Performance Metrics for Evaluating Battery Management Systems in Drones

AUG 8, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Drone Evolution

The evolution of Battery Management Systems (BMS) in drones has been closely tied to the rapid advancement of unmanned aerial vehicle technology. In the early stages of drone development, BMS were relatively simple, focusing primarily on basic voltage monitoring and rudimentary safety features. As drones became more sophisticated and their applications expanded, the demands on BMS grew exponentially.

The first significant leap in BMS technology for drones came with the introduction of lithium-polymer (LiPo) batteries in the mid-2000s. These high-energy-density power sources required more advanced management systems to ensure safe operation and longevity. This period saw the integration of cell balancing and more accurate state-of-charge estimation techniques into BMS designs.

As drone flight times extended and payloads increased, BMS evolved to incorporate more precise temperature monitoring and thermal management capabilities. This was crucial for maintaining battery performance and safety during extended operations, particularly in challenging environmental conditions.

The mid-2010s marked another pivotal point in BMS drone evolution with the rise of commercial and industrial drone applications. This shift demanded BMS that could provide real-time data on battery health, predict remaining flight time, and optimize performance based on mission parameters. Advanced algorithms for state-of-health estimation and predictive maintenance became integral components of drone BMS.

More recently, the integration of artificial intelligence and machine learning techniques has revolutionized BMS capabilities in drones. These systems can now adapt to varying flight conditions, learn from historical data to improve accuracy, and even predict potential battery issues before they occur. This has significantly enhanced the reliability and efficiency of drone operations across various sectors.

The latest developments in BMS for drones focus on enhancing energy efficiency and extending battery life. Techniques such as dynamic power management, regenerative braking systems for multi-rotor drones, and intelligent charging protocols are being incorporated into state-of-the-art BMS designs. Additionally, there is a growing emphasis on developing BMS that can support alternative energy sources, such as fuel cells or solar power, to complement or replace traditional battery systems in certain drone applications.

As we look to the future, the evolution of BMS in drones is likely to continue at a rapid pace. Emerging trends include the development of ultra-lightweight BMS components, integration with advanced navigation and obstacle avoidance systems, and the incorporation of wireless charging capabilities. These advancements will play a crucial role in enabling the next generation of autonomous, long-endurance drone operations across a wide range of industries and applications.

The first significant leap in BMS technology for drones came with the introduction of lithium-polymer (LiPo) batteries in the mid-2000s. These high-energy-density power sources required more advanced management systems to ensure safe operation and longevity. This period saw the integration of cell balancing and more accurate state-of-charge estimation techniques into BMS designs.

As drone flight times extended and payloads increased, BMS evolved to incorporate more precise temperature monitoring and thermal management capabilities. This was crucial for maintaining battery performance and safety during extended operations, particularly in challenging environmental conditions.

The mid-2010s marked another pivotal point in BMS drone evolution with the rise of commercial and industrial drone applications. This shift demanded BMS that could provide real-time data on battery health, predict remaining flight time, and optimize performance based on mission parameters. Advanced algorithms for state-of-health estimation and predictive maintenance became integral components of drone BMS.

More recently, the integration of artificial intelligence and machine learning techniques has revolutionized BMS capabilities in drones. These systems can now adapt to varying flight conditions, learn from historical data to improve accuracy, and even predict potential battery issues before they occur. This has significantly enhanced the reliability and efficiency of drone operations across various sectors.

The latest developments in BMS for drones focus on enhancing energy efficiency and extending battery life. Techniques such as dynamic power management, regenerative braking systems for multi-rotor drones, and intelligent charging protocols are being incorporated into state-of-the-art BMS designs. Additionally, there is a growing emphasis on developing BMS that can support alternative energy sources, such as fuel cells or solar power, to complement or replace traditional battery systems in certain drone applications.

As we look to the future, the evolution of BMS in drones is likely to continue at a rapid pace. Emerging trends include the development of ultra-lightweight BMS components, integration with advanced navigation and obstacle avoidance systems, and the incorporation of wireless charging capabilities. These advancements will play a crucial role in enabling the next generation of autonomous, long-endurance drone operations across a wide range of industries and applications.

