Piezoelectric Materials in Self-Powered Sensor Technologies

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Materials Evolution and Research Objectives

Piezoelectric materials have undergone significant evolution since their discovery in 1880 by the Curie brothers. The initial observation of the piezoelectric effect in quartz crystals laid the foundation for a field that has expanded dramatically over the past century. Early developments focused primarily on natural crystals, but the mid-20th century witnessed a paradigm shift with the introduction of synthetic piezoelectric ceramics, particularly lead zirconate titanate (PZT), which offered superior electromechanical coupling coefficients and became the industry standard.

The 1990s marked another pivotal era with increased research into lead-free alternatives, driven by environmental regulations and health concerns. Materials such as barium titanate (BaTiO3), sodium potassium niobate (KNN), and bismuth sodium titanate (BNT) emerged as promising candidates, though they initially struggled to match PZT's performance metrics. Recent advancements in material science and nanotechnology have significantly narrowed this performance gap.

The miniaturization trend in electronics has propelled research into piezoelectric thin films and nanostructures, enabling integration with microelectromechanical systems (MEMS) and flexible electronics. Particularly noteworthy is the discovery of enhanced piezoelectric properties in nanostructured materials, where size-dependent effects can dramatically improve energy conversion efficiency—a critical factor for self-powered sensor applications.

Current research objectives in piezoelectric materials for self-powered sensors focus on several key areas. First, enhancing energy conversion efficiency to maximize power generation from ambient mechanical energy sources such as vibration, pressure, and human motion. This involves optimizing material composition, crystal structure, and device architecture to achieve higher piezoelectric coefficients and lower energy losses.

Second, developing multifunctional piezoelectric materials that can simultaneously harvest energy and sense environmental parameters represents a significant research direction. These materials could enable truly autonomous sensor systems by eliminating the need for external power sources while maintaining high sensing performance.

Third, improving the mechanical flexibility and durability of piezoelectric materials is crucial for wearable and implantable self-powered sensors. This includes research into polymer-based piezoelectrics, composite materials, and novel fabrication techniques that can produce robust yet flexible energy harvesting components.

Finally, addressing scalability and cost-effectiveness in manufacturing processes remains a critical objective. The transition from laboratory prototypes to commercially viable self-powered sensor technologies requires economical production methods that maintain material performance while enabling mass production.

The 1990s marked another pivotal era with increased research into lead-free alternatives, driven by environmental regulations and health concerns. Materials such as barium titanate (BaTiO3), sodium potassium niobate (KNN), and bismuth sodium titanate (BNT) emerged as promising candidates, though they initially struggled to match PZT's performance metrics. Recent advancements in material science and nanotechnology have significantly narrowed this performance gap.

The miniaturization trend in electronics has propelled research into piezoelectric thin films and nanostructures, enabling integration with microelectromechanical systems (MEMS) and flexible electronics. Particularly noteworthy is the discovery of enhanced piezoelectric properties in nanostructured materials, where size-dependent effects can dramatically improve energy conversion efficiency—a critical factor for self-powered sensor applications.

Current research objectives in piezoelectric materials for self-powered sensors focus on several key areas. First, enhancing energy conversion efficiency to maximize power generation from ambient mechanical energy sources such as vibration, pressure, and human motion. This involves optimizing material composition, crystal structure, and device architecture to achieve higher piezoelectric coefficients and lower energy losses.

Second, developing multifunctional piezoelectric materials that can simultaneously harvest energy and sense environmental parameters represents a significant research direction. These materials could enable truly autonomous sensor systems by eliminating the need for external power sources while maintaining high sensing performance.

Third, improving the mechanical flexibility and durability of piezoelectric materials is crucial for wearable and implantable self-powered sensors. This includes research into polymer-based piezoelectrics, composite materials, and novel fabrication techniques that can produce robust yet flexible energy harvesting components.

Finally, addressing scalability and cost-effectiveness in manufacturing processes remains a critical objective. The transition from laboratory prototypes to commercially viable self-powered sensor technologies requires economical production methods that maintain material performance while enabling mass production.

