Sodium silicate-based anti-corrosion solutions for marine environments

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Marine Corrosion Protection Background and Objectives

Marine corrosion is a pervasive and costly problem that affects various industries, particularly those operating in coastal and offshore environments. The harsh marine environment, characterized by high salinity, humidity, and temperature fluctuations, accelerates the degradation of materials, leading to significant economic losses and safety concerns. As global maritime activities continue to expand, the need for effective and sustainable anti-corrosion solutions has become increasingly critical.

The evolution of marine corrosion protection technologies has seen significant advancements over the years. Traditional methods such as cathodic protection and protective coatings have been widely used but often come with limitations in terms of durability, environmental impact, and cost-effectiveness. In recent years, there has been a growing interest in developing more innovative and eco-friendly solutions to combat marine corrosion.

Sodium silicate-based anti-corrosion solutions have emerged as a promising alternative in this field. These solutions offer several advantages, including their non-toxic nature, abundance of raw materials, and potential for long-lasting protection. The use of sodium silicate in marine environments builds upon its established applications in other industries, where it has demonstrated excellent corrosion inhibition properties.

The primary objective of researching sodium silicate-based anti-corrosion solutions for marine environments is to develop a highly effective, environmentally friendly, and economically viable method to protect marine structures and equipment from corrosion. This research aims to address the limitations of current anti-corrosion technologies while leveraging the unique properties of sodium silicate compounds.

Key goals of this research include optimizing the composition and application methods of sodium silicate-based solutions for maximum effectiveness in marine conditions, investigating the long-term performance and durability of these solutions under various environmental stresses, and assessing their compatibility with different materials commonly used in marine applications. Additionally, the research seeks to explore potential synergies between sodium silicate-based solutions and existing corrosion protection methods to create comprehensive and robust anti-corrosion systems.

By focusing on sodium silicate-based solutions, this research aligns with the growing trend towards sustainable and environmentally responsible technologies in the marine industry. It also addresses the increasing regulatory pressures to reduce the use of toxic substances in marine environments, positioning sodium silicate-based anti-corrosion solutions as a forward-looking approach to marine asset protection.

The evolution of marine corrosion protection technologies has seen significant advancements over the years. Traditional methods such as cathodic protection and protective coatings have been widely used but often come with limitations in terms of durability, environmental impact, and cost-effectiveness. In recent years, there has been a growing interest in developing more innovative and eco-friendly solutions to combat marine corrosion.

Sodium silicate-based anti-corrosion solutions have emerged as a promising alternative in this field. These solutions offer several advantages, including their non-toxic nature, abundance of raw materials, and potential for long-lasting protection. The use of sodium silicate in marine environments builds upon its established applications in other industries, where it has demonstrated excellent corrosion inhibition properties.

The primary objective of researching sodium silicate-based anti-corrosion solutions for marine environments is to develop a highly effective, environmentally friendly, and economically viable method to protect marine structures and equipment from corrosion. This research aims to address the limitations of current anti-corrosion technologies while leveraging the unique properties of sodium silicate compounds.

Key goals of this research include optimizing the composition and application methods of sodium silicate-based solutions for maximum effectiveness in marine conditions, investigating the long-term performance and durability of these solutions under various environmental stresses, and assessing their compatibility with different materials commonly used in marine applications. Additionally, the research seeks to explore potential synergies between sodium silicate-based solutions and existing corrosion protection methods to create comprehensive and robust anti-corrosion systems.

By focusing on sodium silicate-based solutions, this research aligns with the growing trend towards sustainable and environmentally responsible technologies in the marine industry. It also addresses the increasing regulatory pressures to reduce the use of toxic substances in marine environments, positioning sodium silicate-based anti-corrosion solutions as a forward-looking approach to marine asset protection.

