Investigating Anisotropic Growth in Hydroxyapatite Crystals for Biomedical Use

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydroxyapatite Crystal Growth Background and Objectives

Hydroxyapatite (HA) is a naturally occurring mineral form of calcium apatite, with the chemical formula Ca10(PO4)6(OH)2. It is the primary inorganic component of bone and teeth, making it a crucial material in the field of biomedicine. The study of hydroxyapatite crystal growth, particularly its anisotropic nature, has gained significant attention in recent years due to its potential applications in bone tissue engineering, dental implants, and drug delivery systems.

The development of hydroxyapatite-based materials has a rich history dating back to the 1960s when researchers first recognized its biocompatibility and osteoconductive properties. Since then, the field has evolved rapidly, with a focus on understanding and controlling the crystal growth process to enhance its performance in various biomedical applications.

Anisotropic growth in hydroxyapatite crystals refers to the preferential growth along specific crystallographic directions, resulting in non-uniform crystal shapes. This phenomenon is of particular interest as it can significantly influence the material's mechanical properties, bioactivity, and overall performance in biological environments.

The primary objective of investigating anisotropic growth in hydroxyapatite crystals for biomedical use is to gain a deeper understanding of the underlying mechanisms that govern this process. By elucidating these mechanisms, researchers aim to develop novel strategies for controlling crystal morphology, size, and orientation, which can lead to improved biomaterials with enhanced functionality.

Key goals in this research area include:

1. Identifying the factors that influence anisotropic growth, such as solution chemistry, temperature, pH, and the presence of organic additives.

2. Developing methods to precisely control the crystal growth process, allowing for the synthesis of HA crystals with tailored shapes and sizes.

3. Exploring the relationship between crystal morphology and biological performance, including cell adhesion, proliferation, and differentiation.

4. Investigating the potential of anisotropic HA crystals in drug delivery applications, particularly in terms of loading capacity and release kinetics.

5. Enhancing the mechanical properties of HA-based materials through controlled anisotropic growth, with the aim of improving their performance in load-bearing applications.

As the field progresses, researchers are increasingly focusing on interdisciplinary approaches, combining materials science, chemistry, biology, and engineering to address the complex challenges associated with hydroxyapatite crystal growth. The ultimate goal is to translate these fundamental insights into practical applications that can significantly improve patient outcomes in various biomedical fields.

The development of hydroxyapatite-based materials has a rich history dating back to the 1960s when researchers first recognized its biocompatibility and osteoconductive properties. Since then, the field has evolved rapidly, with a focus on understanding and controlling the crystal growth process to enhance its performance in various biomedical applications.

Anisotropic growth in hydroxyapatite crystals refers to the preferential growth along specific crystallographic directions, resulting in non-uniform crystal shapes. This phenomenon is of particular interest as it can significantly influence the material's mechanical properties, bioactivity, and overall performance in biological environments.

The primary objective of investigating anisotropic growth in hydroxyapatite crystals for biomedical use is to gain a deeper understanding of the underlying mechanisms that govern this process. By elucidating these mechanisms, researchers aim to develop novel strategies for controlling crystal morphology, size, and orientation, which can lead to improved biomaterials with enhanced functionality.

Key goals in this research area include:

1. Identifying the factors that influence anisotropic growth, such as solution chemistry, temperature, pH, and the presence of organic additives.

2. Developing methods to precisely control the crystal growth process, allowing for the synthesis of HA crystals with tailored shapes and sizes.

3. Exploring the relationship between crystal morphology and biological performance, including cell adhesion, proliferation, and differentiation.

4. Investigating the potential of anisotropic HA crystals in drug delivery applications, particularly in terms of loading capacity and release kinetics.

5. Enhancing the mechanical properties of HA-based materials through controlled anisotropic growth, with the aim of improving their performance in load-bearing applications.

As the field progresses, researchers are increasingly focusing on interdisciplinary approaches, combining materials science, chemistry, biology, and engineering to address the complex challenges associated with hydroxyapatite crystal growth. The ultimate goal is to translate these fundamental insights into practical applications that can significantly improve patient outcomes in various biomedical fields.

