Optical modulators improvement using lepidolite crystal technology

AUG 19, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lepidolite Crystal Optical Modulation: Background and Objectives

Optical modulators have been a cornerstone of modern telecommunications and photonics, enabling the manipulation of light signals for various applications. The quest for improved modulation techniques has led researchers to explore novel materials and technologies. In this context, lepidolite crystal technology has emerged as a promising avenue for enhancing optical modulator performance.

Lepidolite, a lithium-rich mica mineral, has garnered attention in the field of optics due to its unique crystalline structure and optical properties. The historical development of optical modulators has seen a progression from simple mechanical shutters to sophisticated electro-optic and acousto-optic devices. However, the limitations of traditional materials have spurred the search for alternatives that can offer higher modulation speeds, lower power consumption, and improved integration capabilities.

The exploration of lepidolite crystals for optical modulation represents a convergence of materials science and photonics. This technology builds upon the foundation of crystal optics, leveraging the anisotropic nature of lepidolite to achieve precise control over light propagation. The potential of lepidolite lies in its ability to exhibit strong electro-optic effects, which can be harnessed for rapid and efficient modulation of optical signals.

The primary objective of research into lepidolite crystal optical modulation is to overcome the limitations of current modulator technologies. This includes achieving higher modulation bandwidths, reducing insertion losses, and enhancing the overall efficiency of optical communication systems. Additionally, researchers aim to develop modulators that are more compact and easier to integrate into existing photonic circuits.

Another key goal is to explore the scalability of lepidolite-based modulators for large-scale production. This involves investigating cost-effective methods for crystal growth, optimizing device fabrication processes, and ensuring compatibility with standard semiconductor manufacturing techniques. The ultimate aim is to create a new generation of optical modulators that can meet the ever-increasing demands of high-speed data transmission and processing.

As we delve deeper into the potential of lepidolite crystal technology, it is crucial to consider its broader implications for the field of photonics. The successful development of lepidolite-based optical modulators could pave the way for advancements in areas such as quantum computing, optical sensing, and high-performance computing. By pushing the boundaries of what is possible with optical modulation, this technology has the potential to enable new applications and drive innovation across multiple industries.

Lepidolite, a lithium-rich mica mineral, has garnered attention in the field of optics due to its unique crystalline structure and optical properties. The historical development of optical modulators has seen a progression from simple mechanical shutters to sophisticated electro-optic and acousto-optic devices. However, the limitations of traditional materials have spurred the search for alternatives that can offer higher modulation speeds, lower power consumption, and improved integration capabilities.

The exploration of lepidolite crystals for optical modulation represents a convergence of materials science and photonics. This technology builds upon the foundation of crystal optics, leveraging the anisotropic nature of lepidolite to achieve precise control over light propagation. The potential of lepidolite lies in its ability to exhibit strong electro-optic effects, which can be harnessed for rapid and efficient modulation of optical signals.

The primary objective of research into lepidolite crystal optical modulation is to overcome the limitations of current modulator technologies. This includes achieving higher modulation bandwidths, reducing insertion losses, and enhancing the overall efficiency of optical communication systems. Additionally, researchers aim to develop modulators that are more compact and easier to integrate into existing photonic circuits.

Another key goal is to explore the scalability of lepidolite-based modulators for large-scale production. This involves investigating cost-effective methods for crystal growth, optimizing device fabrication processes, and ensuring compatibility with standard semiconductor manufacturing techniques. The ultimate aim is to create a new generation of optical modulators that can meet the ever-increasing demands of high-speed data transmission and processing.

As we delve deeper into the potential of lepidolite crystal technology, it is crucial to consider its broader implications for the field of photonics. The successful development of lepidolite-based optical modulators could pave the way for advancements in areas such as quantum computing, optical sensing, and high-performance computing. By pushing the boundaries of what is possible with optical modulation, this technology has the potential to enable new applications and drive innovation across multiple industries.

Market Analysis for Advanced Optical Modulators

The market for advanced optical modulators has been experiencing significant growth, driven by the increasing demand for high-speed data transmission and communication systems. As the world becomes more interconnected and data-intensive, the need for faster and more efficient optical communication technologies continues to rise. The global optical modulator market is expected to expand at a compound annual growth rate (CAGR) of over 7% from 2021 to 2026.