Market Analysis for Marine Anti-Corrosion Solutions

The marine anti-corrosion solutions market is experiencing significant growth, driven by the increasing demand for protective coatings in offshore structures, ships, and coastal infrastructure. The global market for marine coatings was valued at $3.31 billion in 2020 and is projected to reach $5.37 billion by 2028, growing at a CAGR of 6.2% from 2021 to 2028. This growth is primarily attributed to the expansion of maritime trade, rising investments in offshore oil and gas exploration, and the growing focus on sustainable and environmentally friendly anti-corrosion solutions.

Sodium silicate-based anti-corrosion solutions are gaining traction in the marine industry due to their eco-friendly nature and effectiveness in harsh marine environments. These solutions offer excellent corrosion resistance, durability, and cost-effectiveness compared to traditional anti-corrosion methods. The market for sodium silicate-based coatings is expected to witness substantial growth in the coming years, with a projected CAGR of 5.8% from 2021 to 2026.

The Asia-Pacific region dominates the marine anti-corrosion solutions market, accounting for over 40% of the global market share. This is primarily due to the presence of major shipbuilding nations such as China, South Korea, and Japan, as well as the rapid growth of offshore oil and gas activities in the region. North America and Europe follow closely, driven by stringent environmental regulations and the need for advanced corrosion protection in aging maritime infrastructure.

Key market drivers include the increasing focus on extending the lifespan of marine assets, rising awareness about the economic impact of corrosion, and the growing adoption of advanced coating technologies. The shipping industry, in particular, is a major consumer of anti-corrosion solutions, with an estimated annual spend of $2.5 billion on protective coatings.

However, the market faces challenges such as volatile raw material prices, stringent environmental regulations, and the need for continuous innovation to meet evolving industry requirements. The COVID-19 pandemic has also impacted the market, causing supply chain disruptions and temporary slowdowns in shipbuilding and offshore activities.

Despite these challenges, the future outlook for sodium silicate-based anti-corrosion solutions in marine environments remains promising. The shift towards sustainable and non-toxic alternatives, coupled with ongoing research and development efforts, is expected to drive market growth. Emerging applications in renewable energy sectors, such as offshore wind farms, are also creating new opportunities for market expansion.

Sodium silicate-based anti-corrosion solutions are gaining traction in the marine industry due to their eco-friendly nature and effectiveness in harsh marine environments. These solutions offer excellent corrosion resistance, durability, and cost-effectiveness compared to traditional anti-corrosion methods. The market for sodium silicate-based coatings is expected to witness substantial growth in the coming years, with a projected CAGR of 5.8% from 2021 to 2026.

The Asia-Pacific region dominates the marine anti-corrosion solutions market, accounting for over 40% of the global market share. This is primarily due to the presence of major shipbuilding nations such as China, South Korea, and Japan, as well as the rapid growth of offshore oil and gas activities in the region. North America and Europe follow closely, driven by stringent environmental regulations and the need for advanced corrosion protection in aging maritime infrastructure.

Key market drivers include the increasing focus on extending the lifespan of marine assets, rising awareness about the economic impact of corrosion, and the growing adoption of advanced coating technologies. The shipping industry, in particular, is a major consumer of anti-corrosion solutions, with an estimated annual spend of $2.5 billion on protective coatings.

However, the market faces challenges such as volatile raw material prices, stringent environmental regulations, and the need for continuous innovation to meet evolving industry requirements. The COVID-19 pandemic has also impacted the market, causing supply chain disruptions and temporary slowdowns in shipbuilding and offshore activities.

Despite these challenges, the future outlook for sodium silicate-based anti-corrosion solutions in marine environments remains promising. The shift towards sustainable and non-toxic alternatives, coupled with ongoing research and development efforts, is expected to drive market growth. Emerging applications in renewable energy sectors, such as offshore wind farms, are also creating new opportunities for market expansion.

Current Challenges in Marine Corrosion Prevention

Marine corrosion prevention remains a significant challenge in the maritime industry, with the harsh saltwater environment constantly threatening the integrity of ships, offshore structures, and coastal installations. Despite advancements in anti-corrosion technologies, several key issues persist in effectively protecting marine assets from degradation.

