Sodium silicate in developing self-healing concrete technologies

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Concrete Background and Objectives

Self-healing concrete represents a groundbreaking advancement in construction technology, addressing the persistent challenge of concrete deterioration. This innovative material incorporates self-repairing mechanisms to autonomously heal cracks and fissures, potentially revolutionizing the durability and longevity of concrete structures. The development of self-healing concrete has gained significant momentum over the past two decades, driven by the need for more sustainable and resilient infrastructure.

The primary objective of research on sodium silicate in developing self-healing concrete technologies is to enhance the material's ability to repair itself without external intervention. Sodium silicate, also known as water glass, has emerged as a promising agent for this purpose due to its unique chemical properties and compatibility with concrete matrices. By incorporating sodium silicate into concrete mixtures, researchers aim to create a responsive system that can effectively seal cracks and prevent further deterioration.

The evolution of self-healing concrete technology can be traced back to the early 2000s when the concept first gained traction in academic circles. Initial studies focused on biological approaches, such as the use of bacteria to precipitate calcium carbonate. However, the exploration of chemical agents like sodium silicate has opened up new avenues for achieving more reliable and cost-effective self-healing mechanisms.

Current research efforts are directed towards optimizing the integration of sodium silicate into concrete mixtures, understanding the kinetics of the healing process, and evaluating the long-term performance of self-healed structures. The goal is to develop a technology that can significantly extend the service life of concrete infrastructure, reduce maintenance costs, and minimize the environmental impact associated with frequent repairs and replacements.

The potential applications of self-healing concrete with sodium silicate are vast, ranging from bridges and highways to marine structures and underground facilities. As urbanization continues to accelerate globally, the demand for durable and low-maintenance construction materials is expected to grow exponentially. This technology holds the promise of addressing critical infrastructure challenges while aligning with sustainability goals and resource conservation efforts.

In the context of sodium silicate research for self-healing concrete, key technical objectives include optimizing the concentration and distribution of sodium silicate within the concrete matrix, enhancing the triggering mechanisms for the healing process, and improving the overall efficiency and reliability of the self-repair function. Additionally, researchers are working to overcome challenges related to the long-term stability of sodium silicate in concrete and its performance under various environmental conditions.

The primary objective of research on sodium silicate in developing self-healing concrete technologies is to enhance the material's ability to repair itself without external intervention. Sodium silicate, also known as water glass, has emerged as a promising agent for this purpose due to its unique chemical properties and compatibility with concrete matrices. By incorporating sodium silicate into concrete mixtures, researchers aim to create a responsive system that can effectively seal cracks and prevent further deterioration.

The evolution of self-healing concrete technology can be traced back to the early 2000s when the concept first gained traction in academic circles. Initial studies focused on biological approaches, such as the use of bacteria to precipitate calcium carbonate. However, the exploration of chemical agents like sodium silicate has opened up new avenues for achieving more reliable and cost-effective self-healing mechanisms.

Current research efforts are directed towards optimizing the integration of sodium silicate into concrete mixtures, understanding the kinetics of the healing process, and evaluating the long-term performance of self-healed structures. The goal is to develop a technology that can significantly extend the service life of concrete infrastructure, reduce maintenance costs, and minimize the environmental impact associated with frequent repairs and replacements.

The potential applications of self-healing concrete with sodium silicate are vast, ranging from bridges and highways to marine structures and underground facilities. As urbanization continues to accelerate globally, the demand for durable and low-maintenance construction materials is expected to grow exponentially. This technology holds the promise of addressing critical infrastructure challenges while aligning with sustainability goals and resource conservation efforts.

In the context of sodium silicate research for self-healing concrete, key technical objectives include optimizing the concentration and distribution of sodium silicate within the concrete matrix, enhancing the triggering mechanisms for the healing process, and improving the overall efficiency and reliability of the self-repair function. Additionally, researchers are working to overcome challenges related to the long-term stability of sodium silicate in concrete and its performance under various environmental conditions.

Market Analysis for Self-Healing Concrete

The self-healing concrete market is experiencing significant growth driven by increasing infrastructure investments and the need for sustainable construction materials. This innovative technology addresses the persistent challenge of concrete deterioration, offering potential cost savings in maintenance and repair over the lifecycle of structures. The global self-healing concrete market is projected to expand rapidly, with estimates suggesting a compound annual growth rate exceeding 25% through 2030.

