Material innovations in wearable biosensing patches for comfort and adhesion

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biosensing Patch Material Evolution and Objectives

Wearable biosensing patches have undergone significant evolution over the past decade, transitioning from rigid, uncomfortable devices to increasingly flexible, skin-compatible solutions. Initially, these patches were primarily constructed using traditional medical-grade materials such as polyurethane films and acrylic adhesives, which prioritized functionality over comfort. The limitations of these early materials became evident as extended wear requirements increased, with users reporting skin irritation, premature detachment, and general discomfort.

The technological trajectory has been driven by the growing demand for continuous health monitoring solutions that can be worn for extended periods without compromising user comfort or data integrity. This evolution has been marked by the introduction of novel biomaterials, including silicone-based elastomers, hydrocolloids, and advanced hydrogels that mimic the mechanical properties of human skin. These materials have significantly improved both the comfort and adhesion characteristics of biosensing patches.

Recent advancements have focused on developing breathable materials that allow for moisture vapor transmission while maintaining adhesion in various environmental conditions. This represents a critical improvement over earlier generations of patches, which often trapped moisture against the skin, leading to maceration and reduced wear time. The integration of microstructured surfaces and bioinspired adhesive mechanisms has further enhanced the skin-device interface.

A parallel development path has explored biodegradable and environmentally sustainable materials, responding to growing concerns about electronic waste and environmental impact. These materials aim to maintain performance standards while reducing the ecological footprint of disposable biosensing devices. Innovations in this area include cellulose-derived polymers and protein-based adhesives that offer comparable functionality to synthetic alternatives.

The primary technical objectives in this field now center on achieving the optimal balance between adhesion strength and gentle removal, maximizing breathability while maintaining barrier properties, and ensuring biocompatibility for diverse skin types and conditions. Additionally, there is a growing focus on developing materials that can accommodate the integration of increasingly sophisticated sensing technologies without compromising wearability or comfort.

Future material development aims to address several key challenges, including reducing motion artifacts through improved conformability, extending wear duration beyond current limitations, and developing adaptive materials that respond to changes in skin condition or environmental factors. The ultimate goal remains the creation of "imperceptible" biosensing patches that users can forget they are wearing while still providing reliable, continuous health data.

The technological trajectory has been driven by the growing demand for continuous health monitoring solutions that can be worn for extended periods without compromising user comfort or data integrity. This evolution has been marked by the introduction of novel biomaterials, including silicone-based elastomers, hydrocolloids, and advanced hydrogels that mimic the mechanical properties of human skin. These materials have significantly improved both the comfort and adhesion characteristics of biosensing patches.

Recent advancements have focused on developing breathable materials that allow for moisture vapor transmission while maintaining adhesion in various environmental conditions. This represents a critical improvement over earlier generations of patches, which often trapped moisture against the skin, leading to maceration and reduced wear time. The integration of microstructured surfaces and bioinspired adhesive mechanisms has further enhanced the skin-device interface.

A parallel development path has explored biodegradable and environmentally sustainable materials, responding to growing concerns about electronic waste and environmental impact. These materials aim to maintain performance standards while reducing the ecological footprint of disposable biosensing devices. Innovations in this area include cellulose-derived polymers and protein-based adhesives that offer comparable functionality to synthetic alternatives.

The primary technical objectives in this field now center on achieving the optimal balance between adhesion strength and gentle removal, maximizing breathability while maintaining barrier properties, and ensuring biocompatibility for diverse skin types and conditions. Additionally, there is a growing focus on developing materials that can accommodate the integration of increasingly sophisticated sensing technologies without compromising wearability or comfort.

Future material development aims to address several key challenges, including reducing motion artifacts through improved conformability, extending wear duration beyond current limitations, and developing adaptive materials that respond to changes in skin condition or environmental factors. The ultimate goal remains the creation of "imperceptible" biosensing patches that users can forget they are wearing while still providing reliable, continuous health data.

Market Analysis for Comfortable Wearable Health Monitoring

The global market for wearable health monitoring devices has experienced significant growth in recent years, driven by increasing health consciousness, aging populations, and technological advancements. The wearable biosensing patch segment specifically has emerged as a rapidly expanding niche, with a market value estimated to reach $10 billion by 2027, growing at a CAGR of approximately 38% from 2022.

