. This has led to the creation of sensors capable of detecting a wide range of analytes, from environmental pollutants to biological markers.

The technological trajectory of sodium silicate in nanosensors has been driven by the increasing demand for miniaturized, highly sensitive, and cost-effective sensing devices. As industries and research institutions seek more efficient ways to monitor and analyze various substances, the role of sodium silicate in nanoscale sensors has become increasingly prominent. This trend is expected to continue, with ongoing research focusing on improving sensor performance, expanding the range of detectable analytes, and developing new fabrication techniques.

Current research goals in this field include enhancing the long-term stability of sodium silicate-based nanosensors, improving their selectivity in complex environments, and developing multi-functional sensors capable of simultaneous detection of multiple analytes. Additionally, there is a growing interest in integrating these sensors with other emerging technologies, such as artificial intelligence and Internet of Things (IoT) devices, to create more comprehensive and intelligent sensing systems.

As we look towards the future, the potential applications of sodium silicate in nanoscale sensors are vast and diverse. From environmental monitoring and healthcare diagnostics to industrial process control and food safety, these sensors are poised to play a crucial role in addressing global challenges. The ongoing technological advancements and interdisciplinary collaborations in this field are expected to drive further innovations, pushing the boundaries of what is possible in nanoscale sensing technology.

The primary objective of incorporating sodium silicate into nanoscale sensors is to enhance their sensitivity, selectivity, and stability. Sodium silicate's ability to form stable, porous structures at the nanoscale makes it an ideal candidate for sensor fabrication. These porous structures provide a high surface area-to-volume ratio, which is essential for improving sensor performance by increasing the number of active sites for target molecule interactions.

Over the past decade, the field has witnessed significant advancements in the synthesis and application of sodium silicate-based nanosensors. Researchers have developed novel methods to control the morphology and porosity of sodium silicate nanostructures, tailoring them for specific sensing applications. This has led to the creation of sensors capable of detecting a wide range of analytes, from environmental pollutants to biological markers.

The technological trajectory of sodium silicate in nanosensors has been driven by the increasing demand for miniaturized, highly sensitive, and cost-effective sensing devices. As industries and research institutions seek more efficient ways to monitor and analyze various substances, the role of sodium silicate in nanoscale sensors has become increasingly prominent. This trend is expected to continue, with ongoing research focusing on improving sensor performance, expanding the range of detectable analytes, and developing new fabrication techniques.

Current research goals in this field include enhancing the long-term stability of sodium silicate-based nanosensors, improving their selectivity in complex environments, and developing multi-functional sensors capable of simultaneous detection of multiple analytes. Additionally, there is a growing interest in integrating these sensors with other emerging technologies, such as artificial intelligence and Internet of Things (IoT) devices, to create more comprehensive and intelligent sensing systems.

As we look towards the future, the potential applications of sodium silicate in nanoscale sensors are vast and diverse. From environmental monitoring and healthcare diagnostics to industrial process control and food safety, these sensors are poised to play a crucial role in addressing global challenges. The ongoing technological advancements and interdisciplinary collaborations in this field are expected to drive further innovations, pushing the boundaries of what is possible in nanoscale sensing technology.

Market Analysis for Nanoscale Sensor Applications

The market for nanoscale sensors incorporating sodium silicate is experiencing significant growth, driven by advancements in nanotechnology and increasing demand for high-precision sensing applications. Sodium silicate plays a crucial role in enhancing the performance and functionality of these sensors, particularly in areas such as environmental monitoring, healthcare diagnostics, and industrial process control.

In the environmental monitoring sector, nanoscale sensors utilizing sodium silicate are gaining traction for their ability to detect minute concentrations of pollutants and contaminants in air and water. The global environmental sensor market is projected to expand rapidly, with a substantial portion attributed to nanoscale sensor technologies. This growth is fueled by stringent environmental regulations and increasing public awareness of pollution-related health risks.

The healthcare diagnostics market presents another significant opportunity for sodium silicate-based nanoscale sensors. These sensors offer rapid, highly sensitive, and cost-effective solutions for point-of-care testing and early disease detection. The global biosensors market, which includes nanoscale sensors, is expected to see robust growth in the coming years, driven by the rising prevalence of chronic diseases and the need for personalized medicine.

In industrial process control, nanoscale sensors incorporating sodium silicate are finding applications in quality control, safety monitoring, and optimization of manufacturing processes. The industrial sensor market is witnessing steady growth, with nanoscale sensors playing an increasingly important role in enabling smart manufacturing and Industry 4.0 initiatives.

The automotive industry is another key market for nanoscale sensors, with applications ranging from engine performance monitoring to advanced driver assistance systems. The integration of sodium silicate in these sensors can enhance their durability and sensitivity, contributing to improved vehicle safety and efficiency.