Key factors fueling market demand include the rising focus on infrastructure longevity, particularly in regions prone to harsh environmental conditions. Governments and private sector entities are increasingly recognizing the long-term economic benefits of self-healing concrete, despite its higher initial costs compared to traditional concrete. The technology's ability to reduce maintenance requirements and extend the service life of structures aligns well with sustainability goals, further driving adoption.

The construction industry, historically slow to embrace new technologies, is showing growing interest in self-healing concrete. This shift is partly due to stricter building codes and sustainability regulations in many countries. The market is seeing increased demand from various sectors, including transportation infrastructure (bridges, highways), marine structures, underground construction, and high-rise buildings.

Geographically, North America and Europe are currently leading the self-healing concrete market, with Asia-Pacific expected to show the fastest growth in the coming years. This regional growth is attributed to rapid urbanization, extensive infrastructure development projects, and increasing awareness of sustainable construction practices in countries like China and India.

The market for self-healing concrete incorporating sodium silicate is particularly promising. Sodium silicate-based systems offer advantages such as cost-effectiveness, ease of integration into existing concrete mixing processes, and proven efficacy in crack healing. These factors position sodium silicate as a key component in the broader self-healing concrete market, likely to capture a significant share as the technology gains wider acceptance.

However, challenges remain in market penetration. These include the need for more extensive long-term performance data, standardization of testing methods, and regulatory approvals. Additionally, educating stakeholders about the benefits and applications of self-healing concrete, particularly those utilizing sodium silicate, is crucial for market expansion. As research continues and more real-world applications demonstrate success, the market is expected to overcome these barriers, leading to broader adoption across the construction industry.

Key factors fueling market demand include the rising focus on infrastructure longevity, particularly in regions prone to harsh environmental conditions. Governments and private sector entities are increasingly recognizing the long-term economic benefits of self-healing concrete, despite its higher initial costs compared to traditional concrete. The technology's ability to reduce maintenance requirements and extend the service life of structures aligns well with sustainability goals, further driving adoption.

The construction industry, historically slow to embrace new technologies, is showing growing interest in self-healing concrete. This shift is partly due to stricter building codes and sustainability regulations in many countries. The market is seeing increased demand from various sectors, including transportation infrastructure (bridges, highways), marine structures, underground construction, and high-rise buildings.

Geographically, North America and Europe are currently leading the self-healing concrete market, with Asia-Pacific expected to show the fastest growth in the coming years. This regional growth is attributed to rapid urbanization, extensive infrastructure development projects, and increasing awareness of sustainable construction practices in countries like China and India.

The market for self-healing concrete incorporating sodium silicate is particularly promising. Sodium silicate-based systems offer advantages such as cost-effectiveness, ease of integration into existing concrete mixing processes, and proven efficacy in crack healing. These factors position sodium silicate as a key component in the broader self-healing concrete market, likely to capture a significant share as the technology gains wider acceptance.

However, challenges remain in market penetration. These include the need for more extensive long-term performance data, standardization of testing methods, and regulatory approvals. Additionally, educating stakeholders about the benefits and applications of self-healing concrete, particularly those utilizing sodium silicate, is crucial for market expansion. As research continues and more real-world applications demonstrate success, the market is expected to overcome these barriers, leading to broader adoption across the construction industry.

Sodium Silicate: Current State and Challenges

Sodium silicate, also known as water glass, has emerged as a promising agent in the development of self-healing concrete technologies. However, its current state and implementation face several challenges that require further research and innovation.

The use of sodium silicate in self-healing concrete has shown significant potential in enhancing the durability and longevity of concrete structures. When cracks form in concrete, sodium silicate can react with calcium hydroxide present in the cement matrix to form calcium silicate hydrate (C-S-H) gel. This gel fills the cracks, effectively sealing them and preventing further deterioration.

One of the primary challenges in utilizing sodium silicate for self-healing concrete is controlling its reactivity. The rapid reaction of sodium silicate with calcium hydroxide can lead to premature setting and reduced workability of the concrete mix. This issue necessitates careful consideration of the timing and method of sodium silicate incorporation into the concrete matrix.

Another significant challenge is ensuring the long-term effectiveness of the self-healing mechanism. While initial crack-sealing results are promising, questions remain about the durability of the healed cracks over extended periods and under various environmental conditions. Researchers are exploring ways to enhance the longevity of the healing effect, including the development of encapsulation techniques to protect the sodium silicate until it is needed.