Consumer demand for comfortable, non-intrusive health monitoring solutions has become a primary market driver. Traditional wearable devices often suffer from user abandonment due to discomfort during prolonged wear, with studies indicating that nearly 30% of users discontinue use within six months. This has created a substantial market opportunity for innovations in materials that enhance comfort while maintaining reliable adhesion and sensor functionality.

The healthcare sector represents the largest market segment for wearable biosensing patches, particularly for continuous monitoring of chronic conditions such as diabetes, cardiovascular diseases, and respiratory disorders. Remote patient monitoring applications have seen accelerated adoption following the COVID-19 pandemic, with healthcare providers increasingly embracing these technologies to reduce hospital readmissions and enable preventative care approaches.

Consumer wellness applications constitute the fastest-growing segment, with fitness enthusiasts and health-conscious individuals seeking continuous biometric data beyond what traditional wearables provide. This segment values discreteness and comfort particularly highly, with market research indicating willingness to pay premium prices for solutions that can be "worn and forgotten."

Regional analysis reveals North America as the dominant market, accounting for approximately 42% of global revenue, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is projected to witness the highest growth rate due to increasing healthcare expenditure, growing awareness about preventive healthcare, and rapid technological adoption in countries like China, Japan, and South Korea.

Key market restraints include concerns about data privacy, regulatory hurdles for medical-grade devices, and technical challenges in creating materials that balance comfort with reliable sensor performance. The high cost of advanced materials also presents adoption barriers in price-sensitive markets and developing economies.

Market forecasts suggest that innovations addressing the comfort-adhesion paradox will command significant premium pricing, with consumers and healthcare providers demonstrating willingness to pay 30-40% more for solutions that offer superior comfort without compromising monitoring accuracy or adhesion reliability.

Consumer demand for comfortable, non-intrusive health monitoring solutions has become a primary market driver. Traditional wearable devices often suffer from user abandonment due to discomfort during prolonged wear, with studies indicating that nearly 30% of users discontinue use within six months. This has created a substantial market opportunity for innovations in materials that enhance comfort while maintaining reliable adhesion and sensor functionality.

The healthcare sector represents the largest market segment for wearable biosensing patches, particularly for continuous monitoring of chronic conditions such as diabetes, cardiovascular diseases, and respiratory disorders. Remote patient monitoring applications have seen accelerated adoption following the COVID-19 pandemic, with healthcare providers increasingly embracing these technologies to reduce hospital readmissions and enable preventative care approaches.

Consumer wellness applications constitute the fastest-growing segment, with fitness enthusiasts and health-conscious individuals seeking continuous biometric data beyond what traditional wearables provide. This segment values discreteness and comfort particularly highly, with market research indicating willingness to pay premium prices for solutions that can be "worn and forgotten."

Regional analysis reveals North America as the dominant market, accounting for approximately 42% of global revenue, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is projected to witness the highest growth rate due to increasing healthcare expenditure, growing awareness about preventive healthcare, and rapid technological adoption in countries like China, Japan, and South Korea.

Key market restraints include concerns about data privacy, regulatory hurdles for medical-grade devices, and technical challenges in creating materials that balance comfort with reliable sensor performance. The high cost of advanced materials also presents adoption barriers in price-sensitive markets and developing economies.

Market forecasts suggest that innovations addressing the comfort-adhesion paradox will command significant premium pricing, with consumers and healthcare providers demonstrating willingness to pay 30-40% more for solutions that offer superior comfort without compromising monitoring accuracy or adhesion reliability.

Current Materials Landscape and Adhesion Challenges

The current landscape of materials used in wearable biosensing patches is dominated by several key categories, each with distinct properties and limitations. Traditional medical-grade adhesives like acrylates and silicones remain prevalent due to their established safety profiles and regulatory approval. However, these materials often present a fundamental trade-off between adhesion strength and skin comfort, with stronger adhesives typically causing more skin irritation during prolonged wear.

