Sodium silicate utilization in controlled release fertilizers

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Silicate in CRF: Background and Objectives

Sodium silicate, also known as water glass, has emerged as a promising component in the development of controlled release fertilizers (CRFs). The utilization of this versatile compound in agricultural applications has gained significant attention due to its potential to enhance nutrient delivery efficiency and reduce environmental impact. The evolution of CRF technology has been driven by the need to address the limitations of conventional fertilizers, such as nutrient leaching and rapid release rates.

The primary objective of incorporating sodium silicate into CRFs is to create a more sustainable and efficient nutrient delivery system. By leveraging the unique properties of sodium silicate, researchers aim to develop fertilizers that can release nutrients gradually over extended periods, aligning with crop growth cycles and minimizing nutrient losses. This approach not only optimizes plant nutrition but also contributes to reducing the environmental footprint of agricultural practices.

Historically, the use of sodium silicate in agriculture dates back to the early 20th century, primarily as a soil amendment. However, its application in CRFs represents a more recent technological advancement. The integration of sodium silicate into CRF formulations has been driven by a growing understanding of its potential to form protective coatings and matrices that can modulate nutrient release kinetics.

The technological trajectory of sodium silicate in CRFs has been characterized by continuous improvements in formulation techniques and a deeper understanding of the underlying mechanisms governing nutrient release. Early attempts focused on simple coating methods, while more recent innovations explore complex encapsulation technologies and hybrid systems that combine sodium silicate with other materials to achieve precise control over nutrient availability.

As the agricultural sector faces increasing pressure to improve resource efficiency and minimize environmental impact, the development of sodium silicate-based CRFs aligns with broader sustainability goals. These include reducing nutrient runoff, improving crop yields, and optimizing fertilizer use efficiency. The ongoing research in this field seeks to unlock the full potential of sodium silicate as a key component in next-generation fertilizers.

The technical objectives of sodium silicate utilization in CRFs encompass several key areas. These include enhancing the mechanical strength and durability of fertilizer granules, improving water resistance to prevent premature nutrient release, and developing smart release mechanisms that respond to environmental cues such as soil pH or moisture levels. Additionally, researchers are exploring ways to tailor the release profiles of different nutrients by manipulating the chemical and physical properties of sodium silicate matrices.

As the field progresses, there is a growing focus on understanding the long-term effects of sodium silicate-based CRFs on soil health, microbial communities, and overall ecosystem dynamics. This holistic approach aims to ensure that the benefits of improved nutrient management are balanced with the preservation of soil quality and biodiversity.

The primary objective of incorporating sodium silicate into CRFs is to create a more sustainable and efficient nutrient delivery system. By leveraging the unique properties of sodium silicate, researchers aim to develop fertilizers that can release nutrients gradually over extended periods, aligning with crop growth cycles and minimizing nutrient losses. This approach not only optimizes plant nutrition but also contributes to reducing the environmental footprint of agricultural practices.

Historically, the use of sodium silicate in agriculture dates back to the early 20th century, primarily as a soil amendment. However, its application in CRFs represents a more recent technological advancement. The integration of sodium silicate into CRF formulations has been driven by a growing understanding of its potential to form protective coatings and matrices that can modulate nutrient release kinetics.

The technological trajectory of sodium silicate in CRFs has been characterized by continuous improvements in formulation techniques and a deeper understanding of the underlying mechanisms governing nutrient release. Early attempts focused on simple coating methods, while more recent innovations explore complex encapsulation technologies and hybrid systems that combine sodium silicate with other materials to achieve precise control over nutrient availability.

As the agricultural sector faces increasing pressure to improve resource efficiency and minimize environmental impact, the development of sodium silicate-based CRFs aligns with broader sustainability goals. These include reducing nutrient runoff, improving crop yields, and optimizing fertilizer use efficiency. The ongoing research in this field seeks to unlock the full potential of sodium silicate as a key component in next-generation fertilizers.

The technical objectives of sodium silicate utilization in CRFs encompass several key areas. These include enhancing the mechanical strength and durability of fertilizer granules, improving water resistance to prevent premature nutrient release, and developing smart release mechanisms that respond to environmental cues such as soil pH or moisture levels. Additionally, researchers are exploring ways to tailor the release profiles of different nutrients by manipulating the chemical and physical properties of sodium silicate matrices.

As the field progresses, there is a growing focus on understanding the long-term effects of sodium silicate-based CRFs on soil health, microbial communities, and overall ecosystem dynamics. This holistic approach aims to ensure that the benefits of improved nutrient management are balanced with the preservation of soil quality and biodiversity.