One of the primary challenges is the aggressive nature of seawater, which contains high concentrations of chloride ions. These ions readily penetrate protective coatings and initiate corrosion processes, particularly in areas with compromised or damaged protective layers. The constant exposure to moisture, oxygen, and varying temperatures further accelerates corrosion rates, making it difficult to maintain long-term protection.

Another significant hurdle is the development of anti-corrosion solutions that can withstand the dynamic marine environment. Mechanical stresses from waves, currents, and impacts can cause coating failures, exposing underlying materials to corrosive elements. Additionally, marine growth and biofouling can compromise the effectiveness of protective coatings, necessitating frequent maintenance and reapplication.

The environmental impact of traditional anti-corrosion methods poses a growing concern. Many conventional coatings contain toxic compounds that can harm marine ecosystems. Stricter regulations on the use of environmentally harmful substances have led to the need for more sustainable, yet equally effective, corrosion prevention solutions.

Cost-effectiveness remains a significant challenge in marine corrosion prevention. The frequent need for maintenance, reapplication of coatings, and potential downtime for repairs can result in substantial operational expenses for maritime industries. Developing long-lasting, low-maintenance solutions that can reduce these costs while maintaining optimal protection is a key focus area for researchers and manufacturers.

The variability of marine environments across different geographical locations adds another layer of complexity. Anti-corrosion solutions that work well in temperate waters may not be as effective in tropical or arctic conditions. This necessitates the development of versatile protection systems that can adapt to diverse marine settings.

Lastly, the integration of new materials and technologies in marine structures presents unique corrosion challenges. As the industry moves towards using advanced composites and alloys, understanding their corrosion behavior and developing tailored protection strategies becomes crucial. This requires ongoing research and innovation in material science and corrosion prevention techniques.

One of the primary challenges is the aggressive nature of seawater, which contains high concentrations of chloride ions. These ions readily penetrate protective coatings and initiate corrosion processes, particularly in areas with compromised or damaged protective layers. The constant exposure to moisture, oxygen, and varying temperatures further accelerates corrosion rates, making it difficult to maintain long-term protection.

Another significant hurdle is the development of anti-corrosion solutions that can withstand the dynamic marine environment. Mechanical stresses from waves, currents, and impacts can cause coating failures, exposing underlying materials to corrosive elements. Additionally, marine growth and biofouling can compromise the effectiveness of protective coatings, necessitating frequent maintenance and reapplication.

The environmental impact of traditional anti-corrosion methods poses a growing concern. Many conventional coatings contain toxic compounds that can harm marine ecosystems. Stricter regulations on the use of environmentally harmful substances have led to the need for more sustainable, yet equally effective, corrosion prevention solutions.

Cost-effectiveness remains a significant challenge in marine corrosion prevention. The frequent need for maintenance, reapplication of coatings, and potential downtime for repairs can result in substantial operational expenses for maritime industries. Developing long-lasting, low-maintenance solutions that can reduce these costs while maintaining optimal protection is a key focus area for researchers and manufacturers.

The variability of marine environments across different geographical locations adds another layer of complexity. Anti-corrosion solutions that work well in temperate waters may not be as effective in tropical or arctic conditions. This necessitates the development of versatile protection systems that can adapt to diverse marine settings.

Lastly, the integration of new materials and technologies in marine structures presents unique corrosion challenges. As the industry moves towards using advanced composites and alloys, understanding their corrosion behavior and developing tailored protection strategies becomes crucial. This requires ongoing research and innovation in material science and corrosion prevention techniques.