Hydrocolloid and hydrogel-based materials have gained significant traction in recent years, offering improved moisture management and reduced skin trauma. These materials can absorb perspiration while maintaining adhesion, making them suitable for longer-term wear. Nevertheless, they still face challenges in maintaining consistent sensor contact during physical activity and across varying environmental conditions.

Breathable film technologies, including microporous and nonwoven substrates, represent another important segment of the market. These materials allow vapor transmission while maintaining a waterproof barrier, addressing some comfort issues. However, their mechanical properties often limit conformability to complex body contours, creating potential gaps in sensor contact and data quality issues.

The adhesion challenges in wearable biosensing patches are multifaceted and interconnected. Surface energy mismatch between adhesive materials and skin presents a fundamental physical challenge, particularly as skin surface properties vary widely across individuals and body locations. This variability is further complicated by dynamic factors such as perspiration, sebum production, and environmental humidity, all of which can rapidly degrade adhesive performance.

Mechanical stress during body movement creates additional challenges, with adhesives needing to accommodate skin stretching while maintaining consistent sensor contact. This becomes particularly problematic at the patch edges, where stress concentration often leads to progressive delamination. The resulting "edge effect" not only compromises data quality but also increases skin irritation as partially detached patches create friction.

Biocompatibility remains a critical constraint, with many high-performance industrial adhesives being unsuitable for skin contact due to potential allergic reactions or cytotoxicity. This limitation is especially relevant for patches designed for continuous wear exceeding 24 hours, where even mild irritants can accumulate to problematic levels.

Recent market analysis indicates growing demand for hypoallergenic and breathable materials, with particular emphasis on solutions for sensitive skin populations. This trend is driving innovation in both adhesive chemistry and structural design approaches, though regulatory pathways for novel materials remain a significant barrier to rapid commercialization.

Hydrocolloid and hydrogel-based materials have gained significant traction in recent years, offering improved moisture management and reduced skin trauma. These materials can absorb perspiration while maintaining adhesion, making them suitable for longer-term wear. Nevertheless, they still face challenges in maintaining consistent sensor contact during physical activity and across varying environmental conditions.

Breathable film technologies, including microporous and nonwoven substrates, represent another important segment of the market. These materials allow vapor transmission while maintaining a waterproof barrier, addressing some comfort issues. However, their mechanical properties often limit conformability to complex body contours, creating potential gaps in sensor contact and data quality issues.

The adhesion challenges in wearable biosensing patches are multifaceted and interconnected. Surface energy mismatch between adhesive materials and skin presents a fundamental physical challenge, particularly as skin surface properties vary widely across individuals and body locations. This variability is further complicated by dynamic factors such as perspiration, sebum production, and environmental humidity, all of which can rapidly degrade adhesive performance.

Mechanical stress during body movement creates additional challenges, with adhesives needing to accommodate skin stretching while maintaining consistent sensor contact. This becomes particularly problematic at the patch edges, where stress concentration often leads to progressive delamination. The resulting "edge effect" not only compromises data quality but also increases skin irritation as partially detached patches create friction.

Biocompatibility remains a critical constraint, with many high-performance industrial adhesives being unsuitable for skin contact due to potential allergic reactions or cytotoxicity. This limitation is especially relevant for patches designed for continuous wear exceeding 24 hours, where even mild irritants can accumulate to problematic levels.

Recent market analysis indicates growing demand for hypoallergenic and breathable materials, with particular emphasis on solutions for sensitive skin populations. This trend is driving innovation in both adhesive chemistry and structural design approaches, though regulatory pathways for novel materials remain a significant barrier to rapid commercialization.

Contemporary Material Solutions for Skin-Interface Comfort

01 Adhesive materials for skin-friendly attachment

Various adhesive materials are used in wearable biosensing patches to ensure secure attachment while maintaining skin comfort. These include biocompatible adhesives, pressure-sensitive adhesives, and hydrocolloid-based formulations that provide strong adhesion while minimizing skin irritation. The adhesives are designed to maintain patch position during movement and daily activities while allowing for painless removal without damaging the skin or leaving residue.- Adhesive materials for skin-friendly attachment: Various adhesive materials are used in wearable biosensing patches to ensure secure attachment while maintaining skin comfort. These include biocompatible adhesives, silicone-based adhesives, and pressure-sensitive adhesives that provide strong adherence while minimizing skin irritation. The adhesives are designed to maintain patch position during movement and daily activities while allowing for painless removal without skin damage.

