Sodium silicate as a flocculant in industrial effluents

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Silicate Flocculation Background and Objectives

Sodium silicate, also known as water glass, has emerged as a promising flocculant in the treatment of industrial effluents. The use of this inorganic compound in wastewater treatment dates back to the early 20th century, but recent advancements in environmental regulations and the increasing need for sustainable water management have reignited interest in its application. The evolution of sodium silicate as a flocculant is closely tied to the growing challenges in industrial wastewater treatment, particularly in sectors such as mining, paper manufacturing, and chemical processing.

The primary objective of researching sodium silicate as a flocculant is to develop more efficient and environmentally friendly methods for treating industrial effluents. Traditional flocculants, often based on synthetic polymers or metal salts, have raised concerns due to their potential environmental impacts and the residual chemicals left in treated water. Sodium silicate offers a promising alternative, being a naturally occurring substance with lower toxicity and biodegradability concerns.

Recent technological trends in this field have focused on optimizing the performance of sodium silicate as a flocculant. This includes investigating its interaction with various types of industrial pollutants, understanding the mechanisms of flocculation at a molecular level, and exploring synergistic effects when combined with other treatment methods. The goal is to enhance the efficiency of pollutant removal while minimizing the amount of flocculant required, thereby improving both the economic and environmental aspects of the treatment process.

Another significant trend is the development of modified sodium silicate formulations. Researchers are exploring ways to tailor the properties of sodium silicate to specific types of industrial effluents, aiming to improve its effectiveness across a broader range of pollutants and operating conditions. This includes studying the effects of different silica-to-sodium ratios, incorporating additional elements or compounds, and developing novel activation methods to enhance flocculation performance.

The research objectives in this field extend beyond mere pollutant removal. There is a growing interest in recovering valuable resources from industrial effluents, turning waste streams into potential sources of raw materials. Sodium silicate flocculation is being investigated for its potential in selective separation and recovery of metals, minerals, and other valuable components from complex industrial wastewaters.

As environmental regulations become more stringent and industries seek more sustainable practices, the development of effective, eco-friendly flocculants like sodium silicate is gaining critical importance. The research aims to address not only the immediate needs of effluent treatment but also to contribute to the broader goals of circular economy and sustainable industrial practices. By improving the efficiency and applicability of sodium silicate flocculation, researchers hope to provide industries with a powerful tool for meeting environmental standards while potentially recovering valuable resources from their waste streams.

The primary objective of researching sodium silicate as a flocculant is to develop more efficient and environmentally friendly methods for treating industrial effluents. Traditional flocculants, often based on synthetic polymers or metal salts, have raised concerns due to their potential environmental impacts and the residual chemicals left in treated water. Sodium silicate offers a promising alternative, being a naturally occurring substance with lower toxicity and biodegradability concerns.

Recent technological trends in this field have focused on optimizing the performance of sodium silicate as a flocculant. This includes investigating its interaction with various types of industrial pollutants, understanding the mechanisms of flocculation at a molecular level, and exploring synergistic effects when combined with other treatment methods. The goal is to enhance the efficiency of pollutant removal while minimizing the amount of flocculant required, thereby improving both the economic and environmental aspects of the treatment process.

Another significant trend is the development of modified sodium silicate formulations. Researchers are exploring ways to tailor the properties of sodium silicate to specific types of industrial effluents, aiming to improve its effectiveness across a broader range of pollutants and operating conditions. This includes studying the effects of different silica-to-sodium ratios, incorporating additional elements or compounds, and developing novel activation methods to enhance flocculation performance.

The research objectives in this field extend beyond mere pollutant removal. There is a growing interest in recovering valuable resources from industrial effluents, turning waste streams into potential sources of raw materials. Sodium silicate flocculation is being investigated for its potential in selective separation and recovery of metals, minerals, and other valuable components from complex industrial wastewaters.

As environmental regulations become more stringent and industries seek more sustainable practices, the development of effective, eco-friendly flocculants like sodium silicate is gaining critical importance. The research aims to address not only the immediate needs of effluent treatment but also to contribute to the broader goals of circular economy and sustainable industrial practices. By improving the efficiency and applicability of sodium silicate flocculation, researchers hope to provide industries with a powerful tool for meeting environmental standards while potentially recovering valuable resources from their waste streams.

