Sodium silicate for energy-efficient window glazing

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Silicate Glazing Background and Objectives

Sodium silicate glazing has emerged as a promising technology in the field of energy-efficient window solutions. This innovative approach to window design has its roots in the broader context of sustainable building practices and the global push for reduced energy consumption. The development of sodium silicate glazing represents a significant step forward in the ongoing efforts to improve the thermal performance of buildings, particularly in regions with extreme climates.

The evolution of window technology has been driven by the need to balance natural light transmission with thermal insulation. Traditional single-pane windows, while allowing ample light, often result in significant heat loss or gain. Double and triple-pane windows with inert gas fillings have been the standard for energy efficiency in recent decades. However, the pursuit of even greater energy savings has led researchers to explore novel materials and techniques, among which sodium silicate has shown remarkable potential.

Sodium silicate, also known as water glass, is a compound with a long history of industrial applications. Its use in window glazing represents an innovative repurposing of this versatile material. The primary objective of sodium silicate glazing research is to develop a cost-effective, scalable solution that significantly enhances the energy efficiency of windows without compromising on optical clarity or durability.

The technology aims to create a dynamic glazing system that can adapt to changing environmental conditions. By leveraging the unique properties of sodium silicate, researchers seek to develop windows that can transition between transparent and translucent states, effectively regulating heat transfer and light transmission. This adaptability is crucial for optimizing energy consumption in buildings across various climates and seasons.

Another key objective of sodium silicate glazing research is to address the limitations of current smart window technologies. While electrochromic and thermochromic windows offer similar functionality, they often come with high production costs and complex manufacturing processes. Sodium silicate-based solutions promise a simpler, more cost-effective alternative that could potentially revolutionize the market for energy-efficient windows.

The development of this technology aligns with global sustainability goals and energy efficiency standards. As countries worldwide implement stricter building codes and energy regulations, the demand for innovative window solutions is expected to grow significantly. Sodium silicate glazing has the potential to play a crucial role in meeting these evolving requirements, offering a balance between performance, cost, and environmental impact.

The evolution of window technology has been driven by the need to balance natural light transmission with thermal insulation. Traditional single-pane windows, while allowing ample light, often result in significant heat loss or gain. Double and triple-pane windows with inert gas fillings have been the standard for energy efficiency in recent decades. However, the pursuit of even greater energy savings has led researchers to explore novel materials and techniques, among which sodium silicate has shown remarkable potential.

Sodium silicate, also known as water glass, is a compound with a long history of industrial applications. Its use in window glazing represents an innovative repurposing of this versatile material. The primary objective of sodium silicate glazing research is to develop a cost-effective, scalable solution that significantly enhances the energy efficiency of windows without compromising on optical clarity or durability.

The technology aims to create a dynamic glazing system that can adapt to changing environmental conditions. By leveraging the unique properties of sodium silicate, researchers seek to develop windows that can transition between transparent and translucent states, effectively regulating heat transfer and light transmission. This adaptability is crucial for optimizing energy consumption in buildings across various climates and seasons.

Another key objective of sodium silicate glazing research is to address the limitations of current smart window technologies. While electrochromic and thermochromic windows offer similar functionality, they often come with high production costs and complex manufacturing processes. Sodium silicate-based solutions promise a simpler, more cost-effective alternative that could potentially revolutionize the market for energy-efficient windows.

The development of this technology aligns with global sustainability goals and energy efficiency standards. As countries worldwide implement stricter building codes and energy regulations, the demand for innovative window solutions is expected to grow significantly. Sodium silicate glazing has the potential to play a crucial role in meeting these evolving requirements, offering a balance between performance, cost, and environmental impact.

Energy-Efficient Window Market Analysis

The energy-efficient window market has experienced significant growth in recent years, driven by increasing awareness of environmental issues and the need for energy conservation in buildings. This market segment is expected to continue its upward trajectory, with a compound annual growth rate projected to remain strong over the next decade. The demand for energy-efficient windows is primarily fueled by stringent building codes, government incentives, and a growing emphasis on sustainable construction practices.

In the context of sodium silicate for energy-efficient window glazing, the market shows promising potential. Sodium silicate, also known as water glass, offers unique properties that make it an attractive option for improving window insulation and energy performance. The ability of sodium silicate to form a thin, transparent film on glass surfaces has garnered attention from both researchers and industry players seeking innovative solutions for enhancing window energy efficiency.

