Wearable biosensing patches integrated with textile substrates

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Textile-Integrated Biosensing Patch Evolution and Objectives

Wearable biosensing patches integrated with textiles represent a significant evolution in the field of wearable health monitoring technology. This technological domain emerged from the convergence of traditional textiles and advanced electronic sensing capabilities, creating a new class of smart textiles capable of continuous physiological monitoring. The evolution began in the early 2000s with rudimentary integration of rigid sensors onto fabric substrates, progressing through several key developmental phases to today's sophisticated, flexible, and seamlessly integrated biosensing systems.

The initial phase focused primarily on attaching conventional electronic components to textiles, resulting in bulky and often uncomfortable wearable solutions. By the mid-2010s, advancements in flexible electronics and conductive materials enabled the development of more conformable biosensing patches that could be more effectively integrated with textile substrates. This period saw significant improvements in sensor miniaturization and the development of stretchable interconnects that could withstand the mechanical stresses associated with textile movement.

Recent technological breakthroughs have centered on the development of textile-based sensors that are inherently part of the fabric structure rather than merely attached components. These innovations include conductive yarns, screen-printed electrodes on textiles, and fabric-based microfluidic systems capable of capturing and analyzing bodily fluids such as sweat. The integration of these sensing capabilities directly into everyday garments represents a paradigm shift from "wearing technology" to "technology that is worn."

The primary objective of current research in textile-integrated biosensing patches is to achieve seamless integration that maintains both the comfort and aesthetic qualities of traditional textiles while providing reliable, continuous health monitoring capabilities. This includes developing systems that can withstand washing cycles, prolonged wear, and various environmental conditions without degradation of sensing performance.

Another critical goal is the enhancement of power management systems, moving toward energy-autonomous solutions through innovations in energy harvesting from body movement, temperature differentials, or ambient light. This would eliminate the need for frequent battery replacements or recharging, significantly improving user experience and adoption rates.

Looking forward, the field aims to expand beyond physiological monitoring to include environmental sensing capabilities, creating comprehensive health monitoring ecosystems that can correlate personal health data with environmental factors. Additionally, there is growing interest in developing textile-integrated biosensing systems capable of therapeutic interventions, such as drug delivery or electrical stimulation, based on real-time physiological data analysis.

The initial phase focused primarily on attaching conventional electronic components to textiles, resulting in bulky and often uncomfortable wearable solutions. By the mid-2010s, advancements in flexible electronics and conductive materials enabled the development of more conformable biosensing patches that could be more effectively integrated with textile substrates. This period saw significant improvements in sensor miniaturization and the development of stretchable interconnects that could withstand the mechanical stresses associated with textile movement.

Recent technological breakthroughs have centered on the development of textile-based sensors that are inherently part of the fabric structure rather than merely attached components. These innovations include conductive yarns, screen-printed electrodes on textiles, and fabric-based microfluidic systems capable of capturing and analyzing bodily fluids such as sweat. The integration of these sensing capabilities directly into everyday garments represents a paradigm shift from "wearing technology" to "technology that is worn."

The primary objective of current research in textile-integrated biosensing patches is to achieve seamless integration that maintains both the comfort and aesthetic qualities of traditional textiles while providing reliable, continuous health monitoring capabilities. This includes developing systems that can withstand washing cycles, prolonged wear, and various environmental conditions without degradation of sensing performance.

Another critical goal is the enhancement of power management systems, moving toward energy-autonomous solutions through innovations in energy harvesting from body movement, temperature differentials, or ambient light. This would eliminate the need for frequent battery replacements or recharging, significantly improving user experience and adoption rates.

Looking forward, the field aims to expand beyond physiological monitoring to include environmental sensing capabilities, creating comprehensive health monitoring ecosystems that can correlate personal health data with environmental factors. Additionally, there is growing interest in developing textile-integrated biosensing systems capable of therapeutic interventions, such as drug delivery or electrical stimulation, based on real-time physiological data analysis.

