Optimizing HDPE for Transformative Fashion Textiles

HDPE in Fashion: Evolution and Objectives

High-density polyethylene (HDPE) has emerged as a transformative material in the fashion industry, marking a significant shift in textile innovation. Originally developed in the 1950s for industrial applications, HDPE has undergone a remarkable evolution to become a viable option for sustainable and high-performance fashion textiles. This journey reflects the industry's growing emphasis on eco-friendly materials and circular economy principles.

The evolution of HDPE in fashion textiles can be traced through several key stages. Initially, HDPE was primarily used in packaging and construction due to its durability and chemical resistance. However, as sustainability concerns grew in the fashion industry, researchers began exploring HDPE's potential as a textile material. The breakthrough came with the development of advanced spinning techniques that could transform HDPE into fine, flexible fibers suitable for clothing.

In recent years, the objectives for optimizing HDPE in fashion have become increasingly focused. One primary goal is to enhance the material's breathability and moisture-wicking properties, making it more comfortable for everyday wear. Another crucial objective is to improve HDPE's dyeability, as traditional dyeing methods often struggle with this synthetic material. Researchers are also working on increasing the fabric's elasticity and recovery, aiming to create HDPE textiles that can compete with traditional stretch fabrics in performance wear.

Sustainability remains a central objective in HDPE optimization for fashion. The industry aims to develop closed-loop recycling systems for HDPE textiles, ensuring that garments can be easily recycled into new products at the end of their lifecycle. This aligns with the broader goal of reducing the fashion industry's environmental footprint and moving towards a more circular economy model.

Another key objective is to expand the aesthetic possibilities of HDPE textiles. Designers and material scientists are collaborating to create HDPE fabrics with varied textures, finishes, and draping qualities, challenging the perception of synthetic materials as inferior to natural fibers in terms of look and feel. This push for aesthetic diversity is crucial for wider adoption in high-end fashion and everyday wear.

As the fashion industry continues to grapple with issues of sustainability and performance, the optimization of HDPE for textiles represents a promising frontier. The objectives set forth in this field not only aim to improve the material's functional properties but also to revolutionize the way we think about synthetic fabrics in fashion. By addressing these challenges, HDPE has the potential to become a cornerstone material in the future of sustainable and innovative fashion design.

Market Analysis: HDPE Textiles Demand

The demand for HDPE textiles in the fashion industry is experiencing a significant upward trend, driven by the growing emphasis on sustainability and innovative materials. As consumers become more environmentally conscious, there is an increasing preference for eco-friendly and recyclable fabrics, positioning HDPE as a promising alternative to traditional textiles.

The global market for HDPE textiles is expected to expand rapidly in the coming years, with the fashion sector playing a crucial role in this growth. Major fashion brands and retailers are actively seeking sustainable material options to reduce their environmental footprint and meet consumer expectations. This shift in market dynamics is creating substantial opportunities for HDPE textile manufacturers and suppliers.

One of the key drivers of HDPE textile demand is its potential to address the issue of plastic waste in the fashion industry. By repurposing HDPE from post-consumer waste into high-quality textiles, manufacturers can contribute to the circular economy while meeting the growing demand for sustainable fashion. This aligns with the increasing adoption of closed-loop production systems by leading fashion companies.

The performance characteristics of HDPE textiles are also fueling market demand. These materials offer excellent durability, moisture resistance, and lightweight properties, making them suitable for a wide range of fashion applications. From outdoor wear to everyday clothing, HDPE textiles are finding diverse uses in the industry, further expanding their market potential.

Geographically, developed markets such as North America and Europe are currently leading the adoption of HDPE textiles in fashion. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in demand as awareness of sustainable fashion increases and local manufacturers invest in HDPE textile production capabilities.

The market for HDPE textiles is not without challenges. Competition from other sustainable materials, such as recycled polyester and organic cotton, remains strong. Additionally, the need for further technological advancements to improve the aesthetic and tactile qualities of HDPE fabrics presents both a challenge and an opportunity for innovation in the sector.