Biomedical Applications and Market Analysis

The biomedical applications of hydroxyapatite (HA) crystals with anisotropic growth have garnered significant attention in recent years due to their unique properties and potential to revolutionize various medical treatments. The market for HA-based biomaterials is experiencing robust growth, driven by increasing demand for advanced bone grafts, dental implants, and drug delivery systems.

In orthopedics, anisotropic HA crystals show promise in enhancing bone regeneration and improving the integration of implants with natural bone tissue. The elongated crystal structure mimics the natural architecture of bone, promoting faster healing and stronger mechanical properties. This has led to the development of novel bone graft substitutes and coatings for metallic implants, addressing the growing need for effective solutions in an aging population with rising incidences of osteoporosis and bone-related disorders.

The dental industry represents another significant market for anisotropic HA crystals. These materials are being incorporated into dental implants and restorative materials to improve osseointegration and long-term stability. The global dental implants market, valued at over $4 billion in 2020, is expected to see substantial growth, with HA-based materials playing a crucial role in this expansion.

In the field of drug delivery, anisotropic HA crystals offer unique advantages for controlled release systems. Their high surface area and tunable porosity allow for efficient drug loading and sustained release profiles. This application is particularly promising for the delivery of antibiotics, growth factors, and anti-cancer drugs, addressing the need for localized and targeted therapies in various medical conditions.

The global market for hydroxyapatite-based products is projected to reach $3.65 billion by 2025, with a compound annual growth rate of 6.1% from 2020 to 2025. The increasing adoption of minimally invasive surgical procedures and the rising prevalence of dental and orthopedic disorders are key factors driving this growth. North America currently holds the largest market share, followed by Europe and Asia-Pacific, with the latter expected to witness the fastest growth due to improving healthcare infrastructure and rising medical tourism.

However, challenges remain in scaling up the production of anisotropic HA crystals while maintaining consistent quality and properties. Regulatory hurdles and the need for extensive clinical trials also present barriers to market entry for new products. Despite these challenges, ongoing research and development efforts are focused on optimizing crystal growth techniques and exploring novel applications, indicating a promising future for anisotropic HA crystals in the biomedical field.

In orthopedics, anisotropic HA crystals show promise in enhancing bone regeneration and improving the integration of implants with natural bone tissue. The elongated crystal structure mimics the natural architecture of bone, promoting faster healing and stronger mechanical properties. This has led to the development of novel bone graft substitutes and coatings for metallic implants, addressing the growing need for effective solutions in an aging population with rising incidences of osteoporosis and bone-related disorders.

The dental industry represents another significant market for anisotropic HA crystals. These materials are being incorporated into dental implants and restorative materials to improve osseointegration and long-term stability. The global dental implants market, valued at over $4 billion in 2020, is expected to see substantial growth, with HA-based materials playing a crucial role in this expansion.

In the field of drug delivery, anisotropic HA crystals offer unique advantages for controlled release systems. Their high surface area and tunable porosity allow for efficient drug loading and sustained release profiles. This application is particularly promising for the delivery of antibiotics, growth factors, and anti-cancer drugs, addressing the need for localized and targeted therapies in various medical conditions.

The global market for hydroxyapatite-based products is projected to reach $3.65 billion by 2025, with a compound annual growth rate of 6.1% from 2020 to 2025. The increasing adoption of minimally invasive surgical procedures and the rising prevalence of dental and orthopedic disorders are key factors driving this growth. North America currently holds the largest market share, followed by Europe and Asia-Pacific, with the latter expected to witness the fastest growth due to improving healthcare infrastructure and rising medical tourism.

However, challenges remain in scaling up the production of anisotropic HA crystals while maintaining consistent quality and properties. Regulatory hurdles and the need for extensive clinical trials also present barriers to market entry for new products. Despite these challenges, ongoing research and development efforts are focused on optimizing crystal growth techniques and exploring novel applications, indicating a promising future for anisotropic HA crystals in the biomedical field.