Market Analysis for Wearable Health Monitoring Textiles

The wearable health monitoring textile market is experiencing unprecedented growth, driven by increasing health consciousness and technological advancements in biosensing patches integrated with textiles. Current market valuations indicate that the global smart textile market reached approximately 3.6 billion USD in 2022, with health monitoring applications representing nearly 40% of this segment. Industry forecasts project a compound annual growth rate (CAGR) of 26.2% from 2023 to 2030, significantly outpacing traditional textile sectors.

Consumer demand analysis reveals three primary market segments: athletic performance monitoring (representing 45% of current demand), chronic disease management (30%), and preventive healthcare (25%). The athletic segment is currently the largest, but chronic disease management is expected to show the fastest growth rate due to aging populations worldwide and increasing prevalence of lifestyle diseases.

Regional market distribution shows North America leading with approximately 38% market share, followed by Europe (29%), Asia-Pacific (24%), and rest of the world (9%). However, the Asia-Pacific region is projected to witness the highest growth rate over the next five years, primarily driven by increasing healthcare expenditure in China and India, coupled with rapid technological adoption.

Key demand drivers include the rising prevalence of chronic diseases requiring continuous monitoring, growing fitness consciousness among millennials and Gen Z consumers, and increasing healthcare costs pushing the market toward preventive care solutions. The COVID-19 pandemic has further accelerated this trend, with a 34% increase in consumer interest for remote health monitoring solutions since 2020.

Market challenges include consumer concerns regarding data privacy (cited by 62% of potential users), durability of textile-integrated electronics (average expected lifespan currently at 6-8 months), and relatively high price points (current premium of 3-4x compared to non-smart alternatives). Additionally, regulatory hurdles vary significantly across regions, with medical-grade devices facing more stringent approval processes than wellness-oriented products.

Consumer preference analysis indicates strong demand for non-invasive, comfortable, and washable solutions with seamless data integration to smartphones and healthcare systems. Battery life remains a critical factor, with 78% of consumers expressing preference for devices lasting at least one week between charges. The subscription-based service model is gaining traction, with approximately 40% of current users opting for bundled hardware-software solutions rather than one-time purchases.

Consumer demand analysis reveals three primary market segments: athletic performance monitoring (representing 45% of current demand), chronic disease management (30%), and preventive healthcare (25%). The athletic segment is currently the largest, but chronic disease management is expected to show the fastest growth rate due to aging populations worldwide and increasing prevalence of lifestyle diseases.

Regional market distribution shows North America leading with approximately 38% market share, followed by Europe (29%), Asia-Pacific (24%), and rest of the world (9%). However, the Asia-Pacific region is projected to witness the highest growth rate over the next five years, primarily driven by increasing healthcare expenditure in China and India, coupled with rapid technological adoption.

Key demand drivers include the rising prevalence of chronic diseases requiring continuous monitoring, growing fitness consciousness among millennials and Gen Z consumers, and increasing healthcare costs pushing the market toward preventive care solutions. The COVID-19 pandemic has further accelerated this trend, with a 34% increase in consumer interest for remote health monitoring solutions since 2020.

Market challenges include consumer concerns regarding data privacy (cited by 62% of potential users), durability of textile-integrated electronics (average expected lifespan currently at 6-8 months), and relatively high price points (current premium of 3-4x compared to non-smart alternatives). Additionally, regulatory hurdles vary significantly across regions, with medical-grade devices facing more stringent approval processes than wellness-oriented products.

Consumer preference analysis indicates strong demand for non-invasive, comfortable, and washable solutions with seamless data integration to smartphones and healthcare systems. Battery life remains a critical factor, with 78% of consumers expressing preference for devices lasting at least one week between charges. The subscription-based service model is gaining traction, with approximately 40% of current users opting for bundled hardware-software solutions rather than one-time purchases.

Current Challenges in Textile-Based Biosensor Integration

Despite significant advancements in wearable biosensing technology, the integration of biosensors with textile substrates presents several persistent challenges that impede widespread commercial adoption. The fundamental issue lies in achieving seamless integration while maintaining both sensor functionality and textile properties. Current textile-based biosensors struggle with durability concerns, as repeated mechanical stress from washing, bending, and stretching often leads to performance degradation and sensor failure over time.

