Innovative Uses of Silicone Rubber in Fashion Design

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber in Fashion: Evolution and Objectives

Silicone rubber has emerged as a revolutionary material in the fashion industry, transforming the way designers approach garment construction and aesthetic expression. The evolution of silicone rubber in fashion can be traced back to the mid-20th century when it was primarily used in industrial applications. However, its unique properties, including flexibility, durability, and water resistance, soon caught the attention of innovative fashion designers.

The 1960s marked the beginning of silicone rubber's integration into fashion, with avant-garde designers experimenting with its potential in creating futuristic and unconventional garments. This period saw the material being used primarily as an accent or novelty feature in clothing and accessories. As manufacturing techniques improved in the following decades, silicone rubber became more versatile and accessible to a broader range of designers.

The 1990s and early 2000s witnessed a significant leap in silicone rubber's application in fashion. Designers began to explore its potential for creating form-fitting garments, utilizing its stretchability and ability to mold to the body's contours. This period also saw the development of more sophisticated silicone-based textiles, allowing for greater integration with traditional fabrics.

In recent years, the use of silicone rubber in fashion has expanded dramatically, driven by advancements in material science and a growing emphasis on sustainable and innovative design practices. Designers are now leveraging silicone rubber's unique properties to create waterproof and weatherproof clothing, develop new textures and surface treatments, and even incorporate smart technology into wearables.

The objectives of using silicone rubber in fashion design are multifaceted. Primarily, designers aim to push the boundaries of traditional garment construction, creating pieces that offer enhanced functionality without compromising on style. This includes developing clothing that is more durable, easier to care for, and adaptable to various environmental conditions.

Another key objective is to explore new aesthetic possibilities. Silicone rubber's malleability allows for the creation of three-dimensional structures and textures that are difficult or impossible to achieve with conventional fabrics. This opens up new avenues for artistic expression in fashion, enabling designers to create truly unique and innovative pieces.

Furthermore, the fashion industry is increasingly focusing on sustainability, and silicone rubber plays a role in this trend. Its durability and potential for recycling make it an attractive option for designers looking to create long-lasting, eco-friendly garments. The material's versatility also allows for the development of multifunctional clothing, potentially reducing the need for multiple specialized garments.

As technology continues to advance, the integration of smart features into clothing becomes an increasingly important objective. Silicone rubber's properties make it an ideal material for embedding sensors, conductive elements, and other tech components into garments, paving the way for a new era of interactive and responsive fashion.

The 1960s marked the beginning of silicone rubber's integration into fashion, with avant-garde designers experimenting with its potential in creating futuristic and unconventional garments. This period saw the material being used primarily as an accent or novelty feature in clothing and accessories. As manufacturing techniques improved in the following decades, silicone rubber became more versatile and accessible to a broader range of designers.

The 1990s and early 2000s witnessed a significant leap in silicone rubber's application in fashion. Designers began to explore its potential for creating form-fitting garments, utilizing its stretchability and ability to mold to the body's contours. This period also saw the development of more sophisticated silicone-based textiles, allowing for greater integration with traditional fabrics.

In recent years, the use of silicone rubber in fashion has expanded dramatically, driven by advancements in material science and a growing emphasis on sustainable and innovative design practices. Designers are now leveraging silicone rubber's unique properties to create waterproof and weatherproof clothing, develop new textures and surface treatments, and even incorporate smart technology into wearables.

The objectives of using silicone rubber in fashion design are multifaceted. Primarily, designers aim to push the boundaries of traditional garment construction, creating pieces that offer enhanced functionality without compromising on style. This includes developing clothing that is more durable, easier to care for, and adaptable to various environmental conditions.

Another key objective is to explore new aesthetic possibilities. Silicone rubber's malleability allows for the creation of three-dimensional structures and textures that are difficult or impossible to achieve with conventional fabrics. This opens up new avenues for artistic expression in fashion, enabling designers to create truly unique and innovative pieces.