Market Analysis for Self-Powered Sensor Applications

The self-powered sensor market is experiencing robust growth, driven by increasing demand for autonomous sensing systems across multiple industries. The global market for self-powered sensors was valued at approximately 12 billion USD in 2022 and is projected to reach 27 billion USD by 2028, representing a compound annual growth rate (CAGR) of 14.5%. This growth trajectory is supported by the expanding Internet of Things (IoT) ecosystem, which requires distributed sensing capabilities with minimal maintenance requirements.

Industrial applications currently constitute the largest market segment, accounting for 35% of total demand. These applications include condition monitoring, predictive maintenance, and process control in manufacturing environments where conventional wired or battery-powered sensors present installation challenges or maintenance burdens. The automotive sector follows closely at 28% market share, with applications in tire pressure monitoring systems, structural health monitoring, and various engine and chassis sensors.

Healthcare and wearable technology represent the fastest-growing application segment, with a projected CAGR of 19.2% through 2028. This growth is fueled by increasing consumer interest in continuous health monitoring and the medical sector's push toward remote patient monitoring solutions. Piezoelectric-based self-powered sensors are particularly valuable in this context due to their ability to harvest energy from body movements and vibrations.

Regionally, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate at 17.3% annually, driven by rapid industrialization, smart city initiatives, and increasing IoT adoption across China, Japan, South Korea, and India.

Key market drivers include the growing need for maintenance-free sensing solutions in remote or inaccessible locations, increasing focus on energy efficiency and sustainability, and the miniaturization trend in electronics. The reduction in power requirements for sensor operation and data transmission technologies has further expanded the application scope for self-powered sensors.

Market challenges include relatively higher initial costs compared to conventional sensors, performance limitations in low-vibration environments, and integration complexities with existing systems. Despite these challenges, the long-term cost benefits through eliminated battery replacement and reduced maintenance are shifting the value proposition favorably toward self-powered solutions.

Consumer awareness regarding energy harvesting technologies remains limited but is gradually improving as commercial applications become more visible. Market education remains a critical factor for accelerating adoption rates, particularly in consumer-facing applications.

Industrial applications currently constitute the largest market segment, accounting for 35% of total demand. These applications include condition monitoring, predictive maintenance, and process control in manufacturing environments where conventional wired or battery-powered sensors present installation challenges or maintenance burdens. The automotive sector follows closely at 28% market share, with applications in tire pressure monitoring systems, structural health monitoring, and various engine and chassis sensors.

Healthcare and wearable technology represent the fastest-growing application segment, with a projected CAGR of 19.2% through 2028. This growth is fueled by increasing consumer interest in continuous health monitoring and the medical sector's push toward remote patient monitoring solutions. Piezoelectric-based self-powered sensors are particularly valuable in this context due to their ability to harvest energy from body movements and vibrations.

Regionally, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate at 17.3% annually, driven by rapid industrialization, smart city initiatives, and increasing IoT adoption across China, Japan, South Korea, and India.

Key market drivers include the growing need for maintenance-free sensing solutions in remote or inaccessible locations, increasing focus on energy efficiency and sustainability, and the miniaturization trend in electronics. The reduction in power requirements for sensor operation and data transmission technologies has further expanded the application scope for self-powered sensors.

Market challenges include relatively higher initial costs compared to conventional sensors, performance limitations in low-vibration environments, and integration complexities with existing systems. Despite these challenges, the long-term cost benefits through eliminated battery replacement and reduced maintenance are shifting the value proposition favorably toward self-powered solutions.

Consumer awareness regarding energy harvesting technologies remains limited but is gradually improving as commercial applications become more visible. Market education remains a critical factor for accelerating adoption rates, particularly in consumer-facing applications.

Global Piezoelectric Technology Landscape and Barriers

The global piezoelectric technology landscape is characterized by significant regional disparities in research focus, industrial application, and market maturity. North America, particularly the United States, leads in advanced piezoelectric material research with substantial investments in defense applications and medical ultrasound technologies. Major research institutions like MIT, Stanford, and national laboratories maintain cutting-edge capabilities in novel piezoelectric composites and thin-film technologies for self-powered sensing applications.