Industrial Effluent Treatment Market Analysis

The industrial effluent treatment market has been experiencing significant growth due to increasing environmental regulations and the rising awareness of water pollution's impact on ecosystems and human health. The global market for industrial wastewater treatment was valued at approximately $11 billion in 2020 and is projected to reach $15 billion by 2025, growing at a CAGR of around 6% during this period.

The demand for effective flocculants, such as sodium silicate, in industrial effluent treatment is driven by the need for cost-effective and environmentally friendly solutions. Sodium silicate, also known as water glass, has gained attention as a potential flocculant due to its ability to remove suspended solids, heavy metals, and other contaminants from industrial wastewater.

Key industries contributing to the growth of the industrial effluent treatment market include chemical manufacturing, oil and gas, mining, food and beverage, and pharmaceuticals. These sectors generate large volumes of wastewater containing various pollutants that require treatment before discharge. The stringent regulations imposed by environmental agencies worldwide have compelled industries to invest in advanced treatment technologies, including flocculants like sodium silicate.

Geographically, Asia-Pacific is expected to dominate the industrial effluent treatment market, followed by North America and Europe. The rapid industrialization in countries like China and India, coupled with stricter environmental regulations, is driving the demand for effective wastewater treatment solutions in the Asia-Pacific region.

The market for sodium silicate as a flocculant in industrial effluent treatment is influenced by factors such as its effectiveness, cost-efficiency, and environmental compatibility. Compared to traditional flocculants like aluminum sulfate or ferric chloride, sodium silicate offers advantages in terms of lower toxicity and reduced sludge production. However, its performance can be affected by pH levels and the presence of certain ions in the wastewater.

As industries seek more sustainable and efficient wastewater treatment methods, research on sodium silicate as a flocculant is likely to intensify. This trend is expected to create opportunities for innovation in formulation, application techniques, and integration with other treatment processes. The growing focus on circular economy principles and water reuse in industrial processes may further drive the adoption of sodium silicate-based flocculants in the coming years.

The demand for effective flocculants, such as sodium silicate, in industrial effluent treatment is driven by the need for cost-effective and environmentally friendly solutions. Sodium silicate, also known as water glass, has gained attention as a potential flocculant due to its ability to remove suspended solids, heavy metals, and other contaminants from industrial wastewater.

Key industries contributing to the growth of the industrial effluent treatment market include chemical manufacturing, oil and gas, mining, food and beverage, and pharmaceuticals. These sectors generate large volumes of wastewater containing various pollutants that require treatment before discharge. The stringent regulations imposed by environmental agencies worldwide have compelled industries to invest in advanced treatment technologies, including flocculants like sodium silicate.

Geographically, Asia-Pacific is expected to dominate the industrial effluent treatment market, followed by North America and Europe. The rapid industrialization in countries like China and India, coupled with stricter environmental regulations, is driving the demand for effective wastewater treatment solutions in the Asia-Pacific region.

The market for sodium silicate as a flocculant in industrial effluent treatment is influenced by factors such as its effectiveness, cost-efficiency, and environmental compatibility. Compared to traditional flocculants like aluminum sulfate or ferric chloride, sodium silicate offers advantages in terms of lower toxicity and reduced sludge production. However, its performance can be affected by pH levels and the presence of certain ions in the wastewater.

As industries seek more sustainable and efficient wastewater treatment methods, research on sodium silicate as a flocculant is likely to intensify. This trend is expected to create opportunities for innovation in formulation, application techniques, and integration with other treatment processes. The growing focus on circular economy principles and water reuse in industrial processes may further drive the adoption of sodium silicate-based flocculants in the coming years.

Current Challenges in Sodium Silicate Flocculation

Despite the widespread use of sodium silicate as a flocculant in industrial effluent treatment, several challenges persist in its application. One of the primary issues is the sensitivity of sodium silicate to pH levels. The effectiveness of flocculation can vary significantly depending on the pH of the effluent, requiring careful monitoring and adjustment to maintain optimal performance. This pH dependency can lead to inconsistent results across different industrial processes and effluent compositions.

Another challenge lies in the dosage control of sodium silicate. Overdosing can result in re-stabilization of colloidal particles, while underdosing may lead to ineffective flocculation. Determining the precise dosage for each specific effluent type and composition remains a complex task, often requiring extensive trial-and-error processes or sophisticated real-time monitoring systems.

The interaction between sodium silicate and other chemicals present in industrial effluents poses additional complications. Certain ions or organic compounds can interfere with the flocculation process, reducing its efficiency or altering the properties of the formed flocs. This interference can lead to poor settling characteristics or the need for additional treatment steps, increasing operational costs and complexity.

