Wearable biosensing patches with stretchable electronic circuits

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Stretchable Electronics Background and Objectives

Stretchable electronics represents a revolutionary paradigm shift in the field of electronic devices, evolving from traditional rigid circuit boards to flexible, conformable systems that can maintain functionality while being stretched, twisted, or deformed. This technological evolution began in the early 2000s with pioneering work on organic semiconductors and has accelerated significantly over the past decade with advancements in materials science, fabrication techniques, and system integration approaches.

The development trajectory of stretchable electronics has been driven by the fundamental limitations of conventional electronics when applied to non-planar surfaces, particularly the human body. Traditional rigid electronics cannot conform to the complex topography and dynamic nature of biological tissues, creating a significant technological gap in human-machine interfaces. This limitation has spurred research into novel materials and architectures that can bridge this gap.

Current stretchable electronic systems typically employ one of three approaches: intrinsically stretchable materials, geometrically engineered rigid components, or hybrid systems combining both strategies. Each approach offers distinct advantages and challenges in terms of electrical performance, mechanical durability, and manufacturing scalability. The field has progressed from simple stretchable conductors to fully integrated systems incorporating sensors, processing units, and communication modules.

The primary objective of research on wearable biosensing patches with stretchable electronic circuits is to develop seamlessly integrated bioelectronic systems that can continuously monitor physiological parameters without impeding natural body movement or causing discomfort. These systems aim to enable long-term health monitoring outside clinical settings, providing real-time data for preventive healthcare and personalized medicine.

Technical goals in this domain include achieving mechanical properties that match human tissue (elasticity of 10-100 kPa), maintaining electrical performance under mechanical deformation (>30% strain without significant degradation), ensuring biocompatibility for extended skin contact, and developing low-power operation for practical wearability. Additionally, researchers aim to create manufacturing processes that can transition from laboratory prototypes to mass production.

The evolution of this technology is increasingly focused on multifunctional capabilities, where a single patch can simultaneously monitor multiple biomarkers while providing therapeutic functionalities. This convergence of sensing and actuation represents the next frontier in stretchable electronics, potentially enabling closed-loop systems that can both detect physiological abnormalities and deliver appropriate interventions.

As the field matures, standardization of testing protocols and performance metrics has become essential to enable meaningful comparisons between different technological approaches and to accelerate clinical translation and commercialization of these promising biomedical technologies.

The development trajectory of stretchable electronics has been driven by the fundamental limitations of conventional electronics when applied to non-planar surfaces, particularly the human body. Traditional rigid electronics cannot conform to the complex topography and dynamic nature of biological tissues, creating a significant technological gap in human-machine interfaces. This limitation has spurred research into novel materials and architectures that can bridge this gap.

Current stretchable electronic systems typically employ one of three approaches: intrinsically stretchable materials, geometrically engineered rigid components, or hybrid systems combining both strategies. Each approach offers distinct advantages and challenges in terms of electrical performance, mechanical durability, and manufacturing scalability. The field has progressed from simple stretchable conductors to fully integrated systems incorporating sensors, processing units, and communication modules.

The primary objective of research on wearable biosensing patches with stretchable electronic circuits is to develop seamlessly integrated bioelectronic systems that can continuously monitor physiological parameters without impeding natural body movement or causing discomfort. These systems aim to enable long-term health monitoring outside clinical settings, providing real-time data for preventive healthcare and personalized medicine.

Technical goals in this domain include achieving mechanical properties that match human tissue (elasticity of 10-100 kPa), maintaining electrical performance under mechanical deformation (>30% strain without significant degradation), ensuring biocompatibility for extended skin contact, and developing low-power operation for practical wearability. Additionally, researchers aim to create manufacturing processes that can transition from laboratory prototypes to mass production.

The evolution of this technology is increasingly focused on multifunctional capabilities, where a single patch can simultaneously monitor multiple biomarkers while providing therapeutic functionalities. This convergence of sensing and actuation represents the next frontier in stretchable electronics, potentially enabling closed-loop systems that can both detect physiological abnormalities and deliver appropriate interventions.

As the field matures, standardization of testing protocols and performance metrics has become essential to enable meaningful comparisons between different technological approaches and to accelerate clinical translation and commercialization of these promising biomedical technologies.