Signal quality and consistency remain problematic in real-world applications. Environmental factors such as moisture, temperature variations, and motion artifacts significantly affect measurement accuracy. The interface between rigid electronic components and flexible textiles creates mechanical stress points that compromise long-term reliability, particularly when subjected to the dynamic movements of the human body.

Power management presents another significant hurdle. Most current solutions rely on bulky batteries that compromise the comfort and wearability of textile-integrated sensors. While energy harvesting technologies show promise, they have not yet reached the efficiency levels required for continuous, reliable operation of biosensing systems in everyday scenarios.

Manufacturing scalability poses considerable challenges for commercialization. Current fabrication methods often involve complex, multi-step processes that are difficult to scale for mass production. The integration of electronic components with textiles typically requires specialized equipment and expertise, resulting in high production costs that limit market accessibility.

Biocompatibility and user comfort issues persist in existing designs. Many conductive materials and sensing elements cause skin irritation during prolonged contact or change properties when exposed to sweat and body oils. The balance between sensor performance and textile comfort remains difficult to achieve, with many solutions sacrificing one for the other.

Data processing and connectivity infrastructure present additional challenges. Most textile-based biosensors generate continuous data streams that require substantial processing power, yet must operate within the constraints of wearable form factors. Wireless communication protocols must balance power efficiency with reliable data transmission, while addressing privacy and security concerns inherent in health monitoring applications.

Regulatory hurdles further complicate commercialization efforts. The classification of textile-based biosensors often falls into ambiguous categories between medical devices and consumer electronics, creating uncertainty regarding certification requirements and compliance standards. This regulatory complexity increases development costs and time-to-market for innovative solutions.

Signal quality and consistency remain problematic in real-world applications. Environmental factors such as moisture, temperature variations, and motion artifacts significantly affect measurement accuracy. The interface between rigid electronic components and flexible textiles creates mechanical stress points that compromise long-term reliability, particularly when subjected to the dynamic movements of the human body.

Power management presents another significant hurdle. Most current solutions rely on bulky batteries that compromise the comfort and wearability of textile-integrated sensors. While energy harvesting technologies show promise, they have not yet reached the efficiency levels required for continuous, reliable operation of biosensing systems in everyday scenarios.

Manufacturing scalability poses considerable challenges for commercialization. Current fabrication methods often involve complex, multi-step processes that are difficult to scale for mass production. The integration of electronic components with textiles typically requires specialized equipment and expertise, resulting in high production costs that limit market accessibility.

Biocompatibility and user comfort issues persist in existing designs. Many conductive materials and sensing elements cause skin irritation during prolonged contact or change properties when exposed to sweat and body oils. The balance between sensor performance and textile comfort remains difficult to achieve, with many solutions sacrificing one for the other.

Data processing and connectivity infrastructure present additional challenges. Most textile-based biosensors generate continuous data streams that require substantial processing power, yet must operate within the constraints of wearable form factors. Wireless communication protocols must balance power efficiency with reliable data transmission, while addressing privacy and security concerns inherent in health monitoring applications.

Regulatory hurdles further complicate commercialization efforts. The classification of textile-based biosensors often falls into ambiguous categories between medical devices and consumer electronics, creating uncertainty regarding certification requirements and compliance standards. This regulatory complexity increases development costs and time-to-market for innovative solutions.

Existing Integration Methods for Textile-Based Biosensors

01 Flexible and adhesive biosensing patches

Wearable biosensing patches designed with flexible and adhesive materials that conform to the body's contours for continuous monitoring. These patches incorporate stretchable electronics and skin-friendly adhesives to ensure comfort during extended wear while maintaining reliable sensor contact with the skin. The flexible design allows for natural movement without compromising data collection accuracy or causing skin irritation.- Flexible and adhesive biosensing patches: Wearable biosensing patches designed with flexible and adhesive materials that conform to the body's contours for continuous monitoring. These patches incorporate stretchable substrates and biocompatible adhesives to ensure comfort during prolonged wear while maintaining reliable sensor contact with the skin. The flexible design allows for natural movement without compromising data collection accuracy or causing skin irritation.