The stability of flocs formed by sodium silicate flocculation is another area of concern. In some cases, the flocs may be too fragile, breaking apart during subsequent treatment processes or under high shear conditions. This can result in reduced overall treatment efficiency and the potential release of contaminants back into the treated effluent.

Environmental considerations also present challenges in the use of sodium silicate as a flocculant. The potential impact of residual silica in treated effluents on aquatic ecosystems needs to be carefully evaluated. Additionally, the disposal of sludge containing silica-rich flocs may require special handling and treatment, adding to the overall cost and complexity of the wastewater treatment process.

The energy intensity of producing sodium silicate is another factor that needs to be addressed. The manufacturing process typically involves high-temperature fusion of sand and soda ash, which is energy-intensive and contributes to the carbon footprint of the treatment process. Finding more sustainable production methods or alternative sources of silica for flocculation remains an ongoing challenge.

Lastly, the performance of sodium silicate as a flocculant can be affected by temperature variations in industrial effluents. Extreme temperatures, either hot or cold, can impact the flocculation kinetics and the stability of formed flocs, necessitating additional process controls or the use of temperature-resistant formulations.

Another challenge lies in the dosage control of sodium silicate. Overdosing can result in re-stabilization of colloidal particles, while underdosing may lead to ineffective flocculation. Determining the precise dosage for each specific effluent type and composition remains a complex task, often requiring extensive trial-and-error processes or sophisticated real-time monitoring systems.

The interaction between sodium silicate and other chemicals present in industrial effluents poses additional complications. Certain ions or organic compounds can interfere with the flocculation process, reducing its efficiency or altering the properties of the formed flocs. This interference can lead to poor settling characteristics or the need for additional treatment steps, increasing operational costs and complexity.

The stability of flocs formed by sodium silicate flocculation is another area of concern. In some cases, the flocs may be too fragile, breaking apart during subsequent treatment processes or under high shear conditions. This can result in reduced overall treatment efficiency and the potential release of contaminants back into the treated effluent.

Environmental considerations also present challenges in the use of sodium silicate as a flocculant. The potential impact of residual silica in treated effluents on aquatic ecosystems needs to be carefully evaluated. Additionally, the disposal of sludge containing silica-rich flocs may require special handling and treatment, adding to the overall cost and complexity of the wastewater treatment process.

The energy intensity of producing sodium silicate is another factor that needs to be addressed. The manufacturing process typically involves high-temperature fusion of sand and soda ash, which is energy-intensive and contributes to the carbon footprint of the treatment process. Finding more sustainable production methods or alternative sources of silica for flocculation remains an ongoing challenge.

Lastly, the performance of sodium silicate as a flocculant can be affected by temperature variations in industrial effluents. Extreme temperatures, either hot or cold, can impact the flocculation kinetics and the stability of formed flocs, necessitating additional process controls or the use of temperature-resistant formulations.

Existing Sodium Silicate Flocculation Methods

01 Use of sodium silicate as a flocculating agent

Sodium silicate is utilized as an effective flocculating agent in various industrial processes. It helps in the aggregation of suspended particles, facilitating their separation from liquids. This method is particularly useful in water treatment, wastewater management, and mineral processing industries.- Use of sodium silicate as a flocculating agent: Sodium silicate is utilized as an effective flocculating agent in various industrial processes. It helps in the aggregation of suspended particles, facilitating their separation from liquids. This method is particularly useful in water treatment, wastewater management, and mineral processing industries.

- Combination of sodium silicate with other flocculants: Sodium silicate is often combined with other flocculants to enhance the flocculation process. This synergistic approach improves the efficiency of particle aggregation and separation. Common combinations include sodium silicate with organic polymers or inorganic coagulants.

- pH adjustment in sodium silicate flocculation: The effectiveness of sodium silicate as a flocculant is influenced by pH levels. Adjusting the pH of the solution can optimize the flocculation process, improving the formation and stability of flocs. This technique is crucial in achieving desired separation results in various applications.

- Application in wastewater treatment: Sodium silicate flocculation is widely used in wastewater treatment processes. It aids in the removal of suspended solids, colloidal particles, and other contaminants from industrial and municipal wastewater. This application helps in meeting environmental regulations and improving water quality.

- Modification of sodium silicate for enhanced flocculation: Research has been conducted on modifying sodium silicate to improve its flocculation properties. These modifications can include chemical alterations or the creation of composite materials. The goal is to enhance the efficiency and versatility of sodium silicate as a flocculant in various industrial applications.