Current Challenges in Anisotropic Hydroxyapatite Synthesis

The synthesis of anisotropic hydroxyapatite (HAp) crystals for biomedical applications faces several significant challenges. One of the primary obstacles is achieving precise control over crystal growth direction and morphology. The anisotropic growth of HAp is highly sensitive to synthesis conditions, making it difficult to consistently produce crystals with desired shapes and sizes.

A major challenge lies in the complex interplay between various synthesis parameters. Factors such as pH, temperature, reactant concentrations, and the presence of additives all significantly influence the growth kinetics and resulting crystal morphology. Slight variations in these parameters can lead to unpredictable changes in crystal shape and orientation, hampering reproducibility and scalability of the synthesis process.

The selection of appropriate precursors and additives presents another hurdle. While certain organic molecules and ions can promote anisotropic growth, their incorporation may alter the chemical composition and properties of the final HAp crystals. Balancing the benefits of shape control with the need for high purity and biocompatibility remains a significant challenge.

Controlling the nucleation and growth rates of HAp crystals is crucial for achieving desired anisotropic structures. However, the rapid precipitation kinetics of HAp often results in poorly controlled growth and the formation of irregular or agglomerated particles. Developing methods to slow down and regulate the crystallization process without compromising the final product quality is an ongoing challenge.

The characterization and quality control of anisotropic HAp crystals pose additional difficulties. Traditional bulk analysis techniques may not provide sufficient information about crystal orientation and surface properties. Advanced microscopy and spectroscopy methods are often required, which can be time-consuming and costly for routine quality assurance.

Scaling up the synthesis of anisotropic HAp crystals from laboratory to industrial production presents its own set of challenges. Maintaining uniform conditions throughout larger reaction volumes and ensuring consistent product quality across batches require careful process optimization and control strategies.

Lastly, the translation of anisotropic HAp crystals from synthesis to practical biomedical applications faces hurdles in terms of stability and performance. Ensuring that the unique properties of these crystals are preserved during processing, sterilization, and storage, while also meeting regulatory requirements for medical use, remains a significant challenge in the field.

A major challenge lies in the complex interplay between various synthesis parameters. Factors such as pH, temperature, reactant concentrations, and the presence of additives all significantly influence the growth kinetics and resulting crystal morphology. Slight variations in these parameters can lead to unpredictable changes in crystal shape and orientation, hampering reproducibility and scalability of the synthesis process.

The selection of appropriate precursors and additives presents another hurdle. While certain organic molecules and ions can promote anisotropic growth, their incorporation may alter the chemical composition and properties of the final HAp crystals. Balancing the benefits of shape control with the need for high purity and biocompatibility remains a significant challenge.

Controlling the nucleation and growth rates of HAp crystals is crucial for achieving desired anisotropic structures. However, the rapid precipitation kinetics of HAp often results in poorly controlled growth and the formation of irregular or agglomerated particles. Developing methods to slow down and regulate the crystallization process without compromising the final product quality is an ongoing challenge.

The characterization and quality control of anisotropic HAp crystals pose additional difficulties. Traditional bulk analysis techniques may not provide sufficient information about crystal orientation and surface properties. Advanced microscopy and spectroscopy methods are often required, which can be time-consuming and costly for routine quality assurance.

Scaling up the synthesis of anisotropic HAp crystals from laboratory to industrial production presents its own set of challenges. Maintaining uniform conditions throughout larger reaction volumes and ensuring consistent product quality across batches require careful process optimization and control strategies.

Lastly, the translation of anisotropic HAp crystals from synthesis to practical biomedical applications faces hurdles in terms of stability and performance. Ensuring that the unique properties of these crystals are preserved during processing, sterilization, and storage, while also meeting regulatory requirements for medical use, remains a significant challenge in the field.

Current Methods for Controlling Anisotropic Growth

01 Controlling crystal growth direction

Methods for controlling the anisotropic growth of hydroxyapatite crystals by manipulating growth conditions, such as temperature, pH, and additives. This allows for the preferential growth along specific crystallographic axes, resulting in elongated or plate-like crystal morphologies.- Controlled anisotropic growth of hydroxyapatite crystals: Methods for controlling the anisotropic growth of hydroxyapatite crystals, including the use of specific growth conditions, additives, and templates to influence crystal morphology and orientation. This approach allows for the tailoring of crystal properties for various applications in biomaterials and tissue engineering.