- Multimodal physiological monitoring systems: Advanced biosensing patches capable of simultaneously monitoring multiple physiological parameters such as heart rate, temperature, blood oxygen levels, and sweat composition. These integrated systems combine various sensor types within a single patch platform to provide comprehensive health data. The multimodal approach enables more accurate health assessments by correlating different physiological signals and detecting patterns that might not be apparent from single-parameter monitoring.

- Wireless data transmission and power management: Biosensing patches equipped with wireless communication capabilities for real-time data transmission to smartphones or cloud platforms. These systems incorporate energy-efficient microcontrollers and optimized power management solutions, including thin-film batteries or energy harvesting technologies. The wireless design eliminates the need for physical connections, enhancing user comfort while enabling continuous remote monitoring and timely medical interventions.

- Specialized biomarker detection patches: Wearable patches designed to detect specific biomarkers in bodily fluids such as sweat, interstitial fluid, or through non-invasive transdermal sensing. These patches incorporate specialized biochemical sensors, including enzymatic electrodes, immunosensors, or molecularly imprinted polymers to target particular analytes. Applications include glucose monitoring, stress hormone detection, electrolyte balance assessment, and early disease biomarker identification.

- Smart patch systems with integrated analytics: Advanced biosensing patches that incorporate on-device data processing capabilities and artificial intelligence algorithms for real-time health analytics. These smart systems can detect anomalies, predict health events, and provide personalized feedback directly to users or healthcare providers. The integration of edge computing reduces dependency on continuous connectivity while enabling more sophisticated analysis of physiological data patterns for preventive healthcare applications.

02 Biomarker detection and analysis systems

Biosensing patches equipped with specialized sensors for detecting and analyzing various biomarkers in bodily fluids such as sweat, interstitial fluid, or blood. These systems can monitor glucose levels, electrolytes, metabolites, hormones, and other biochemical markers. The patches incorporate microfluidic channels and electrochemical sensors to collect and analyze samples non-invasively, providing real-time health data for medical monitoring or fitness applications.Expand Specific Solutions03 Wireless data transmission and connectivity

Integration of wireless communication technologies in biosensing patches for seamless data transmission to smartphones, tablets, or cloud platforms. These patches feature low-power Bluetooth, NFC, or other wireless protocols to transmit collected biometric data in real-time or at scheduled intervals. The connectivity allows for remote monitoring by healthcare providers, automated alerts for abnormal readings, and integration with health management applications.Expand Specific Solutions04 Energy harvesting and power management

Advanced power management systems and energy harvesting technologies for extended operation of wearable biosensing patches. These innovations include miniaturized batteries, solar cells, thermal energy harvesters, or motion-based power generation to extend the operational life of the patches. Power optimization algorithms and low-energy components ensure continuous monitoring without frequent charging or replacement.Expand Specific Solutions05 Multi-parameter physiological monitoring

Comprehensive biosensing patches capable of simultaneously monitoring multiple physiological parameters such as heart rate, body temperature, respiratory rate, blood pressure, oxygen saturation, and motion. These multi-functional patches integrate various sensor types within a single wearable device to provide holistic health monitoring. Advanced algorithms process the combined data to deliver more accurate health assessments and detect correlations between different physiological metrics.Expand Specific Solutions

Leading Companies and Research Institutions in Smart Textiles

The wearable biosensing patches integrated with textile substrates market is in an early growth phase, characterized by rapid technological innovation and expanding applications. The global market size is estimated to reach $2-3 billion by 2025, growing at a CAGR of approximately 20%. Technology maturity varies across players: established companies like Philips, Intel, and Eli Lilly are leveraging their R&D capabilities to develop advanced solutions, while universities (North Carolina State, Fudan, Northwestern) are pioneering fundamental research. Specialized firms like VivaLNK and Onera Technologies are driving innovation with flexible, textile-integrated sensors. Emerging players such as Prevayl Innovations and GoerTek are focusing on consumer applications, while medical device companies (Nipro, Fresenius) are targeting healthcare applications with regulatory-compliant solutions. The convergence of textile engineering, electronics miniaturization, and biomedical sensing is accelerating commercialization across multiple sectors.