Europe demonstrates strength in precision engineering applications of piezoelectric materials, with Germany, France, and Switzerland hosting specialized manufacturers focused on high-performance actuators and sensors. The European landscape is distinguished by strong university-industry collaborations, particularly in automotive and industrial automation sectors, where piezoelectric self-powered sensors are increasingly deployed for condition monitoring.

The Asia-Pacific region, led by Japan, South Korea, and China, has emerged as the manufacturing powerhouse for piezoelectric components. Japan maintains historical leadership in piezoelectric ceramics through companies like Murata and Kyocera, while China has rapidly expanded production capacity, though often focusing on more standardized components rather than cutting-edge materials.

Despite global progress, significant barriers impede wider adoption of piezoelectric materials in self-powered sensor technologies. Technical challenges include limited energy conversion efficiency, with most piezoelectric harvesters achieving only 10-30% efficiency under optimal conditions. Material fatigue and degradation under continuous mechanical stress remain persistent issues, particularly in harsh environmental applications where temperature fluctuations and humidity can accelerate performance deterioration.

Scalability presents another major barrier, as manufacturing processes for advanced piezoelectric materials often involve complex deposition techniques or precise doping procedures that are difficult to scale economically. The cost-performance ratio remains unfavorable for mass-market applications, restricting piezoelectric self-powered sensors to specialized high-value applications.

Standardization gaps further complicate technology adoption, with inconsistent testing protocols and performance metrics across regions creating market fragmentation. This hampers interoperability and slows integration into existing sensor networks and IoT ecosystems. Additionally, intellectual property landscapes are increasingly complex, with patent thickets forming around key innovations in flexible piezoelectric materials and nanostructured composites.

Environmental concerns also present emerging barriers, as many high-performance piezoelectric materials contain lead and other toxic elements, facing increasing regulatory scrutiny, particularly in Europe under RoHS directives. Research into lead-free alternatives has intensified but often results in performance compromises that limit application potential in self-powered sensing systems.

Europe demonstrates strength in precision engineering applications of piezoelectric materials, with Germany, France, and Switzerland hosting specialized manufacturers focused on high-performance actuators and sensors. The European landscape is distinguished by strong university-industry collaborations, particularly in automotive and industrial automation sectors, where piezoelectric self-powered sensors are increasingly deployed for condition monitoring.

The Asia-Pacific region, led by Japan, South Korea, and China, has emerged as the manufacturing powerhouse for piezoelectric components. Japan maintains historical leadership in piezoelectric ceramics through companies like Murata and Kyocera, while China has rapidly expanded production capacity, though often focusing on more standardized components rather than cutting-edge materials.

Despite global progress, significant barriers impede wider adoption of piezoelectric materials in self-powered sensor technologies. Technical challenges include limited energy conversion efficiency, with most piezoelectric harvesters achieving only 10-30% efficiency under optimal conditions. Material fatigue and degradation under continuous mechanical stress remain persistent issues, particularly in harsh environmental applications where temperature fluctuations and humidity can accelerate performance deterioration.

Scalability presents another major barrier, as manufacturing processes for advanced piezoelectric materials often involve complex deposition techniques or precise doping procedures that are difficult to scale economically. The cost-performance ratio remains unfavorable for mass-market applications, restricting piezoelectric self-powered sensors to specialized high-value applications.

Standardization gaps further complicate technology adoption, with inconsistent testing protocols and performance metrics across regions creating market fragmentation. This hampers interoperability and slows integration into existing sensor networks and IoT ecosystems. Additionally, intellectual property landscapes are increasingly complex, with patent thickets forming around key innovations in flexible piezoelectric materials and nanostructured composites.

Environmental concerns also present emerging barriers, as many high-performance piezoelectric materials contain lead and other toxic elements, facing increasing regulatory scrutiny, particularly in Europe under RoHS directives. Research into lead-free alternatives has intensified but often results in performance compromises that limit application potential in self-powered sensing systems.