Market Analysis for Wearable Biosensing Patches

The global market for wearable biosensing patches with stretchable electronic circuits is experiencing robust growth, driven by increasing health consciousness and the rising prevalence of chronic diseases. Current market valuations indicate that this sector reached approximately 7.5 billion USD in 2022 and is projected to expand at a compound annual growth rate of 21.3% through 2030, potentially reaching 38 billion USD by the end of the forecast period.

Consumer demand for these advanced biosensing solutions stems primarily from healthcare applications, with continuous health monitoring representing the largest market segment. The ability of these patches to provide real-time physiological data without restricting movement has created significant value propositions across multiple sectors including clinical care, remote patient monitoring, sports performance, and occupational safety.

Demographic trends are further amplifying market potential, with aging populations in developed economies requiring more consistent health monitoring. Concurrently, the growing middle class in emerging markets is increasingly adopting wearable health technologies, expanding the addressable market. The COVID-19 pandemic has accelerated this trend by highlighting the importance of remote health monitoring capabilities.

Regional analysis reveals North America currently dominates the market with approximately 42% share, followed by Europe at 28% and Asia-Pacific at 23%. However, the highest growth rates are projected in Asia-Pacific markets, particularly China and India, where healthcare infrastructure development and increasing disposable incomes are creating favorable conditions for market expansion.

Consumer preferences are evolving toward solutions that offer longer battery life, improved comfort, enhanced data accuracy, and seamless integration with mobile health platforms. Market research indicates that 78% of potential users consider comfort and unobtrusiveness as critical factors in adoption decisions, while 65% prioritize battery longevity.

The reimbursement landscape is gradually becoming more favorable as insurance providers and healthcare systems recognize the cost-effectiveness of preventive monitoring. Several developed markets have begun implementing coverage policies for specific medical-grade biosensing applications, though consumer-grade devices largely remain direct-to-consumer purchases.

Regulatory environments vary significantly by region, with medical-grade biosensing patches facing stringent approval processes in most markets. The FDA in the United States has established specific guidance for wearable biosensors, while the European Union applies the Medical Device Regulation framework. These regulatory considerations significantly impact market entry strategies and product development timelines.

Consumer demand for these advanced biosensing solutions stems primarily from healthcare applications, with continuous health monitoring representing the largest market segment. The ability of these patches to provide real-time physiological data without restricting movement has created significant value propositions across multiple sectors including clinical care, remote patient monitoring, sports performance, and occupational safety.

Demographic trends are further amplifying market potential, with aging populations in developed economies requiring more consistent health monitoring. Concurrently, the growing middle class in emerging markets is increasingly adopting wearable health technologies, expanding the addressable market. The COVID-19 pandemic has accelerated this trend by highlighting the importance of remote health monitoring capabilities.

Regional analysis reveals North America currently dominates the market with approximately 42% share, followed by Europe at 28% and Asia-Pacific at 23%. However, the highest growth rates are projected in Asia-Pacific markets, particularly China and India, where healthcare infrastructure development and increasing disposable incomes are creating favorable conditions for market expansion.

Consumer preferences are evolving toward solutions that offer longer battery life, improved comfort, enhanced data accuracy, and seamless integration with mobile health platforms. Market research indicates that 78% of potential users consider comfort and unobtrusiveness as critical factors in adoption decisions, while 65% prioritize battery longevity.

The reimbursement landscape is gradually becoming more favorable as insurance providers and healthcare systems recognize the cost-effectiveness of preventive monitoring. Several developed markets have begun implementing coverage policies for specific medical-grade biosensing applications, though consumer-grade devices largely remain direct-to-consumer purchases.

Regulatory environments vary significantly by region, with medical-grade biosensing patches facing stringent approval processes in most markets. The FDA in the United States has established specific guidance for wearable biosensors, while the European Union applies the Medical Device Regulation framework. These regulatory considerations significantly impact market entry strategies and product development timelines.