North Carolina State University

Technical Solution: North Carolina State University has pioneered textile-based biosensing technology through their innovative "e-textiles" platform. Their approach focuses on directly embedding sensing capabilities into the fabric structure rather than merely attaching sensors to textiles. The university has developed specialized conductive yarns and fibers that can be woven or knitted into everyday fabrics while maintaining textile properties like drapeability and washability. Their biosensing patches utilize a combination of screen-printed electrodes, conductive polymers, and specialized textile treatments to create sensing zones within garments[3]. The technology incorporates distributed sensor networks throughout the textile that can monitor multiple physiological parameters simultaneously, including ECG, EMG, respiration, and motion. A key innovation is their development of textile-based interconnects that maintain electrical functionality even under mechanical deformation, solving a critical challenge in wearable textile electronics[4]. Their patches also feature specialized encapsulation techniques that protect electronic components while allowing breathability.

Strengths: Truly textile-integrated approach maintains fabric comfort and aesthetics; washable and durable designs suitable for everyday use; scalable manufacturing processes compatible with existing textile production. Weaknesses: Lower sensor sensitivity compared to rigid electronics; potential signal degradation over time with repeated washing and wear; challenges in power management for textile-integrated systems.

Koninklijke Philips NV

Technical Solution: Philips has developed an advanced commercial platform for wearable biosensing patches integrated with textiles, focusing on clinical-grade monitoring in both healthcare and consumer applications. Their technology utilizes a modular approach where sensing components can be easily attached to and detached from specially designed textile substrates. The biosensing patches incorporate Philips' proprietary sensor fusion algorithms that combine data from multiple sensing modalities to provide accurate physiological measurements while compensating for motion artifacts and environmental factors[5]. Their system features miniaturized, flexible printed circuit boards (PCBs) with specialized textile-compatible connectors that maintain reliable electrical connections despite body movement. Philips' patches employ low-power Bluetooth technology for wireless data transmission to smartphones or dedicated receivers, enabling continuous monitoring without frequent battery changes. The company has also developed specialized adhesives and attachment mechanisms that allow secure sensor placement on textiles while maintaining comfort during extended wear periods[6]. Their technology includes advanced power management systems that optimize battery life through adaptive sampling rates based on user activity levels.

Strengths: Clinical-grade accuracy validated through extensive medical testing; established manufacturing infrastructure enabling mass production; comprehensive ecosystem including software platforms for data analysis. Weaknesses: Higher cost compared to consumer-grade alternatives; proprietary systems may limit interoperability with third-party devices; relatively larger form factor compared to purely research-focused solutions.

Key Patents and Innovations in Textile Biosensing Technology

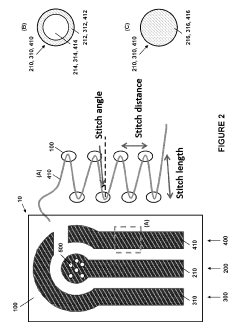

Embroidered electrochemical biosensors and related methods

PatentActiveUS20190137436A1

Innovation

- Development of self-powered textile biosensors using a bio-micro-electromechanical system (bioMEMS) platform with embroidered electrochemical sensors integrated into flexible substrates, featuring working, counter, and reference electrodes made from conductive fibers, which can detect target analytes through enzyme or capture probes, enabling continuous health monitoring and point-of-care diagnostics.

Materials Science Advancements for Flexible Biosensing Patches

Recent advancements in materials science have revolutionized the development of flexible biosensing patches, enabling seamless integration with textile substrates. The evolution of these materials has progressed from rigid electronic components to highly flexible, stretchable, and conformable structures that maintain functionality under mechanical deformation.