The distribution and dispersion of sodium silicate within the concrete matrix pose additional challenges. Achieving uniform distribution is crucial for consistent self-healing performance throughout the concrete structure. Current research focuses on developing innovative methods for incorporating sodium silicate, such as microencapsulation or vascular networks, to ensure its availability at potential crack locations.

Environmental factors also present challenges in the application of sodium silicate for self-healing concrete. Temperature fluctuations, humidity levels, and exposure to various chemicals can affect the efficacy of the self-healing process. Researchers are investigating ways to optimize the performance of sodium silicate-based self-healing systems under diverse environmental conditions.

Cost-effectiveness remains a concern in the widespread adoption of sodium silicate-based self-healing concrete technologies. While the potential long-term benefits are significant, the initial costs associated with incorporating sodium silicate and developing suitable delivery systems can be higher than traditional concrete formulations. Ongoing research aims to develop more economical methods for large-scale implementation.

In conclusion, while sodium silicate shows great promise in self-healing concrete technologies, several challenges must be addressed to fully realize its potential. Continued research and development efforts are focused on overcoming these obstacles to create more efficient, durable, and cost-effective self-healing concrete solutions.

The use of sodium silicate in self-healing concrete has shown significant potential in enhancing the durability and longevity of concrete structures. When cracks form in concrete, sodium silicate can react with calcium hydroxide present in the cement matrix to form calcium silicate hydrate (C-S-H) gel. This gel fills the cracks, effectively sealing them and preventing further deterioration.

One of the primary challenges in utilizing sodium silicate for self-healing concrete is controlling its reactivity. The rapid reaction of sodium silicate with calcium hydroxide can lead to premature setting and reduced workability of the concrete mix. This issue necessitates careful consideration of the timing and method of sodium silicate incorporation into the concrete matrix.

Another significant challenge is ensuring the long-term effectiveness of the self-healing mechanism. While initial crack-sealing results are promising, questions remain about the durability of the healed cracks over extended periods and under various environmental conditions. Researchers are exploring ways to enhance the longevity of the healing effect, including the development of encapsulation techniques to protect the sodium silicate until it is needed.

The distribution and dispersion of sodium silicate within the concrete matrix pose additional challenges. Achieving uniform distribution is crucial for consistent self-healing performance throughout the concrete structure. Current research focuses on developing innovative methods for incorporating sodium silicate, such as microencapsulation or vascular networks, to ensure its availability at potential crack locations.

Environmental factors also present challenges in the application of sodium silicate for self-healing concrete. Temperature fluctuations, humidity levels, and exposure to various chemicals can affect the efficacy of the self-healing process. Researchers are investigating ways to optimize the performance of sodium silicate-based self-healing systems under diverse environmental conditions.

Cost-effectiveness remains a concern in the widespread adoption of sodium silicate-based self-healing concrete technologies. While the potential long-term benefits are significant, the initial costs associated with incorporating sodium silicate and developing suitable delivery systems can be higher than traditional concrete formulations. Ongoing research aims to develop more economical methods for large-scale implementation.

In conclusion, while sodium silicate shows great promise in self-healing concrete technologies, several challenges must be addressed to fully realize its potential. Continued research and development efforts are focused on overcoming these obstacles to create more efficient, durable, and cost-effective self-healing concrete solutions.

Sodium Silicate-Based Self-Healing Solutions

01 Self-healing concrete compositions using sodium silicate

Sodium silicate is incorporated into concrete mixtures to create self-healing properties. When cracks form, the sodium silicate reacts with calcium hydroxide in the concrete to form calcium silicate hydrate gel, which fills and seals the cracks. This enhances the durability and longevity of concrete structures.- Self-healing concrete compositions using sodium silicate: Concrete compositions incorporating sodium silicate for self-healing properties. These mixtures can autonomously repair cracks and damages, improving the durability and lifespan of concrete structures. The sodium silicate reacts with calcium hydroxide in the concrete to form calcium silicate hydrate, which fills and seals cracks.

- Encapsulation techniques for sodium silicate in self-healing materials: Methods for encapsulating sodium silicate within various carriers or microcapsules for use in self-healing materials. These techniques allow for the controlled release of the healing agent when cracks or damage occur, enhancing the effectiveness of the self-healing process.