As the fashion industry continues to evolve towards more sustainable practices, the demand for HDPE textiles is projected to grow substantially. This trend is likely to be reinforced by regulatory pressures, consumer preferences, and corporate sustainability commitments, creating a favorable market environment for HDPE textile producers and innovators in the coming years.

HDPE Textile Challenges

The optimization of High-Density Polyethylene (HDPE) for fashion textiles presents several significant challenges that need to be addressed. One of the primary obstacles is the inherent stiffness and lack of flexibility of HDPE, which is not naturally suited for comfortable, wearable garments. This characteristic makes it difficult to achieve the drape and softness typically associated with traditional textile materials.

Another major challenge lies in the thermal properties of HDPE. The material has a relatively low melting point compared to other synthetic fibers, which can lead to issues in processing and limit its application in certain clothing items that may be exposed to high temperatures during use or care. This thermal sensitivity also affects the dyeing and finishing processes, as many conventional textile treatments require heat that could potentially compromise the integrity of HDPE fibers.

The surface properties of HDPE pose additional challenges for its use in fashion textiles. The material is naturally hydrophobic, which can result in poor moisture management and reduced comfort for the wearer. This characteristic also makes it difficult to apply finishes or treatments that are water-based, limiting the range of possible aesthetic and functional enhancements.

Durability and wear resistance are areas where HDPE shows promise, but also present challenges. While the material is known for its strength, adapting it to withstand the repeated flexing, stretching, and abrasion that clothing undergoes during regular use requires careful engineering. Balancing the need for durability with the desire for a soft hand-feel and pleasant tactile experience is a complex task.

Environmental concerns also play a significant role in the challenges faced when optimizing HDPE for fashion textiles. Although HDPE is recyclable, the additives and treatments necessary to make it suitable for clothing may complicate the recycling process. Additionally, the fashion industry's increasing focus on sustainability demands that any new material or process be environmentally friendly throughout its lifecycle, from production to disposal.

Lastly, there are technical challenges in the manufacturing process itself. Adapting existing textile machinery to work effectively with HDPE, or developing new equipment specifically for this purpose, requires significant investment and innovation. The extrusion and spinning of HDPE fibers that are fine enough for clothing while maintaining the desired properties is a complex engineering problem that demands precise control over numerous variables.

Current HDPE Optimization Techniques

01 Composition optimization

Optimizing the composition of HDPE by incorporating additives, modifiers, or blending with other polymers to enhance its properties. This can include improving mechanical strength, thermal stability, or processability. The optimized composition can lead to better performance in various applications.- Composition optimization for HDPE: Improving the properties of HDPE through the optimization of its composition. This includes blending HDPE with other polymers or additives to enhance specific characteristics such as strength, durability, or processability. The composition can be tailored to meet specific application requirements.

- Processing techniques for HDPE optimization: Developing and refining processing techniques to optimize HDPE properties. This involves adjusting parameters such as temperature, pressure, and cooling rates during extrusion, injection molding, or other manufacturing processes to achieve desired material characteristics and performance.

- Catalyst systems for HDPE production: Designing and implementing advanced catalyst systems to improve HDPE production. This includes developing new catalysts or modifying existing ones to enhance polymerization efficiency, control molecular weight distribution, and improve overall product quality.

- HDPE recycling and sustainability: Optimizing HDPE recycling processes and improving the sustainability of HDPE products. This involves developing methods to efficiently recycle HDPE, incorporate recycled content into new products, and reduce environmental impact throughout the material's lifecycle.

- HDPE nanocomposites and reinforcement: Developing HDPE nanocomposites and reinforcement techniques to enhance material properties. This includes incorporating nanofillers, fibers, or other reinforcing agents to improve mechanical strength, barrier properties, or other specific characteristics of HDPE-based materials.