Drone BMS Market Needs

The market for Battery Management Systems (BMS) in drones is experiencing rapid growth, driven by the increasing adoption of unmanned aerial vehicles (UAVs) across various industries. As drones become more sophisticated and their applications expand, the demand for efficient and reliable BMS solutions has surged. The primary market need is for BMS that can optimize battery performance, extend flight time, and enhance overall drone reliability.

One of the key drivers of this market is the growing use of drones in commercial and industrial sectors. Industries such as agriculture, construction, and logistics are increasingly relying on drones for tasks like crop monitoring, site surveying, and package delivery. These applications require drones with longer flight times and higher payload capacities, placing greater demands on battery performance and management.

Safety considerations are another crucial factor shaping the drone BMS market. As drones operate in diverse environments and carry out critical missions, the need for robust safety features in BMS has become paramount. This includes advanced monitoring capabilities to prevent overcharging, over-discharging, and thermal runaway, which are essential for preventing accidents and ensuring regulatory compliance.

The market also shows a strong demand for BMS solutions that can provide real-time data and analytics. Drone operators and fleet managers require accurate information on battery health, state of charge, and remaining flight time to optimize their operations and maintenance schedules. This has led to the development of more sophisticated BMS with advanced telemetry and predictive maintenance capabilities.

Weight and size optimization are critical considerations in the drone BMS market. As drones strive for longer flight times and increased payload capacity, there is a growing need for lightweight, compact BMS solutions that do not significantly impact the drone's overall weight or aerodynamics. This has spurred innovation in miniaturization and integration of BMS components.

The market is also seeing increased demand for BMS that can support fast charging and swappable battery systems. This is particularly important for commercial drone operations where minimizing downtime is crucial. BMS that can facilitate rapid charging without compromising battery life, as well as those that support hot-swappable battery packs, are gaining traction in the market.

Lastly, there is a growing emphasis on environmental sustainability in the drone industry, which is reflected in the BMS market. There is an increasing demand for BMS solutions that can optimize battery life cycles, reduce waste, and support the use of more environmentally friendly battery chemistries. This trend aligns with broader industry efforts to reduce the environmental impact of drone operations and improve overall sustainability.

One of the key drivers of this market is the growing use of drones in commercial and industrial sectors. Industries such as agriculture, construction, and logistics are increasingly relying on drones for tasks like crop monitoring, site surveying, and package delivery. These applications require drones with longer flight times and higher payload capacities, placing greater demands on battery performance and management.

Safety considerations are another crucial factor shaping the drone BMS market. As drones operate in diverse environments and carry out critical missions, the need for robust safety features in BMS has become paramount. This includes advanced monitoring capabilities to prevent overcharging, over-discharging, and thermal runaway, which are essential for preventing accidents and ensuring regulatory compliance.

The market also shows a strong demand for BMS solutions that can provide real-time data and analytics. Drone operators and fleet managers require accurate information on battery health, state of charge, and remaining flight time to optimize their operations and maintenance schedules. This has led to the development of more sophisticated BMS with advanced telemetry and predictive maintenance capabilities.

Weight and size optimization are critical considerations in the drone BMS market. As drones strive for longer flight times and increased payload capacity, there is a growing need for lightweight, compact BMS solutions that do not significantly impact the drone's overall weight or aerodynamics. This has spurred innovation in miniaturization and integration of BMS components.

The market is also seeing increased demand for BMS that can support fast charging and swappable battery systems. This is particularly important for commercial drone operations where minimizing downtime is crucial. BMS that can facilitate rapid charging without compromising battery life, as well as those that support hot-swappable battery packs, are gaining traction in the market.

Lastly, there is a growing emphasis on environmental sustainability in the drone industry, which is reflected in the BMS market. There is an increasing demand for BMS solutions that can optimize battery life cycles, reduce waste, and support the use of more environmentally friendly battery chemistries. This trend aligns with broader industry efforts to reduce the environmental impact of drone operations and improve overall sustainability.