- Synthesis of hydroxyapatite nanostructures: Techniques for synthesizing hydroxyapatite nanostructures with controlled size, shape, and anisotropy. These methods often involve hydrothermal processes, sol-gel techniques, or biomimetic approaches to produce nanocrystals, nanorods, or other anisotropic forms of hydroxyapatite for use in biomedical applications.

- Surface modification of hydroxyapatite crystals: Processes for modifying the surface of hydroxyapatite crystals to enhance their properties or direct their growth. This can include the use of organic molecules, polymers, or other surface-active agents to influence crystal growth and orientation, resulting in anisotropic structures with improved functionality.

- Electrochemical deposition of hydroxyapatite: Methods for electrochemical deposition of hydroxyapatite coatings with controlled crystal orientation and anisotropy. These techniques allow for the formation of aligned crystal structures on various substrates, which can be beneficial for applications in implant coatings and bone tissue engineering.

- Biomimetic approaches for hydroxyapatite crystal growth: Strategies inspired by natural biomineralization processes to guide the anisotropic growth of hydroxyapatite crystals. These approaches often involve the use of organic matrices, proteins, or other biomolecules to mimic the conditions found in biological systems, resulting in highly controlled crystal growth and orientation.

02 Biomimetic synthesis approaches

Techniques inspired by natural biomineralization processes to achieve anisotropic growth of hydroxyapatite crystals. These methods often involve the use of organic templates or matrices to guide crystal growth and orientation, mimicking the formation of biological apatite structures.Expand Specific Solutions03 Electrochemical deposition methods

Electrochemical techniques for depositing hydroxyapatite crystals with controlled anisotropic growth. These methods utilize electric fields and carefully controlled electrolyte compositions to influence crystal nucleation and growth, resulting in oriented crystal structures.Expand Specific Solutions04 Hydrothermal synthesis techniques

High-pressure, high-temperature hydrothermal methods for synthesizing hydroxyapatite crystals with anisotropic growth. These techniques often employ specialized reactors and precise control of reaction parameters to achieve desired crystal morphologies and orientations.Expand Specific Solutions05 Surface modification and functionalization

Approaches for modifying the surface of hydroxyapatite crystals to promote anisotropic growth or to enhance specific properties. This may involve the use of surfactants, polymers, or other functional molecules to selectively inhibit or promote growth along certain crystal faces.Expand Specific Solutions

Key Players in Hydroxyapatite Research and Production

The investigation of anisotropic growth in hydroxyapatite crystals for biomedical use is in a developing stage, with significant potential for growth. The market is expanding due to increasing demand for advanced biomaterials in orthopedics and dentistry. While the technology is not fully mature, several key players are making substantial progress. Universities like Northwestern, MIT, and Kyoto University are leading academic research, while companies such as Promimic AB and Geistlich Pharma AG are focusing on commercial applications. The involvement of national research institutes like NIMS in Japan and AIST indicates strong governmental interest in advancing this technology.

Northwestern University

Technical Solution: Northwestern University has developed a novel approach to control the anisotropic growth of hydroxyapatite (HA) crystals for biomedical applications. Their method involves using organic modifiers and precise control of synthesis conditions to manipulate the crystal growth along specific crystallographic directions. The researchers have successfully produced HA nanocrystals with tailored aspect ratios and morphologies, ranging from nanorods to nanoplates[1]. These anisotropic HA crystals have shown enhanced mechanical properties and improved biological performance in bone tissue engineering applications[2]. The university has also explored the use of these crystals in drug delivery systems and dental materials, leveraging their unique surface properties and controlled dissolution rates[3].

Strengths: Precise control over crystal morphology, enhanced mechanical properties, and improved biological performance. Weaknesses: Potential scalability issues for large-scale production and the need for further in vivo studies to fully validate long-term biocompatibility.