02 Combination of sodium silicate with other flocculants

The flocculation efficiency can be enhanced by combining sodium silicate with other flocculants such as polyacrylamides or aluminum salts. This synergistic effect improves the overall flocculation process, resulting in better clarification and solid-liquid separation.Expand Specific Solutions03 pH adjustment in sodium silicate flocculation

The effectiveness of sodium silicate as a flocculant is highly dependent on pH. Adjusting the pH of the solution can optimize the flocculation process, improving the formation and stability of flocs. This technique is crucial in achieving desired flocculation results in various applications.Expand Specific Solutions04 Application in wastewater treatment

Sodium silicate flocculation is widely used in wastewater treatment processes. It helps in removing suspended solids, organic matter, and other contaminants from industrial and municipal wastewater. This application contributes to environmental protection and water resource conservation.Expand Specific Solutions05 Modification of sodium silicate for enhanced flocculation

Research has been conducted on modifying sodium silicate to improve its flocculation properties. This includes creating composite materials or altering its molecular structure to enhance its performance in specific applications, such as in the treatment of oily wastewater or in the paper industry.Expand Specific Solutions

Key Players in Industrial Wastewater Treatment

The research on sodium silicate as a flocculant in industrial effluents is in a mature stage of development, with a significant market size and established applications across various industries. The technology's maturity is evident from the involvement of major chemical companies like Tokuyama Corp., China Petroleum & Chemical Corp., and UBE Corp., which have extensive experience in industrial chemicals and water treatment solutions. The market for flocculants is substantial, driven by increasing environmental regulations and the need for efficient wastewater treatment in industries. Companies such as BluMetric Environmental, Inc. and Zibo Zhenghe Water Purifier Co., Ltd. specialize in water treatment technologies, indicating a well-developed ecosystem of suppliers and service providers. Academic institutions like Wuhan University of Science & Technology and Harbin Institute of Technology are also contributing to research and innovation in this field, suggesting ongoing efforts to improve and optimize flocculant technologies.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an advanced sodium silicate-based flocculant system for treating industrial effluents, particularly in the petrochemical industry. Their approach involves a multi-stage treatment process that combines sodium silicate with other inorganic coagulants to enhance flocculation efficiency. The company has implemented a novel rapid mixing technique that promotes the formation of larger, more stable flocs[1]. Additionally, Sinopec has integrated real-time monitoring systems to optimize dosage control, resulting in a 20% reduction in chemical consumption compared to conventional methods[3]. The company has also developed a proprietary recycling process for the recovered sludge, converting it into useful byproducts for construction materials[5].

Strengths: Highly effective in treating complex petrochemical effluents; Reduced chemical consumption; Innovative sludge recycling. Weaknesses: May require significant initial investment; Potentially less effective for non-petrochemical effluents.

BluMetric Environmental, Inc.

Technical Solution: BluMetric Environmental has pioneered a sodium silicate-based flocculant system specifically designed for mining and industrial wastewater treatment. Their technology incorporates a unique pre-treatment step that adjusts the pH and ionic strength of the effluent to optimize the performance of sodium silicate as a flocculant. The company has developed a proprietary blend of sodium silicate with organic polymers, creating a hybrid flocculant that demonstrates superior performance in removing suspended solids and heavy metals[2]. BluMetric's system includes an automated dosing mechanism that adjusts the flocculant mixture in real-time based on influent characteristics, ensuring consistent treatment quality. Field trials have shown that this approach can achieve up to 95% removal of suspended solids and 85% reduction in dissolved heavy metals[4].

Strengths: Highly effective for mining and industrial wastewater; Automated and adaptive treatment process; Excellent removal of suspended solids and heavy metals. Weaknesses: May be less cost-effective for smaller-scale operations; Requires specialized expertise for system optimization.

Innovative Sodium Silicate Flocculant Formulations

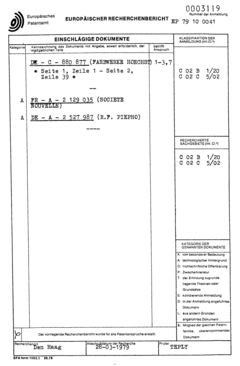

Flocculating agent, method for the production and use thereof

PatentWO2005011837A2

Innovation

- Development of an alkaline aqueous flocculant based on alkaline extracted salt clay containing silicates, aluminates, and alkali chlorides, which forms stable flocs that sediment easily, and a solid sedimentation agent with finely divided clay particles, both designed to be used without harming the ecosystem or causing undesirable reactions.