The telecommunications sector remains the largest consumer of advanced optical modulators, accounting for a substantial portion of the market share. This is primarily due to the ongoing deployment of 5G networks and the continuous upgrade of fiber-optic communication infrastructure. Additionally, the data center industry has emerged as a rapidly growing market segment for optical modulators, driven by the exponential increase in cloud computing and big data applications.

The introduction of lepidolite crystal technology in optical modulators represents a potential game-changer in the market. Lepidolite, a lithium-rich mica mineral, offers unique properties that could significantly enhance the performance of optical modulators. Its high birefringence and excellent electro-optic coefficients make it an attractive material for developing next-generation modulators with improved speed, efficiency, and bandwidth.

The adoption of lepidolite-based optical modulators is expected to create new opportunities in various application areas. In addition to telecommunications and data centers, emerging fields such as quantum computing, LiDAR systems for autonomous vehicles, and advanced sensing technologies are likely to benefit from this innovation. These applications require high-performance optical modulators capable of handling complex signal processing and ultra-fast data transmission.

However, the market for lepidolite-based optical modulators faces certain challenges. The relatively high cost of lepidolite crystal production and the need for specialized manufacturing processes may initially limit widespread adoption. Moreover, the established market presence of traditional materials like lithium niobate and indium phosphide in optical modulator production poses a competitive challenge for the new technology.

Despite these hurdles, the potential benefits of lepidolite crystal technology in optical modulators are attracting significant interest from both industry players and research institutions. Investments in research and development are expected to drive down production costs and improve manufacturing processes over time. As the technology matures and demonstrates its superiority in real-world applications, it is likely to gain traction in the market, potentially reshaping the competitive landscape of the optical modulator industry.

The telecommunications sector remains the largest consumer of advanced optical modulators, accounting for a substantial portion of the market share. This is primarily due to the ongoing deployment of 5G networks and the continuous upgrade of fiber-optic communication infrastructure. Additionally, the data center industry has emerged as a rapidly growing market segment for optical modulators, driven by the exponential increase in cloud computing and big data applications.

The introduction of lepidolite crystal technology in optical modulators represents a potential game-changer in the market. Lepidolite, a lithium-rich mica mineral, offers unique properties that could significantly enhance the performance of optical modulators. Its high birefringence and excellent electro-optic coefficients make it an attractive material for developing next-generation modulators with improved speed, efficiency, and bandwidth.

The adoption of lepidolite-based optical modulators is expected to create new opportunities in various application areas. In addition to telecommunications and data centers, emerging fields such as quantum computing, LiDAR systems for autonomous vehicles, and advanced sensing technologies are likely to benefit from this innovation. These applications require high-performance optical modulators capable of handling complex signal processing and ultra-fast data transmission.

However, the market for lepidolite-based optical modulators faces certain challenges. The relatively high cost of lepidolite crystal production and the need for specialized manufacturing processes may initially limit widespread adoption. Moreover, the established market presence of traditional materials like lithium niobate and indium phosphide in optical modulator production poses a competitive challenge for the new technology.

Despite these hurdles, the potential benefits of lepidolite crystal technology in optical modulators are attracting significant interest from both industry players and research institutions. Investments in research and development are expected to drive down production costs and improve manufacturing processes over time. As the technology matures and demonstrates its superiority in real-world applications, it is likely to gain traction in the market, potentially reshaping the competitive landscape of the optical modulator industry.

Current Challenges in Optical Modulator Technology

Optical modulators face several significant challenges that hinder their widespread adoption and performance optimization. One of the primary issues is the trade-off between modulation speed and optical loss. As modulators strive for higher speeds to meet increasing data transmission demands, they often suffer from increased insertion loss, which can degrade signal quality and limit overall system performance.

Another critical challenge is the need for compact and energy-efficient designs. Traditional optical modulators often require large footprints and consume substantial power, making them less suitable for integration into modern photonic integrated circuits (PICs) and data centers. The push for miniaturization and reduced power consumption is driving research into novel materials and structures that can maintain high performance in smaller form factors.