BMS Tech Challenges

Battery Management Systems (BMS) in drones face several significant technical challenges that impact their performance and reliability. One of the primary issues is the need for accurate and real-time monitoring of battery parameters in a highly dynamic environment. Drones operate under varying load conditions, with rapid changes in power demand during takeoff, landing, and maneuvering. This requires BMS to have fast response times and adaptive algorithms to maintain optimal battery performance.

Weight and size constraints pose another major challenge for drone BMS. The limited payload capacity of drones necessitates lightweight and compact BMS solutions, which can be difficult to achieve without compromising functionality. This often leads to trade-offs between system capabilities and physical specifications, potentially affecting the overall performance of the BMS.

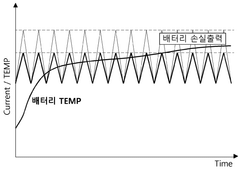

Thermal management is a critical concern for drone BMS. The high-power density of drone batteries, combined with the compact design and limited cooling options, can lead to rapid temperature increases. Effective thermal management is essential to prevent overheating, which can degrade battery performance, reduce lifespan, and pose safety risks. Developing efficient cooling mechanisms within the tight space and weight constraints of drones remains a significant technical hurdle.

The harsh operating conditions of drones present additional challenges for BMS. Exposure to vibrations, shocks, and extreme temperatures can affect the accuracy of sensors and the reliability of electronic components. Ensuring the robustness and durability of BMS hardware in these conditions is crucial for maintaining consistent performance and safety.

Power efficiency is another key challenge. Drone BMS must minimize their own power consumption to maximize flight time. This requires the development of low-power electronics and efficient algorithms that can perform complex calculations and control functions without significantly draining the battery.

Balancing cell voltages in multi-cell battery packs is particularly challenging in drone applications due to the rapid charge and discharge cycles. Achieving uniform cell performance and preventing individual cell degradation requires sophisticated balancing algorithms and hardware, which must operate effectively under the dynamic conditions of drone flight.

Safety features in drone BMS face unique challenges due to the potential consequences of battery failure during flight. Implementing robust fault detection, prediction, and mitigation systems within the constraints of drone design is critical. This includes developing reliable methods for detecting thermal runaway, short circuits, and other battery anomalies, as well as implementing fail-safe mechanisms to ensure safe landing in case of battery issues.

Weight and size constraints pose another major challenge for drone BMS. The limited payload capacity of drones necessitates lightweight and compact BMS solutions, which can be difficult to achieve without compromising functionality. This often leads to trade-offs between system capabilities and physical specifications, potentially affecting the overall performance of the BMS.

Thermal management is a critical concern for drone BMS. The high-power density of drone batteries, combined with the compact design and limited cooling options, can lead to rapid temperature increases. Effective thermal management is essential to prevent overheating, which can degrade battery performance, reduce lifespan, and pose safety risks. Developing efficient cooling mechanisms within the tight space and weight constraints of drones remains a significant technical hurdle.

The harsh operating conditions of drones present additional challenges for BMS. Exposure to vibrations, shocks, and extreme temperatures can affect the accuracy of sensors and the reliability of electronic components. Ensuring the robustness and durability of BMS hardware in these conditions is crucial for maintaining consistent performance and safety.

Power efficiency is another key challenge. Drone BMS must minimize their own power consumption to maximize flight time. This requires the development of low-power electronics and efficient algorithms that can perform complex calculations and control functions without significantly draining the battery.

Balancing cell voltages in multi-cell battery packs is particularly challenging in drone applications due to the rapid charge and discharge cycles. Achieving uniform cell performance and preventing individual cell degradation requires sophisticated balancing algorithms and hardware, which must operate effectively under the dynamic conditions of drone flight.

Safety features in drone BMS face unique challenges due to the potential consequences of battery failure during flight. Implementing robust fault detection, prediction, and mitigation systems within the constraints of drone design is critical. This includes developing reliable methods for detecting thermal runaway, short circuits, and other battery anomalies, as well as implementing fail-safe mechanisms to ensure safe landing in case of battery issues.