Existing Sodium Silicate Anti-Corrosion Solutions

01 Sodium silicate-based corrosion inhibitors

Sodium silicate is widely used as a base for anti-corrosion solutions due to its ability to form protective films on metal surfaces. These solutions typically contain sodium silicate in combination with other additives to enhance their protective properties and durability. The silicate forms a barrier that prevents corrosive agents from reaching the metal surface, thus providing effective protection against corrosion.- Sodium silicate-based corrosion inhibitors: Sodium silicate is widely used as a base for anti-corrosion solutions due to its ability to form protective films on metal surfaces. These solutions typically contain sodium silicate in combination with other additives to enhance their protective properties. The silicate forms a barrier that prevents corrosive agents from reaching the metal surface, thus providing effective corrosion protection.

- Silicate-based coatings for metal protection: Silicate-based coatings are applied to metal surfaces to provide a durable protective layer against corrosion. These coatings often incorporate sodium silicate as a key component, along with other materials such as inorganic compounds or polymers. The resulting coating forms a hard, adherent layer that resists chemical attack and physical damage, effectively protecting the underlying metal from corrosion.

- Sodium silicate in anti-corrosion formulations for specific applications: Specialized anti-corrosion formulations containing sodium silicate are developed for specific industrial applications, such as cooling systems, boilers, or concrete reinforcement. These formulations are tailored to address the unique corrosion challenges in each environment, often combining sodium silicate with other corrosion inhibitors, pH adjusters, or scale inhibitors to provide comprehensive protection.

- Environmentally friendly anti-corrosion solutions: There is a growing trend towards developing environmentally friendly anti-corrosion solutions based on sodium silicate. These formulations aim to replace traditional, potentially harmful corrosion inhibitors with more sustainable alternatives. Sodium silicate, being non-toxic and biodegradable, serves as an excellent base for these green anti-corrosion products, which may also incorporate natural additives or bio-based compounds.

- Synergistic combinations with sodium silicate for enhanced corrosion protection: Research focuses on identifying synergistic combinations of sodium silicate with other compounds to enhance corrosion protection. These combinations may include organic inhibitors, nanoparticles, or other inorganic compounds that work in concert with sodium silicate to provide superior anti-corrosion performance. The resulting formulations often exhibit improved durability, broader spectrum protection, or self-healing properties compared to sodium silicate alone.

02 Silicate-based coatings for metal protection

Silicate-based coatings are applied to metal surfaces to create a protective layer against corrosion. These coatings often incorporate sodium silicate along with other components to improve adhesion, hardness, and resistance to various environmental factors. The coatings can be formulated to provide long-lasting protection for different types of metals and alloys in various industrial applications.Expand Specific Solutions03 Sodium silicate in anti-corrosion formulations for concrete

Sodium silicate is used in anti-corrosion formulations specifically designed for concrete structures. These formulations help protect reinforcing steel within concrete from corrosion by creating a passivating layer and reducing the penetration of corrosive agents. The silicate reacts with calcium hydroxide in concrete to form calcium silicate hydrate, which enhances the overall durability and corrosion resistance of the structure.Expand Specific Solutions04 Synergistic combinations with sodium silicate for enhanced corrosion protection

Anti-corrosion solutions often combine sodium silicate with other compounds to create synergistic effects and improve overall protection. These combinations may include organic corrosion inhibitors, polymers, or other inorganic compounds. The resulting formulations offer enhanced corrosion resistance, better adhesion to metal surfaces, and improved durability in various environmental conditions.Expand Specific Solutions05 Environmentally friendly sodium silicate-based corrosion inhibitors

There is a growing focus on developing environmentally friendly anti-corrosion solutions using sodium silicate as a key component. These formulations aim to replace traditional, potentially harmful corrosion inhibitors with more sustainable alternatives. The use of sodium silicate in combination with natural or biodegradable additives helps create effective anti-corrosion solutions that have minimal environmental impact while maintaining high performance standards.Expand Specific Solutions