- Self-healing coatings with sodium silicate: Development of self-healing coatings that incorporate sodium silicate as a healing agent. These coatings can automatically repair scratches, chips, or other forms of damage, extending the protective lifespan of the coated surface and reducing maintenance requirements.

- Sodium silicate-based self-healing systems for polymers and composites: Integration of sodium silicate into polymer matrices and composite materials to create self-healing capabilities. When damage occurs, the sodium silicate is released and reacts to form a healing product, restoring the material's integrity and mechanical properties.

- Optimization of sodium silicate concentration for self-healing efficiency: Research on determining the optimal concentration of sodium silicate in self-healing systems to maximize healing efficiency while maintaining the desired material properties. This includes studies on the effects of different sodium silicate ratios and their impact on the healing mechanism and overall material performance.

02 Encapsulation techniques for sodium silicate in self-healing materials

Various encapsulation methods are used to incorporate sodium silicate into self-healing materials. These include microencapsulation, vascular networks, and hollow fibers. The encapsulated sodium silicate is released when damage occurs, initiating the self-healing process.Expand Specific Solutions03 Self-healing coatings with sodium silicate

Sodium silicate is used in self-healing coatings for metal surfaces to prevent corrosion. When the coating is damaged, the sodium silicate reacts with metal ions to form a protective layer, effectively sealing the damaged area and preventing further corrosion.Expand Specific Solutions04 Sodium silicate-based self-healing geopolymers

Geopolymers incorporating sodium silicate exhibit self-healing properties. These materials can repair microcracks through the formation of new geopolymer products, enhancing their durability and mechanical properties over time.Expand Specific Solutions05 Smart self-healing systems using sodium silicate and complementary agents

Advanced self-healing systems combine sodium silicate with other agents such as bacteria, supplementary cementitious materials, or chemical activators. These combinations enhance the self-healing efficiency and broaden the range of applications for self-healing materials.Expand Specific Solutions

Key Players in Self-Healing Concrete Industry

The research on sodium silicate in developing self-healing concrete technologies is in its early stages, with the market still emerging. The global self-healing concrete market is projected to grow significantly, driven by increasing infrastructure investments and sustainability concerns. While the technology shows promise, it is not yet fully mature or widely adopted. Companies like Schlumberger, Worcester Polytechnic Institute, and Wuhan University of Technology are actively involved in research and development, focusing on improving the efficiency and cost-effectiveness of self-healing concrete solutions. As the technology advances, collaboration between academic institutions and industry players is likely to accelerate innovation and market adoption.

University Of Jinan

Technical Solution: University of Jinan has developed an innovative approach to self-healing concrete using sodium silicate. Their method involves encapsulating sodium silicate solution in microcapsules made from a biodegradable polymer. When cracks form in the concrete, these capsules rupture, releasing the sodium silicate. This compound reacts with calcium hydroxide in the concrete to form calcium silicate hydrate gel, effectively sealing the cracks[1]. The university's research has shown that this method can heal cracks up to 0.3 mm wide within 28 days, significantly improving the concrete's durability and reducing maintenance costs[2]. They have also explored combining this technique with other self-healing mechanisms, such as bacteria-based healing, to create a more robust and versatile self-healing concrete system[3].

Strengths: Effective crack-sealing, environmentally friendly due to biodegradable capsules, and potential for integration with other healing mechanisms. Weaknesses: Limited to smaller crack widths, and the long-term stability of encapsulated sodium silicate needs further investigation.

Wuhan University of Technology

Technical Solution: Wuhan University of Technology has pioneered a novel approach to self-healing concrete using sodium silicate-based microcapsules. Their research focuses on optimizing the encapsulation process to improve the stability and reactivity of sodium silicate. They have developed a double-layer microcapsule structure, with an outer layer of calcium alginate and an inner layer of silica gel, which enhances the protection of sodium silicate and controls its release rate[4]. This technology has demonstrated the ability to heal cracks up to 0.5 mm wide within 14 days under wet-dry cycles. Additionally, they have investigated the use of nano-silica to enhance the pozzolanic reaction of sodium silicate, further improving the healing efficiency[5]. Their studies have shown that this method can restore up to 85% of the original compressive strength in damaged concrete specimens[6].