Current BMS Solutions

01 Performance monitoring and analysis

Battery Management Systems (BMS) utilize performance monitoring and analysis techniques to evaluate system efficiency, track battery health, and optimize overall performance. These methods involve collecting and analyzing data on various battery parameters, such as voltage, current, and temperature, to provide insights into system behavior and identify potential issues.- Performance monitoring and analysis: Battery Management Systems (BMS) employ various metrics to monitor and analyze battery performance. These metrics include voltage, current, temperature, and state of charge. Advanced systems use machine learning algorithms to predict battery health and optimize performance based on historical data and usage patterns.

- Fault detection and diagnostics: BMS performance metrics include fault detection and diagnostic capabilities. These systems use real-time data analysis to identify potential issues, such as cell imbalances or thermal runaway, before they become critical. This proactive approach helps in maintaining battery health and extending its lifespan.

- Energy efficiency and optimization: BMS performance is measured by its ability to optimize energy usage and improve overall efficiency. This includes metrics related to charge/discharge cycles, energy throughput, and power management. Advanced systems use predictive algorithms to balance performance and longevity, adapting to various operating conditions and user behaviors.

- Safety and thermal management: Safety-related performance metrics are crucial in BMS. These include thermal management efficiency, overcharge/overdischarge protection, and short circuit prevention. Advanced systems use sophisticated algorithms to maintain optimal operating temperatures and prevent thermal runaway, ensuring safe and reliable battery operation.

- Data integration and communication: BMS performance is also measured by its ability to integrate with other systems and communicate data effectively. This includes metrics related to data transmission speed, accuracy, and reliability. Advanced systems offer real-time monitoring, remote diagnostics, and seamless integration with vehicle or grid management systems, enhancing overall performance and user experience.

02 Fault detection and diagnostics

BMS incorporate fault detection and diagnostic capabilities to identify and address potential issues in battery systems. These features use advanced algorithms and machine learning techniques to analyze battery data, detect anomalies, and predict potential failures, enabling proactive maintenance and improving system reliability.Expand Specific Solutions03 Energy efficiency and optimization

BMS focus on improving energy efficiency and optimizing battery performance through various techniques. These include intelligent charge/discharge management, load balancing, and adaptive control strategies to maximize battery life, reduce energy waste, and enhance overall system efficiency.Expand Specific Solutions04 Data management and analytics

BMS employ sophisticated data management and analytics tools to process and interpret large volumes of battery-related information. These systems use advanced algorithms and cloud-based platforms to store, analyze, and visualize data, enabling better decision-making and performance optimization.Expand Specific Solutions05 Integration with IoT and smart grid systems

Modern BMS are designed to integrate with Internet of Things (IoT) devices and smart grid systems, enabling enhanced connectivity and communication. This integration allows for real-time monitoring, remote management, and improved coordination with other energy systems, leading to more efficient and responsive battery management.Expand Specific Solutions

Core BMS Innovations

Autonomous drone battery management

PatentPendingUS20250026508A1

Innovation

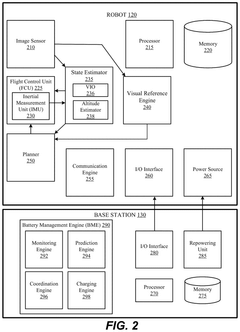

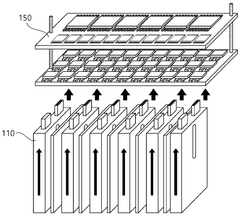

- A drone system with a swappable battery and a base station that predicts the drone's return timing, charges the battery accordingly, and performs a battery swap upon the drone's return, ensuring efficient battery management.

Drone battery charging control device

PatentWO2025079761A1

Innovation

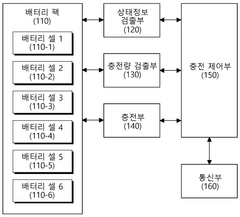

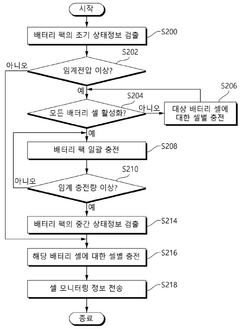

- A drone battery charging control device that includes a state information detection unit, a charging volume detector, a charging unit, and a charging control unit. This system detects initial and intermediate state information of battery cells, adjusts the charging mode (CC-CV, MCC-CV, boost, pulse) based on cell conditions, and manages charging to prevent overheating and damage.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of battery management systems (BMS) for drones. As the use of unmanned aerial vehicles continues to expand across various industries, regulatory bodies have established stringent guidelines to ensure the safe operation of these devices, particularly concerning their power systems.