Furthermore, the fashion industry is increasingly focusing on sustainability, and silicone rubber plays a role in this trend. Its durability and potential for recycling make it an attractive option for designers looking to create long-lasting, eco-friendly garments. The material's versatility also allows for the development of multifunctional clothing, potentially reducing the need for multiple specialized garments.

As technology continues to advance, the integration of smart features into clothing becomes an increasingly important objective. Silicone rubber's properties make it an ideal material for embedding sensors, conductive elements, and other tech components into garments, paving the way for a new era of interactive and responsive fashion.

Market Demand for Innovative Fashion Materials

The fashion industry is experiencing a growing demand for innovative materials that can enhance both the aesthetic appeal and functionality of clothing and accessories. Silicone rubber, with its unique properties, has emerged as a promising material in this context. Market research indicates a significant increase in consumer interest for fashion items incorporating novel materials, with a particular focus on those offering improved comfort, durability, and versatility.

The global market for smart textiles and innovative fabrics is projected to expand rapidly, driven by consumer preferences for clothing that adapts to various environmental conditions and personal needs. Silicone rubber, known for its flexibility, water resistance, and heat tolerance, aligns well with these market trends. Fashion designers and brands are increasingly exploring the potential of silicone rubber to create garments and accessories that stand out in a competitive market.

Consumer surveys reveal a rising interest in fashion items that offer enhanced performance features without compromising on style. This trend is particularly pronounced among younger demographics, who prioritize both fashion-forward designs and practical functionality in their clothing choices. Silicone rubber's ability to be molded into various shapes and textures while maintaining its protective properties makes it an attractive option for designers looking to meet these consumer demands.

The athleisure and sportswear segments have shown particularly strong potential for silicone rubber applications. As consumers increasingly seek clothing that transitions seamlessly between workout sessions and casual wear, materials that offer moisture-wicking properties, flexibility, and durability are in high demand. Silicone rubber's characteristics make it well-suited for integration into sportswear, potentially enhancing performance and comfort.

Furthermore, the luxury fashion sector has shown interest in innovative materials as a means of differentiation. High-end brands are exploring the use of silicone rubber in avant-garde designs, leveraging its unique tactile qualities and moldability to create distinctive textures and forms. This trend indicates a growing market for premium fashion items that incorporate novel materials as a key selling point.

The sustainability aspect of silicone rubber also aligns with increasing consumer demand for eco-friendly fashion options. As a durable and long-lasting material, silicone rubber has the potential to contribute to the creation of more sustainable fashion items with extended lifespans, addressing concerns about fast fashion and disposable clothing.

The global market for smart textiles and innovative fabrics is projected to expand rapidly, driven by consumer preferences for clothing that adapts to various environmental conditions and personal needs. Silicone rubber, known for its flexibility, water resistance, and heat tolerance, aligns well with these market trends. Fashion designers and brands are increasingly exploring the potential of silicone rubber to create garments and accessories that stand out in a competitive market.

Consumer surveys reveal a rising interest in fashion items that offer enhanced performance features without compromising on style. This trend is particularly pronounced among younger demographics, who prioritize both fashion-forward designs and practical functionality in their clothing choices. Silicone rubber's ability to be molded into various shapes and textures while maintaining its protective properties makes it an attractive option for designers looking to meet these consumer demands.

The athleisure and sportswear segments have shown particularly strong potential for silicone rubber applications. As consumers increasingly seek clothing that transitions seamlessly between workout sessions and casual wear, materials that offer moisture-wicking properties, flexibility, and durability are in high demand. Silicone rubber's characteristics make it well-suited for integration into sportswear, potentially enhancing performance and comfort.

Furthermore, the luxury fashion sector has shown interest in innovative materials as a means of differentiation. High-end brands are exploring the use of silicone rubber in avant-garde designs, leveraging its unique tactile qualities and moldability to create distinctive textures and forms. This trend indicates a growing market for premium fashion items that incorporate novel materials as a key selling point.