02 Processing techniques

Developing and refining processing techniques for HDPE, such as extrusion, injection molding, or blow molding. This involves optimizing parameters like temperature, pressure, and cooling rates to achieve desired product characteristics and improve overall efficiency in manufacturing.Expand Specific Solutions03 Recycling and sustainability

Focusing on methods to improve the recycling of HDPE products and enhance their sustainability. This includes developing techniques for efficient sorting, cleaning, and reprocessing of recycled HDPE, as well as incorporating recycled content into new products without compromising quality.Expand Specific Solutions04 Surface modification

Enhancing the surface properties of HDPE through various modification techniques. This can involve treatments to improve adhesion, printability, or compatibility with other materials. Surface modification can expand the range of applications for HDPE products.Expand Specific Solutions05 Application-specific optimization

Tailoring HDPE properties for specific applications such as packaging, automotive parts, or construction materials. This involves optimizing the polymer structure, molecular weight distribution, or incorporating specific additives to meet the unique requirements of each application.Expand Specific Solutions

Key HDPE Textile Innovators

The optimization of HDPE for transformative fashion textiles is in a nascent stage, with significant growth potential in the sustainable fashion market. The industry is transitioning from research to early commercialization, driven by increasing demand for eco-friendly materials. Key players like Dow Global Technologies LLC, ExxonMobil Chemical Patents, Inc., and LG Chem Ltd. are at the forefront of HDPE innovation, leveraging their expertise in polymer science. Academic institutions such as Massachusetts Institute of Technology and Indian Institute of Technology Bombay are contributing to technological advancements. The market is characterized by a mix of established petrochemical companies and emerging specialized textile firms, indicating a dynamic and competitive landscape with varying levels of technological maturity.

Dow Global Technologies LLC

Equistar Chemicals LP

Breakthrough HDPE Textile Patents

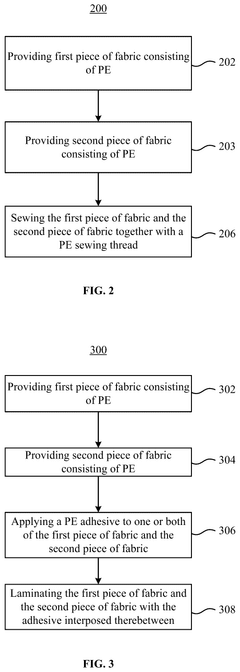

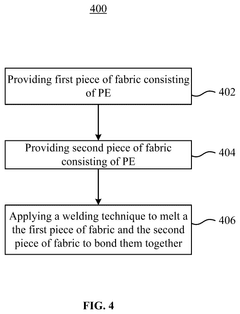

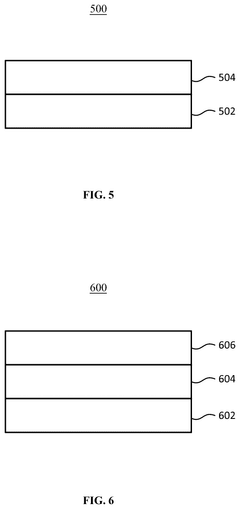

- Development of 100% polyethylene (PE) textiles for apparel, footwear, and bedding, utilizing PE sewing threads, adhesives, or ultrasonic welding to connect PE yarns, and integration of an infrared transparent insulation layer with a metallized sheet for enhanced performance and recyclability.

- A hybrid fabric comprising high-performance polyethylene (HPPE) fibers with a tensile modulus of at least 110 GPa and non-polymeric fibers, where the cross-sectional area of the HPPE fibers is equal to or smaller than that of the non-polymeric fibers, is used, eliminating the need for pretreatment and maintaining high impact resistance while improving tensile strength and modulus.

Sustainability Impact of HDPE Textiles

The adoption of HDPE (High-Density Polyethylene) in fashion textiles presents a significant opportunity for enhancing sustainability in the apparel industry. HDPE, traditionally used in packaging and construction, offers unique properties that can revolutionize textile production and contribute to a more environmentally friendly fashion ecosystem.