Technical Challenges in Stretchable Circuit Development

The development of stretchable electronic circuits for wearable biosensing patches faces numerous technical challenges that currently limit their widespread adoption and commercial viability. Material compatibility represents one of the most significant hurdles, as traditional electronic components are inherently rigid and brittle, contrasting sharply with the mechanical requirements of skin-interfacing devices. Engineers must develop novel materials that maintain electrical functionality while accommodating repeated mechanical deformation without performance degradation.

Mechanical durability presents another critical challenge, with stretchable circuits needing to withstand thousands of stretching cycles, bending, twisting, and compression while maintaining consistent electrical performance. Current solutions often show performance deterioration after repeated mechanical stress, limiting their practical lifespan for continuous health monitoring applications.

Fabrication scalability remains problematic as many laboratory-demonstrated stretchable electronics rely on complex, multi-step manufacturing processes that are difficult to scale for mass production. Techniques like direct ink writing and screen printing show promise but struggle with resolution limitations and material compatibility issues when integrating multiple functional components.

Electrical performance stability under deformation constitutes a fundamental challenge, as conductivity pathways in stretchable circuits can experience significant resistance changes during stretching. This variability introduces noise and measurement errors in biosensing applications where signal precision is paramount. Current approaches using serpentine patterns or liquid metal conductors each present their own limitations in terms of design complexity or long-term reliability.

Biocompatibility and encapsulation present additional complications, as materials must not only be non-toxic and non-irritating to skin but also effectively protect sensitive electronic components from sweat, moisture, and environmental contaminants. Current encapsulation materials often compromise the overall system flexibility or fail to provide adequate long-term protection against biofluids.

Power management represents another significant obstacle, with conventional rigid batteries incompatible with stretchable form factors. Alternative solutions like stretchable batteries or energy harvesting technologies currently suffer from limited energy density or inconsistent power generation, restricting continuous operation capabilities.

Integration complexity further complicates development, as combining sensing elements, signal processing circuits, power sources, and wireless communication modules into a cohesive stretchable system requires sophisticated design approaches that balance mechanical, electrical, and thermal considerations. The interconnection between rigid and stretchable components creates particular vulnerability points that often fail under mechanical stress.

Mechanical durability presents another critical challenge, with stretchable circuits needing to withstand thousands of stretching cycles, bending, twisting, and compression while maintaining consistent electrical performance. Current solutions often show performance deterioration after repeated mechanical stress, limiting their practical lifespan for continuous health monitoring applications.

Fabrication scalability remains problematic as many laboratory-demonstrated stretchable electronics rely on complex, multi-step manufacturing processes that are difficult to scale for mass production. Techniques like direct ink writing and screen printing show promise but struggle with resolution limitations and material compatibility issues when integrating multiple functional components.

Electrical performance stability under deformation constitutes a fundamental challenge, as conductivity pathways in stretchable circuits can experience significant resistance changes during stretching. This variability introduces noise and measurement errors in biosensing applications where signal precision is paramount. Current approaches using serpentine patterns or liquid metal conductors each present their own limitations in terms of design complexity or long-term reliability.

Biocompatibility and encapsulation present additional complications, as materials must not only be non-toxic and non-irritating to skin but also effectively protect sensitive electronic components from sweat, moisture, and environmental contaminants. Current encapsulation materials often compromise the overall system flexibility or fail to provide adequate long-term protection against biofluids.

Power management represents another significant obstacle, with conventional rigid batteries incompatible with stretchable form factors. Alternative solutions like stretchable batteries or energy harvesting technologies currently suffer from limited energy density or inconsistent power generation, restricting continuous operation capabilities.

Integration complexity further complicates development, as combining sensing elements, signal processing circuits, power sources, and wireless communication modules into a cohesive stretchable system requires sophisticated design approaches that balance mechanical, electrical, and thermal considerations. The interconnection between rigid and stretchable components creates particular vulnerability points that often fail under mechanical stress.

Current Stretchable Circuit Design Approaches

01 Stretchable electronic circuits for wearable biosensing patches

Stretchable electronic circuits are essential components of wearable biosensing patches, allowing the devices to conform to the body's contours and movements. These circuits are designed with materials and structures that can withstand mechanical deformation while maintaining electrical functionality. The stretchability enables comfortable, continuous monitoring of physiological parameters without restricting the wearer's movement or causing discomfort during daily activities.- Stretchable electronic circuits for wearable biosensing patches: Stretchable electronic circuits are essential components of wearable biosensing patches that can conform to the body's contours. These circuits are designed to maintain functionality while being stretched, bent, or twisted, allowing for continuous monitoring of physiological parameters. The stretchable nature of these circuits enables comfortable wear on various body parts and accommodates natural body movements without compromising the sensing capabilities.