Geographically, North America and Europe currently lead in the adoption of nanoscale sensor technologies, owing to their strong research and development infrastructure and early adoption of advanced technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and government initiatives promoting nanotechnology research.

Despite the promising market outlook, challenges such as high initial development costs and concerns regarding long-term stability and reliability of nanoscale sensors may impact market growth. However, ongoing research and development efforts are addressing these issues, potentially opening up new market opportunities and applications for sodium silicate-based nanoscale sensors.

In the environmental monitoring sector, nanoscale sensors utilizing sodium silicate are gaining traction for their ability to detect minute concentrations of pollutants and contaminants in air and water. The global environmental sensor market is projected to expand rapidly, with a substantial portion attributed to nanoscale sensor technologies. This growth is fueled by stringent environmental regulations and increasing public awareness of pollution-related health risks.

The healthcare diagnostics market presents another significant opportunity for sodium silicate-based nanoscale sensors. These sensors offer rapid, highly sensitive, and cost-effective solutions for point-of-care testing and early disease detection. The global biosensors market, which includes nanoscale sensors, is expected to see robust growth in the coming years, driven by the rising prevalence of chronic diseases and the need for personalized medicine.

In industrial process control, nanoscale sensors incorporating sodium silicate are finding applications in quality control, safety monitoring, and optimization of manufacturing processes. The industrial sensor market is witnessing steady growth, with nanoscale sensors playing an increasingly important role in enabling smart manufacturing and Industry 4.0 initiatives.

The automotive industry is another key market for nanoscale sensors, with applications ranging from engine performance monitoring to advanced driver assistance systems. The integration of sodium silicate in these sensors can enhance their durability and sensitivity, contributing to improved vehicle safety and efficiency.

Geographically, North America and Europe currently lead in the adoption of nanoscale sensor technologies, owing to their strong research and development infrastructure and early adoption of advanced technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and government initiatives promoting nanotechnology research.

Despite the promising market outlook, challenges such as high initial development costs and concerns regarding long-term stability and reliability of nanoscale sensors may impact market growth. However, ongoing research and development efforts are addressing these issues, potentially opening up new market opportunities and applications for sodium silicate-based nanoscale sensors.

Current Challenges in Sodium Silicate-based Nanosensors

Despite the promising potential of sodium silicate in nanoscale sensors, several significant challenges currently hinder their widespread adoption and optimal performance. One of the primary obstacles is the stability of sodium silicate-based nanosensors in diverse environmental conditions. These sensors often exhibit sensitivity to changes in pH, temperature, and humidity, which can lead to inconsistent readings and reduced reliability in real-world applications.

Another critical challenge lies in the precise control of sodium silicate nanostructures during the fabrication process. The formation of uniform and reproducible nanostructures is crucial for sensor performance, yet achieving consistent results across large-scale production remains difficult. This variability can lead to inconsistencies in sensor sensitivity and response times, limiting their commercial viability.

The integration of sodium silicate-based nanosensors with existing electronic systems presents another hurdle. Compatibility issues may arise when interfacing these sensors with conventional readout circuits, potentially compromising the overall system performance. Additionally, the development of efficient signal processing algorithms tailored to the unique characteristics of sodium silicate nanosensors is an ongoing challenge.

Selectivity is another area of concern for these nanosensors. While sodium silicate demonstrates sensitivity to various analytes, achieving high selectivity for specific target molecules in complex mixtures remains challenging. Cross-sensitivity to interfering substances can lead to false positives or reduced accuracy in sensor readings, limiting their applicability in certain fields such as medical diagnostics or environmental monitoring.

The long-term stability and durability of sodium silicate-based nanosensors also pose significant challenges. Degradation of the sensor material over time, particularly when exposed to harsh environments or repeated use, can affect the sensor's lifespan and reliability. Developing strategies to enhance the robustness of these sensors without compromising their sensitivity is a key area of ongoing research.

Furthermore, the biocompatibility of sodium silicate nanosensors is a critical consideration for applications in biomedical sensing. While sodium silicate is generally considered non-toxic, the potential long-term effects of nanoparticle accumulation in biological systems require further investigation to ensure safety in in vivo applications.

Lastly, the cost-effectiveness of sodium silicate-based nanosensors compared to existing sensing technologies remains a challenge. While these sensors offer unique advantages, the current production costs and scalability issues may limit their competitiveness in certain market segments. Addressing these economic factors is crucial for the widespread adoption of this technology across various industries.

Another critical challenge lies in the precise control of sodium silicate nanostructures during the fabrication process. The formation of uniform and reproducible nanostructures is crucial for sensor performance, yet achieving consistent results across large-scale production remains difficult. This variability can lead to inconsistencies in sensor sensitivity and response times, limiting their commercial viability.