The sustainability aspect of silicone rubber also aligns with increasing consumer demand for eco-friendly fashion options. As a durable and long-lasting material, silicone rubber has the potential to contribute to the creation of more sustainable fashion items with extended lifespans, addressing concerns about fast fashion and disposable clothing.

Current Applications and Challenges in Silicone Fashion

Silicone rubber has emerged as a versatile material in fashion design, offering unique properties that have revolutionized the industry. Current applications of silicone in fashion span a wide range of products, from accessories to full garments. One of the most prominent uses is in the creation of waterproof and weather-resistant outerwear. Designers have incorporated silicone-coated fabrics into raincoats, jackets, and footwear, providing enhanced protection against the elements while maintaining a sleek aesthetic.

In the realm of haute couture, silicone has been employed to create avant-garde designs that push the boundaries of traditional fashion. Designers have utilized the material's moldable nature to craft sculptural pieces that defy conventional garment construction. These creations often feature intricate textures, three-dimensional forms, and translucent effects that are difficult to achieve with traditional textiles.

The lingerie and swimwear sectors have also embraced silicone for its skin-like properties and ability to create seamless, invisible edges. Bra inserts, adhesive bras, and nipple covers made from silicone have become staples in many wardrobes, offering comfort and discretion. In swimwear, silicone-based fabrics provide excellent water resistance and quick-drying capabilities.

Despite its numerous applications, the use of silicone in fashion faces several challenges. One significant issue is the material's environmental impact. Silicone is not biodegradable, raising concerns about its long-term effects on ecosystems. The fashion industry, already under scrutiny for its environmental footprint, must address these sustainability concerns to justify the continued use of silicone in clothing and accessories.

Another challenge lies in the manufacturing process of silicone-based fashion items. The production of silicone rubber requires specialized equipment and expertise, which can be costly and limit accessibility for smaller designers or brands. Additionally, the curing process for silicone can be time-consuming, potentially slowing down production timelines in an industry that values rapid turnaround.

Durability and maintenance of silicone fashion pieces also present challenges. While silicone is generally resistant to wear and tear, it can degrade over time, especially when exposed to extreme temperatures or certain chemicals. Cleaning and caring for silicone-infused garments may require special techniques, which can be inconvenient for consumers accustomed to traditional fabric care methods.

Lastly, there are aesthetic limitations to consider. While silicone offers unique design possibilities, its synthetic appearance may not appeal to all consumers or fit every fashion context. Designers must balance the innovative potential of silicone with market preferences and the need for wearable, commercially viable products.

In the realm of haute couture, silicone has been employed to create avant-garde designs that push the boundaries of traditional fashion. Designers have utilized the material's moldable nature to craft sculptural pieces that defy conventional garment construction. These creations often feature intricate textures, three-dimensional forms, and translucent effects that are difficult to achieve with traditional textiles.

The lingerie and swimwear sectors have also embraced silicone for its skin-like properties and ability to create seamless, invisible edges. Bra inserts, adhesive bras, and nipple covers made from silicone have become staples in many wardrobes, offering comfort and discretion. In swimwear, silicone-based fabrics provide excellent water resistance and quick-drying capabilities.

Despite its numerous applications, the use of silicone in fashion faces several challenges. One significant issue is the material's environmental impact. Silicone is not biodegradable, raising concerns about its long-term effects on ecosystems. The fashion industry, already under scrutiny for its environmental footprint, must address these sustainability concerns to justify the continued use of silicone in clothing and accessories.

Another challenge lies in the manufacturing process of silicone-based fashion items. The production of silicone rubber requires specialized equipment and expertise, which can be costly and limit accessibility for smaller designers or brands. Additionally, the curing process for silicone can be time-consuming, potentially slowing down production timelines in an industry that values rapid turnaround.

Durability and maintenance of silicone fashion pieces also present challenges. While silicone is generally resistant to wear and tear, it can degrade over time, especially when exposed to extreme temperatures or certain chemicals. Cleaning and caring for silicone-infused garments may require special techniques, which can be inconvenient for consumers accustomed to traditional fabric care methods.