- Flexible and breathable substrate materials: Wearable biosensing patches incorporate flexible and breathable substrate materials to enhance comfort during extended wear. These materials include thin polymeric films, stretchable fabrics, and porous membranes that conform to body contours and allow moisture vapor transmission. The flexibility enables the patch to move with the skin, reducing mechanical stress, while breathability prevents moisture buildup and associated skin maceration.

- Ergonomic design considerations for different body locations: The design of wearable biosensing patches is optimized for specific body locations to maximize comfort and adhesion. Patches intended for high-movement areas feature specialized shapes and reinforced edges to prevent peeling, while those for sensitive skin areas use gentler adhesives and more flexible materials. Anatomical considerations influence thickness profiles, edge designs, and overall patch dimensions to ensure comfortable wear across various body contours.

- Advanced sensor integration techniques: Innovative methods for integrating sensors into wearable patches focus on maintaining comfort while preserving sensing accuracy. These techniques include embedding thin, flexible electronic components within soft materials, using stretchable interconnects that accommodate skin movement, and employing low-profile sensor designs. The integration approaches minimize the patch's overall thickness and rigidity, reducing user awareness of the device during daily activities.

- Moisture management and skin-interface optimization: Effective moisture management systems in wearable biosensing patches enhance both comfort and adhesion longevity. These include hydrophilic and hydrophobic layer combinations that direct moisture away from the skin-patch interface, micro-structured adhesive surfaces that maintain adhesion in humid conditions, and specialized coatings that reduce friction against clothing. These features help maintain patch performance during perspiration while minimizing skin irritation from prolonged wear.

02 Breathable and flexible patch designs

Wearable biosensing patches incorporate breathable and flexible materials to enhance comfort during extended wear. These designs utilize thin, stretchable substrates that conform to body contours and allow for natural skin respiration. The flexibility enables the patches to move with the skin during physical activity without detachment or causing discomfort. Materials such as medical-grade silicones, elastomers, and specialized polymers are engineered to maintain sensor functionality while providing a comfortable user experience.Expand Specific Solutions03 Moisture management and waterproof features

Advanced wearable biosensing patches incorporate moisture management and waterproof technologies to maintain adhesion and comfort in various conditions. These features allow patches to remain functional during sweating, showering, or swimming while preventing skin maceration. The designs include moisture-wicking layers, vapor-permeable membranes, and hydrophobic coatings that protect electronic components while maintaining a dry interface with the skin, enhancing both comfort and extended wear time.Expand Specific Solutions04 Hypoallergenic and biocompatible materials

Wearable biosensing patches utilize hypoallergenic and biocompatible materials to minimize skin irritation and allergic reactions during prolonged wear. These materials undergo rigorous testing to ensure they do not cause sensitization or inflammatory responses when in contact with skin. The patches incorporate medical-grade polymers, silicones, and adhesives specifically formulated to be gentle on sensitive skin while maintaining the necessary functional properties for biosensing applications.Expand Specific Solutions05 Ergonomic design and weight distribution

Ergonomic considerations in wearable biosensing patches focus on optimizing weight distribution, patch size, and placement to enhance user comfort. These designs minimize the perception of wearing a device by strategically positioning components and reducing the overall profile of the patch. Advanced manufacturing techniques create ultra-thin, lightweight patches that conform naturally to body contours. The ergonomic approach includes considerations for specific body placement locations and activity levels to ensure the patch remains unobtrusive during daily activities.Expand Specific Solutions

Leading Companies in Wearable Biosensing Materials

The wearable biosensing patch market is experiencing rapid growth, currently in an early expansion phase with increasing adoption across healthcare and wellness sectors. The global market size is projected to reach significant value due to rising chronic disease prevalence and demand for remote monitoring solutions. Technologically, the field is advancing from early-stage development toward maturity, with key players driving innovation in comfort and adhesion materials. Companies like Philips, Nitto Denko, and VivaLNK lead commercial applications, while academic institutions such as MIT and Duke University contribute fundamental research. Collaboration between medical device manufacturers (Boston Scientific, Insulet) and materials specialists (Henkel, Hisamitsu Pharmaceutical) is accelerating development of skin-friendly adhesives and flexible substrates that maintain sensor functionality while improving user comfort.