Market Analysis for Controlled Release Fertilizers

The controlled release fertilizer (CRF) market has been experiencing significant growth in recent years, driven by the increasing demand for sustainable agricultural practices and the need for improved nutrient management. The global CRF market was valued at approximately $2.3 billion in 2020 and is projected to reach $3.7 billion by 2026, growing at a CAGR of 6.8% during the forecast period.

The adoption of CRFs has been particularly strong in developed regions such as North America and Europe, where environmental regulations and the push for precision agriculture have been key drivers. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth potential due to increasing awareness of the benefits of CRFs and government initiatives to promote sustainable farming practices.

Sodium silicate-based CRFs represent a promising segment within the broader CRF market. These products offer several advantages, including improved nutrient retention, reduced leaching, and enhanced plant resilience. The market for sodium silicate CRFs is expected to grow at a faster rate than the overall CRF market, with a projected CAGR of 8.5% from 2021 to 2027.

Key factors driving the demand for sodium silicate CRFs include their ability to improve soil structure, increase crop yields, and reduce environmental impact. Additionally, the rising costs of traditional fertilizers and the need for more efficient nutrient delivery systems are contributing to the market growth.

The agriculture sector remains the primary end-user for sodium silicate CRFs, accounting for over 70% of the market share. However, there is growing interest from other sectors such as horticulture, turf management, and forestry, which are expected to contribute to market expansion in the coming years.

Geographically, North America and Europe currently dominate the sodium silicate CRF market, collectively accounting for approximately 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate, driven by increasing agricultural intensification and government support for sustainable farming practices in countries like China and India.

Despite the positive outlook, the market faces challenges such as the higher initial cost of CRFs compared to conventional fertilizers and the need for education and awareness among farmers about the long-term benefits of these products. Overcoming these barriers will be crucial for accelerating market penetration and realizing the full potential of sodium silicate CRFs in the global agricultural landscape.

The adoption of CRFs has been particularly strong in developed regions such as North America and Europe, where environmental regulations and the push for precision agriculture have been key drivers. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth potential due to increasing awareness of the benefits of CRFs and government initiatives to promote sustainable farming practices.

Sodium silicate-based CRFs represent a promising segment within the broader CRF market. These products offer several advantages, including improved nutrient retention, reduced leaching, and enhanced plant resilience. The market for sodium silicate CRFs is expected to grow at a faster rate than the overall CRF market, with a projected CAGR of 8.5% from 2021 to 2027.

Key factors driving the demand for sodium silicate CRFs include their ability to improve soil structure, increase crop yields, and reduce environmental impact. Additionally, the rising costs of traditional fertilizers and the need for more efficient nutrient delivery systems are contributing to the market growth.

The agriculture sector remains the primary end-user for sodium silicate CRFs, accounting for over 70% of the market share. However, there is growing interest from other sectors such as horticulture, turf management, and forestry, which are expected to contribute to market expansion in the coming years.

Geographically, North America and Europe currently dominate the sodium silicate CRF market, collectively accounting for approximately 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate, driven by increasing agricultural intensification and government support for sustainable farming practices in countries like China and India.

Despite the positive outlook, the market faces challenges such as the higher initial cost of CRFs compared to conventional fertilizers and the need for education and awareness among farmers about the long-term benefits of these products. Overcoming these barriers will be crucial for accelerating market penetration and realizing the full potential of sodium silicate CRFs in the global agricultural landscape.

Sodium Silicate Technology: Current Status and Challenges

Sodium silicate technology in controlled release fertilizers has made significant strides in recent years, yet it still faces several challenges that hinder its widespread adoption. The current status of this technology is characterized by a growing interest in its potential to improve nutrient use efficiency and reduce environmental impact. However, the practical implementation of sodium silicate in fertilizer formulations remains limited due to various technical and economic constraints.

One of the primary challenges is the controlled release mechanism itself. While sodium silicate shows promise as a coating material for fertilizer granules, achieving consistent and predictable release rates across diverse soil conditions and crop types remains difficult. Researchers are grappling with the complexities of soil chemistry and how it interacts with silicate-based coatings to influence nutrient release patterns.

Another significant hurdle is the scalability of production processes. Current manufacturing methods for sodium silicate-based controlled release fertilizers are often labor-intensive and costly, making it challenging to produce these products at a scale that can compete with conventional fertilizers in terms of price. This economic barrier has slowed the adoption of the technology in large-scale agricultural operations.