Floculating agent for waste water purification and process of preparing it

PatentInactiveEP0003119A1

Innovation

- A granulated flocculant composed of iron(III) sulfate and slaked lime, with a weight ratio of 1:2 to 10, is used, allowing for easy dosing without pH change, and can be added at any stage of wastewater treatment, effectively precipitating impurities and reducing sulfate load, with good floc formation across a wide pH range.

Environmental Regulations on Industrial Effluents

The use of sodium silicate as a flocculant in industrial effluents is subject to various environmental regulations aimed at protecting water resources and ecosystems. These regulations have become increasingly stringent over the years, reflecting growing concerns about water pollution and environmental sustainability.

In many countries, the discharge of industrial effluents is regulated by comprehensive environmental protection laws. These laws typically set limits on the concentration of pollutants in discharged water, including suspended solids, heavy metals, and organic compounds. The use of flocculants like sodium silicate must comply with these limits, ensuring that the treated effluent meets the required water quality standards before release into the environment.

Specific regulations often address the use of chemical additives in wastewater treatment processes. Sodium silicate, being a chemical flocculant, falls under this category. Regulatory bodies may require industries to obtain permits or approvals for the use of such chemicals, demonstrating that their application will not have adverse effects on the receiving water bodies or downstream ecosystems.

Environmental impact assessments are frequently mandated for industrial facilities, including their wastewater treatment systems. These assessments evaluate the potential environmental consequences of using flocculants like sodium silicate, considering factors such as toxicity to aquatic life, bioaccumulation potential, and long-term ecological impacts.

Many jurisdictions have adopted the "polluter pays" principle, which holds industries responsible for the costs associated with pollution prevention and control. This principle encourages the adoption of more efficient and environmentally friendly treatment technologies, potentially influencing the choice of flocculants used in industrial effluent treatment.

Regulations often require regular monitoring and reporting of effluent quality, including parameters affected by the use of flocculants. Industries must maintain detailed records of their wastewater treatment processes, including the types and quantities of chemicals used. This information may be subject to periodic audits by regulatory authorities to ensure compliance with environmental standards.

In recent years, there has been a trend towards promoting the use of more sustainable and biodegradable flocculants. While sodium silicate is generally considered less harmful than some synthetic alternatives, regulations may encourage or mandate the exploration of even more environmentally friendly options where feasible.

International agreements and conventions, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal, can also influence national regulations on industrial effluent treatment. These agreements often set global standards for waste management and pollution control, which may indirectly affect the use of flocculants in industrial processes.

In many countries, the discharge of industrial effluents is regulated by comprehensive environmental protection laws. These laws typically set limits on the concentration of pollutants in discharged water, including suspended solids, heavy metals, and organic compounds. The use of flocculants like sodium silicate must comply with these limits, ensuring that the treated effluent meets the required water quality standards before release into the environment.

Specific regulations often address the use of chemical additives in wastewater treatment processes. Sodium silicate, being a chemical flocculant, falls under this category. Regulatory bodies may require industries to obtain permits or approvals for the use of such chemicals, demonstrating that their application will not have adverse effects on the receiving water bodies or downstream ecosystems.

Environmental impact assessments are frequently mandated for industrial facilities, including their wastewater treatment systems. These assessments evaluate the potential environmental consequences of using flocculants like sodium silicate, considering factors such as toxicity to aquatic life, bioaccumulation potential, and long-term ecological impacts.

Many jurisdictions have adopted the "polluter pays" principle, which holds industries responsible for the costs associated with pollution prevention and control. This principle encourages the adoption of more efficient and environmentally friendly treatment technologies, potentially influencing the choice of flocculants used in industrial effluent treatment.

Regulations often require regular monitoring and reporting of effluent quality, including parameters affected by the use of flocculants. Industries must maintain detailed records of their wastewater treatment processes, including the types and quantities of chemicals used. This information may be subject to periodic audits by regulatory authorities to ensure compliance with environmental standards.

In recent years, there has been a trend towards promoting the use of more sustainable and biodegradable flocculants. While sodium silicate is generally considered less harmful than some synthetic alternatives, regulations may encourage or mandate the exploration of even more environmentally friendly options where feasible.