The Federal Aviation Administration (FAA) in the United States has set forth comprehensive regulations for drone operations, including specific requirements for battery management systems. These regulations emphasize the importance of reliable performance metrics to evaluate BMS effectiveness. Key safety considerations include thermal management, overcharge protection, and fail-safe mechanisms.

Thermal management is a critical aspect of BMS safety regulations. Drones operating in diverse environmental conditions must maintain optimal battery temperature to prevent thermal runaway and potential fire hazards. Performance metrics for thermal management include temperature monitoring accuracy, heat dissipation efficiency, and thermal stability under various load conditions.

Overcharge protection is another vital safety feature mandated by regulations. BMS must incorporate robust mechanisms to prevent overcharging, which can lead to battery degradation and safety risks. Metrics for evaluating overcharge protection include voltage monitoring precision, cut-off response time, and the ability to balance individual cell voltages within battery packs.

Fail-safe mechanisms are essential components of BMS safety regulations. These systems ensure that drones can safely land or maintain controlled flight in the event of battery-related issues. Performance metrics for fail-safe systems include fault detection speed, emergency power reserve capacity, and the effectiveness of automated landing procedures.

Regulatory bodies also require extensive testing and certification processes for drone BMS. These processes involve rigorous performance evaluations under simulated extreme conditions, including rapid charge/discharge cycles, impact resistance, and environmental stress tests. Metrics used in these certifications include cycle life, capacity retention, and overall system reliability.

International standards, such as those set by the International Electrotechnical Commission (IEC), provide additional guidelines for BMS performance metrics. These standards emphasize the importance of interoperability, data logging capabilities, and communication protocols between the BMS and other drone systems.

As drone technology continues to advance, safety regulations are evolving to address new challenges. Emerging areas of focus include cybersecurity measures to protect BMS from potential hacking attempts and the integration of artificial intelligence for predictive maintenance and enhanced safety features. Performance metrics in these areas are still being defined but are likely to include intrusion detection capabilities and the accuracy of AI-driven predictive models.

The Federal Aviation Administration (FAA) in the United States has set forth comprehensive regulations for drone operations, including specific requirements for battery management systems. These regulations emphasize the importance of reliable performance metrics to evaluate BMS effectiveness. Key safety considerations include thermal management, overcharge protection, and fail-safe mechanisms.

Thermal management is a critical aspect of BMS safety regulations. Drones operating in diverse environmental conditions must maintain optimal battery temperature to prevent thermal runaway and potential fire hazards. Performance metrics for thermal management include temperature monitoring accuracy, heat dissipation efficiency, and thermal stability under various load conditions.

Overcharge protection is another vital safety feature mandated by regulations. BMS must incorporate robust mechanisms to prevent overcharging, which can lead to battery degradation and safety risks. Metrics for evaluating overcharge protection include voltage monitoring precision, cut-off response time, and the ability to balance individual cell voltages within battery packs.

Fail-safe mechanisms are essential components of BMS safety regulations. These systems ensure that drones can safely land or maintain controlled flight in the event of battery-related issues. Performance metrics for fail-safe systems include fault detection speed, emergency power reserve capacity, and the effectiveness of automated landing procedures.

Regulatory bodies also require extensive testing and certification processes for drone BMS. These processes involve rigorous performance evaluations under simulated extreme conditions, including rapid charge/discharge cycles, impact resistance, and environmental stress tests. Metrics used in these certifications include cycle life, capacity retention, and overall system reliability.

International standards, such as those set by the International Electrotechnical Commission (IEC), provide additional guidelines for BMS performance metrics. These standards emphasize the importance of interoperability, data logging capabilities, and communication protocols between the BMS and other drone systems.