Lastly, there are aesthetic limitations to consider. While silicone offers unique design possibilities, its synthetic appearance may not appeal to all consumers or fit every fashion context. Designers must balance the innovative potential of silicone with market preferences and the need for wearable, commercially viable products.

Existing Silicone Rubber Techniques in Fashion Design

01 Composition and formulation of silicone rubber

Silicone rubber compositions typically include silicone polymers, fillers, and curing agents. The formulation can be adjusted to achieve specific properties such as hardness, elasticity, and heat resistance. Various additives may be incorporated to enhance performance characteristics or processing abilities.- Composition and preparation of silicone rubber: Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to enhance specific properties such as strength, flexibility, or heat resistance.

- Modification of silicone rubber properties: The properties of silicone rubber can be modified through the addition of specific compounds or by altering the molecular structure. This can include improving thermal stability, increasing electrical conductivity, enhancing mechanical strength, or adjusting the rubber's hardness or elasticity to suit particular applications.

- Applications of silicone rubber: Silicone rubber finds wide-ranging applications across various industries due to its unique properties. It is used in medical devices, automotive parts, electrical insulation, cookware, and construction materials. Its biocompatibility, heat resistance, and durability make it particularly valuable in specialized fields such as aerospace and healthcare.

- Silicone rubber composites and blends: Silicone rubber can be combined with other materials to create composites or blends with enhanced properties. This includes mixing with other polymers, incorporating nanoparticles, or adding specific fillers to improve characteristics such as strength, flame retardancy, or chemical resistance. These composites often offer superior performance compared to pure silicone rubber.

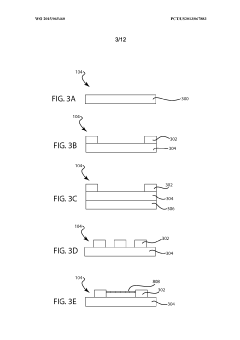

- Manufacturing processes for silicone rubber products: Various manufacturing processes are employed to produce silicone rubber products, including injection molding, extrusion, compression molding, and liquid silicone rubber (LSR) molding. Each process has its advantages and is suited to different types of products or production scales. Innovations in these processes focus on improving efficiency, reducing waste, and enhancing product quality.

02 Manufacturing processes for silicone rubber products

Different manufacturing techniques are employed to produce silicone rubber products, including molding, extrusion, and calendering. The choice of process depends on the desired shape, size, and properties of the final product. Curing methods such as heat curing or room temperature vulcanization are used to set the rubber.Expand Specific Solutions03 Modifications and improvements to silicone rubber

Ongoing research focuses on enhancing the properties of silicone rubber through various modifications. This includes the development of new polymer structures, incorporation of nanoparticles, and creation of hybrid materials. These modifications aim to improve mechanical strength, thermal stability, and chemical resistance.Expand Specific Solutions04 Applications of silicone rubber in various industries

Silicone rubber finds widespread use across multiple industries due to its unique properties. It is used in medical devices, automotive parts, electrical insulation, consumer products, and construction materials. The material's biocompatibility, durability, and resistance to extreme temperatures make it suitable for diverse applications.Expand Specific Solutions05 Environmental and safety considerations in silicone rubber production

The production and use of silicone rubber involve considerations for environmental impact and safety. Research is ongoing to develop more sustainable production methods, reduce waste, and improve the recyclability of silicone rubber products. Safety measures in manufacturing processes and end-use applications are also important aspects of silicone rubber technology.Expand Specific Solutions

Key Players in Silicone-Based Fashion Innovation

The innovative use of silicone rubber in fashion design is an emerging trend in the industry, currently in its early growth stage. The market size is expanding as designers explore the material's unique properties for creating avant-garde and functional clothing. Technologically, silicone rubber applications in fashion are still evolving, with companies like Shin-Etsu Chemical, Dow Silicones, and Wacker Chemie leading the way in material development. These firms are advancing the technology by improving silicone rubber's flexibility, durability, and aesthetic qualities for fashion applications. As the technology matures, we can expect to see more widespread adoption and creative uses of silicone rubber in mainstream fashion design.