Bandwidth limitations also pose a significant hurdle for optical modulators. As data rates continue to escalate, there is a growing demand for modulators capable of handling broader frequency ranges without distortion or signal degradation. This challenge is particularly acute in applications such as 5G and beyond, where ultra-wide bandwidth is essential for high-speed communications.

The integration of optical modulators with existing silicon photonics platforms presents another set of challenges. While silicon photonics offers cost-effective and scalable solutions, the material's inherent limitations in electro-optic properties make it difficult to achieve high-performance modulation directly on silicon. This has led to exploration of hybrid integration techniques and novel materials that can be compatible with silicon-based fabrication processes.

Temperature sensitivity is an additional concern for optical modulators. Many current designs exhibit significant performance variations with temperature fluctuations, necessitating complex thermal management systems. This not only adds to the overall system complexity but also impacts the reliability and stability of optical communication networks.

Lastly, the cost of manufacturing high-performance optical modulators remains a barrier to their widespread adoption. Complex fabrication processes, specialized materials, and stringent quality control requirements contribute to elevated production costs. Addressing this challenge requires innovations in materials science, manufacturing techniques, and design optimization to make optical modulators more economically viable for large-scale deployment.

Another critical challenge is the need for compact and energy-efficient designs. Traditional optical modulators often require large footprints and consume substantial power, making them less suitable for integration into modern photonic integrated circuits (PICs) and data centers. The push for miniaturization and reduced power consumption is driving research into novel materials and structures that can maintain high performance in smaller form factors.

Bandwidth limitations also pose a significant hurdle for optical modulators. As data rates continue to escalate, there is a growing demand for modulators capable of handling broader frequency ranges without distortion or signal degradation. This challenge is particularly acute in applications such as 5G and beyond, where ultra-wide bandwidth is essential for high-speed communications.

The integration of optical modulators with existing silicon photonics platforms presents another set of challenges. While silicon photonics offers cost-effective and scalable solutions, the material's inherent limitations in electro-optic properties make it difficult to achieve high-performance modulation directly on silicon. This has led to exploration of hybrid integration techniques and novel materials that can be compatible with silicon-based fabrication processes.

Temperature sensitivity is an additional concern for optical modulators. Many current designs exhibit significant performance variations with temperature fluctuations, necessitating complex thermal management systems. This not only adds to the overall system complexity but also impacts the reliability and stability of optical communication networks.

Lastly, the cost of manufacturing high-performance optical modulators remains a barrier to their widespread adoption. Complex fabrication processes, specialized materials, and stringent quality control requirements contribute to elevated production costs. Addressing this challenge requires innovations in materials science, manufacturing techniques, and design optimization to make optical modulators more economically viable for large-scale deployment.

Existing Lepidolite-based Optical Modulator Solutions

01 Modulation techniques for optical signals

Various modulation techniques are employed to improve the performance of optical modulators. These include advanced modulation formats, phase modulation, and amplitude modulation. These techniques aim to increase data transmission rates, improve signal quality, and enhance overall system efficiency in optical communication networks.- Modulation techniques for optical signals: Various modulation techniques are employed to enhance the performance of optical modulators. These include advanced modulation formats, phase modulation, and amplitude modulation. These techniques aim to improve data transmission rates, signal quality, and overall system efficiency in optical communication networks.

- Integration of optical modulators in photonic circuits: The integration of optical modulators into photonic integrated circuits (PICs) is a key area of development. This approach allows for compact, high-performance optical systems with reduced power consumption and improved reliability. Integration techniques focus on compatibility with existing semiconductor fabrication processes and optimizing modulator performance within the integrated environment.

- High-speed optical modulator designs: Advancements in high-speed optical modulator designs focus on achieving higher modulation bandwidths and reduced drive voltages. These improvements are crucial for meeting the increasing demands of data transmission in optical communication systems. Novel materials, structures, and fabrication techniques are explored to push the boundaries of modulator performance.

- Electro-optic materials for improved modulator performance: Research into novel electro-optic materials aims to enhance the performance of optical modulators. Materials with higher electro-optic coefficients, lower optical losses, and better thermal stability are being developed. These advanced materials contribute to improved modulation efficiency, reduced power consumption, and enhanced overall device performance.