Key Players in Marine Anti-Corrosion Industry

The research on sodium silicate-based anti-corrosion solutions for marine environments is in a growth phase, with increasing market size due to rising demand for corrosion protection in maritime industries. The technology is moderately mature, with ongoing advancements. Key players like Henkel AG & Co. KGaA, BASF Corp., and Arkema, Inc. are driving innovation in this field. Companies such as NOF Metal Coating Europe SA and Atotech Deutschland GmbH are also contributing to the development of specialized coatings. Academic institutions like Zhejiang University and Guangdong Ocean University are collaborating with industry partners to enhance the effectiveness of these solutions, indicating a competitive and evolving landscape in this sector.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed a novel sodium silicate-based anti-corrosion solution specifically tailored for marine environments. Their approach utilizes a water-based formulation that combines sodium silicate with organic polymers and corrosion inhibitors. This hybrid system creates a dense, cross-linked network that provides excellent barrier properties against corrosive agents[4]. Henkel's solution incorporates a self-healing mechanism, where the sodium silicate reacts with moisture to form a protective layer in areas of damage or micro-cracks[6]. The company has also developed a proprietary application process that ensures optimal curing and adhesion of the coating in high-humidity marine environments. Field tests have shown that Henkel's solution can provide up to 10 years of corrosion protection in severe marine conditions, significantly outperforming traditional epoxy-based coatings[7].

Strengths: Environmentally friendly water-based formulation, self-healing properties, and long-lasting protection. Weaknesses: May require specialized application equipment and training for optimal performance.

BASF Corp.

Technical Solution: BASF Corp. has developed advanced sodium silicate-based anti-corrosion solutions for marine environments. Their approach involves a multi-layer coating system that incorporates sodium silicate as a key component. The base layer consists of a zinc-rich primer that provides cathodic protection. This is followed by an intermediate layer containing sodium silicate, which forms a protective barrier and enhances adhesion. The top coat is a high-performance polymer that offers additional protection against UV radiation and chemical exposure[1][3]. BASF's solution also incorporates nano-sized silica particles into the sodium silicate layer, which improves its density and reduces permeability to corrosive agents[5]. The company has conducted extensive field tests in various marine environments, demonstrating significant improvements in corrosion resistance compared to traditional coating systems[2].

Strengths: Excellent long-term corrosion protection, environmentally friendly formulation, and proven performance in harsh marine conditions. Weaknesses: Higher initial cost compared to some conventional coatings and potential for longer curing times in certain environmental conditions.

Innovative Sodium Silicate Formulations for Marine Use

Corrosion inhibitor for mg and mg-alloys

PatentWO2010025567A1

Innovation

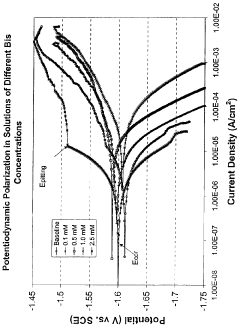

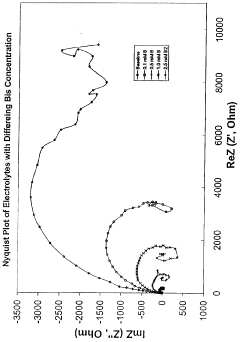

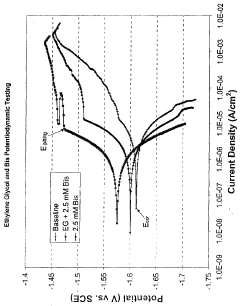

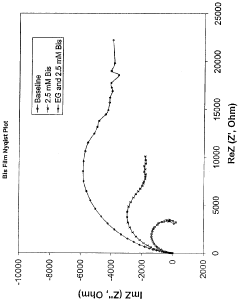

- A composition comprising hydrolyzed Bis-3 silane, an organic co-solvent, and an emulsifying agent is used to form a cross-linked Si-O-Si network without a curing step, which can be added to aqueous solutions to inhibit corrosion in high chloride environments, including seawater and engine coolants.

Coating compositions

PatentInactiveUS6992120B2

Innovation

- Development of seawater-erodible copolymers containing aliphatic silylacrylate monomers at levels between 5 to 22 mol percent, combined with ethylenically unsaturated monomers, to achieve an erosion rate of 2 to 15 μm/month, enabling self-polishing antifoulant marine coatings.