Dow Silicones Corp.

Technical Solution: Dow Silicones Corp. has developed innovative silicone rubber materials specifically for fashion design applications. Their SILASTIC™ brand of silicone elastomers offers a range of properties suitable for creating unique textile effects. These materials can be used to create stretchable, breathable, and water-resistant fabrics that maintain their shape and elasticity over time. Dow's silicone rubbers can be formulated to achieve different levels of softness, durability, and transparency, allowing designers to create garments with novel textures and appearances. The company has also developed techniques for bonding silicone rubber to various fabrics, enabling the creation of hybrid materials that combine the benefits of traditional textiles with the unique properties of silicone[1][3].

Strengths: Versatility in material properties, ability to create unique textile effects, and strong bonding capabilities with other fabrics. Weaknesses: Potentially higher cost compared to traditional materials and specialized processing requirements.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has pioneered the use of silicone rubber in fashion design through its ELASTOSIL® line of products. The company has developed silicone rubber formulations that can be easily molded, printed, or coated onto fabrics to create 3D textures, patterns, and functional elements. Wacker's silicone rubbers offer excellent resistance to UV radiation and weathering, making them ideal for outdoor and sportswear applications. They have also introduced color-stable silicone rubbers that maintain their vibrancy even after prolonged exposure to sunlight. Wacker's innovations include silicone rubber compounds that can be used in 3D printing, allowing for the creation of complex, customized fashion accessories and embellishments[2][4].

Strengths: Advanced formulations for 3D textures and patterns, color stability, and compatibility with 3D printing technologies. Weaknesses: May require specialized equipment for processing and application in fashion design.

Breakthrough Silicone Technologies for Fashion

Flexibility-controlled composite material and method of manufacture

PatentWO2015065460A1

Innovation

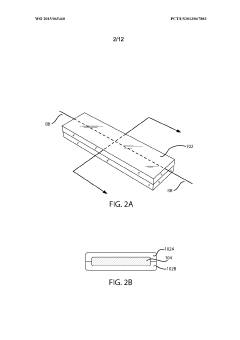

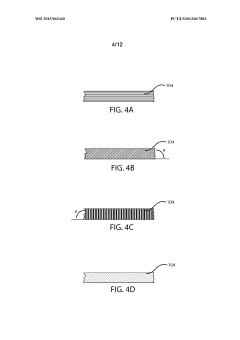

- A composite material is created by combining a flexible silicone rubber with a second material that resists elongation, such as fiber strands or woven fabric, which is encapsulated within the silicone rubber, allowing for controlled modification of flexibility characteristics through the orientation and configuration of the second material.

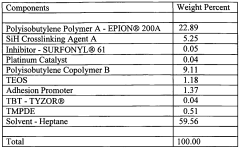

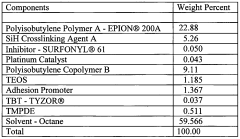

Improved PIB barrier coating composition for permeation reduction of silicone rubber parts

PatentWO2005035637A1

Innovation

- A cured polyisobutylene coating composition is applied to untreated silicone rubber substrates, comprising a polyisobutylene polymer, crosslinking agent, catalyst, and an adhesion promoter containing polysiloxane and epoxy silane, eliminating the need for surface treatment.

Sustainability Aspects of Silicone in Fashion

Silicone rubber has emerged as a promising material in sustainable fashion design, offering unique properties that align with the industry's growing focus on environmental responsibility. The sustainability aspects of silicone in fashion are multifaceted, encompassing both environmental and social considerations.

From an environmental perspective, silicone rubber demonstrates several advantages. Its durability and resistance to degradation contribute to longer-lasting garments and accessories, potentially reducing the need for frequent replacements and mitigating the fast fashion cycle. This longevity can significantly decrease the overall environmental impact of fashion products throughout their lifecycle.