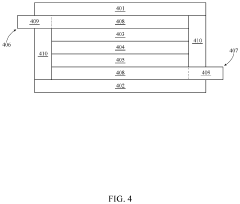

- Materials and fabrication techniques for stretchable biosensors: Various materials and fabrication techniques are employed to create stretchable biosensing patches. These include the use of elastomeric substrates, serpentine or wavy conductive patterns, and composite materials that combine rigid electronic components with flexible interconnects. Advanced manufacturing methods such as screen printing, transfer printing, and direct writing are utilized to fabricate these stretchable electronic systems that can withstand mechanical deformation while maintaining electrical performance.

- Integration of sensing elements in stretchable platforms: The integration of various sensing elements into stretchable platforms enables comprehensive physiological monitoring. These sensing elements may include temperature sensors, electrochemical sensors, strain gauges, and electrodes for electrophysiological measurements. The strategic placement and connection of these elements within the stretchable matrix allow for multi-parameter monitoring while maintaining the overall flexibility and stretchability of the biosensing patch.

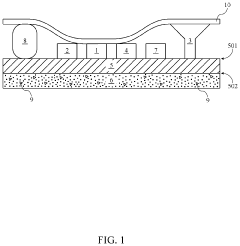

- Mechanical design strategies for enhanced stretchability: Specific mechanical design strategies are employed to enhance the stretchability of electronic circuits in biosensing patches. These include the use of geometric patterns such as serpentine, fractal, or kirigami designs that can unfold or reconfigure under strain. Additionally, layered structures with neutral mechanical planes, island-bridge configurations, and pre-strained assembly techniques are utilized to minimize stress concentration and increase the overall stretchability of the device.

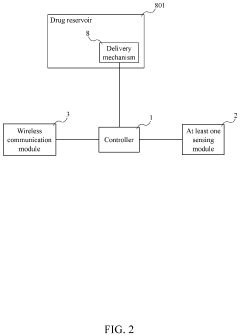

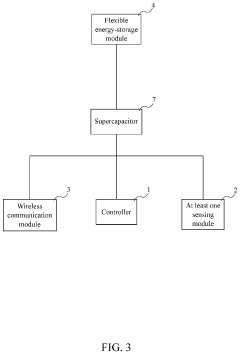

- Interface and communication systems for stretchable biosensors: Stretchable biosensing patches incorporate interface and communication systems that enable data transmission and power management. These systems include wireless communication modules, energy harvesting components, and stretchable antennas that maintain functionality during deformation. The integration of these elements allows for real-time data collection, processing, and transmission to external devices while preserving the mechanical compliance of the entire system.

02 Materials and fabrication techniques for stretchable biosensors

Various materials and fabrication techniques are employed to create stretchable biosensing patches. These include the use of elastomeric substrates, serpentine or wavy conductive patterns, and composite materials that combine rigid electronic components with flexible interconnects. Advanced manufacturing methods such as screen printing, transfer printing, and direct writing enable the creation of complex electronic circuits on stretchable substrates, resulting in highly functional and reliable wearable biosensors.Expand Specific Solutions03 Integration of sensing elements in stretchable platforms

The integration of various sensing elements into stretchable platforms is crucial for wearable biosensing patches. These sensing elements may include electrochemical sensors, temperature sensors, strain gauges, and optical sensors. The challenge lies in maintaining the functionality and accuracy of these sensing elements while subjected to mechanical deformation. Novel integration approaches ensure that the sensors can reliably detect and measure physiological parameters even when the patch is stretched or compressed during body movement.Expand Specific Solutions04 Power management and wireless communication in stretchable biosensors

Effective power management and wireless communication capabilities are essential for practical wearable biosensing patches. Stretchable batteries, energy harvesting systems, and low-power circuit designs extend the operational lifetime of these devices. Wireless communication modules integrated into the stretchable platform enable real-time data transmission to smartphones or other monitoring devices, allowing for continuous health monitoring without the need for wired connections that would restrict movement and comfort.Expand Specific Solutions05 Applications and clinical validation of stretchable biosensing patches