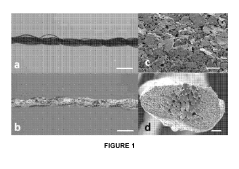

Conductive polymers such as PEDOT:PSS and polyaniline have emerged as critical materials, offering excellent electrical properties while maintaining flexibility. These polymers can be formulated as inks for direct printing onto textiles, creating conductive pathways without compromising the fabric's inherent properties. Additionally, carbon-based nanomaterials including graphene and carbon nanotubes provide exceptional electrical conductivity with minimal thickness, allowing for ultrathin sensing layers that conform to body contours.

Substrate materials have similarly evolved, with biocompatible elastomers like PDMS (polydimethylsiloxane) and thermoplastic polyurethanes (TPUs) serving as flexible foundations for sensor components. These materials offer stretchability exceeding 100% while maintaining structural integrity, crucial for applications on dynamic body surfaces. Recent innovations include self-healing polymers that can recover from mechanical damage, extending device lifespan in real-world conditions.

Adhesion technologies have addressed the critical challenge of maintaining stable interfaces between electronic components and textile substrates. Novel approaches include plasma treatment of textile surfaces to enhance chemical bonding, and the development of specialized adhesives that maintain flexibility while ensuring component attachment. Researchers have also explored mechanical interlocking mechanisms where conductive materials penetrate the textile structure, creating robust connections resistant to washing and mechanical stress.

Encapsulation materials represent another frontier, with multilayer barrier films providing protection against moisture and environmental contaminants while maintaining gas permeability for skin health. Breathable fluoropolymers and parylene variants offer nanoscale protection without compromising sensor performance or user comfort.

The integration of these material advances has enabled unprecedented capabilities in textile-integrated biosensing. For instance, silver nanowire networks embedded in elastomeric matrices can maintain conductivity even at 50% strain, while graphene-based sensors printed directly onto treated cotton fabrics have demonstrated stable electrochemical performance through multiple washing cycles. These developments point toward truly wearable, comfortable biosensing systems that users can forget they're wearing while continuously monitoring vital physiological parameters.

Conductive polymers such as PEDOT:PSS and polyaniline have emerged as critical materials, offering excellent electrical properties while maintaining flexibility. These polymers can be formulated as inks for direct printing onto textiles, creating conductive pathways without compromising the fabric's inherent properties. Additionally, carbon-based nanomaterials including graphene and carbon nanotubes provide exceptional electrical conductivity with minimal thickness, allowing for ultrathin sensing layers that conform to body contours.

Substrate materials have similarly evolved, with biocompatible elastomers like PDMS (polydimethylsiloxane) and thermoplastic polyurethanes (TPUs) serving as flexible foundations for sensor components. These materials offer stretchability exceeding 100% while maintaining structural integrity, crucial for applications on dynamic body surfaces. Recent innovations include self-healing polymers that can recover from mechanical damage, extending device lifespan in real-world conditions.

Adhesion technologies have addressed the critical challenge of maintaining stable interfaces between electronic components and textile substrates. Novel approaches include plasma treatment of textile surfaces to enhance chemical bonding, and the development of specialized adhesives that maintain flexibility while ensuring component attachment. Researchers have also explored mechanical interlocking mechanisms where conductive materials penetrate the textile structure, creating robust connections resistant to washing and mechanical stress.

Encapsulation materials represent another frontier, with multilayer barrier films providing protection against moisture and environmental contaminants while maintaining gas permeability for skin health. Breathable fluoropolymers and parylene variants offer nanoscale protection without compromising sensor performance or user comfort.

The integration of these material advances has enabled unprecedented capabilities in textile-integrated biosensing. For instance, silver nanowire networks embedded in elastomeric matrices can maintain conductivity even at 50% strain, while graphene-based sensors printed directly onto treated cotton fabrics have demonstrated stable electrochemical performance through multiple washing cycles. These developments point toward truly wearable, comfortable biosensing systems that users can forget they're wearing while continuously monitoring vital physiological parameters.