The integration of sodium silicate-based nanosensors with existing electronic systems presents another hurdle. Compatibility issues may arise when interfacing these sensors with conventional readout circuits, potentially compromising the overall system performance. Additionally, the development of efficient signal processing algorithms tailored to the unique characteristics of sodium silicate nanosensors is an ongoing challenge.

Selectivity is another area of concern for these nanosensors. While sodium silicate demonstrates sensitivity to various analytes, achieving high selectivity for specific target molecules in complex mixtures remains challenging. Cross-sensitivity to interfering substances can lead to false positives or reduced accuracy in sensor readings, limiting their applicability in certain fields such as medical diagnostics or environmental monitoring.

The long-term stability and durability of sodium silicate-based nanosensors also pose significant challenges. Degradation of the sensor material over time, particularly when exposed to harsh environments or repeated use, can affect the sensor's lifespan and reliability. Developing strategies to enhance the robustness of these sensors without compromising their sensitivity is a key area of ongoing research.

Furthermore, the biocompatibility of sodium silicate nanosensors is a critical consideration for applications in biomedical sensing. While sodium silicate is generally considered non-toxic, the potential long-term effects of nanoparticle accumulation in biological systems require further investigation to ensure safety in in vivo applications.

Lastly, the cost-effectiveness of sodium silicate-based nanosensors compared to existing sensing technologies remains a challenge. While these sensors offer unique advantages, the current production costs and scalability issues may limit their competitiveness in certain market segments. Addressing these economic factors is crucial for the widespread adoption of this technology across various industries.

Existing Sodium Silicate Nanosensor Solutions

01 Use in detergent compositions

Sodium silicate is commonly used in detergent compositions due to its alkaline properties and ability to soften water. It acts as a builder, helping to remove dirt and stains while protecting washing machines from corrosion. The inclusion of sodium silicate in detergents can improve cleaning efficiency and extend the life of appliances.- Use in detergent compositions: Sodium silicate is commonly used in detergent compositions as a builder and alkalinity source. It helps to soften water, remove dirt and stains, and protect washing machines from corrosion. The inclusion of sodium silicate in detergent formulations can improve cleaning performance and stability of the product.

- Application in cement and concrete: Sodium silicate is utilized in the production of cement and concrete materials. It acts as a binder, sealant, and hardening accelerator. The addition of sodium silicate can improve the strength, durability, and water resistance of cement-based products, making it valuable in construction applications.

- Use in fire-resistant coatings: Sodium silicate is employed in the formulation of fire-resistant coatings and materials. When exposed to high temperatures, it forms a protective barrier that helps prevent the spread of fire. This property makes it useful in various applications, including building materials and industrial coatings.

- Application in water treatment: Sodium silicate is used in water treatment processes for various purposes. It can act as a coagulant aid, helping to remove suspended particles from water. Additionally, it can be used to control corrosion in water distribution systems and industrial cooling systems by forming a protective film on metal surfaces.

- Use in catalysts and adsorbents: Sodium silicate serves as a precursor in the synthesis of various catalysts and adsorbents. It can be used to produce zeolites, silica gels, and other porous materials with high surface areas. These materials find applications in catalysis, gas separation, and purification processes in various industries.

02 Application in cement and concrete

Sodium silicate is utilized in the production of cement and concrete materials. It can act as a binder, accelerator, or sealant in various construction applications. The addition of sodium silicate can improve the strength, durability, and water resistance of cement-based products, making it valuable in the construction industry.Expand Specific Solutions03 Use in fire-resistant coatings

Sodium silicate is employed in the formulation of fire-resistant coatings and materials. When exposed to high temperatures, it forms a protective barrier that helps prevent the spread of fire. This property makes it useful in various applications, including building materials, textiles, and industrial coatings.Expand Specific Solutions04 Application in water treatment

Sodium silicate is used in water treatment processes for various purposes. It can act as a coagulant aid, helping to remove suspended particles from water. Additionally, it can be used to control corrosion in water distribution systems and to remove heavy metals from contaminated water sources.Expand Specific Solutions05 Use in catalysts and adsorbents

Sodium silicate serves as a precursor in the synthesis of various catalysts and adsorbents. It can be used to produce zeolites, silica gels, and other porous materials with high surface areas. These materials find applications in industrial processes, such as petroleum refining, gas separation, and environmental remediation.Expand Specific Solutions

Key Players in Nanoscale Sensor Industry

The role of sodium silicate in nanoscale sensors is an emerging field with significant potential for growth. The market is in its early stages, with a relatively small but rapidly expanding size. Technological maturity is still developing, as research institutions and companies explore innovative applications. Key players include Yale University, Zhejiang University, and Washington University in St. Louis, who are conducting cutting-edge research. Industry involvement is growing, with companies like IBM and Siemens Matsushita Components showing interest. The competitive landscape is characterized by collaboration between academia and industry, with a focus on developing novel sensor technologies that leverage the unique properties of sodium silicate at the nanoscale.