HDPE textiles demonstrate remarkable durability and longevity, potentially extending the lifecycle of garments and reducing the need for frequent replacements. This durability directly addresses the issue of fast fashion and its associated environmental impacts. By creating clothing that lasts longer, HDPE textiles can help decrease overall textile waste and the demand for new raw materials.

The production process of HDPE textiles also offers sustainability advantages. Compared to traditional textile materials like cotton or polyester, HDPE requires less water and energy to manufacture. This reduction in resource consumption translates to a lower carbon footprint and decreased strain on water resources, particularly in water-stressed regions where textile production is prevalent.

Furthermore, HDPE is fully recyclable, presenting an opportunity for closed-loop systems in fashion. Garments made from HDPE can be collected at the end of their useful life and recycled into new textile products or other plastic items, reducing landfill waste and the need for virgin materials. This recyclability aligns with circular economy principles, which are increasingly important in sustainable fashion.

HDPE textiles also have the potential to reduce microfiber pollution, a growing environmental concern associated with synthetic fabrics. The structure of HDPE fibers may result in less shedding during washing and wear, potentially decreasing the release of microplastics into water systems.

However, the sustainability impact of HDPE textiles is not without challenges. The material's origin in fossil fuels raises questions about its long-term sustainability. To address this, research into bio-based HDPE alternatives derived from renewable sources is crucial for improving the overall environmental profile of HDPE textiles.

Additionally, the implementation of effective collection and recycling systems for HDPE garments is essential to realize the full sustainability potential of this material. Without proper infrastructure, the benefits of recyclability may not be fully realized.

In conclusion, while HDPE textiles offer promising sustainability benefits in terms of durability, resource efficiency, and recyclability, their overall impact depends on the development of supporting systems and continued innovation in material sourcing and processing. As the fashion industry seeks more sustainable solutions, HDPE textiles represent a compelling area for further exploration and development.

HDPE Textile Safety Regulations

The safety regulations surrounding HDPE textiles in the fashion industry are crucial for ensuring consumer protection and environmental sustainability. These regulations primarily focus on chemical safety, physical properties, and environmental impact.

Chemical safety regulations for HDPE textiles address potential hazards associated with additives, colorants, and processing aids used in manufacturing. Regulatory bodies such as the European Chemicals Agency (ECHA) and the U.S. Environmental Protection Agency (EPA) have established guidelines for acceptable levels of substances like phthalates, heavy metals, and formaldehyde in textile products. Manufacturers must comply with these standards to ensure their HDPE textiles are safe for human contact and do not pose health risks.

Physical property regulations for HDPE textiles encompass factors such as tensile strength, abrasion resistance, and flammability. Standards set by organizations like the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) define the minimum requirements for these properties. Compliance with these standards ensures that HDPE textiles used in fashion applications meet durability and safety expectations.

Environmental impact regulations for HDPE textiles have gained significant importance in recent years. These regulations address issues such as biodegradability, recyclability, and the overall lifecycle impact of the material. The European Union's Circular Economy Action Plan, for instance, emphasizes the need for textile products to be designed for longevity and easy recycling. Manufacturers of HDPE textiles must consider these environmental regulations when developing their products for the fashion industry.

Labeling and certification requirements form another crucial aspect of HDPE textile safety regulations. Various eco-labels and certifications, such as OEKO-TEX Standard 100 and Global Recycled Standard (GRS), provide consumers with assurance regarding the safety and sustainability of textile products. These certifications often involve rigorous testing and auditing processes to verify compliance with chemical, physical, and environmental standards.

As the fashion industry continues to explore innovative applications of HDPE textiles, regulatory bodies are adapting their frameworks to address emerging concerns. This includes regulations related to microplastic pollution, as HDPE fibers may contribute to this environmental issue. Ongoing research and collaboration between industry stakeholders and regulatory agencies are essential for developing comprehensive and effective safety regulations that balance innovation with consumer and environmental protection.