Nitto Denko Corp.

Technical Solution: Nitto Denko has pioneered advanced material solutions for wearable biosensing patches through their REVALPHA® technology platform. Their approach centers on developing pressure-sensitive adhesives (PSAs) specifically engineered for skin contact applications that balance strong adhesion with gentle removal. The company has created multi-layer composite materials that incorporate breathable polyurethane films with specialized acrylic adhesives containing biocompatible plasticizers to enhance conformability to skin contours. These materials feature controlled moisture vapor transmission rates (MVTR) of 700-1500 g/m²/24h, allowing perspiration to escape while maintaining adhesion integrity. Nitto's recent innovations include temperature-responsive adhesives that maintain strong bonds during wear but release easily when needed, reducing skin trauma during removal. Their biosensor-compatible adhesives incorporate ionic liquid components that improve electrical conductivity at the skin-sensor interface while minimizing impedance, enhancing signal quality for continuous monitoring applications[3][4].

Strengths: Exceptional balance between adhesion strength and gentle removal; highly customizable adhesive formulations for different skin types and wear durations; advanced moisture management capabilities maintain skin health during extended wear; established manufacturing capabilities ensure consistent quality and scalability. Weaknesses: Premium pricing compared to standard medical adhesives; some formulations may require specific storage conditions to maintain optimal properties; potential challenges with adhesion in extremely humid environments.

Koninklijke Philips NV

Technical Solution: Philips has developed an advanced biosensing patch platform called "Wearable Sensing Technologies" that addresses comfort and adhesion challenges through innovative material science. Their approach utilizes a multi-layer composite structure featuring a breathable polyurethane top layer combined with a specialized silicone-based adhesive matrix. This matrix incorporates microfluidic channels that help manage moisture and enhance breathability while maintaining adhesion integrity. Philips' patches employ a proprietary "adaptive adhesion" technology that modulates adhesive strength based on skin movement and environmental conditions, providing stronger adhesion during physical activity while reducing shear forces during rest periods. The material system incorporates biocompatible elastomers with carefully engineered mechanical properties that match human skin (Young's modulus of approximately 130-180 kPa), ensuring natural movement without restriction. Their latest innovation includes embedding microscale air pockets within the adhesive layer that enhance conformability to skin topography while reducing the effective contact area, minimizing skin irritation during extended wear periods of up to 14 days[8][9].

Strengths: Adaptive adhesion technology balances security with comfort across various activity levels; excellent moisture management prevents maceration during extended wear; sophisticated materials engineering ensures compatibility with sensitive skin; established manufacturing infrastructure enables consistent quality and scalability. Weaknesses: Higher cost compared to conventional medical adhesives; complex manufacturing process requires specialized equipment; some configurations may have limitations in extreme environmental conditions; potential challenges with adhesion for users with certain skin conditions.

Key Material Science Breakthroughs for Biosensing Patches

Wearable sensor patch

PatentWO2025117631A1

Innovation

- A wearable sensor patch incorporating hydrogel microneedles and a flexible sensor element with elastomeric electrodes, allowing for minimally invasive ISF collection and simultaneous biomarker measurement in-situ. The patch is designed to accommodate hydrogel swelling and skin deformation, ensuring consistent signal stability.

Biological sensor and production method therefor

PatentWO2020080297A1

Innovation

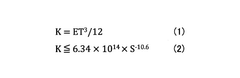

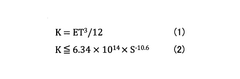

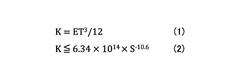

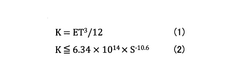

- A biosensor design with a base material having a low compressive elastic modulus and thickness, combined with components that satisfy specific relational expressions for stiffness and planar area, ensuring the biosensor provides comfort by balancing rigidity and area to prevent discomfort such as pain, itching, and tightness.