Yale University

Technical Solution: Yale University has developed innovative nanoscale sensors utilizing sodium silicate as a key component. Their approach involves incorporating sodium silicate into a sol-gel matrix to create highly sensitive and selective gas sensors[1]. The sodium silicate acts as a network former and modifier, enhancing the porosity and surface area of the sensing material. This results in improved adsorption of target gas molecules and increased sensitivity. Yale researchers have also explored the use of sodium silicate in conjunction with metal oxide nanoparticles to create hybrid sensors with enhanced stability and selectivity[3]. These sensors have shown promising results in detecting volatile organic compounds (VOCs) and other environmental pollutants at parts per billion (ppb) levels[5].

Strengths: High sensitivity and selectivity, improved stability, and ability to detect low concentrations of target gases. Weaknesses: Potential interference from humidity and temperature variations, and the need for careful control of the sol-gel process to ensure reproducibility.

Zhejiang University

Technical Solution: Zhejiang University has made significant advancements in the use of sodium silicate for nanoscale sensors, particularly in the field of electrochemical sensing. Their research team has developed a novel method of using sodium silicate as a precursor for the synthesis of mesoporous silica nanoparticles (MSNs)[2]. These MSNs are then functionalized with various organic groups to create highly sensitive and selective electrochemical sensors. The sodium silicate-derived MSNs provide a large surface area and uniform pore structure, which enhances the loading capacity of sensing molecules and improves electron transfer kinetics[4]. Zhejiang University researchers have successfully applied these sensors for the detection of heavy metal ions, biomolecules, and pharmaceutical compounds with detection limits in the nanomolar range[6].

Strengths: High surface area and uniform pore structure leading to improved sensitivity, versatility in detecting various analytes, and potential for miniaturization. Weaknesses: Complexity in the synthesis process and potential for sensor fouling in complex sample matrices.