Sichuan University

Technical Solution: Sichuan University has made significant strides in investigating anisotropic growth of hydroxyapatite crystals for biomedical use. Their research focuses on developing biomimetic approaches to synthesize HA crystals with controlled anisotropy. The university has pioneered a method using natural polymers as templates to guide the growth of HA crystals, mimicking the process observed in natural bone formation[4]. This approach has resulted in HA crystals with highly oriented c-axis growth, resembling the nanostructure of natural bone. Additionally, they have explored the incorporation of ionic substitutions, such as strontium and magnesium, to further enhance the biological properties of the anisotropic HA crystals[5]. The university has also developed composite scaffolds combining these anisotropic HA crystals with biodegradable polymers for bone tissue engineering applications[6].

Strengths: Biomimetic approach closely resembling natural bone structure, enhanced biological properties through ionic substitutions. Weaknesses: Potential challenges in maintaining consistent crystal orientation in large-scale production, and the need for extensive clinical trials to prove efficacy in vivo.

Innovative Approaches in Anisotropic Hydroxyapatite Synthesis

Process for modifying drug crystal formation

PatentInactiveUS20090209639A1

Innovation

- A process involving suspending acicular crystals in a solvent system that affects crystal habit, combined with temperature oscillation, to retard the preferred growth direction and enhance less preferred growth directions, thereby modifying the crystal habit and increasing bulk density without requiring additional steps like sonication or shear forces.

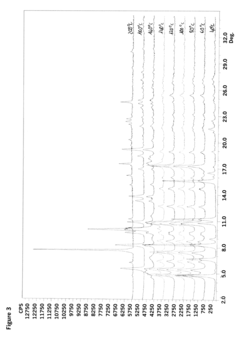

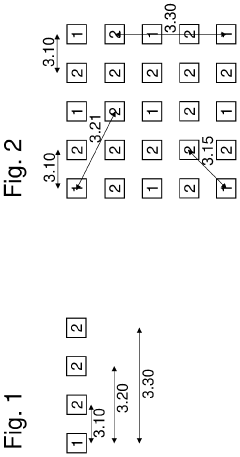

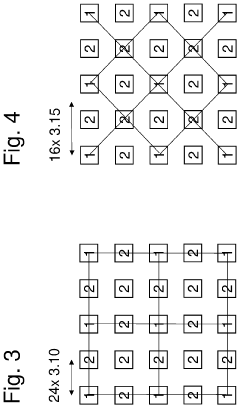

Non-invasive measurement of physiological parameters or substance concentrations in human tissue

PatentActiveUS20230349825A1

Innovation

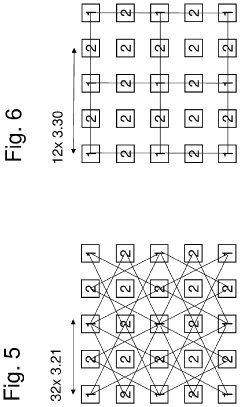

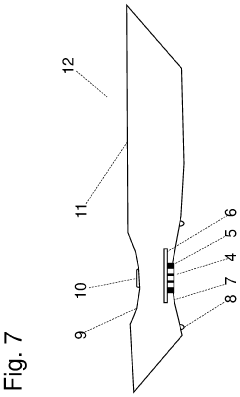

- A device with a planar arrangement of multiple optical emitters and detectors having different wavelength characteristics, allowing for a high spectral resolution and dynamic range, which reduces the influence of interfering substances and achieves precise, repeatable measurements by combining emitter-detector pairs with varying distances and orientations.

Regulatory Framework for Biomedical Hydroxyapatite Use

The regulatory framework for biomedical hydroxyapatite use is a critical aspect of the development and application of anisotropic hydroxyapatite crystals in medical settings. This framework encompasses various regulatory bodies, guidelines, and standards that govern the use of hydroxyapatite-based materials in biomedical applications.

At the forefront of this regulatory landscape is the U.S. Food and Drug Administration (FDA), which plays a pivotal role in overseeing the safety and efficacy of medical devices and materials. The FDA classifies hydroxyapatite-based products under different categories depending on their intended use and risk level. For instance, hydroxyapatite coatings on implants may be classified as Class II devices, requiring premarket notification (510(k)) before commercialization.