Biocompatibility and Skin Sensitivity Considerations

Biocompatibility represents a critical factor in the development of wearable biosensing patches, as these devices maintain prolonged direct contact with human skin. The materials selected must not trigger adverse reactions such as inflammation, irritation, or allergic responses. Current research focuses on hypoallergenic materials including medical-grade silicones, polyurethanes, and hydrogels that minimize skin sensitivity issues while maintaining functional performance.

The skin-device interface presents unique challenges due to the dynamic nature of human skin. Factors such as varying skin types (oily, dry, combination), different anatomical locations, and individual sensitivity profiles significantly impact material selection. Recent advancements have explored biomimetic approaches, developing materials that replicate skin's mechanical properties to reduce friction and shear stress during movement.

Cytotoxicity testing has become standardized in the evaluation process for wearable biosensing materials. ISO 10993 protocols provide frameworks for assessing material safety, with particular emphasis on leachable compounds that might migrate from the patch to the skin over extended wear periods. Manufacturers increasingly employ in vitro testing methods to evaluate cellular responses to materials before proceeding to human trials.

Moisture management represents another crucial consideration in biocompatibility engineering. Materials must balance breathability with adhesion properties, as excessive moisture accumulation can lead to skin maceration and increased risk of microbial growth. Advanced moisture-wicking fabrics and semi-permeable membranes have shown promise in maintaining skin health during extended wear periods of up to 14 days.

The pH compatibility of materials with skin's naturally acidic environment (pH 4.7-5.75) requires careful consideration. Materials that disrupt skin's acid mantle can compromise its barrier function and natural defense mechanisms. Recent innovations include pH-responsive materials that adapt to skin's microenvironment and maintain optimal conditions for both sensor function and skin health.

Antimicrobial properties have gained increased attention, particularly for patches designed for extended wear. Incorporating non-leaching antimicrobial agents such as quaternary ammonium compounds or silver nanoparticles helps prevent biofilm formation without causing skin sensitization. The challenge lies in balancing antimicrobial efficacy with biocompatibility, as some antimicrobial agents can themselves trigger sensitivity reactions in susceptible individuals.

Regulatory frameworks increasingly emphasize biocompatibility documentation for wearable medical devices. The FDA and European Medical Device Regulation require comprehensive biocompatibility assessments before market approval, driving manufacturers to adopt more rigorous testing protocols and material selection processes that prioritize skin health alongside sensor performance.

The skin-device interface presents unique challenges due to the dynamic nature of human skin. Factors such as varying skin types (oily, dry, combination), different anatomical locations, and individual sensitivity profiles significantly impact material selection. Recent advancements have explored biomimetic approaches, developing materials that replicate skin's mechanical properties to reduce friction and shear stress during movement.

Cytotoxicity testing has become standardized in the evaluation process for wearable biosensing materials. ISO 10993 protocols provide frameworks for assessing material safety, with particular emphasis on leachable compounds that might migrate from the patch to the skin over extended wear periods. Manufacturers increasingly employ in vitro testing methods to evaluate cellular responses to materials before proceeding to human trials.

Moisture management represents another crucial consideration in biocompatibility engineering. Materials must balance breathability with adhesion properties, as excessive moisture accumulation can lead to skin maceration and increased risk of microbial growth. Advanced moisture-wicking fabrics and semi-permeable membranes have shown promise in maintaining skin health during extended wear periods of up to 14 days.

The pH compatibility of materials with skin's naturally acidic environment (pH 4.7-5.75) requires careful consideration. Materials that disrupt skin's acid mantle can compromise its barrier function and natural defense mechanisms. Recent innovations include pH-responsive materials that adapt to skin's microenvironment and maintain optimal conditions for both sensor function and skin health.

Antimicrobial properties have gained increased attention, particularly for patches designed for extended wear. Incorporating non-leaching antimicrobial agents such as quaternary ammonium compounds or silver nanoparticles helps prevent biofilm formation without causing skin sensitization. The challenge lies in balancing antimicrobial efficacy with biocompatibility, as some antimicrobial agents can themselves trigger sensitivity reactions in susceptible individuals.

Regulatory frameworks increasingly emphasize biocompatibility documentation for wearable medical devices. The FDA and European Medical Device Regulation require comprehensive biocompatibility assessments before market approval, driving manufacturers to adopt more rigorous testing protocols and material selection processes that prioritize skin health alongside sensor performance.