Stretchable biosensing patches have diverse applications in healthcare, sports, and wellness monitoring. These include continuous monitoring of vital signs, detection of specific biomarkers, tracking of physical activity, and assessment of wound healing. Clinical validation studies demonstrate the accuracy, reliability, and user acceptance of these devices in real-world settings. The non-invasive nature and comfort of stretchable patches make them particularly suitable for long-term monitoring of patients with chronic conditions and for preventive healthcare applications.Expand Specific Solutions

Leading Companies in Wearable Biosensing Technology

The wearable biosensing patches with stretchable electronic circuits market is in a growth phase, characterized by increasing adoption across healthcare monitoring applications. The market is expanding rapidly, driven by rising demand for remote patient monitoring solutions and advancements in flexible electronics. Companies like VivaLNK have pioneered breathable thin film substrates with integrated circuits, while established players such as Philips, Samsung, and Intel are leveraging their technological expertise to develop sophisticated biosensing solutions. Academic institutions including MIT, Tsinghua University, and Imperial College are advancing fundamental research in stretchable electronics. The technology is approaching commercial maturity with early applications in healthcare monitoring, though challenges remain in durability, power management, and large-scale manufacturing for broader consumer adoption.

VivaLNK, Inc.

Technical Solution: VivaLNK has developed a proprietary eSkin™ technology platform that combines ultra-thin, flexible electronics with medical-grade adhesives to create continuous monitoring wearable patches. Their biosensing patches incorporate stretchable electronic circuits that conform to body contours while maintaining reliable data collection. The company's Vital Scout patch monitors stress levels, recovery status, and activity through continuous ECG and motion sensing, while their multi-vital medical patch can monitor ECG, heart rate, respiratory rate, and temperature simultaneously for up to 120 hours of continuous use. The patches utilize a proprietary material that allows for up to 240% stretchability while maintaining electrical conductivity and signal integrity, enabling comfortable long-term wear even during movement and physical activity.

Strengths: Superior comfort and conformability due to proprietary stretchable materials; extended wear time (up to 5 days) compared to rigid alternatives; wireless connectivity for real-time monitoring. Weaknesses: Limited to specific vital sign monitoring applications; potential skin irritation with extended wear; higher cost compared to traditional medical monitoring devices.

Koninklijke Philips NV

Technical Solution: Philips has pioneered advanced wearable biosensing patches through their BioTel Heart and Philips Wearable Sensing technologies. Their patches incorporate stretchable electronic circuits based on printed electronics on flexible substrates that can conform to body contours while maintaining monitoring accuracy. The company's latest generation of patches features a proprietary "island-bridge" architecture where rigid electronic components (islands) are interconnected by stretchable conductive traces (bridges) that can withstand up to 300% strain without performance degradation. These patches integrate multiple sensors including ECG, PPG, temperature, and motion sensors in a single form factor. Philips' patches utilize low-power Bluetooth technology for continuous data transmission and implement proprietary algorithms for artifact rejection and signal processing to ensure clinical-grade data quality even during patient movement.

Strengths: Comprehensive integration of multiple sensing modalities in a single patch; clinical-grade accuracy validated in hospital settings; established global distribution network and regulatory approvals. Weaknesses: Higher cost compared to simpler monitoring solutions; battery life limitations for continuous monitoring applications; requires specialized manufacturing processes that may limit production scaling.

Key Patents in Stretchable Biosensing Materials

Electronic wearable patch for medical uses

PatentPendingUS20220072229A1

Innovation

- A wearable patch with a flexible or stretchable circuit, integrated supercapacitor, and wireless communication, featuring sensors for physiological parameter measurement, a processing device for medical condition analysis, and a flexible battery powered by UV curable ink, allowing for comfortable skin application and efficient medical data transmission.

Wearable sensor patch

PatentWO2025117631A1

Innovation

- A wearable sensor patch incorporating hydrogel microneedles and a flexible sensor element with elastomeric electrodes, allowing for minimally invasive ISF collection and simultaneous biomarker measurement in-situ. The patch is designed to accommodate hydrogel swelling and skin deformation, ensuring consistent signal stability.