Current Self-Powered Sensing Technical Solutions

01 Piezoelectric materials for energy harvesting

Piezoelectric materials can convert mechanical energy into electrical energy, making them ideal for energy harvesting applications. These materials generate an electric charge in response to applied mechanical stress, allowing for the capture of energy from ambient vibrations, movements, or pressure. This technology is particularly useful for powering small electronic devices, sensors, and wireless systems in environments where conventional power sources are impractical.- Piezoelectric materials for energy harvesting applications: Piezoelectric materials can be used to convert mechanical energy into electrical energy, making them ideal for energy harvesting applications. These materials generate an electric charge in response to applied mechanical stress, allowing for the capture of energy from ambient vibrations, movements, or pressure. This technology enables self-powered devices and systems that can operate without external power sources, particularly useful in remote sensing, wearable technology, and IoT applications.

- Advanced piezoelectric ceramic compositions: Various ceramic compositions have been developed to enhance piezoelectric properties. These include lead-based ceramics like PZT (lead zirconate titanate) and lead-free alternatives such as barium titanate, sodium potassium niobate, and bismuth sodium titanate. These compositions are engineered to optimize properties such as piezoelectric coefficient, electromechanical coupling factor, and temperature stability. Dopants and additives are incorporated to tailor specific characteristics for different applications.

- Piezoelectric materials in medical devices and healthcare: Piezoelectric materials are increasingly used in medical applications due to their ability to convert mechanical energy to electrical signals and vice versa. They are incorporated into ultrasound transducers, surgical tools, implantable sensors, drug delivery systems, and diagnostic equipment. These materials enable precise control, high sensitivity, and miniaturization of medical devices, contributing to advances in minimally invasive procedures, point-of-care diagnostics, and patient monitoring systems.

- Flexible and polymer-based piezoelectric materials: Flexible piezoelectric materials, including polymer-based compositions like PVDF (polyvinylidene fluoride) and its copolymers, offer advantages over traditional ceramic piezoelectrics. These materials can be fabricated into thin films, fibers, and complex shapes, making them suitable for wearable electronics, flexible sensors, and conformable devices. Their mechanical flexibility, lightweight nature, and biocompatibility enable applications in soft robotics, electronic skin, and implantable devices where rigid ceramics would be unsuitable.

- Piezoelectric MEMS and nanostructured materials: Micro-electromechanical systems (MEMS) and nanostructured piezoelectric materials represent cutting-edge developments in the field. These include piezoelectric thin films, nanowires, nanotubes, and nanocomposites that exhibit enhanced properties compared to their bulk counterparts. The reduced dimensions and engineered structures allow for improved sensitivity, higher operating frequencies, and integration with semiconductor technologies. Applications include high-precision sensors, actuators, resonators, filters, and next-generation electronic components.

02 Advanced piezoelectric ceramic compositions

Various ceramic compositions have been developed to enhance piezoelectric properties. These include lead-based ceramics like PZT (lead zirconate titanate) and lead-free alternatives such as barium titanate, sodium potassium niobate, and bismuth-based compounds. These materials are engineered with specific dopants and processing techniques to optimize properties such as piezoelectric coefficient, coupling factor, and temperature stability for different applications.Expand Specific Solutions03 Piezoelectric materials in medical devices

Piezoelectric materials are increasingly used in medical applications due to their ability to convert electrical signals to mechanical movement and vice versa. They are utilized in ultrasound imaging transducers, surgical tools, drug delivery systems, and implantable sensors. These materials enable precise control, miniaturization, and improved functionality in medical devices, contributing to less invasive procedures and better patient outcomes.Expand Specific Solutions04 Flexible and thin-film piezoelectric materials

Recent developments in piezoelectric technology include flexible and thin-film piezoelectric materials that can conform to curved surfaces or be integrated into compact devices. These materials are fabricated using techniques such as sol-gel processing, sputtering, or electrospinning to create nanoscale structures with piezoelectric properties. Flexible piezoelectric materials enable applications in wearable electronics, flexible sensors, and conformable energy harvesters.Expand Specific Solutions05 Piezoelectric actuators and transducers