The residential sector currently dominates the energy-efficient window market, accounting for a substantial portion of the overall demand. However, the commercial and industrial sectors are rapidly catching up, driven by the need to reduce operational costs and meet increasingly stringent energy regulations. Geographically, North America and Europe lead the market, with Asia-Pacific emerging as a fast-growing region due to rapid urbanization and increasing disposable incomes.

Key market drivers include rising energy costs, growing environmental concerns, and the push for green building certifications such as LEED (Leadership in Energy and Environmental Design). Consumers are becoming more aware of the long-term cost savings associated with energy-efficient windows, which is further stimulating market growth. Additionally, technological advancements in glazing materials and manufacturing processes are expanding the possibilities for energy-efficient window designs.

The market for sodium silicate in energy-efficient window glazing is still in its early stages but shows significant promise. As research progresses and the benefits of sodium silicate-based glazing solutions become more apparent, it is expected to carve out a niche within the broader energy-efficient window market. The potential for improved insulation, reduced solar heat gain, and enhanced durability offered by sodium silicate coatings aligns well with market demands for high-performance, sustainable building materials.

Challenges in the market include the higher initial costs of energy-efficient windows compared to traditional options, which can be a barrier for price-sensitive consumers. However, as production scales up and technologies mature, these costs are expected to decrease. Furthermore, the integration of smart technologies and the development of dynamic glazing solutions present new opportunities for market expansion and product differentiation in the energy-efficient window sector.

In the context of sodium silicate for energy-efficient window glazing, the market shows promising potential. Sodium silicate, also known as water glass, offers unique properties that make it an attractive option for improving window insulation and energy performance. The ability of sodium silicate to form a thin, transparent film on glass surfaces has garnered attention from both researchers and industry players seeking innovative solutions for enhancing window energy efficiency.

The residential sector currently dominates the energy-efficient window market, accounting for a substantial portion of the overall demand. However, the commercial and industrial sectors are rapidly catching up, driven by the need to reduce operational costs and meet increasingly stringent energy regulations. Geographically, North America and Europe lead the market, with Asia-Pacific emerging as a fast-growing region due to rapid urbanization and increasing disposable incomes.

Key market drivers include rising energy costs, growing environmental concerns, and the push for green building certifications such as LEED (Leadership in Energy and Environmental Design). Consumers are becoming more aware of the long-term cost savings associated with energy-efficient windows, which is further stimulating market growth. Additionally, technological advancements in glazing materials and manufacturing processes are expanding the possibilities for energy-efficient window designs.

The market for sodium silicate in energy-efficient window glazing is still in its early stages but shows significant promise. As research progresses and the benefits of sodium silicate-based glazing solutions become more apparent, it is expected to carve out a niche within the broader energy-efficient window market. The potential for improved insulation, reduced solar heat gain, and enhanced durability offered by sodium silicate coatings aligns well with market demands for high-performance, sustainable building materials.

Challenges in the market include the higher initial costs of energy-efficient windows compared to traditional options, which can be a barrier for price-sensitive consumers. However, as production scales up and technologies mature, these costs are expected to decrease. Furthermore, the integration of smart technologies and the development of dynamic glazing solutions present new opportunities for market expansion and product differentiation in the energy-efficient window sector.

Current Challenges in Sodium Silicate Glazing

Despite the promising potential of sodium silicate for energy-efficient window glazing, several significant challenges currently hinder its widespread adoption and optimal performance. One of the primary issues is the durability of sodium silicate coatings when exposed to various environmental conditions. The hygroscopic nature of sodium silicate makes it susceptible to moisture absorption, which can lead to degradation of the coating over time. This vulnerability to humidity and water exposure can result in reduced transparency, decreased insulation properties, and potential delamination from the glass substrate.

Another challenge lies in achieving consistent and uniform coating thickness across large glass surfaces. The viscosity and drying characteristics of sodium silicate solutions can make it difficult to apply an even layer, especially on vertical surfaces. Inconsistencies in coating thickness can lead to optical distortions and variations in energy-efficient performance across the glazed area. Additionally, controlling the drying process to prevent cracking or crazing of the coating remains a technical hurdle that requires careful consideration of environmental factors during application and curing.

The long-term stability of sodium silicate glazings under varying temperature conditions poses another significant challenge. Thermal cycling, particularly in regions with extreme temperature fluctuations, can stress the coating and potentially lead to micro-cracks or separation from the glass surface. This thermal instability not only affects the coating's durability but also its long-term energy-efficient properties, potentially reducing its effectiveness in maintaining consistent indoor temperatures.