The stability of sodium silicate coatings under various environmental conditions is also a concern. Factors such as temperature fluctuations, moisture levels, and microbial activity in the soil can affect the integrity of the coating, potentially leading to premature nutrient release or inconsistent performance. Addressing these stability issues is crucial for ensuring the reliability of sodium silicate-based controlled release fertilizers in real-world applications.

Furthermore, there is a need for more comprehensive field trials and long-term studies to validate the effectiveness of sodium silicate technology across different crops, soil types, and climatic conditions. The lack of extensive real-world data has made it difficult for farmers and agricultural experts to fully assess the benefits and potential drawbacks of these innovative fertilizers.

Regulatory challenges also play a role in the current status of sodium silicate technology. As a relatively new approach to fertilizer formulation, it faces scrutiny from regulatory bodies concerned with environmental safety and agricultural standards. Navigating these regulatory landscapes and obtaining necessary approvals can be time-consuming and costly for manufacturers.

Despite these challenges, ongoing research and development efforts are making progress in addressing many of these issues. Scientists are exploring novel formulations and coating techniques to enhance the performance and consistency of sodium silicate-based controlled release fertilizers. Additionally, collaborations between academic institutions and industry partners are driving innovation in production methods, aiming to improve scalability and reduce costs.

One of the primary challenges is the controlled release mechanism itself. While sodium silicate shows promise as a coating material for fertilizer granules, achieving consistent and predictable release rates across diverse soil conditions and crop types remains difficult. Researchers are grappling with the complexities of soil chemistry and how it interacts with silicate-based coatings to influence nutrient release patterns.

Another significant hurdle is the scalability of production processes. Current manufacturing methods for sodium silicate-based controlled release fertilizers are often labor-intensive and costly, making it challenging to produce these products at a scale that can compete with conventional fertilizers in terms of price. This economic barrier has slowed the adoption of the technology in large-scale agricultural operations.

The stability of sodium silicate coatings under various environmental conditions is also a concern. Factors such as temperature fluctuations, moisture levels, and microbial activity in the soil can affect the integrity of the coating, potentially leading to premature nutrient release or inconsistent performance. Addressing these stability issues is crucial for ensuring the reliability of sodium silicate-based controlled release fertilizers in real-world applications.

Furthermore, there is a need for more comprehensive field trials and long-term studies to validate the effectiveness of sodium silicate technology across different crops, soil types, and climatic conditions. The lack of extensive real-world data has made it difficult for farmers and agricultural experts to fully assess the benefits and potential drawbacks of these innovative fertilizers.

Regulatory challenges also play a role in the current status of sodium silicate technology. As a relatively new approach to fertilizer formulation, it faces scrutiny from regulatory bodies concerned with environmental safety and agricultural standards. Navigating these regulatory landscapes and obtaining necessary approvals can be time-consuming and costly for manufacturers.

Despite these challenges, ongoing research and development efforts are making progress in addressing many of these issues. Scientists are exploring novel formulations and coating techniques to enhance the performance and consistency of sodium silicate-based controlled release fertilizers. Additionally, collaborations between academic institutions and industry partners are driving innovation in production methods, aiming to improve scalability and reduce costs.

Existing Sodium Silicate-based CRF Solutions

01 Controlled release of sodium silicate

Various methods are employed to control the release rate of sodium silicate in different applications. These include encapsulation techniques, use of carrier materials, and formulation adjustments to achieve desired release profiles. Controlled release helps in maintaining the effectiveness of sodium silicate over extended periods.- Controlled release of sodium silicate: Various methods are employed to control the release rate of sodium silicate in different applications. These include encapsulation techniques, use of carrier materials, and formulation adjustments to achieve desired release profiles. Controlled release helps in maintaining the effectiveness of sodium silicate over extended periods.

- Sodium silicate in detergent compositions: Sodium silicate is incorporated into detergent compositions to enhance cleaning performance and provide corrosion protection. The release rate of sodium silicate in these formulations is optimized to ensure its availability during the washing process while preventing premature reactions or degradation.

- Slow-release sodium silicate for concrete protection: Slow-release formulations of sodium silicate are developed for concrete protection applications. These formulations gradually release sodium silicate to react with calcium hydroxide in concrete, forming calcium silicate hydrate gel that enhances durability and reduces permeability of concrete structures.

- Sodium silicate release in water treatment: The release rate of sodium silicate is crucial in water treatment applications. Controlled release mechanisms are designed to maintain optimal silica levels in water systems, preventing scale formation and corrosion. Various delivery systems and formulations are developed to achieve the desired release profiles.