Biocompatibility and Safety Considerations

Biocompatibility remains a critical consideration in the development of wearable biosensing patches with stretchable electronic circuits. These devices maintain prolonged contact with human skin, necessitating materials that do not trigger adverse biological responses such as inflammation, irritation, or allergic reactions. Current research focuses on utilizing medical-grade silicones, hypoallergenic adhesives, and biocompatible polymers like polydimethylsiloxane (PDMS) that demonstrate excellent compatibility with human tissue while maintaining the required mechanical properties for stretchable electronics.

Safety considerations extend beyond material selection to encompass electrical safety parameters. Wearable biosensing patches must operate at ultra-low power levels to prevent tissue heating and potential burns. Research indicates that maintaining power densities below 10 mW/cm² significantly reduces thermal risks. Additionally, electrical isolation mechanisms must be implemented to protect users from potential current leakage, particularly when patches are exposed to moisture or during physical activities that induce sweating.

Long-term cytotoxicity testing represents another crucial aspect of biosensor development. Recent studies have established standardized protocols for evaluating the chronic effects of continuous skin contact with these devices, typically requiring testing periods of 7-30 days to assess potential cumulative toxicity. These protocols examine cellular viability, inflammatory marker expression, and tissue morphology changes resulting from extended exposure to patch materials and components.

Regulatory frameworks governing wearable biosensing patches continue to evolve globally. The FDA in the United States has developed specific guidance for skin-contacting wearable electronic medical devices, while the European Union applies the Medical Device Regulation (MDR) framework with particular emphasis on biocompatibility documentation. Manufacturers must navigate these complex regulatory landscapes, which typically require ISO 10993 compliance for biological evaluation of medical devices.

Environmental factors also influence biocompatibility and safety profiles. Researchers must consider how environmental conditions such as humidity, temperature fluctuations, and UV exposure might alter material properties over time, potentially releasing compounds that were initially encapsulated. Recent innovations include self-healing polymers and degradation-resistant encapsulation techniques that maintain biocompatibility despite environmental challenges.

The integration of active pharmaceutical ingredients or antimicrobial components into biosensing patches introduces additional biocompatibility considerations. These functional additives must maintain their intended therapeutic effects without compromising the overall safety profile of the device, requiring specialized testing methodologies that assess both the biocompatibility of the composite system and the efficacy of the active components.

Safety considerations extend beyond material selection to encompass electrical safety parameters. Wearable biosensing patches must operate at ultra-low power levels to prevent tissue heating and potential burns. Research indicates that maintaining power densities below 10 mW/cm² significantly reduces thermal risks. Additionally, electrical isolation mechanisms must be implemented to protect users from potential current leakage, particularly when patches are exposed to moisture or during physical activities that induce sweating.

Long-term cytotoxicity testing represents another crucial aspect of biosensor development. Recent studies have established standardized protocols for evaluating the chronic effects of continuous skin contact with these devices, typically requiring testing periods of 7-30 days to assess potential cumulative toxicity. These protocols examine cellular viability, inflammatory marker expression, and tissue morphology changes resulting from extended exposure to patch materials and components.

Regulatory frameworks governing wearable biosensing patches continue to evolve globally. The FDA in the United States has developed specific guidance for skin-contacting wearable electronic medical devices, while the European Union applies the Medical Device Regulation (MDR) framework with particular emphasis on biocompatibility documentation. Manufacturers must navigate these complex regulatory landscapes, which typically require ISO 10993 compliance for biological evaluation of medical devices.

Environmental factors also influence biocompatibility and safety profiles. Researchers must consider how environmental conditions such as humidity, temperature fluctuations, and UV exposure might alter material properties over time, potentially releasing compounds that were initially encapsulated. Recent innovations include self-healing polymers and degradation-resistant encapsulation techniques that maintain biocompatibility despite environmental challenges.

The integration of active pharmaceutical ingredients or antimicrobial components into biosensing patches introduces additional biocompatibility considerations. These functional additives must maintain their intended therapeutic effects without compromising the overall safety profile of the device, requiring specialized testing methodologies that assess both the biocompatibility of the composite system and the efficacy of the active components.