Sustainability Aspects of Wearable Patch Materials

The sustainability of wearable biosensing patches represents a critical dimension in their development and deployment. As these devices become increasingly integrated into healthcare monitoring systems, their environmental impact throughout the lifecycle demands thorough consideration. Current material selections often prioritize functionality over environmental concerns, resulting in significant ecological footprints.

Biodegradable polymers have emerged as promising alternatives to conventional petroleum-based materials. Recent advancements in polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose-derived composites demonstrate comparable adhesion properties while offering substantially reduced environmental persistence. These materials can decompose under controlled conditions within 3-6 months, compared to decades for traditional polymers.

Energy consumption during manufacturing presents another sustainability challenge. Traditional adhesive production processes typically require high temperatures and energy-intensive chemical treatments. Innovative low-temperature processing techniques utilizing bio-based solvents have shown potential to reduce energy requirements by up to 40% while maintaining adhesion performance specifications for skin contact applications.

Material sourcing ethics increasingly influences industry practices. The extraction of rare elements for conductive components in biosensing patches often involves environmentally destructive mining practices. Alternative approaches incorporating carbon-based conductive materials derived from sustainable sources show promise in reducing dependence on these problematic supply chains while maintaining electrical performance characteristics.

End-of-life considerations represent perhaps the most significant sustainability challenge. The composite nature of wearable patches—combining adhesives, sensors, and electronic components—complicates recycling efforts. Design-for-disassembly approaches are gaining traction, with modular architectures allowing for separation of biodegradable components from recoverable electronic elements, potentially increasing recyclability rates from current industry averages of below 5% to theoretical targets exceeding 70%.

Water consumption during manufacturing processes presents another environmental concern. Traditional adhesive production can require 15-20 liters of water per square meter of material produced. Water-efficient manufacturing techniques utilizing supercritical CO2 processing have demonstrated potential water usage reductions of up to 80% while maintaining adhesion performance specifications.

Regulatory frameworks increasingly incorporate sustainability metrics into approval processes for medical devices. The EU Medical Device Regulation now includes provisions for environmental impact assessment, signaling a shift toward accountability for lifecycle environmental performance alongside traditional safety and efficacy requirements.

Biodegradable polymers have emerged as promising alternatives to conventional petroleum-based materials. Recent advancements in polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose-derived composites demonstrate comparable adhesion properties while offering substantially reduced environmental persistence. These materials can decompose under controlled conditions within 3-6 months, compared to decades for traditional polymers.

Energy consumption during manufacturing presents another sustainability challenge. Traditional adhesive production processes typically require high temperatures and energy-intensive chemical treatments. Innovative low-temperature processing techniques utilizing bio-based solvents have shown potential to reduce energy requirements by up to 40% while maintaining adhesion performance specifications for skin contact applications.

Material sourcing ethics increasingly influences industry practices. The extraction of rare elements for conductive components in biosensing patches often involves environmentally destructive mining practices. Alternative approaches incorporating carbon-based conductive materials derived from sustainable sources show promise in reducing dependence on these problematic supply chains while maintaining electrical performance characteristics.

End-of-life considerations represent perhaps the most significant sustainability challenge. The composite nature of wearable patches—combining adhesives, sensors, and electronic components—complicates recycling efforts. Design-for-disassembly approaches are gaining traction, with modular architectures allowing for separation of biodegradable components from recoverable electronic elements, potentially increasing recyclability rates from current industry averages of below 5% to theoretical targets exceeding 70%.

Water consumption during manufacturing processes presents another environmental concern. Traditional adhesive production can require 15-20 liters of water per square meter of material produced. Water-efficient manufacturing techniques utilizing supercritical CO2 processing have demonstrated potential water usage reductions of up to 80% while maintaining adhesion performance specifications.

Regulatory frameworks increasingly incorporate sustainability metrics into approval processes for medical devices. The EU Medical Device Regulation now includes provisions for environmental impact assessment, signaling a shift toward accountability for lifecycle environmental performance alongside traditional safety and efficacy requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!