Moreover, silicone rubber is inherently inert and non-toxic, posing minimal risk to ecosystems when disposed of properly. Unlike many synthetic materials derived from petroleum, silicone is primarily made from silicon, an abundant element found in sand. This reduces dependence on fossil fuels and potentially lowers the carbon footprint associated with material production.

The recyclability of silicone rubber further enhances its sustainability profile. While not biodegradable, silicone can be effectively recycled through specialized processes, allowing for the recovery and reuse of the material in various applications. This circular approach aligns with the principles of a sustainable economy and helps minimize waste in the fashion industry.

In terms of production, silicone rubber manufacturing generally requires less energy compared to many traditional textile materials. The lower energy consumption translates to reduced greenhouse gas emissions, contributing to the overall sustainability of fashion products incorporating silicone elements.

From a social sustainability standpoint, the use of silicone in fashion design can promote ethical production practices. The material's versatility allows for innovative designs that can be produced locally, potentially supporting small-scale manufacturers and artisans. This localized production model can foster community development and reduce the carbon footprint associated with long-distance transportation.

Additionally, the hypoallergenic nature of silicone makes it a suitable option for individuals with sensitive skin or allergies, promoting inclusivity in fashion. This aspect of social sustainability ensures that a wider range of consumers can access and enjoy fashion products without compromising their health or comfort.

However, it is important to note that the sustainability of silicone in fashion is not without challenges. The energy-intensive process of converting silicon into silicone rubber and the current limitations in widespread silicone recycling infrastructure present areas for improvement. As the fashion industry continues to evolve, addressing these challenges will be crucial in fully realizing the sustainable potential of silicone rubber in fashion design.

From an environmental perspective, silicone rubber demonstrates several advantages. Its durability and resistance to degradation contribute to longer-lasting garments and accessories, potentially reducing the need for frequent replacements and mitigating the fast fashion cycle. This longevity can significantly decrease the overall environmental impact of fashion products throughout their lifecycle.

Moreover, silicone rubber is inherently inert and non-toxic, posing minimal risk to ecosystems when disposed of properly. Unlike many synthetic materials derived from petroleum, silicone is primarily made from silicon, an abundant element found in sand. This reduces dependence on fossil fuels and potentially lowers the carbon footprint associated with material production.

The recyclability of silicone rubber further enhances its sustainability profile. While not biodegradable, silicone can be effectively recycled through specialized processes, allowing for the recovery and reuse of the material in various applications. This circular approach aligns with the principles of a sustainable economy and helps minimize waste in the fashion industry.

In terms of production, silicone rubber manufacturing generally requires less energy compared to many traditional textile materials. The lower energy consumption translates to reduced greenhouse gas emissions, contributing to the overall sustainability of fashion products incorporating silicone elements.

From a social sustainability standpoint, the use of silicone in fashion design can promote ethical production practices. The material's versatility allows for innovative designs that can be produced locally, potentially supporting small-scale manufacturers and artisans. This localized production model can foster community development and reduce the carbon footprint associated with long-distance transportation.

Additionally, the hypoallergenic nature of silicone makes it a suitable option for individuals with sensitive skin or allergies, promoting inclusivity in fashion. This aspect of social sustainability ensures that a wider range of consumers can access and enjoy fashion products without compromising their health or comfort.

However, it is important to note that the sustainability of silicone in fashion is not without challenges. The energy-intensive process of converting silicon into silicone rubber and the current limitations in widespread silicone recycling infrastructure present areas for improvement. As the fashion industry continues to evolve, addressing these challenges will be crucial in fully realizing the sustainable potential of silicone rubber in fashion design.

Wearability and Comfort Considerations

The integration of silicone rubber in fashion design presents unique challenges and opportunities in terms of wearability and comfort. Silicone rubber's inherent properties, such as flexibility, durability, and water resistance, make it an attractive material for innovative fashion applications. However, designers must carefully consider several factors to ensure that silicone-based garments and accessories meet the comfort requirements of wearers.