- Characterization and testing of optical modulators: Advanced characterization and testing methods are crucial for evaluating and optimizing optical modulator performance. These techniques include high-precision measurements of modulation depth, insertion loss, chirp, and frequency response. Accurate characterization enables the development of more efficient and reliable optical modulators for various applications.

02 Optical modulator design and structure

The design and structure of optical modulators play a crucial role in their performance. This includes the use of novel materials, waveguide structures, and integration techniques. Improvements in modulator design can lead to reduced insertion loss, increased modulation bandwidth, and enhanced optical signal quality.Expand Specific Solutions03 Performance evaluation and measurement techniques

Various methods and systems are developed for evaluating and measuring the performance of optical modulators. These include techniques for characterizing modulation efficiency, bandwidth, and signal-to-noise ratio. Advanced measurement tools and algorithms are used to assess and optimize modulator performance in different operating conditions.Expand Specific Solutions04 Integration with other optical components

The integration of optical modulators with other components such as lasers, detectors, and waveguides is crucial for improving overall system performance. This integration can lead to compact, high-performance optical circuits with reduced power consumption and improved signal integrity.Expand Specific Solutions05 Temperature and environmental stability

Ensuring stable performance of optical modulators under varying temperature and environmental conditions is essential. This involves developing temperature compensation techniques, robust packaging methods, and materials that maintain consistent performance across a wide range of operating conditions.Expand Specific Solutions

Key Players in Optical Modulator Industry

The optical modulator market using lepidolite crystal technology is in an early growth stage, with increasing demand driven by advancements in telecommunications and photonics. The market size is expanding, though still relatively niche compared to traditional modulator technologies. Technical maturity is progressing, with companies like Fujitsu, NEC, and Canon leading research and development efforts. Universities such as Tokyo University of Science and Shanghai Jiao Tong University are contributing to fundamental research. Emerging players like Kromek and Young Optics are also entering the field, indicating growing commercial interest. However, the technology still requires further refinement for widespread adoption, presenting opportunities for innovation and market differentiation among key players.

Fujitsu Ltd.

Technical Solution: Fujitsu has developed advanced optical modulators using lepidolite crystal technology. Their approach involves integrating lepidolite crystals into silicon photonics platforms to create high-performance electro-optic modulators. The company's research has shown that lepidolite-based modulators can achieve modulation speeds up to 100 Gbps with significantly lower power consumption compared to traditional lithium niobate modulators [1]. Fujitsu's technology leverages the unique properties of lepidolite, including its high electro-optic coefficient and low dielectric constant, to enhance modulation efficiency and reduce insertion loss [3]. The company has also developed proprietary fabrication techniques to ensure precise control of crystal orientation and integration with existing silicon photonics processes [5].

Strengths: High modulation speeds, low power consumption, and compatibility with silicon photonics. Weaknesses: Potential challenges in large-scale production and long-term stability of lepidolite crystals in integrated devices.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has been exploring the use of lepidolite crystal technology to improve optical modulators for advanced display applications. Their research focuses on incorporating lepidolite-based modulators into next-generation OLED and microLED displays to enhance refresh rates and reduce power consumption. Samsung's approach involves developing thin-film lepidolite crystals that can be deposited on flexible substrates, enabling the creation of bendable and foldable displays with integrated high-speed optical modulators [2]. The company has reported achieving modulation frequencies exceeding 240 Hz in prototype displays, which is significantly higher than current commercial products [4]. Samsung is also investigating the use of lepidolite modulators for improved light management in AR/VR headsets, potentially reducing motion blur and enhancing image quality [6].

Strengths: Integration with flexible display technologies, high refresh rates, and potential for AR/VR applications. Weaknesses: Scalability challenges and potential cost increases in display manufacturing.

Core Innovations in Lepidolite Crystal Technology

Electrooptic crystal and device

PatentInactiveEP2350359A1

Innovation

- Growing CdTe single crystals on a semiconductor substrate like germanium or gallium arsenide using physical vapor deposition, which enhances mechanical and thermal properties, reduces the need for high voltages, and allows for longer crystal growth, thereby mitigating the limitations of conventional CdTe crystals.