Core Innovations in Sodium Silicate Nanosensor Design

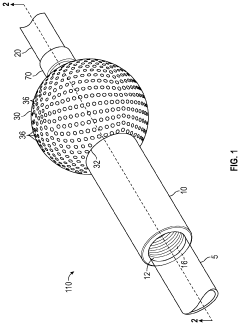

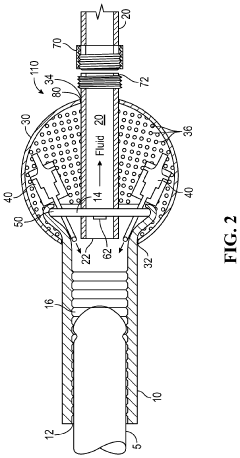

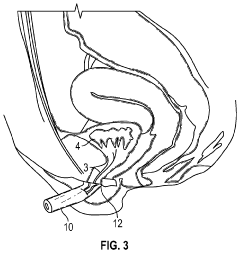

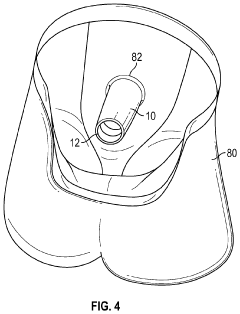

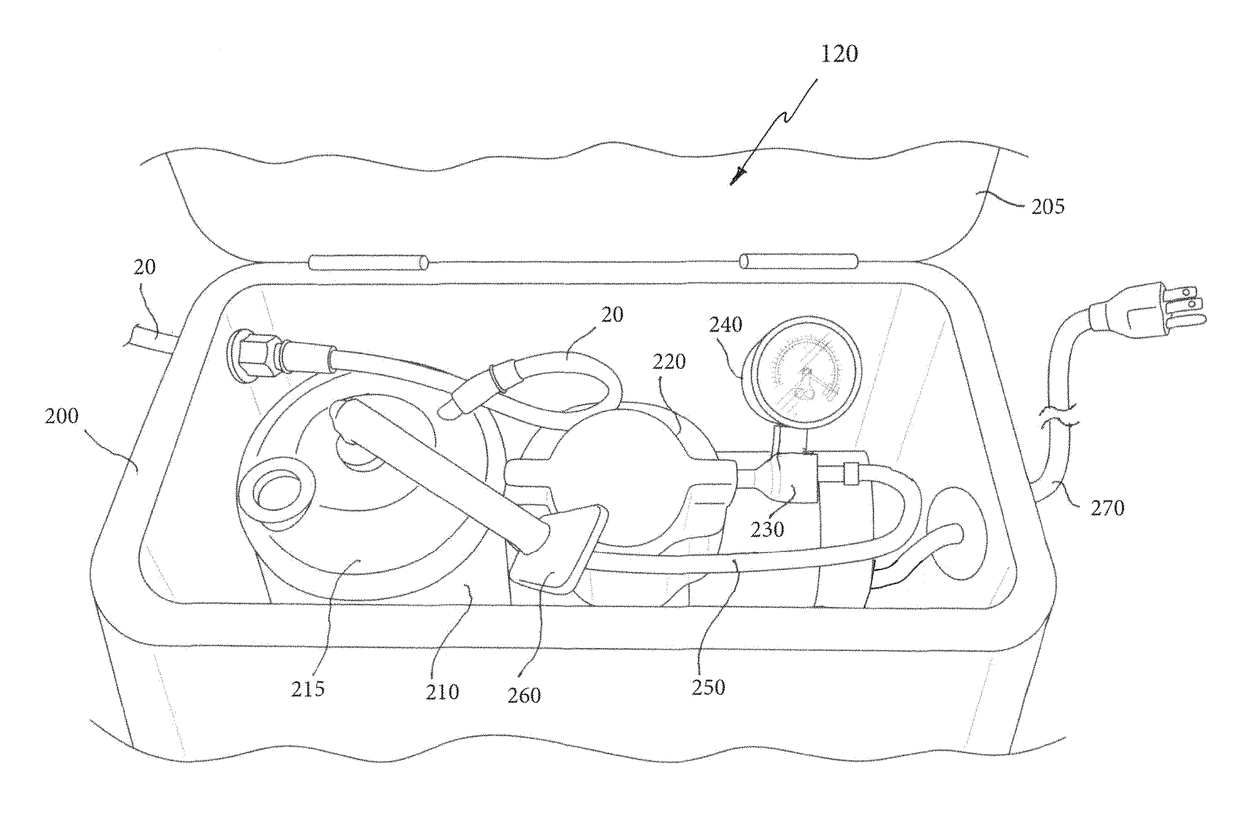

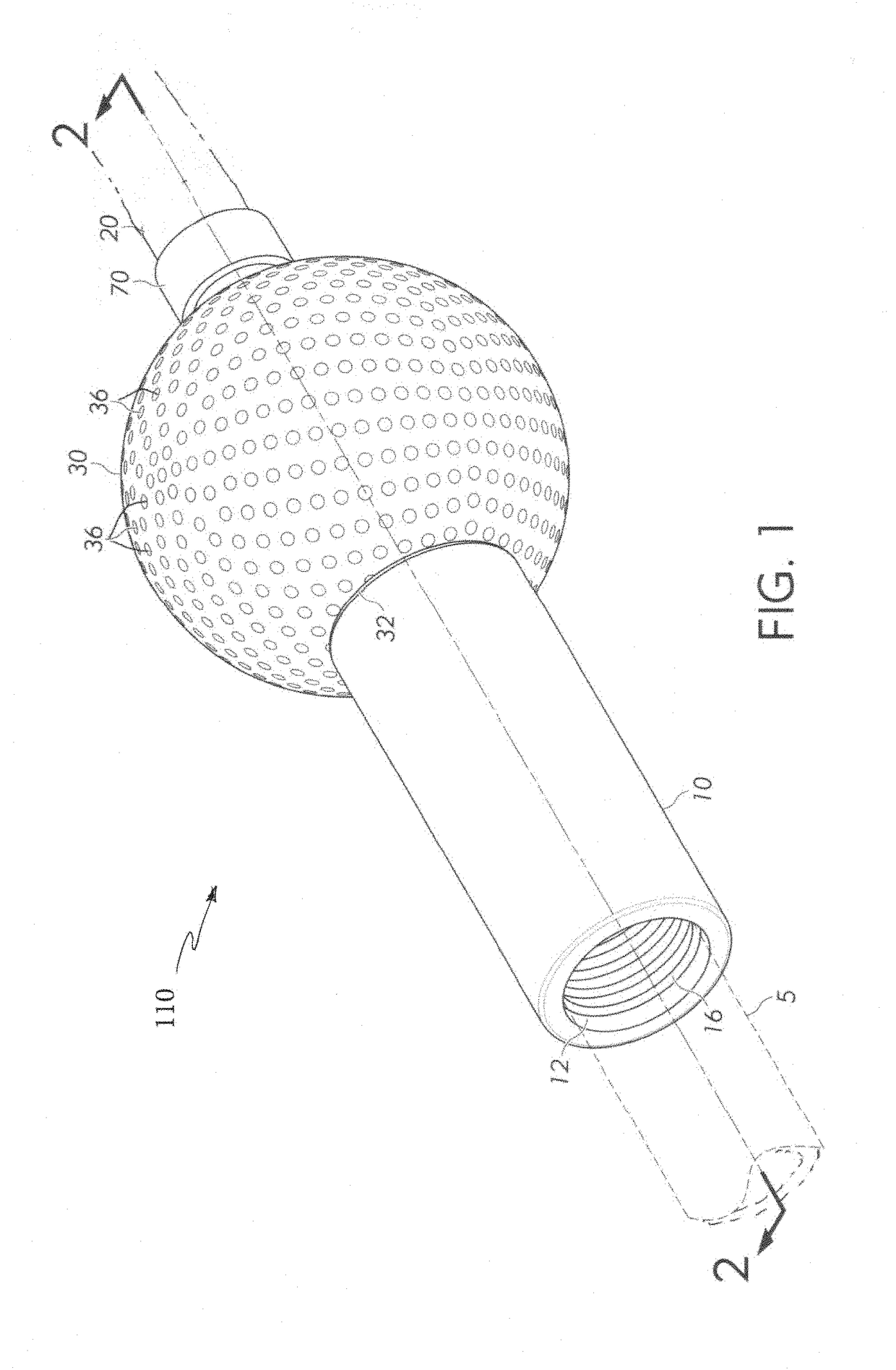

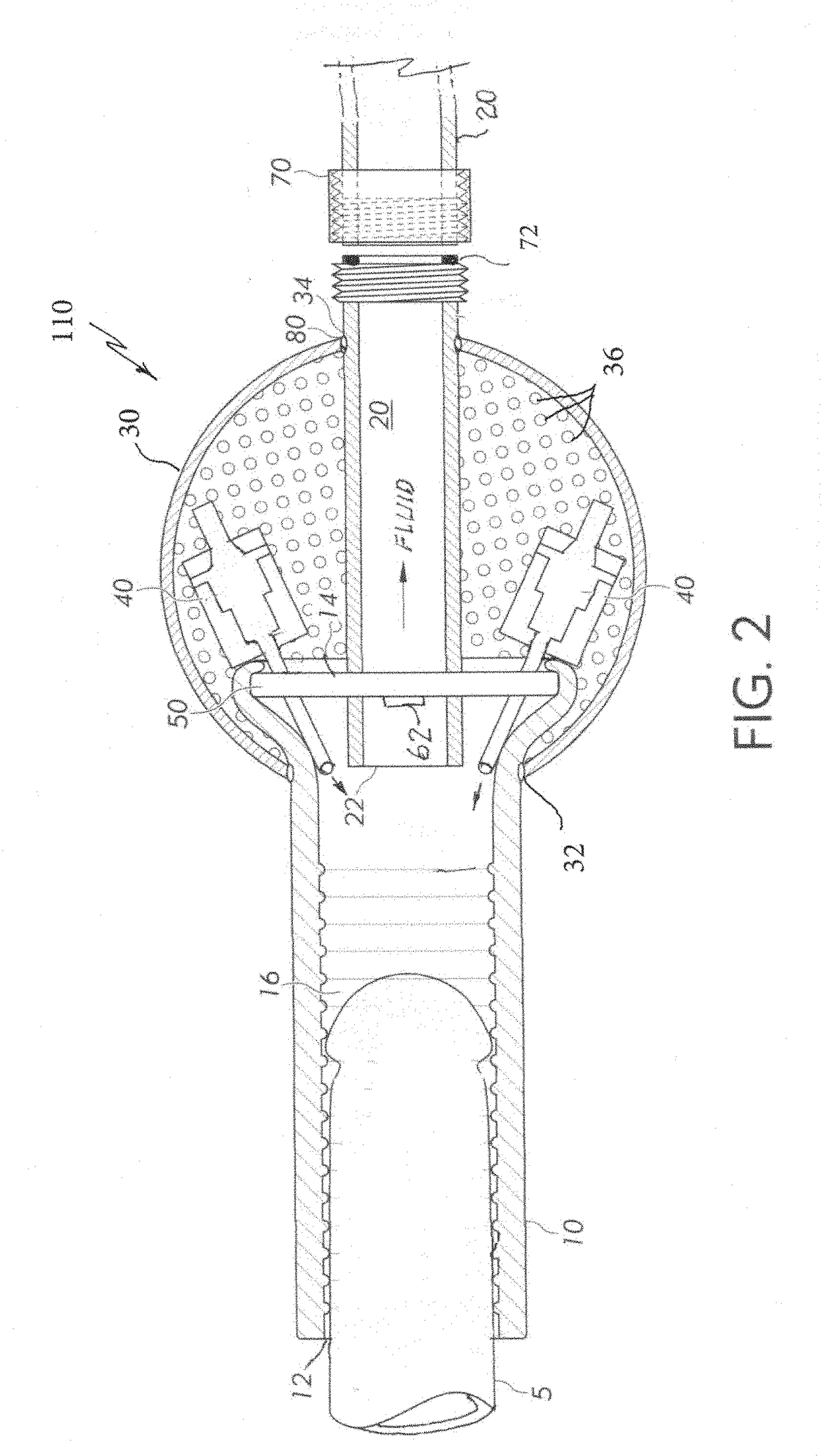

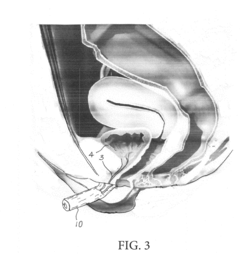

Automated collection and analysis of body fluids

PatentActiveUS20230404549A1

Innovation

- A urine collection system comprising a tube and canister that uses suction to join with the urethra, with a liquid sensor to detect urine presence and a vacuum generator to maintain a seal, allowing for continuous urine collection and analysis of substances like occult blood, proteins, glucose, and drugs, using sensors and a digital processor for data logging and analysis.

Automated urine collector-analyzer

PatentActiveUS20170241978A1

Innovation

- A collector-analyzer apparatus with a flexible interconnection tube connecting an interface portion to the urethra and a receiver portion, utilizing suction for secure attachment, and equipped with sensors for urine analysis, allowing for leak-free urination and continuous monitoring with wireless data transmission.

Environmental Impact of Sodium Silicate in Nanosensors

The environmental impact of sodium silicate in nanosensors is a critical consideration as these advanced sensing technologies become more prevalent. Sodium silicate, while offering unique properties for nanoscale sensor applications, also presents potential environmental concerns that must be carefully evaluated.

One of the primary environmental considerations is the fate of sodium silicate nanoparticles after the sensor's lifecycle. As nanosensors degrade or are disposed of, there is a risk of these particles entering ecosystems. The small size of nanoparticles allows them to penetrate biological barriers more easily than larger particles, potentially accumulating in organisms and moving through food chains. This bioaccumulation could have unforeseen consequences on various species and ecosystem dynamics.