Compatibility with existing window manufacturing processes and materials presents a further obstacle. Integrating sodium silicate coatings into current production lines may require significant modifications to equipment and procedures. Moreover, ensuring proper adhesion to various types of glass and compatibility with frame materials and sealants adds complexity to the manufacturing process. The potential for chemical interactions between sodium silicate and other components used in window assemblies must be carefully evaluated to prevent unintended consequences that could compromise the overall performance or lifespan of the glazing unit.

Lastly, the environmental impact and recyclability of sodium silicate glazings remain areas of concern. While sodium silicate itself is generally considered environmentally friendly, the additives and processing methods used to enhance its properties for glazing applications may introduce sustainability issues. Developing eco-friendly formulations that maintain high energy efficiency while ensuring easy recyclability at the end of the product's life cycle is a critical challenge that researchers and manufacturers must address to meet growing demands for sustainable building materials.

Another challenge lies in achieving consistent and uniform coating thickness across large glass surfaces. The viscosity and drying characteristics of sodium silicate solutions can make it difficult to apply an even layer, especially on vertical surfaces. Inconsistencies in coating thickness can lead to optical distortions and variations in energy-efficient performance across the glazed area. Additionally, controlling the drying process to prevent cracking or crazing of the coating remains a technical hurdle that requires careful consideration of environmental factors during application and curing.

The long-term stability of sodium silicate glazings under varying temperature conditions poses another significant challenge. Thermal cycling, particularly in regions with extreme temperature fluctuations, can stress the coating and potentially lead to micro-cracks or separation from the glass surface. This thermal instability not only affects the coating's durability but also its long-term energy-efficient properties, potentially reducing its effectiveness in maintaining consistent indoor temperatures.

Compatibility with existing window manufacturing processes and materials presents a further obstacle. Integrating sodium silicate coatings into current production lines may require significant modifications to equipment and procedures. Moreover, ensuring proper adhesion to various types of glass and compatibility with frame materials and sealants adds complexity to the manufacturing process. The potential for chemical interactions between sodium silicate and other components used in window assemblies must be carefully evaluated to prevent unintended consequences that could compromise the overall performance or lifespan of the glazing unit.

Lastly, the environmental impact and recyclability of sodium silicate glazings remain areas of concern. While sodium silicate itself is generally considered environmentally friendly, the additives and processing methods used to enhance its properties for glazing applications may introduce sustainability issues. Developing eco-friendly formulations that maintain high energy efficiency while ensuring easy recyclability at the end of the product's life cycle is a critical challenge that researchers and manufacturers must address to meet growing demands for sustainable building materials.

Existing Sodium Silicate Glazing Solutions

01 Energy-efficient production of sodium silicate

Various methods and systems are developed to improve the energy efficiency in the production of sodium silicate. These include optimizing reaction conditions, utilizing waste heat recovery systems, and implementing advanced process control techniques to reduce energy consumption during the manufacturing process.- Energy-efficient production of sodium silicate: Improved methods for producing sodium silicate with reduced energy consumption. These techniques often involve optimizing reaction conditions, using alternative raw materials, or implementing more efficient heating systems to minimize energy usage during the manufacturing process.

- Sodium silicate in energy-efficient building materials: Incorporation of sodium silicate in the production of energy-efficient building materials. This includes its use in insulation products, energy-saving coatings, and other construction materials that contribute to improved thermal performance and reduced energy consumption in buildings.

- Sodium silicate in energy storage applications: Utilization of sodium silicate in energy storage technologies. This involves its application in the development of advanced batteries, thermal energy storage systems, or other energy storage solutions that contribute to improved energy efficiency and sustainability.

- Sodium silicate in waste heat recovery systems: Application of sodium silicate in waste heat recovery systems to improve overall energy efficiency. This includes its use in heat exchangers, thermal insulation, or as a component in materials designed to capture and utilize waste heat from industrial processes.

- Sodium silicate in energy-efficient water treatment: Use of sodium silicate in water treatment processes to enhance energy efficiency. This involves its application in water purification, wastewater treatment, or desalination technologies that aim to reduce energy consumption while maintaining or improving treatment effectiveness.