Environmental Impact of Anti-Corrosion Solutions

The environmental impact of sodium silicate-based anti-corrosion solutions in marine environments is a critical consideration for their widespread adoption. These solutions offer promising protection against corrosion, but their potential effects on marine ecosystems must be carefully evaluated.

Sodium silicate-based coatings form a protective barrier on metal surfaces, effectively reducing corrosion rates in seawater. This can lead to a significant decrease in the release of metal ions and corrosion byproducts into marine environments. Consequently, the use of these solutions may help mitigate the negative impacts of metal pollution on marine flora and fauna.

However, the introduction of sodium silicate into marine ecosystems may alter local pH levels and silica concentrations. While silica is naturally present in seawater, excessive amounts could potentially disrupt the balance of marine microorganisms, particularly diatoms and other silica-dependent species. The long-term effects of increased silica levels on marine food webs and ecosystem dynamics require further investigation.

The production and application of sodium silicate-based solutions also have environmental implications. The manufacturing process of sodium silicate involves high-temperature reactions, which can contribute to carbon emissions if not managed sustainably. Additionally, the disposal of used or expired anti-corrosion solutions must be carefully controlled to prevent contamination of water bodies.

On the positive side, the extended lifespan of marine structures and vessels treated with sodium silicate-based solutions can indirectly benefit the environment. By reducing the frequency of repairs and replacements, these solutions can help decrease the overall environmental footprint associated with marine infrastructure maintenance.

The potential for bioaccumulation of silica compounds in marine organisms is another area that requires thorough examination. While silicon is generally considered non-toxic, the long-term effects of exposure to elevated levels of sodium silicate in marine food chains are not yet fully understood. Comprehensive studies on various trophic levels are necessary to assess any potential risks.

In conclusion, while sodium silicate-based anti-corrosion solutions show promise in protecting marine structures, their environmental impact must be carefully monitored and managed. Balancing the benefits of corrosion protection with potential ecological effects is crucial for sustainable implementation in marine environments. Future research should focus on optimizing formulations to minimize environmental risks while maximizing protective properties.

Sodium silicate-based coatings form a protective barrier on metal surfaces, effectively reducing corrosion rates in seawater. This can lead to a significant decrease in the release of metal ions and corrosion byproducts into marine environments. Consequently, the use of these solutions may help mitigate the negative impacts of metal pollution on marine flora and fauna.

However, the introduction of sodium silicate into marine ecosystems may alter local pH levels and silica concentrations. While silica is naturally present in seawater, excessive amounts could potentially disrupt the balance of marine microorganisms, particularly diatoms and other silica-dependent species. The long-term effects of increased silica levels on marine food webs and ecosystem dynamics require further investigation.

The production and application of sodium silicate-based solutions also have environmental implications. The manufacturing process of sodium silicate involves high-temperature reactions, which can contribute to carbon emissions if not managed sustainably. Additionally, the disposal of used or expired anti-corrosion solutions must be carefully controlled to prevent contamination of water bodies.

On the positive side, the extended lifespan of marine structures and vessels treated with sodium silicate-based solutions can indirectly benefit the environment. By reducing the frequency of repairs and replacements, these solutions can help decrease the overall environmental footprint associated with marine infrastructure maintenance.

The potential for bioaccumulation of silica compounds in marine organisms is another area that requires thorough examination. While silicon is generally considered non-toxic, the long-term effects of exposure to elevated levels of sodium silicate in marine food chains are not yet fully understood. Comprehensive studies on various trophic levels are necessary to assess any potential risks.

In conclusion, while sodium silicate-based anti-corrosion solutions show promise in protecting marine structures, their environmental impact must be carefully monitored and managed. Balancing the benefits of corrosion protection with potential ecological effects is crucial for sustainable implementation in marine environments. Future research should focus on optimizing formulations to minimize environmental risks while maximizing protective properties.