Water systems are particularly vulnerable to the release of sodium silicate nanoparticles. These particles can alter water chemistry, potentially affecting pH levels and mineral composition. Such changes may impact aquatic life, from microorganisms to fish, disrupting delicate ecological balances. Additionally, the increased silica content in water bodies could lead to algal blooms, further compromising water quality and aquatic habitats.

The production process of sodium silicate for nanosensors also carries environmental implications. Manufacturing often involves energy-intensive processes and the use of chemicals that may contribute to air and water pollution if not properly managed. The extraction of raw materials for sodium silicate production can lead to habitat destruction and landscape alterations, particularly in mining areas.

However, it's important to note that the use of sodium silicate in nanosensors may also offer environmental benefits. These sensors can enable more precise environmental monitoring, potentially leading to early detection of pollutants or ecological changes. This improved sensing capability could contribute to more effective environmental protection strategies and resource management.

The long-term persistence of sodium silicate nanoparticles in the environment is another area of concern. Unlike some organic materials, these inorganic particles may not readily biodegrade, potentially leading to accumulation in soils and sediments over time. This persistence could have lasting effects on soil chemistry and microbial communities, which play crucial roles in nutrient cycling and ecosystem health.

To mitigate these environmental risks, research into biodegradable or environmentally benign alternatives for nanosensor components is ongoing. Additionally, the development of effective recycling and disposal methods for nanosensors containing sodium silicate is crucial to minimize environmental impact. Regulatory frameworks and industry standards are also evolving to address the unique challenges posed by nanomaterials in environmental contexts.

One of the primary environmental considerations is the fate of sodium silicate nanoparticles after the sensor's lifecycle. As nanosensors degrade or are disposed of, there is a risk of these particles entering ecosystems. The small size of nanoparticles allows them to penetrate biological barriers more easily than larger particles, potentially accumulating in organisms and moving through food chains. This bioaccumulation could have unforeseen consequences on various species and ecosystem dynamics.

Water systems are particularly vulnerable to the release of sodium silicate nanoparticles. These particles can alter water chemistry, potentially affecting pH levels and mineral composition. Such changes may impact aquatic life, from microorganisms to fish, disrupting delicate ecological balances. Additionally, the increased silica content in water bodies could lead to algal blooms, further compromising water quality and aquatic habitats.

The production process of sodium silicate for nanosensors also carries environmental implications. Manufacturing often involves energy-intensive processes and the use of chemicals that may contribute to air and water pollution if not properly managed. The extraction of raw materials for sodium silicate production can lead to habitat destruction and landscape alterations, particularly in mining areas.

However, it's important to note that the use of sodium silicate in nanosensors may also offer environmental benefits. These sensors can enable more precise environmental monitoring, potentially leading to early detection of pollutants or ecological changes. This improved sensing capability could contribute to more effective environmental protection strategies and resource management.