- Sodium silicate release in coating applications: In coating applications, the release rate of sodium silicate is tailored to provide protective properties over time. This includes the development of sol-gel coatings and other formulations where sodium silicate is released gradually to form a protective barrier on various substrates, enhancing corrosion resistance and durability.

02 Sodium silicate in detergent compositions

Sodium silicate is incorporated into detergent compositions to enhance cleaning performance and provide corrosion protection. The release rate of sodium silicate in these formulations is optimized to ensure its availability during the washing process while preventing premature reaction with other ingredients.Expand Specific Solutions03 Slow-release sodium silicate for concrete protection

Slow-release formulations of sodium silicate are developed for concrete protection applications. These formulations gradually release sodium silicate to react with calcium hydroxide in concrete, forming calcium silicate hydrate gel that enhances durability and reduces permeability of concrete structures.Expand Specific Solutions04 Sodium silicate release in water treatment

The release rate of sodium silicate is crucial in water treatment applications. Controlled release mechanisms are employed to maintain optimal silica levels in water systems, preventing scale formation and corrosion. Various techniques are used to achieve the desired release profile based on specific water treatment requirements.Expand Specific Solutions05 Sodium silicate release in agricultural applications

Sodium silicate is used in agricultural formulations for its beneficial effects on plant growth and pest resistance. The release rate is carefully controlled to ensure sustained availability of silica to plants throughout the growing season. Slow-release formulations are developed to improve the efficiency of sodium silicate application in agriculture.Expand Specific Solutions

Key Players in CRF and Sodium Silicate Industries

The sodium silicate utilization in controlled release fertilizers market is in a growth phase, driven by increasing demand for sustainable agriculture solutions. The global market size for controlled release fertilizers is projected to expand significantly in the coming years. Technologically, the field is advancing rapidly, with companies like SABIC Agri-Nutrients Co., Kingenta Ecological Engineering Group, and Koch Agronomic Services leading innovation. These firms are developing sophisticated coating technologies and improved nutrient delivery systems. Research institutions such as Zhejiang University and Jilin University are contributing to technological advancements, indicating a collaborative ecosystem between industry and academia in this sector.

SABIC Agri-Nutrients Co.

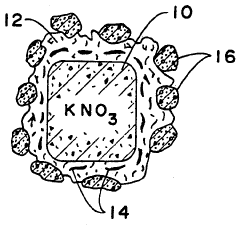

Technical Solution: SABIC Agri-Nutrients has developed a range of controlled release fertilizers utilizing sodium silicate technology. Their approach involves creating a hybrid coating system that combines sodium silicate with biodegradable polymers. This coating forms a semi-permeable membrane around fertilizer granules, allowing for controlled nutrient release. SABIC's technology incorporates varying ratios of sodium silicate and polymers to achieve different release profiles, catering to diverse crop needs and environmental conditions[9]. The company has also developed a method to incorporate beneficial microorganisms into their sodium silicate-based coatings, potentially enhancing soil health alongside nutrient delivery[10].

Strengths: Versatile release profiles, integration of beneficial microorganisms, and use of biodegradable materials. Weaknesses: Potential variability in release rates under extreme environmental conditions and higher production costs.

Kingenta Ecological Engineering Group Co., Ltd.

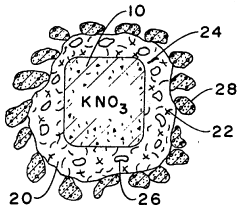

Technical Solution: Kingenta has developed a novel controlled release fertilizer (CRF) utilizing sodium silicate as a key component. Their technology involves encapsulating conventional fertilizer granules with a coating containing sodium silicate and other materials. This coating forms a semi-permeable membrane that regulates nutrient release. The sodium silicate in the coating reacts with soil moisture to create a gel-like barrier, which slowly dissolves over time, allowing for gradual nutrient release[1][3]. The company has also incorporated nanomaterials into their sodium silicate-based coatings to further enhance controlled release properties[5].

Strengths: Improved nutrient use efficiency, reduced environmental impact, and potential for customized release profiles. Weaknesses: Higher production costs compared to conventional fertilizers and potential for inconsistent release rates in varying soil conditions.

Innovative Approaches in Sodium Silicate CRF Development

N-p-ca-mg complex nutrient coated by sio2

PatentActiveEP4317117A1

Innovation

- A slow-release fertilizer composition using magnesium ammonium phosphate and calcium ammonium phosphate encapsulated within silicon dioxide, which acts as a non-polluting scaffold, providing a sustained nutrient release without the need for polymer coatings, and can be formulated as a powder, prill, or granule.