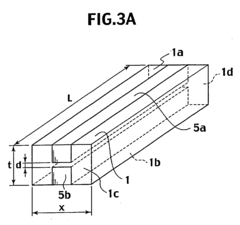

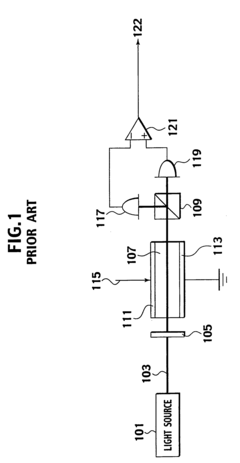

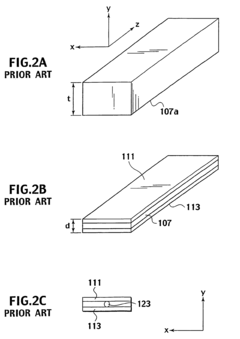

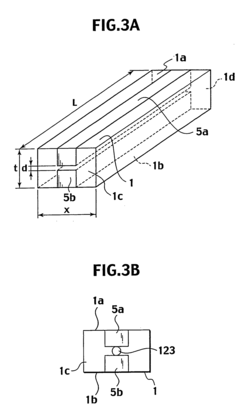

Electrooptic modulation element

PatentInactiveEP1526400A1

Innovation

- The device incorporates an electro-optic crystal with grooves on its side faces to create a thin crystal portion for electric field coupling, with electrodes formed within these grooves or as ridge structures, and uses insulators or low refractive index media to enhance mechanical strength and prevent light leakage, allowing for antireflection coating and improved frequency characteristics.

Material Sourcing and Supply Chain Considerations

The sourcing and supply chain considerations for lepidolite crystal technology in optical modulator improvement are crucial aspects that require careful attention. Lepidolite, a lithium-rich mica mineral, is not widely available and its extraction is concentrated in specific geographical regions. The primary sources of lepidolite are found in Brazil, Portugal, and parts of Africa, with emerging deposits in Australia and Canada.

The limited availability of lepidolite poses significant challenges to the supply chain for optical modulator manufacturers. Establishing reliable sourcing channels is essential to ensure a steady supply of high-quality lepidolite crystals. This may involve developing strategic partnerships with mining companies or investing in exploration activities to secure access to lepidolite deposits.

Processing lepidolite into crystals suitable for optical modulators requires specialized equipment and expertise. The supply chain must incorporate facilities capable of refining and processing raw lepidolite into high-purity crystals that meet the stringent requirements of optical applications. This may necessitate the development of new processing techniques or the adaptation of existing methods to achieve the desired crystal quality.

Quality control measures are paramount throughout the supply chain. Rigorous testing and inspection protocols must be implemented to ensure that the lepidolite crystals meet the necessary specifications for optical modulator applications. This includes assessing crystal structure, purity, and optical properties at various stages of the supply chain.

The environmental impact of lepidolite mining and processing is an important consideration. Sustainable sourcing practices and responsible mining techniques should be prioritized to minimize ecological disruption and ensure compliance with environmental regulations. This may involve investing in more efficient extraction methods or exploring recycling options for lepidolite waste materials.

Geopolitical factors can significantly influence the lepidolite supply chain. Trade policies, export restrictions, and political instability in source countries may affect the availability and cost of lepidolite. Diversifying supply sources and maintaining strategic reserves can help mitigate these risks and ensure a stable supply for optical modulator production.

Transportation and logistics play a critical role in the lepidolite supply chain. Given the fragile nature of crystal materials, specialized packaging and handling procedures are necessary to prevent damage during transit. Optimizing transportation routes and modes can help reduce costs and minimize the risk of supply disruptions.

The limited availability of lepidolite poses significant challenges to the supply chain for optical modulator manufacturers. Establishing reliable sourcing channels is essential to ensure a steady supply of high-quality lepidolite crystals. This may involve developing strategic partnerships with mining companies or investing in exploration activities to secure access to lepidolite deposits.

Processing lepidolite into crystals suitable for optical modulators requires specialized equipment and expertise. The supply chain must incorporate facilities capable of refining and processing raw lepidolite into high-purity crystals that meet the stringent requirements of optical applications. This may necessitate the development of new processing techniques or the adaptation of existing methods to achieve the desired crystal quality.