In the European Union, the regulatory framework is governed by the Medical Device Regulation (MDR) and the In Vitro Diagnostic Regulation (IVDR). These regulations set stringent requirements for the safety and performance of medical devices, including those incorporating hydroxyapatite. Manufacturers must demonstrate compliance with essential requirements and obtain CE marking before placing their products on the European market.

International standards, such as those developed by the International Organization for Standardization (ISO), provide crucial guidance for the production and testing of hydroxyapatite materials. ISO 13779 series, for example, specifically addresses hydroxyapatite implants, outlining requirements for their chemical composition, crystallinity, and mechanical properties.

The regulatory framework also encompasses good manufacturing practices (GMP) and quality management systems (QMS) specific to medical devices. These ensure that hydroxyapatite-based products are consistently produced and controlled according to quality standards appropriate for their intended use.

Biocompatibility testing is a fundamental component of the regulatory process for hydroxyapatite materials. Standards such as ISO 10993 provide guidelines for evaluating the biological safety of medical devices, including those containing hydroxyapatite. This involves a series of in vitro and in vivo tests to assess potential cytotoxicity, sensitization, and local tissue effects.

As research into anisotropic growth in hydroxyapatite crystals advances, regulatory bodies may need to adapt their frameworks to address novel properties and applications. This could involve developing new testing methodologies or revising existing guidelines to ensure the safety and efficacy of these advanced materials in biomedical use.

Regulatory compliance also extends to post-market surveillance and vigilance systems. Manufacturers are required to monitor the performance of their hydroxyapatite-based products in real-world settings and report any adverse events or safety concerns to the relevant authorities.

At the forefront of this regulatory landscape is the U.S. Food and Drug Administration (FDA), which plays a pivotal role in overseeing the safety and efficacy of medical devices and materials. The FDA classifies hydroxyapatite-based products under different categories depending on their intended use and risk level. For instance, hydroxyapatite coatings on implants may be classified as Class II devices, requiring premarket notification (510(k)) before commercialization.

In the European Union, the regulatory framework is governed by the Medical Device Regulation (MDR) and the In Vitro Diagnostic Regulation (IVDR). These regulations set stringent requirements for the safety and performance of medical devices, including those incorporating hydroxyapatite. Manufacturers must demonstrate compliance with essential requirements and obtain CE marking before placing their products on the European market.

International standards, such as those developed by the International Organization for Standardization (ISO), provide crucial guidance for the production and testing of hydroxyapatite materials. ISO 13779 series, for example, specifically addresses hydroxyapatite implants, outlining requirements for their chemical composition, crystallinity, and mechanical properties.

The regulatory framework also encompasses good manufacturing practices (GMP) and quality management systems (QMS) specific to medical devices. These ensure that hydroxyapatite-based products are consistently produced and controlled according to quality standards appropriate for their intended use.

Biocompatibility testing is a fundamental component of the regulatory process for hydroxyapatite materials. Standards such as ISO 10993 provide guidelines for evaluating the biological safety of medical devices, including those containing hydroxyapatite. This involves a series of in vitro and in vivo tests to assess potential cytotoxicity, sensitization, and local tissue effects.

As research into anisotropic growth in hydroxyapatite crystals advances, regulatory bodies may need to adapt their frameworks to address novel properties and applications. This could involve developing new testing methodologies or revising existing guidelines to ensure the safety and efficacy of these advanced materials in biomedical use.

Regulatory compliance also extends to post-market surveillance and vigilance systems. Manufacturers are required to monitor the performance of their hydroxyapatite-based products in real-world settings and report any adverse events or safety concerns to the relevant authorities.

Environmental Impact of Hydroxyapatite Production

The production of hydroxyapatite (HA) for biomedical applications, particularly in the context of investigating anisotropic growth in HA crystals, has significant environmental implications that warrant careful consideration. The synthesis of HA typically involves chemical processes that may generate waste products and consume energy, potentially impacting the environment.