Strengths: Advanced encapsulation technology, rapid healing of relatively large cracks, and significant strength recovery. Weaknesses: Complexity of the microcapsule production process and potential cost implications for large-scale application.

Core Innovations in Sodium Silicate Application

A self-curing concrete mix

PatentActiveIN201911024218A

Innovation

- A self-curing concrete mix comprising cement, fine aggregates, coarse aggregates, a self-curing agent (calcium lignosulfonate), and a superplasticizer, which reduces water usage and enhances strength and durability while eliminating the need for harmful waterproofing materials, maintaining strength in seawater exposure.

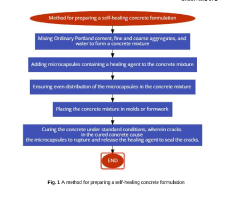

Self-healing concrete formulation: enhancing infrastructure durability

PatentPendingIN202421043358A

Innovation

- Incorporation of microcapsules containing healing agents like sodium silicate or epoxy resin into the concrete matrix, which rupture to release agents that react with moisture and concrete components to form a solid seal, autonomously repairing cracks and restoring structural integrity.

Environmental Impact Assessment

The environmental impact assessment of sodium silicate in developing self-healing concrete technologies reveals both positive and negative aspects. On the positive side, self-healing concrete has the potential to significantly reduce the need for repairs and maintenance of concrete structures, thereby decreasing the overall environmental footprint associated with construction and renovation activities. By extending the lifespan of concrete structures, this technology can lead to a reduction in raw material extraction, energy consumption, and greenhouse gas emissions typically associated with concrete production and replacement.

However, the production and use of sodium silicate in self-healing concrete also present environmental challenges. The manufacturing process of sodium silicate involves high-temperature reactions, which can be energy-intensive and contribute to carbon emissions. Additionally, the extraction of raw materials for sodium silicate production, such as sand and soda ash, may have localized environmental impacts, including habitat disruption and resource depletion.

Water consumption is another factor to consider in the environmental assessment. While self-healing concrete may reduce water usage in maintenance activities, the initial incorporation of sodium silicate into the concrete mix could potentially increase water demand during the production phase. This aspect requires careful evaluation to ensure that the long-term benefits outweigh any short-term increase in resource use.

The leaching of sodium silicate from concrete structures into surrounding soil and water bodies is a potential environmental concern that warrants further investigation. Although sodium silicate is generally considered non-toxic, its long-term effects on aquatic ecosystems and soil chemistry when released in large quantities are not fully understood. Monitoring and mitigation strategies may be necessary to address this issue.

From a lifecycle perspective, the use of sodium silicate in self-healing concrete technologies offers promising environmental benefits. The reduced need for repair and replacement of concrete structures can lead to significant savings in energy, materials, and associated emissions over the long term. However, a comprehensive life cycle assessment is crucial to quantify these benefits and compare them against the environmental costs of producing and incorporating sodium silicate into concrete.

In conclusion, while sodium silicate in self-healing concrete technologies presents notable environmental advantages, particularly in terms of resource conservation and emissions reduction, it also introduces new environmental considerations. Balancing these factors and optimizing the technology to maximize its positive environmental impact will be key to its successful implementation and widespread adoption in sustainable construction practices.

However, the production and use of sodium silicate in self-healing concrete also present environmental challenges. The manufacturing process of sodium silicate involves high-temperature reactions, which can be energy-intensive and contribute to carbon emissions. Additionally, the extraction of raw materials for sodium silicate production, such as sand and soda ash, may have localized environmental impacts, including habitat disruption and resource depletion.

Water consumption is another factor to consider in the environmental assessment. While self-healing concrete may reduce water usage in maintenance activities, the initial incorporation of sodium silicate into the concrete mix could potentially increase water demand during the production phase. This aspect requires careful evaluation to ensure that the long-term benefits outweigh any short-term increase in resource use.

The leaching of sodium silicate from concrete structures into surrounding soil and water bodies is a potential environmental concern that warrants further investigation. Although sodium silicate is generally considered non-toxic, its long-term effects on aquatic ecosystems and soil chemistry when released in large quantities are not fully understood. Monitoring and mitigation strategies may be necessary to address this issue.