Cost-Benefit Analysis of Sodium Silicate Coatings

The cost-benefit analysis of sodium silicate coatings in marine environments reveals a complex interplay of economic factors and performance advantages. Initial application costs for sodium silicate-based solutions are generally lower compared to traditional anti-corrosion coatings, offering an attractive entry point for shipowners and marine infrastructure managers. The raw materials for sodium silicate coatings are abundant and relatively inexpensive, contributing to their cost-effectiveness.

In terms of durability, sodium silicate coatings demonstrate impressive longevity in marine settings, often outlasting conventional alternatives. This extended lifespan translates to reduced maintenance frequency and associated costs over time. The protective barrier formed by sodium silicate effectively shields underlying surfaces from corrosive elements, potentially extending the operational life of marine assets and deferring costly replacements.

Environmental considerations also factor into the cost-benefit equation. Sodium silicate coatings are generally eco-friendly, with minimal toxic components. This characteristic not only aligns with increasingly stringent environmental regulations but may also result in cost savings related to waste disposal and potential environmental fines.

However, the application process for sodium silicate coatings can be more labor-intensive and time-consuming compared to some alternatives. This may lead to higher initial labor costs and potentially extended downtime for vessels or structures during coating application. The specialized skills required for proper application might also necessitate investment in training or hiring of skilled personnel.

Performance-wise, sodium silicate coatings exhibit excellent adhesion and resistance to saltwater corrosion, potentially reducing the frequency and severity of corrosion-related repairs. This can lead to significant long-term savings in maintenance and repair costs. Additionally, the thermal insulation properties of some sodium silicate formulations may contribute to energy efficiency, particularly in temperature-controlled marine environments.

It's important to note that while sodium silicate coatings offer numerous benefits, they may not be suitable for all marine applications. Certain high-wear areas or surfaces subject to extreme mechanical stress might require alternative or supplementary protection methods. The cost-benefit analysis should, therefore, consider the specific requirements of each application scenario.

In conclusion, the cost-benefit analysis of sodium silicate coatings in marine environments generally favors their adoption, particularly when considering long-term economic and environmental factors. However, a thorough assessment of specific application requirements and potential trade-offs is essential for optimal decision-making in marine anti-corrosion strategies.

In terms of durability, sodium silicate coatings demonstrate impressive longevity in marine settings, often outlasting conventional alternatives. This extended lifespan translates to reduced maintenance frequency and associated costs over time. The protective barrier formed by sodium silicate effectively shields underlying surfaces from corrosive elements, potentially extending the operational life of marine assets and deferring costly replacements.

Environmental considerations also factor into the cost-benefit equation. Sodium silicate coatings are generally eco-friendly, with minimal toxic components. This characteristic not only aligns with increasingly stringent environmental regulations but may also result in cost savings related to waste disposal and potential environmental fines.

However, the application process for sodium silicate coatings can be more labor-intensive and time-consuming compared to some alternatives. This may lead to higher initial labor costs and potentially extended downtime for vessels or structures during coating application. The specialized skills required for proper application might also necessitate investment in training or hiring of skilled personnel.

Performance-wise, sodium silicate coatings exhibit excellent adhesion and resistance to saltwater corrosion, potentially reducing the frequency and severity of corrosion-related repairs. This can lead to significant long-term savings in maintenance and repair costs. Additionally, the thermal insulation properties of some sodium silicate formulations may contribute to energy efficiency, particularly in temperature-controlled marine environments.

It's important to note that while sodium silicate coatings offer numerous benefits, they may not be suitable for all marine applications. Certain high-wear areas or surfaces subject to extreme mechanical stress might require alternative or supplementary protection methods. The cost-benefit analysis should, therefore, consider the specific requirements of each application scenario.

In conclusion, the cost-benefit analysis of sodium silicate coatings in marine environments generally favors their adoption, particularly when considering long-term economic and environmental factors. However, a thorough assessment of specific application requirements and potential trade-offs is essential for optimal decision-making in marine anti-corrosion strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!