One of the primary environmental concerns is the use of chemical precursors in HA production. Many synthesis methods require calcium and phosphate sources, which often involve the extraction and processing of raw materials. This can lead to habitat disruption, soil erosion, and water pollution if not managed properly. Additionally, the use of certain solvents or additives in the synthesis process may result in the generation of hazardous waste, necessitating proper disposal methods to prevent environmental contamination.

Energy consumption is another critical factor in the environmental impact of HA production. The synthesis often requires high temperatures or pressure conditions, which demand substantial energy inputs. This energy demand contributes to greenhouse gas emissions if sourced from non-renewable energy sources, exacerbating climate change concerns. However, the adoption of more energy-efficient technologies and renewable energy sources in production facilities can significantly mitigate this impact.

Water usage in HA production is also a notable environmental consideration. The synthesis and purification processes often require substantial amounts of water, which can strain local water resources, especially in water-scarce regions. Implementing water recycling and efficient purification systems can help reduce the overall water footprint of HA production.

The potential for nanoparticle release during the production, handling, and application of HA crystals presents another environmental challenge. As research into anisotropic growth of HA crystals progresses, the manipulation of crystal size and shape at the nanoscale may increase. The environmental fate and potential ecological impacts of these nanoparticles, if released, are not fully understood and require ongoing assessment and mitigation strategies.

On a positive note, the biocompatibility and biodegradability of HA offer potential environmental benefits. As a naturally occurring mineral in bone, HA used in biomedical applications can be metabolized by the body, reducing long-term environmental accumulation compared to non-biodegradable materials. Furthermore, the development of more efficient synthesis methods and the use of bio-based precursors could lead to more sustainable production processes, aligning with circular economy principles.

In conclusion, while the production of HA for biomedical use, particularly in the context of anisotropic crystal growth research, presents several environmental challenges, ongoing advancements in green chemistry and sustainable manufacturing practices offer promising avenues for mitigating these impacts. Balancing the environmental considerations with the significant medical benefits of HA-based materials remains a key focus for researchers and industry stakeholders alike.

One of the primary environmental concerns is the use of chemical precursors in HA production. Many synthesis methods require calcium and phosphate sources, which often involve the extraction and processing of raw materials. This can lead to habitat disruption, soil erosion, and water pollution if not managed properly. Additionally, the use of certain solvents or additives in the synthesis process may result in the generation of hazardous waste, necessitating proper disposal methods to prevent environmental contamination.

Energy consumption is another critical factor in the environmental impact of HA production. The synthesis often requires high temperatures or pressure conditions, which demand substantial energy inputs. This energy demand contributes to greenhouse gas emissions if sourced from non-renewable energy sources, exacerbating climate change concerns. However, the adoption of more energy-efficient technologies and renewable energy sources in production facilities can significantly mitigate this impact.

Water usage in HA production is also a notable environmental consideration. The synthesis and purification processes often require substantial amounts of water, which can strain local water resources, especially in water-scarce regions. Implementing water recycling and efficient purification systems can help reduce the overall water footprint of HA production.

The potential for nanoparticle release during the production, handling, and application of HA crystals presents another environmental challenge. As research into anisotropic growth of HA crystals progresses, the manipulation of crystal size and shape at the nanoscale may increase. The environmental fate and potential ecological impacts of these nanoparticles, if released, are not fully understood and require ongoing assessment and mitigation strategies.

On a positive note, the biocompatibility and biodegradability of HA offer potential environmental benefits. As a naturally occurring mineral in bone, HA used in biomedical applications can be metabolized by the body, reducing long-term environmental accumulation compared to non-biodegradable materials. Furthermore, the development of more efficient synthesis methods and the use of bio-based precursors could lead to more sustainable production processes, aligning with circular economy principles.

In conclusion, while the production of HA for biomedical use, particularly in the context of anisotropic crystal growth research, presents several environmental challenges, ongoing advancements in green chemistry and sustainable manufacturing practices offer promising avenues for mitigating these impacts. Balancing the environmental considerations with the significant medical benefits of HA-based materials remains a key focus for researchers and industry stakeholders alike.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!