Manufacturing Scalability Assessment

The scalability of manufacturing processes represents a critical factor in the commercial viability of wearable biosensing patches with stretchable electronic circuits. Current manufacturing approaches predominantly rely on laboratory-scale techniques that present significant challenges when transitioning to mass production. Conventional microfabrication methods used for rigid electronics cannot be directly applied to stretchable systems, necessitating novel manufacturing paradigms.

Roll-to-roll (R2R) processing emerges as a promising approach for large-scale production of flexible and stretchable electronics. This continuous manufacturing technique allows for high-throughput fabrication of multilayer devices on flexible substrates. However, the integration of stretchable interconnects and sensitive biosensing elements within this process remains technically challenging. Current R2R implementations for stretchable electronics achieve yields of approximately 75-85%, which falls short of the 95%+ yields required for cost-effective mass production.

Additive manufacturing techniques, particularly direct-write printing and aerosol jet printing, offer alternative pathways for scalable production. These methods enable precise deposition of conductive materials onto stretchable substrates without requiring complex lithography steps. The resolution capabilities have improved significantly, with recent systems achieving feature sizes below 10 μm. Nevertheless, printing speeds must increase by an order of magnitude to meet commercial volume requirements.

Material compatibility issues further complicate manufacturing scalability. The diverse materials used in biosensing patches—including elastomers, conductive inks, and encapsulation layers—must maintain consistent performance through multiple processing steps. Current manufacturing processes often require incompatible solvents or curing temperatures, leading to material degradation and reduced device performance. Standardization of materials and processes remains limited, with most manufacturers developing proprietary solutions.

Equipment costs present another barrier to scalable manufacturing. Specialized tools for handling stretchable substrates and depositing materials on non-planar surfaces can cost 3-5 times more than conventional electronics manufacturing equipment. This high capital expenditure requirement limits market entry for smaller manufacturers and increases per-unit production costs.

Quality control and testing methodologies for stretchable electronics lag behind those established for conventional electronics. Automated optical inspection systems struggle with the variable topography of stretchable substrates, while electrical testing must accommodate the dynamic nature of these devices. Development of standardized testing protocols that can be implemented in high-volume manufacturing environments remains an active research area with significant potential for improving manufacturing yields and reducing costs.

Roll-to-roll (R2R) processing emerges as a promising approach for large-scale production of flexible and stretchable electronics. This continuous manufacturing technique allows for high-throughput fabrication of multilayer devices on flexible substrates. However, the integration of stretchable interconnects and sensitive biosensing elements within this process remains technically challenging. Current R2R implementations for stretchable electronics achieve yields of approximately 75-85%, which falls short of the 95%+ yields required for cost-effective mass production.

Additive manufacturing techniques, particularly direct-write printing and aerosol jet printing, offer alternative pathways for scalable production. These methods enable precise deposition of conductive materials onto stretchable substrates without requiring complex lithography steps. The resolution capabilities have improved significantly, with recent systems achieving feature sizes below 10 μm. Nevertheless, printing speeds must increase by an order of magnitude to meet commercial volume requirements.

Material compatibility issues further complicate manufacturing scalability. The diverse materials used in biosensing patches—including elastomers, conductive inks, and encapsulation layers—must maintain consistent performance through multiple processing steps. Current manufacturing processes often require incompatible solvents or curing temperatures, leading to material degradation and reduced device performance. Standardization of materials and processes remains limited, with most manufacturers developing proprietary solutions.

Equipment costs present another barrier to scalable manufacturing. Specialized tools for handling stretchable substrates and depositing materials on non-planar surfaces can cost 3-5 times more than conventional electronics manufacturing equipment. This high capital expenditure requirement limits market entry for smaller manufacturers and increases per-unit production costs.

Quality control and testing methodologies for stretchable electronics lag behind those established for conventional electronics. Automated optical inspection systems struggle with the variable topography of stretchable substrates, while electrical testing must accommodate the dynamic nature of these devices. Development of standardized testing protocols that can be implemented in high-volume manufacturing environments remains an active research area with significant potential for improving manufacturing yields and reducing costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!