Washability and Durability Solutions for Smart Textiles

Washability and durability represent critical challenges for wearable biosensing patches integrated with textile substrates. Traditional electronic components are inherently vulnerable to water exposure, mechanical stress, and repeated washing cycles, which are inevitable in textile applications. The integration of electronic sensing elements with fabrics creates a complex interface where material compatibility, adhesion stability, and environmental resistance must be carefully engineered.

Current washability solutions focus on several protective strategies. Encapsulation techniques using hydrophobic polymers such as polydimethylsiloxane (PDMS) and parylene-C have demonstrated significant water resistance while maintaining flexibility. These materials create a conformal coating that shields sensitive electronic components without compromising the textile's natural drape and comfort. Advanced multi-layer encapsulation approaches combine different materials to achieve both waterproofing and breathability.

Durability enhancements have evolved through structural innovations in circuit design. Serpentine and mesh-like conductive patterns allow for mechanical deformation without fracturing, accommodating the stretching and bending experienced during normal wear and washing. Stretchable conductive inks incorporating silver nanoparticles or carbon-based materials maintain electrical performance even after repeated mechanical stress cycles, with some formulations retaining over 90% conductivity after 50 washing cycles.

Material selection has proven crucial for long-term durability. Textile-compatible conductive materials like PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) offer superior adhesion to fabric substrates compared to traditional metallic conductors. Recent developments in textile-electronic interfaces include plasma treatment processes that enhance adhesion between electronic components and fabric surfaces, creating stronger bonds that withstand mechanical agitation during washing.

Testing protocols have become increasingly standardized, with accelerated aging tests simulating multiple washing cycles under controlled conditions. ISO 6330 standards for textile washing and drying procedures have been adapted specifically for smart textiles, providing benchmarks for washability performance. Industry leaders now routinely test for 20-30 washing cycles as a minimum durability requirement.

Future directions point toward self-healing materials that can automatically repair microdamages caused by washing and wear. Preliminary research shows promising results with conductive polymers containing microcapsules that release healing agents when mechanical damage occurs. Additionally, modular design approaches allowing for removable electronic components before washing offer a practical interim solution while fully washable technologies continue to develop.

Current washability solutions focus on several protective strategies. Encapsulation techniques using hydrophobic polymers such as polydimethylsiloxane (PDMS) and parylene-C have demonstrated significant water resistance while maintaining flexibility. These materials create a conformal coating that shields sensitive electronic components without compromising the textile's natural drape and comfort. Advanced multi-layer encapsulation approaches combine different materials to achieve both waterproofing and breathability.

Durability enhancements have evolved through structural innovations in circuit design. Serpentine and mesh-like conductive patterns allow for mechanical deformation without fracturing, accommodating the stretching and bending experienced during normal wear and washing. Stretchable conductive inks incorporating silver nanoparticles or carbon-based materials maintain electrical performance even after repeated mechanical stress cycles, with some formulations retaining over 90% conductivity after 50 washing cycles.

Material selection has proven crucial for long-term durability. Textile-compatible conductive materials like PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) offer superior adhesion to fabric substrates compared to traditional metallic conductors. Recent developments in textile-electronic interfaces include plasma treatment processes that enhance adhesion between electronic components and fabric surfaces, creating stronger bonds that withstand mechanical agitation during washing.

Testing protocols have become increasingly standardized, with accelerated aging tests simulating multiple washing cycles under controlled conditions. ISO 6330 standards for textile washing and drying procedures have been adapted specifically for smart textiles, providing benchmarks for washability performance. Industry leaders now routinely test for 20-30 washing cycles as a minimum durability requirement.

Future directions point toward self-healing materials that can automatically repair microdamages caused by washing and wear. Preliminary research shows promising results with conductive polymers containing microcapsules that release healing agents when mechanical damage occurs. Additionally, modular design approaches allowing for removable electronic components before washing offer a practical interim solution while fully washable technologies continue to develop.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!