One of the primary considerations is the weight of silicone rubber. While it is generally lightweight, the cumulative effect of using silicone in larger garment areas can lead to increased overall weight. This necessitates strategic placement and thickness optimization to maintain comfort during extended wear. Designers often employ techniques such as creating hollow structures or using silicone as an accent rather than a primary material to mitigate weight concerns.

Breathability is another crucial factor in wearability. Silicone rubber is not naturally porous, which can lead to heat and moisture retention when worn against the skin. To address this, designers have developed innovative solutions such as incorporating micro-perforations or combining silicone with breathable fabrics. These hybrid approaches allow for the benefits of silicone while maintaining necessary air circulation and moisture wicking properties.

The texture and feel of silicone against the skin is an important aspect of comfort. While some individuals may find the smooth, cool touch of silicone pleasant, others might experience discomfort or skin irritation with prolonged contact. Fashion designers are exploring various surface treatments and blending silicone with other materials to create more skin-friendly textures. Additionally, the use of hypoallergenic silicone formulations can help reduce the risk of adverse skin reactions.

Flexibility and movement are critical for wearable fashion items. Silicone rubber's elasticity allows for excellent range of motion, but the thickness and formulation must be carefully calibrated to prevent restriction or excessive cling. Designers are experimenting with different silicone grades and structural designs to achieve the optimal balance between form-fitting properties and freedom of movement.

Thermal regulation is another consideration, as silicone can act as an insulator. This property can be advantageous in certain applications, such as cold-weather gear, but may pose challenges in warmer environments or during physical activity. To address this, some designers are incorporating phase-change materials or developing silicone composites with enhanced thermal management properties.

Lastly, the psychological comfort of wearing silicone-based fashion items must be considered. The unique aesthetic and tactile properties of silicone can influence the wearer's perception of comfort and confidence. Designers are focusing on creating visually appealing and culturally acceptable silicone-integrated designs that not only feel comfortable physically but also align with contemporary fashion sensibilities.

One of the primary considerations is the weight of silicone rubber. While it is generally lightweight, the cumulative effect of using silicone in larger garment areas can lead to increased overall weight. This necessitates strategic placement and thickness optimization to maintain comfort during extended wear. Designers often employ techniques such as creating hollow structures or using silicone as an accent rather than a primary material to mitigate weight concerns.

Breathability is another crucial factor in wearability. Silicone rubber is not naturally porous, which can lead to heat and moisture retention when worn against the skin. To address this, designers have developed innovative solutions such as incorporating micro-perforations or combining silicone with breathable fabrics. These hybrid approaches allow for the benefits of silicone while maintaining necessary air circulation and moisture wicking properties.

The texture and feel of silicone against the skin is an important aspect of comfort. While some individuals may find the smooth, cool touch of silicone pleasant, others might experience discomfort or skin irritation with prolonged contact. Fashion designers are exploring various surface treatments and blending silicone with other materials to create more skin-friendly textures. Additionally, the use of hypoallergenic silicone formulations can help reduce the risk of adverse skin reactions.

Flexibility and movement are critical for wearable fashion items. Silicone rubber's elasticity allows for excellent range of motion, but the thickness and formulation must be carefully calibrated to prevent restriction or excessive cling. Designers are experimenting with different silicone grades and structural designs to achieve the optimal balance between form-fitting properties and freedom of movement.

Thermal regulation is another consideration, as silicone can act as an insulator. This property can be advantageous in certain applications, such as cold-weather gear, but may pose challenges in warmer environments or during physical activity. To address this, some designers are incorporating phase-change materials or developing silicone composites with enhanced thermal management properties.

Lastly, the psychological comfort of wearing silicone-based fashion items must be considered. The unique aesthetic and tactile properties of silicone can influence the wearer's perception of comfort and confidence. Designers are focusing on creating visually appealing and culturally acceptable silicone-integrated designs that not only feel comfortable physically but also align with contemporary fashion sensibilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!