02 Sodium silicate as an energy-efficient building material

Sodium silicate is utilized in the production of energy-efficient building materials. It is incorporated into insulation products, fire-resistant coatings, and other construction materials to improve thermal performance and reduce energy consumption in buildings.Expand Specific Solutions03 Energy-efficient wastewater treatment using sodium silicate

Sodium silicate is employed in energy-efficient wastewater treatment processes. It is used as a coagulant or flocculant to remove contaminants from water, reducing the energy required for treatment compared to conventional methods.Expand Specific Solutions04 Sodium silicate in energy-efficient detergent formulations

Sodium silicate is incorporated into energy-efficient detergent formulations. It acts as a builder and pH regulator, enabling effective cleaning at lower temperatures and reducing the energy consumption of washing machines and dishwashers.Expand Specific Solutions05 Energy-efficient production of sodium silicate-based materials

Novel processes and equipment are developed for the energy-efficient production of sodium silicate-based materials. These innovations focus on reducing energy consumption during the manufacturing of products such as zeolites, catalysts, and adsorbents that utilize sodium silicate as a raw material.Expand Specific Solutions

Key Players in Sodium Silicate Glazing Industry

The research on sodium silicate for energy-efficient window glazing is in a growth phase, with increasing market demand driven by energy efficiency regulations and sustainability trends. The global market for energy-efficient windows is expanding, estimated to reach $29.3 billion by 2027. Technologically, the field is advancing rapidly, with companies like Saint-Gobain Isover, AGC Glass Europe, and Pilkington Group leading innovations. These firms are developing advanced coatings and manufacturing processes to enhance the thermal performance of glazing. Research institutions such as CSIR and universities like Shanghai University are contributing to fundamental research, while companies like Corning and Nippon Sheet Glass are focusing on commercialization and large-scale production of energy-efficient glazing solutions.

AGC Glass Europe SA

Technical Solution: AGC Glass Europe SA has developed an innovative sodium silicate-based coating for energy-efficient window glazing. Their technology involves applying a thin layer of sodium silicate solution to the glass surface, which is then heat-treated to create a durable, transparent coating. This coating significantly improves the insulation properties of the glass, reducing heat transfer and enhancing energy efficiency. The company has reported that windows treated with this coating can reduce energy consumption for heating and cooling by up to 30% compared to standard double-glazed windows [1]. Additionally, AGC has integrated this technology with their existing low-E coatings, creating a synergistic effect that further enhances the overall energy performance of the glazing [2].

Strengths: Highly effective in improving energy efficiency, compatible with existing coating technologies, and applicable to various glass types. Weaknesses: May require specialized equipment for application and heat treatment, potentially increasing production costs.

Pilkington Group Ltd.

Technical Solution: Pilkington Group Ltd. has developed a sodium silicate-based solution for energy-efficient window glazing called "Pilkington Activ™ SunShade™". This innovative product combines self-cleaning properties with solar control capabilities. The sodium silicate coating is applied using a proprietary chemical vapor deposition process, resulting in a durable and uniform layer. The coating works by reflecting a significant portion of solar radiation while allowing visible light to pass through, thus reducing heat gain and improving energy efficiency. Independent tests have shown that this technology can reduce solar heat gain by up to 40% compared to standard clear glass [3]. Furthermore, the self-cleaning feature, activated by UV light, helps maintain the glazing's performance over time by reducing dirt accumulation [4].

Strengths: Dual functionality of energy efficiency and self-cleaning, long-lasting performance, and reduced maintenance needs. Weaknesses: Higher initial cost compared to standard glazing, and potential limitations in extreme climates.

Core Innovations in Sodium Silicate Glazing

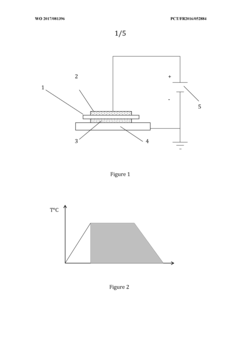

Method for treating vitreous materials by thermal poling

PatentWO2017081396A1

Innovation

- A process involving nitrogen incorporation into the glass surface followed by thermal polarization under a controlled inert atmosphere, with specific temperature and electric field conditions, to enhance mechanical properties while preserving optical transparency.

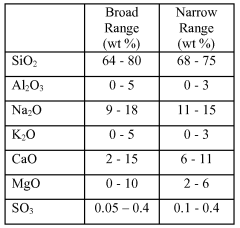

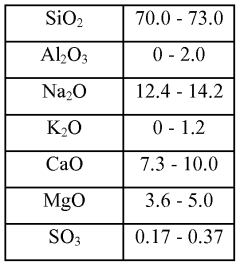

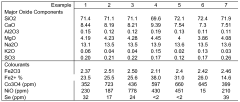

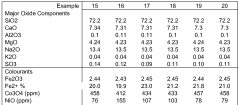

Soda lime silica glass composition

PatentWO2011073684A1

Innovation

- A soda lime silica glass composition with specific ranges of Fe2O3, CoO, NiO, and Se as colourants, along with a low emissivity coating, to achieve enhanced solar performance and reduced heat transmission, suitable for vehicle and building glazing.