The long-term persistence of sodium silicate nanoparticles in the environment is another area of concern. Unlike some organic materials, these inorganic particles may not readily biodegrade, potentially leading to accumulation in soils and sediments over time. This persistence could have lasting effects on soil chemistry and microbial communities, which play crucial roles in nutrient cycling and ecosystem health.

To mitigate these environmental risks, research into biodegradable or environmentally benign alternatives for nanosensor components is ongoing. Additionally, the development of effective recycling and disposal methods for nanosensors containing sodium silicate is crucial to minimize environmental impact. Regulatory frameworks and industry standards are also evolving to address the unique challenges posed by nanomaterials in environmental contexts.

Scalability and Manufacturing Challenges

The scalability and manufacturing challenges associated with incorporating sodium silicate in nanoscale sensors are significant and multifaceted. One of the primary obstacles is achieving consistent and uniform deposition of sodium silicate at the nanoscale level. The precise control required for nanoscale sensor fabrication demands advanced manufacturing techniques that can reliably produce sensors with identical properties across large production runs.

The integration of sodium silicate into existing nanofabrication processes presents another hurdle. Many current manufacturing methods may not be directly compatible with sodium silicate, necessitating the development of new protocols or the modification of existing ones. This adaptation process can be time-consuming and costly, potentially slowing down the transition from laboratory-scale production to industrial-scale manufacturing.

Stability and durability of sodium silicate in nanoscale sensors pose additional challenges. The material's sensitivity to environmental factors such as humidity and temperature fluctuations can affect sensor performance and longevity. Developing robust encapsulation methods to protect the sodium silicate layer without compromising sensor functionality is crucial for large-scale production and deployment.

Cost-effectiveness is another critical factor in scaling up production. While sodium silicate itself is relatively inexpensive, the specialized equipment and processes required for its nanoscale application can significantly increase manufacturing costs. Balancing the enhanced performance of sodium silicate-based sensors against these increased production expenses is essential for commercial viability.

Quality control and characterization of nanoscale sodium silicate layers present unique challenges. Traditional inspection methods may not be suitable for verifying the uniformity and integrity of these ultra-thin layers. Developing new quality assurance techniques that can rapidly and accurately assess large numbers of sensors is vital for maintaining consistent performance across production batches.

The environmental impact of large-scale sodium silicate use in nanoscale sensors must also be considered. Ensuring sustainable sourcing of materials and developing eco-friendly disposal or recycling methods for end-of-life sensors are important aspects of responsible scaling. Additionally, regulatory compliance for nanomaterials in different global markets may introduce complexities in manufacturing and distribution processes.

Addressing these scalability and manufacturing challenges will require collaborative efforts between materials scientists, process engineers, and equipment manufacturers. Innovations in deposition techniques, quality control methods, and materials integration will be key to overcoming these obstacles and realizing the full potential of sodium silicate in nanoscale sensor applications.

The integration of sodium silicate into existing nanofabrication processes presents another hurdle. Many current manufacturing methods may not be directly compatible with sodium silicate, necessitating the development of new protocols or the modification of existing ones. This adaptation process can be time-consuming and costly, potentially slowing down the transition from laboratory-scale production to industrial-scale manufacturing.

Stability and durability of sodium silicate in nanoscale sensors pose additional challenges. The material's sensitivity to environmental factors such as humidity and temperature fluctuations can affect sensor performance and longevity. Developing robust encapsulation methods to protect the sodium silicate layer without compromising sensor functionality is crucial for large-scale production and deployment.

Cost-effectiveness is another critical factor in scaling up production. While sodium silicate itself is relatively inexpensive, the specialized equipment and processes required for its nanoscale application can significantly increase manufacturing costs. Balancing the enhanced performance of sodium silicate-based sensors against these increased production expenses is essential for commercial viability.

Quality control and characterization of nanoscale sodium silicate layers present unique challenges. Traditional inspection methods may not be suitable for verifying the uniformity and integrity of these ultra-thin layers. Developing new quality assurance techniques that can rapidly and accurately assess large numbers of sensors is vital for maintaining consistent performance across production batches.

The environmental impact of large-scale sodium silicate use in nanoscale sensors must also be considered. Ensuring sustainable sourcing of materials and developing eco-friendly disposal or recycling methods for end-of-life sensors are important aspects of responsible scaling. Additionally, regulatory compliance for nanomaterials in different global markets may introduce complexities in manufacturing and distribution processes.

Addressing these scalability and manufacturing challenges will require collaborative efforts between materials scientists, process engineers, and equipment manufacturers. Innovations in deposition techniques, quality control methods, and materials integration will be key to overcoming these obstacles and realizing the full potential of sodium silicate in nanoscale sensor applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!