As drone technology continues to advance, safety regulations are evolving to address new challenges. Emerging areas of focus include cybersecurity measures to protect BMS from potential hacking attempts and the integration of artificial intelligence for predictive maintenance and enhanced safety features. Performance metrics in these areas are still being defined but are likely to include intrusion detection capabilities and the accuracy of AI-driven predictive models.

Environmental Impact

The environmental impact of battery management systems (BMS) in drones is a critical consideration in the development and deployment of unmanned aerial vehicles. As drone technology continues to advance and proliferate, the ecological footprint of these systems becomes increasingly significant. BMS play a crucial role in optimizing battery performance and longevity, which directly influences the environmental sustainability of drone operations.

One of the primary environmental benefits of efficient BMS is the extension of battery life. By accurately monitoring and managing battery health, these systems can significantly reduce the frequency of battery replacements. This, in turn, decreases the demand for new battery production and mitigates the environmental impact associated with battery manufacturing processes, including resource extraction and energy consumption.

Moreover, BMS contribute to the reduction of energy waste during drone operations. Through precise voltage and current regulation, these systems ensure that batteries operate within optimal parameters, maximizing energy efficiency and minimizing unnecessary power consumption. This not only extends flight times but also reduces the overall energy footprint of drone activities.

The environmental impact of BMS also extends to the end-of-life management of drone batteries. Advanced BMS can provide accurate data on battery degradation, enabling more informed decisions about when to retire batteries. This helps prevent premature disposal of functional batteries and ensures that truly depleted batteries are properly recycled, reducing electronic waste and conserving valuable resources.

In the context of lithium-ion batteries, which are commonly used in drones, BMS play a crucial role in preventing thermal runaway and other safety issues. By maintaining safe operating conditions, these systems reduce the risk of battery failures that could lead to environmental contamination or fire hazards, potentially causing ecological damage.

Furthermore, the integration of BMS with renewable energy sources for drone charging stations presents an opportunity to further reduce the environmental impact of drone operations. By optimizing charging cycles and enabling smart grid integration, BMS can facilitate the use of solar or wind power for battery charging, reducing reliance on fossil fuel-based electricity.

As drone applications expand into environmental monitoring and conservation efforts, the role of BMS in ensuring reliable and efficient operations becomes even more critical. Drones equipped with advanced BMS can conduct longer and more frequent missions for tasks such as wildlife tracking, forest fire detection, and pollution monitoring, contributing positively to environmental protection efforts.

One of the primary environmental benefits of efficient BMS is the extension of battery life. By accurately monitoring and managing battery health, these systems can significantly reduce the frequency of battery replacements. This, in turn, decreases the demand for new battery production and mitigates the environmental impact associated with battery manufacturing processes, including resource extraction and energy consumption.

Moreover, BMS contribute to the reduction of energy waste during drone operations. Through precise voltage and current regulation, these systems ensure that batteries operate within optimal parameters, maximizing energy efficiency and minimizing unnecessary power consumption. This not only extends flight times but also reduces the overall energy footprint of drone activities.

The environmental impact of BMS also extends to the end-of-life management of drone batteries. Advanced BMS can provide accurate data on battery degradation, enabling more informed decisions about when to retire batteries. This helps prevent premature disposal of functional batteries and ensures that truly depleted batteries are properly recycled, reducing electronic waste and conserving valuable resources.

In the context of lithium-ion batteries, which are commonly used in drones, BMS play a crucial role in preventing thermal runaway and other safety issues. By maintaining safe operating conditions, these systems reduce the risk of battery failures that could lead to environmental contamination or fire hazards, potentially causing ecological damage.

Furthermore, the integration of BMS with renewable energy sources for drone charging stations presents an opportunity to further reduce the environmental impact of drone operations. By optimizing charging cycles and enabling smart grid integration, BMS can facilitate the use of solar or wind power for battery charging, reducing reliance on fossil fuel-based electricity.

As drone applications expand into environmental monitoring and conservation efforts, the role of BMS in ensuring reliable and efficient operations becomes even more critical. Drones equipped with advanced BMS can conduct longer and more frequent missions for tasks such as wildlife tracking, forest fire detection, and pollution monitoring, contributing positively to environmental protection efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!