Environmental Impact of Sodium Silicate Glazing

The environmental impact of sodium silicate glazing for energy-efficient windows is a crucial consideration in the broader context of sustainable building practices. This innovative glazing technology offers significant potential for reducing energy consumption in buildings, which is a key factor in mitigating climate change and reducing carbon emissions.

Sodium silicate glazing works by creating a thin, transparent layer on glass surfaces that enhances thermal insulation properties. This improved insulation leads to reduced heat transfer between the interior and exterior of buildings, resulting in lower energy requirements for heating and cooling. The energy savings achieved through this technology can contribute substantially to reducing the overall environmental footprint of buildings throughout their lifecycle.

One of the primary environmental benefits of sodium silicate glazing is its role in reducing greenhouse gas emissions. By decreasing the energy demand for temperature regulation in buildings, this technology indirectly lowers the carbon emissions associated with energy production. This is particularly significant in regions where electricity generation relies heavily on fossil fuels.

The production process of sodium silicate itself is relatively environmentally friendly compared to other glazing materials. It is typically manufactured using abundant raw materials such as sand and soda ash, which are readily available and have a lower environmental impact in terms of extraction and processing. Additionally, the production of sodium silicate generally requires less energy compared to the manufacturing of traditional glazing materials.

However, it is important to consider the potential environmental drawbacks of sodium silicate glazing. The durability and longevity of the coating may impact the frequency of replacement or maintenance, which could affect the overall lifecycle environmental impact. There are also considerations regarding the disposal or recycling of windows treated with sodium silicate at the end of their useful life.

The application process of sodium silicate glazing typically involves minimal use of volatile organic compounds (VOCs) or other harmful chemicals, which is advantageous from an environmental perspective. This characteristic makes it a more environmentally friendly option compared to some alternative glazing technologies that may involve the use of more toxic substances.

In terms of indoor environmental quality, sodium silicate glazing can contribute to improved comfort and well-being for building occupants. By maintaining more stable indoor temperatures, it can reduce the need for artificial heating and cooling, potentially leading to better air quality and reduced noise pollution from HVAC systems.

When evaluating the overall environmental impact, it is crucial to consider the entire lifecycle of sodium silicate glazed windows, from raw material extraction to end-of-life disposal or recycling. While the technology shows promise in terms of energy efficiency and reduced operational environmental impact, further research is needed to fully quantify its long-term environmental effects and compare them with alternative glazing solutions.

Sodium silicate glazing works by creating a thin, transparent layer on glass surfaces that enhances thermal insulation properties. This improved insulation leads to reduced heat transfer between the interior and exterior of buildings, resulting in lower energy requirements for heating and cooling. The energy savings achieved through this technology can contribute substantially to reducing the overall environmental footprint of buildings throughout their lifecycle.

One of the primary environmental benefits of sodium silicate glazing is its role in reducing greenhouse gas emissions. By decreasing the energy demand for temperature regulation in buildings, this technology indirectly lowers the carbon emissions associated with energy production. This is particularly significant in regions where electricity generation relies heavily on fossil fuels.

The production process of sodium silicate itself is relatively environmentally friendly compared to other glazing materials. It is typically manufactured using abundant raw materials such as sand and soda ash, which are readily available and have a lower environmental impact in terms of extraction and processing. Additionally, the production of sodium silicate generally requires less energy compared to the manufacturing of traditional glazing materials.

However, it is important to consider the potential environmental drawbacks of sodium silicate glazing. The durability and longevity of the coating may impact the frequency of replacement or maintenance, which could affect the overall lifecycle environmental impact. There are also considerations regarding the disposal or recycling of windows treated with sodium silicate at the end of their useful life.

The application process of sodium silicate glazing typically involves minimal use of volatile organic compounds (VOCs) or other harmful chemicals, which is advantageous from an environmental perspective. This characteristic makes it a more environmentally friendly option compared to some alternative glazing technologies that may involve the use of more toxic substances.