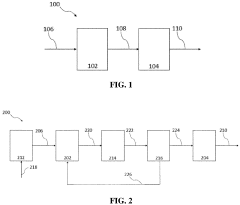

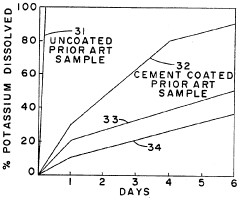

Method of preparing controlled release fertilizers and products thereof

PatentInactiveUS5030267A

Innovation

- Coating water-soluble nutrients with a silicic acid colloid containing a calcium salt, formed by acidifying calcium metasilicate, and mixing with hydraulic cement to create a silica gel matrix with acicular calcium metasilicate crystals, which slows down nutrient release and prevents clustering, while incorporating nitrogen-containing components like cement-coated urea prills and phosphorus sources.

Environmental Impact of Sodium Silicate-based CRFs

The environmental impact of sodium silicate-based Controlled Release Fertilizers (CRFs) is a critical consideration in their development and application. These fertilizers offer potential benefits in terms of nutrient management and agricultural efficiency, but their environmental implications must be carefully evaluated.

Sodium silicate-based CRFs can significantly reduce nutrient leaching compared to conventional fertilizers. The slow-release mechanism allows for a more controlled and sustained nutrient supply, minimizing the risk of excess nutrients entering water bodies. This reduction in leaching can help mitigate eutrophication and algal blooms in aquatic ecosystems, which are major environmental concerns associated with agricultural runoff.

The use of sodium silicate in CRFs may also contribute to improved soil structure and water retention. Silica, a component of sodium silicate, can enhance soil aggregation and porosity, leading to better water infiltration and reduced soil erosion. This can have positive effects on soil health and biodiversity, potentially reducing the need for irrigation and mitigating the impacts of drought.

However, the long-term accumulation of sodium in soils is a potential concern with sodium silicate-based CRFs. Excessive sodium levels can lead to soil salinization, negatively impacting soil structure and plant growth. Careful management and monitoring of soil sodium levels are necessary to prevent these adverse effects, especially in areas prone to salt accumulation.

The production process of sodium silicate-based CRFs should also be considered in environmental impact assessments. The energy requirements and emissions associated with manufacturing these fertilizers may offset some of their environmental benefits. Life cycle analyses are crucial to determine the overall environmental footprint of these products compared to conventional fertilizers.

Biodegradability is another important factor in evaluating the environmental impact of sodium silicate-based CRFs. The rate at which these fertilizers break down in the soil and their potential to leave residues that could affect soil chemistry and microbial communities need to be thoroughly investigated. Ideally, the degradation products should be benign and contribute positively to soil health.

In terms of greenhouse gas emissions, sodium silicate-based CRFs have the potential to reduce nitrous oxide emissions associated with nitrogen fertilizers. The controlled release of nutrients can lead to more efficient uptake by plants, reducing the amount of excess nitrogen available for conversion to nitrous oxide, a potent greenhouse gas.

Sodium silicate-based CRFs can significantly reduce nutrient leaching compared to conventional fertilizers. The slow-release mechanism allows for a more controlled and sustained nutrient supply, minimizing the risk of excess nutrients entering water bodies. This reduction in leaching can help mitigate eutrophication and algal blooms in aquatic ecosystems, which are major environmental concerns associated with agricultural runoff.

The use of sodium silicate in CRFs may also contribute to improved soil structure and water retention. Silica, a component of sodium silicate, can enhance soil aggregation and porosity, leading to better water infiltration and reduced soil erosion. This can have positive effects on soil health and biodiversity, potentially reducing the need for irrigation and mitigating the impacts of drought.

However, the long-term accumulation of sodium in soils is a potential concern with sodium silicate-based CRFs. Excessive sodium levels can lead to soil salinization, negatively impacting soil structure and plant growth. Careful management and monitoring of soil sodium levels are necessary to prevent these adverse effects, especially in areas prone to salt accumulation.

The production process of sodium silicate-based CRFs should also be considered in environmental impact assessments. The energy requirements and emissions associated with manufacturing these fertilizers may offset some of their environmental benefits. Life cycle analyses are crucial to determine the overall environmental footprint of these products compared to conventional fertilizers.