From a lifecycle perspective, the use of sodium silicate in self-healing concrete technologies offers promising environmental benefits. The reduced need for repair and replacement of concrete structures can lead to significant savings in energy, materials, and associated emissions over the long term. However, a comprehensive life cycle assessment is crucial to quantify these benefits and compare them against the environmental costs of producing and incorporating sodium silicate into concrete.

In conclusion, while sodium silicate in self-healing concrete technologies presents notable environmental advantages, particularly in terms of resource conservation and emissions reduction, it also introduces new environmental considerations. Balancing these factors and optimizing the technology to maximize its positive environmental impact will be key to its successful implementation and widespread adoption in sustainable construction practices.

Standardization and Quality Control

The standardization and quality control of self-healing concrete technologies incorporating sodium silicate are crucial for ensuring consistent performance and reliability in construction applications. To achieve this, comprehensive testing protocols and quality assurance measures must be established and implemented throughout the production and application processes.

Standardization efforts should focus on developing uniform methods for incorporating sodium silicate into concrete mixtures. This includes specifying optimal concentrations, particle sizes, and distribution patterns within the concrete matrix. Additionally, guidelines for mixing procedures, curing conditions, and application techniques need to be established to ensure consistent results across different batches and projects.

Quality control measures should encompass both the raw materials and the finished product. For sodium silicate, this involves rigorous testing of its chemical composition, purity, and reactivity. Regular batch testing and certification processes should be implemented to verify that the sodium silicate meets the required specifications before incorporation into concrete mixtures.

In the production of self-healing concrete, quality control should extend to monitoring the uniformity of sodium silicate distribution within the mixture. Advanced imaging techniques, such as X-ray tomography or neutron radiography, can be employed to assess the spatial distribution of sodium silicate particles and identify any potential clustering or segregation issues.

Performance testing is a critical aspect of quality control for self-healing concrete. Standardized test methods need to be developed to evaluate the self-healing capacity, mechanical properties, and durability of the concrete under various environmental conditions. These tests should simulate real-world scenarios, including exposure to different types of cracks, moisture levels, and chemical agents.

To ensure long-term reliability, accelerated aging tests and durability assessments should be conducted to predict the performance of self-healing concrete over extended periods. This includes evaluating the stability of sodium silicate within the concrete matrix and its continued effectiveness in healing cracks over time.

Establishing industry-wide standards and certification processes for self-healing concrete technologies is essential for widespread adoption. This may involve collaboration between research institutions, industry associations, and regulatory bodies to develop consensus-based standards and testing protocols. Such standardization efforts will facilitate quality assurance, promote consistency in product performance, and build confidence among engineers, contractors, and end-users in the reliability of self-healing concrete incorporating sodium silicate.

Standardization efforts should focus on developing uniform methods for incorporating sodium silicate into concrete mixtures. This includes specifying optimal concentrations, particle sizes, and distribution patterns within the concrete matrix. Additionally, guidelines for mixing procedures, curing conditions, and application techniques need to be established to ensure consistent results across different batches and projects.

Quality control measures should encompass both the raw materials and the finished product. For sodium silicate, this involves rigorous testing of its chemical composition, purity, and reactivity. Regular batch testing and certification processes should be implemented to verify that the sodium silicate meets the required specifications before incorporation into concrete mixtures.

In the production of self-healing concrete, quality control should extend to monitoring the uniformity of sodium silicate distribution within the mixture. Advanced imaging techniques, such as X-ray tomography or neutron radiography, can be employed to assess the spatial distribution of sodium silicate particles and identify any potential clustering or segregation issues.

Performance testing is a critical aspect of quality control for self-healing concrete. Standardized test methods need to be developed to evaluate the self-healing capacity, mechanical properties, and durability of the concrete under various environmental conditions. These tests should simulate real-world scenarios, including exposure to different types of cracks, moisture levels, and chemical agents.

To ensure long-term reliability, accelerated aging tests and durability assessments should be conducted to predict the performance of self-healing concrete over extended periods. This includes evaluating the stability of sodium silicate within the concrete matrix and its continued effectiveness in healing cracks over time.

Establishing industry-wide standards and certification processes for self-healing concrete technologies is essential for widespread adoption. This may involve collaboration between research institutions, industry associations, and regulatory bodies to develop consensus-based standards and testing protocols. Such standardization efforts will facilitate quality assurance, promote consistency in product performance, and build confidence among engineers, contractors, and end-users in the reliability of self-healing concrete incorporating sodium silicate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!