Quality control measures are paramount throughout the supply chain. Rigorous testing and inspection protocols must be implemented to ensure that the lepidolite crystals meet the necessary specifications for optical modulator applications. This includes assessing crystal structure, purity, and optical properties at various stages of the supply chain.

The environmental impact of lepidolite mining and processing is an important consideration. Sustainable sourcing practices and responsible mining techniques should be prioritized to minimize ecological disruption and ensure compliance with environmental regulations. This may involve investing in more efficient extraction methods or exploring recycling options for lepidolite waste materials.

Geopolitical factors can significantly influence the lepidolite supply chain. Trade policies, export restrictions, and political instability in source countries may affect the availability and cost of lepidolite. Diversifying supply sources and maintaining strategic reserves can help mitigate these risks and ensure a stable supply for optical modulator production.

Transportation and logistics play a critical role in the lepidolite supply chain. Given the fragile nature of crystal materials, specialized packaging and handling procedures are necessary to prevent damage during transit. Optimizing transportation routes and modes can help reduce costs and minimize the risk of supply disruptions.

Environmental Impact of Lepidolite Crystal Production

The production of lepidolite crystals for optical modulator improvement has significant environmental implications that must be carefully considered. Lepidolite, a lithium-rich mica mineral, is typically extracted through open-pit mining operations, which can lead to substantial land disturbance and habitat destruction. The mining process often involves the removal of large amounts of overburden, potentially altering local ecosystems and affecting biodiversity.

Water usage and pollution are major concerns in lepidolite production. The extraction and processing of the mineral require substantial quantities of water, which can strain local water resources, particularly in arid regions where lepidolite deposits are often found. Additionally, the use of chemicals in the separation and purification processes may result in the contamination of groundwater and surface water if not properly managed.

Air quality is another environmental factor impacted by lepidolite production. Dust generated during mining and processing activities can contribute to particulate matter pollution, potentially affecting both human health and surrounding vegetation. The transportation of raw materials and finished products also contributes to carbon emissions, further impacting air quality and contributing to climate change.

Energy consumption in lepidolite crystal production is considerable, particularly during the refining and purification stages. The high energy demand often relies on fossil fuel-based power sources, leading to increased greenhouse gas emissions. As the demand for lepidolite crystals in optical modulators grows, the cumulative environmental impact of energy consumption becomes increasingly significant.

Waste management poses another environmental challenge. The processing of lepidolite generates tailings and other waste materials that require proper disposal. If not managed correctly, these waste products can lead to soil contamination and potential leaching of harmful substances into the environment.

To mitigate these environmental impacts, sustainable practices in lepidolite production are essential. This includes implementing more efficient extraction techniques, developing closed-loop water systems, adopting renewable energy sources, and improving waste management strategies. Additionally, research into alternative materials or synthetic production methods for optical modulator components could help reduce the reliance on natural lepidolite resources and minimize associated environmental impacts.

Water usage and pollution are major concerns in lepidolite production. The extraction and processing of the mineral require substantial quantities of water, which can strain local water resources, particularly in arid regions where lepidolite deposits are often found. Additionally, the use of chemicals in the separation and purification processes may result in the contamination of groundwater and surface water if not properly managed.

Air quality is another environmental factor impacted by lepidolite production. Dust generated during mining and processing activities can contribute to particulate matter pollution, potentially affecting both human health and surrounding vegetation. The transportation of raw materials and finished products also contributes to carbon emissions, further impacting air quality and contributing to climate change.

Energy consumption in lepidolite crystal production is considerable, particularly during the refining and purification stages. The high energy demand often relies on fossil fuel-based power sources, leading to increased greenhouse gas emissions. As the demand for lepidolite crystals in optical modulators grows, the cumulative environmental impact of energy consumption becomes increasingly significant.

Waste management poses another environmental challenge. The processing of lepidolite generates tailings and other waste materials that require proper disposal. If not managed correctly, these waste products can lead to soil contamination and potential leaching of harmful substances into the environment.

To mitigate these environmental impacts, sustainable practices in lepidolite production are essential. This includes implementing more efficient extraction techniques, developing closed-loop water systems, adopting renewable energy sources, and improving waste management strategies. Additionally, research into alternative materials or synthetic production methods for optical modulator components could help reduce the reliance on natural lepidolite resources and minimize associated environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!