Biodegradability is another important factor in evaluating the environmental impact of sodium silicate-based CRFs. The rate at which these fertilizers break down in the soil and their potential to leave residues that could affect soil chemistry and microbial communities need to be thoroughly investigated. Ideally, the degradation products should be benign and contribute positively to soil health.

In terms of greenhouse gas emissions, sodium silicate-based CRFs have the potential to reduce nitrous oxide emissions associated with nitrogen fertilizers. The controlled release of nutrients can lead to more efficient uptake by plants, reducing the amount of excess nitrogen available for conversion to nitrous oxide, a potent greenhouse gas.

Regulatory Framework for CRF and Soil Amendments

The regulatory framework for controlled release fertilizers (CRFs) and soil amendments incorporating sodium silicate is complex and varies across different regions. In the United States, the Environmental Protection Agency (EPA) regulates fertilizers and soil amendments under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). The EPA requires manufacturers to register their products and provide detailed information on their composition, intended use, and potential environmental impacts.

The European Union has established the Fertilising Products Regulation (EU) 2019/1009, which came into effect in July 2022. This regulation sets out harmonized rules for the marketing of EU fertilizing products, including CRFs and soil amendments. It introduces strict quality, safety, and labeling requirements, as well as limits on contaminants. Products containing sodium silicate must comply with these regulations to be sold within the EU market.

In China, the Ministry of Agriculture and Rural Affairs oversees the regulation of fertilizers and soil amendments. The Fertilizer Registration Management Measures outline the requirements for product registration, quality control, and labeling. Manufacturers must obtain a fertilizer registration certificate before marketing their products, including those containing sodium silicate.

International standards also play a crucial role in the regulatory landscape. The International Organization for Standardization (ISO) has developed several standards relevant to fertilizers and soil amendments, such as ISO 8157 for the determination of water-soluble content in fertilizers. These standards provide a framework for quality assurance and product consistency across borders.

Environmental regulations are increasingly influencing the development and use of CRFs and soil amendments. Many countries have implemented nutrient management plans to reduce the environmental impact of fertilizer use. For instance, the European Union's Nitrates Directive aims to protect water quality by preventing nitrates from agricultural sources polluting ground and surface waters.

Labeling requirements for CRFs and soil amendments containing sodium silicate are typically stringent. Manufacturers must provide accurate information on nutrient content, release patterns, and application rates. In the United States, the Association of American Plant Food Control Officials (AAPFCO) provides uniform standards for fertilizer labeling, which many states adopt into their regulations.

As sustainability concerns grow, regulations are evolving to promote more environmentally friendly fertilizer practices. Some jurisdictions are introducing incentives for the use of slow-release fertilizers and soil amendments that improve nutrient use efficiency. This regulatory trend is likely to favor the development and adoption of innovative CRFs incorporating materials like sodium silicate.

The European Union has established the Fertilising Products Regulation (EU) 2019/1009, which came into effect in July 2022. This regulation sets out harmonized rules for the marketing of EU fertilizing products, including CRFs and soil amendments. It introduces strict quality, safety, and labeling requirements, as well as limits on contaminants. Products containing sodium silicate must comply with these regulations to be sold within the EU market.

In China, the Ministry of Agriculture and Rural Affairs oversees the regulation of fertilizers and soil amendments. The Fertilizer Registration Management Measures outline the requirements for product registration, quality control, and labeling. Manufacturers must obtain a fertilizer registration certificate before marketing their products, including those containing sodium silicate.

International standards also play a crucial role in the regulatory landscape. The International Organization for Standardization (ISO) has developed several standards relevant to fertilizers and soil amendments, such as ISO 8157 for the determination of water-soluble content in fertilizers. These standards provide a framework for quality assurance and product consistency across borders.

Environmental regulations are increasingly influencing the development and use of CRFs and soil amendments. Many countries have implemented nutrient management plans to reduce the environmental impact of fertilizer use. For instance, the European Union's Nitrates Directive aims to protect water quality by preventing nitrates from agricultural sources polluting ground and surface waters.

Labeling requirements for CRFs and soil amendments containing sodium silicate are typically stringent. Manufacturers must provide accurate information on nutrient content, release patterns, and application rates. In the United States, the Association of American Plant Food Control Officials (AAPFCO) provides uniform standards for fertilizer labeling, which many states adopt into their regulations.

As sustainability concerns grow, regulations are evolving to promote more environmentally friendly fertilizer practices. Some jurisdictions are introducing incentives for the use of slow-release fertilizers and soil amendments that improve nutrient use efficiency. This regulatory trend is likely to favor the development and adoption of innovative CRFs incorporating materials like sodium silicate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!