International agreements and conventions, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal, can also influence national regulations on industrial effluent treatment. These agreements often set global standards for waste management and pollution control, which may indirectly affect the use of flocculants in industrial processes.

Cost-Benefit Analysis of Sodium Silicate Flocculants

The cost-benefit analysis of sodium silicate flocculants in industrial effluent treatment reveals a complex interplay of economic and environmental factors. Initial investment costs for implementing sodium silicate-based flocculation systems are generally lower compared to alternative flocculants, such as synthetic polymers or metal salts. The raw materials for sodium silicate production are abundant and relatively inexpensive, contributing to its cost-effectiveness.

Operational costs associated with sodium silicate flocculants are also favorable. The dosage requirements are typically lower than those of other flocculants, reducing the overall chemical consumption and associated expenses. Additionally, sodium silicate's stability and long shelf life minimize storage and handling costs, further enhancing its economic appeal.

The efficiency of sodium silicate in removing suspended solids and reducing turbidity in industrial effluents translates to improved water quality and reduced environmental impact. This can lead to significant cost savings in terms of regulatory compliance and potential fines avoidance. Moreover, the treated water often meets standards for reuse in industrial processes, offering opportunities for water conservation and reduced freshwater procurement costs.

However, the alkaline nature of sodium silicate may necessitate pH adjustment in some applications, potentially incurring additional chemical and equipment costs. The effectiveness of sodium silicate can also be influenced by the specific characteristics of the industrial effluent, such as pH, temperature, and the presence of interfering substances. In certain cases, this may require process optimization or the use of complementary flocculants, impacting the overall cost structure.

From an environmental perspective, sodium silicate flocculants offer several benefits. They are non-toxic, biodegradable, and do not introduce harmful substances into the treated water or resulting sludge. This eco-friendly profile can contribute to a positive corporate image and potentially open doors to green certifications or incentives, indirectly benefiting the company's bottom line.

The sludge generated from sodium silicate flocculation is generally less voluminous and easier to dewater compared to some alternative treatments. This can lead to reduced sludge handling and disposal costs, which often represent a significant portion of wastewater treatment expenses. Furthermore, the silica-rich sludge may have potential applications in construction materials or soil amendments, offering possibilities for value recovery.

In conclusion, the cost-benefit analysis of sodium silicate flocculants demonstrates a favorable economic profile in many industrial effluent treatment scenarios. While the specific benefits may vary depending on the application and local conditions, the combination of low initial and operational costs, environmental compatibility, and potential for resource recovery positions sodium silicate as an attractive option for industrial wastewater management.

Operational costs associated with sodium silicate flocculants are also favorable. The dosage requirements are typically lower than those of other flocculants, reducing the overall chemical consumption and associated expenses. Additionally, sodium silicate's stability and long shelf life minimize storage and handling costs, further enhancing its economic appeal.

The efficiency of sodium silicate in removing suspended solids and reducing turbidity in industrial effluents translates to improved water quality and reduced environmental impact. This can lead to significant cost savings in terms of regulatory compliance and potential fines avoidance. Moreover, the treated water often meets standards for reuse in industrial processes, offering opportunities for water conservation and reduced freshwater procurement costs.

However, the alkaline nature of sodium silicate may necessitate pH adjustment in some applications, potentially incurring additional chemical and equipment costs. The effectiveness of sodium silicate can also be influenced by the specific characteristics of the industrial effluent, such as pH, temperature, and the presence of interfering substances. In certain cases, this may require process optimization or the use of complementary flocculants, impacting the overall cost structure.

From an environmental perspective, sodium silicate flocculants offer several benefits. They are non-toxic, biodegradable, and do not introduce harmful substances into the treated water or resulting sludge. This eco-friendly profile can contribute to a positive corporate image and potentially open doors to green certifications or incentives, indirectly benefiting the company's bottom line.

The sludge generated from sodium silicate flocculation is generally less voluminous and easier to dewater compared to some alternative treatments. This can lead to reduced sludge handling and disposal costs, which often represent a significant portion of wastewater treatment expenses. Furthermore, the silica-rich sludge may have potential applications in construction materials or soil amendments, offering possibilities for value recovery.

In conclusion, the cost-benefit analysis of sodium silicate flocculants demonstrates a favorable economic profile in many industrial effluent treatment scenarios. While the specific benefits may vary depending on the application and local conditions, the combination of low initial and operational costs, environmental compatibility, and potential for resource recovery positions sodium silicate as an attractive option for industrial wastewater management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!