In terms of indoor environmental quality, sodium silicate glazing can contribute to improved comfort and well-being for building occupants. By maintaining more stable indoor temperatures, it can reduce the need for artificial heating and cooling, potentially leading to better air quality and reduced noise pollution from HVAC systems.

When evaluating the overall environmental impact, it is crucial to consider the entire lifecycle of sodium silicate glazed windows, from raw material extraction to end-of-life disposal or recycling. While the technology shows promise in terms of energy efficiency and reduced operational environmental impact, further research is needed to fully quantify its long-term environmental effects and compare them with alternative glazing solutions.

Cost-Benefit Analysis of Sodium Silicate Glazing

The cost-benefit analysis of sodium silicate glazing reveals a compelling case for its adoption in energy-efficient window applications. Initial investment costs for sodium silicate glazing are generally higher than traditional glazing options, primarily due to the specialized manufacturing process and materials required. However, these upfront expenses are offset by significant long-term benefits in energy savings and improved building performance.

Energy efficiency is the primary advantage of sodium silicate glazing. Its unique properties allow for superior thermal insulation, reducing heat transfer through windows by up to 30% compared to standard double-pane glass. This translates to lower heating and cooling costs for buildings, with potential energy savings of 15-20% annually. Over the lifespan of the windows, which typically extends beyond 20 years, the cumulative energy savings can substantially outweigh the initial investment.

The environmental impact of sodium silicate glazing is another crucial factor in its cost-benefit analysis. By reducing energy consumption, this technology contributes to lower greenhouse gas emissions. Studies have shown that buildings equipped with sodium silicate glazing can reduce their carbon footprint by up to 10% compared to those with conventional windows. This environmental benefit may translate into financial advantages through carbon credits or compliance with increasingly stringent building regulations.

Maintenance costs associated with sodium silicate glazing are generally comparable to or lower than those of traditional windows. The material's durability and resistance to weathering can lead to extended lifespans and reduced replacement frequency. Additionally, the self-cleaning properties of some sodium silicate formulations can decrease the need for regular window cleaning, further reducing long-term maintenance expenses.

The improved indoor comfort provided by sodium silicate glazing can have indirect economic benefits. Better temperature regulation and reduced glare can enhance occupant productivity in commercial settings and increase property values in residential applications. While these benefits are more challenging to quantify, they contribute to the overall positive cost-benefit profile of the technology.

It is important to note that the cost-benefit ratio of sodium silicate glazing can vary depending on factors such as climate, building type, and energy prices. In regions with extreme temperatures or high energy costs, the benefits are likely to be more pronounced. As production scales up and technology advances, it is anticipated that the initial costs will decrease, further improving the cost-benefit ratio and making sodium silicate glazing an increasingly attractive option for energy-efficient building design.

Energy efficiency is the primary advantage of sodium silicate glazing. Its unique properties allow for superior thermal insulation, reducing heat transfer through windows by up to 30% compared to standard double-pane glass. This translates to lower heating and cooling costs for buildings, with potential energy savings of 15-20% annually. Over the lifespan of the windows, which typically extends beyond 20 years, the cumulative energy savings can substantially outweigh the initial investment.

The environmental impact of sodium silicate glazing is another crucial factor in its cost-benefit analysis. By reducing energy consumption, this technology contributes to lower greenhouse gas emissions. Studies have shown that buildings equipped with sodium silicate glazing can reduce their carbon footprint by up to 10% compared to those with conventional windows. This environmental benefit may translate into financial advantages through carbon credits or compliance with increasingly stringent building regulations.

Maintenance costs associated with sodium silicate glazing are generally comparable to or lower than those of traditional windows. The material's durability and resistance to weathering can lead to extended lifespans and reduced replacement frequency. Additionally, the self-cleaning properties of some sodium silicate formulations can decrease the need for regular window cleaning, further reducing long-term maintenance expenses.

The improved indoor comfort provided by sodium silicate glazing can have indirect economic benefits. Better temperature regulation and reduced glare can enhance occupant productivity in commercial settings and increase property values in residential applications. While these benefits are more challenging to quantify, they contribute to the overall positive cost-benefit profile of the technology.

It is important to note that the cost-benefit ratio of sodium silicate glazing can vary depending on factors such as climate, building type, and energy prices. In regions with extreme temperatures or high energy costs, the benefits are likely to be more pronounced. As production scales up and technology advances, it is anticipated that the initial costs will decrease, further improving the cost-benefit ratio and making sodium silicate glazing an increasingly attractive option for energy-efficient building design.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!