Piezoelectric materials are widely used in actuators and transducers that require precise movement control or signal conversion. These components utilize the inverse piezoelectric effect, where an applied voltage causes mechanical deformation. Applications include precision positioning systems, speakers, microphones, inkjet printheads, and vibration control devices. The materials are selected and designed to provide specific displacement ranges, force generation capabilities, and frequency responses.Expand Specific Solutions

Industry Leaders in Piezoelectric Sensor Manufacturing

The piezoelectric materials market for self-powered sensor technologies is currently in a growth phase, with an expanding market driven by increasing demand for autonomous sensing systems. The competitive landscape features established players like Taiyo Yuden, which specializes in laminated piezoelectric actuators, and CeramTec GmbH, leveraging their expertise in advanced ceramics. Academic institutions including Johns Hopkins University, Tsinghua University, and Korea Advanced Institute of Science & Technology are driving fundamental research innovations. The technology is approaching maturity in certain applications but remains in development for more advanced self-powered systems. Industrial players such as Sumitomo Chemical, SABIC, and Michelin are exploring integration opportunities, while specialized companies like Insplorion AB are developing novel instrumentation for nanomaterial characterization, creating a diverse ecosystem of competitors across the value chain.

CeramTec GmbH

Technical Solution: CeramTec has developed advanced piezoelectric ceramic materials optimized for self-powered sensor applications across industrial and automotive environments. Their technology centers on modified lead zirconate titanate (PZT) formulations with proprietary dopants that enhance both sensitivity and durability under harsh operating conditions. The company has engineered specialized manufacturing processes that produce piezoelectric components with exceptional batch-to-batch consistency and long-term stability. CeramTec's piezoelectric materials demonstrate high coupling factors (k33 > 0.7) and quality factors exceeding 1000, enabling efficient energy conversion even from low-amplitude mechanical inputs[9]. Their product line includes ruggedized piezoelectric components capable of operating reliably in extreme temperatures (-55°C to 250°C) and high-vibration environments, making them suitable for automotive and industrial monitoring applications. The company has also pioneered lead-free piezoelectric formulations based on potassium sodium niobate (KNN) that deliver comparable performance to traditional PZT while meeting stringent environmental regulations. Recent innovations include multilayer piezoelectric structures with integrated electrode designs that optimize charge collection efficiency, resulting in self-powered sensors that can generate sufficient power for wireless data transmission from typical industrial vibrations[10].

Strengths: Exceptional durability and reliability in harsh environments; precise manufacturing control resulting in consistent performance; comprehensive range of formulations optimized for specific applications. Weaknesses: Higher cost compared to consumer-grade piezoelectric materials; some high-performance formulations still contain lead; limited flexibility compared to polymer-based alternatives.

Tsinghua University

Technical Solution: Tsinghua University has developed advanced piezoelectric nanogenerators (PENGs) for self-powered sensor applications. Their technology utilizes zinc oxide (ZnO) nanowire arrays and lead zirconate titanate (PZT) thin films to convert mechanical energy into electrical signals. The research team has created flexible piezoelectric composites that can be integrated into wearable devices, environmental monitoring systems, and healthcare applications. Their recent innovations include a triboelectric-piezoelectric hybrid nanogenerator that combines both energy harvesting mechanisms to achieve higher output power and efficiency. The university has also pioneered the development of self-powered wireless sensor networks powered entirely by piezoelectric energy harvesters, eliminating the need for battery replacement in remote monitoring applications[1][3]. Their technology demonstrates excellent durability with minimal performance degradation after 100,000 mechanical cycles.

Strengths: Superior energy conversion efficiency compared to single-mechanism harvesters; excellent integration capabilities with flexible electronics; proven long-term stability. Weaknesses: Some designs still rely on lead-based materials raising environmental concerns; output power may be insufficient for higher-power applications without additional energy storage.

Key Patents in Piezoelectric Energy Harvesting

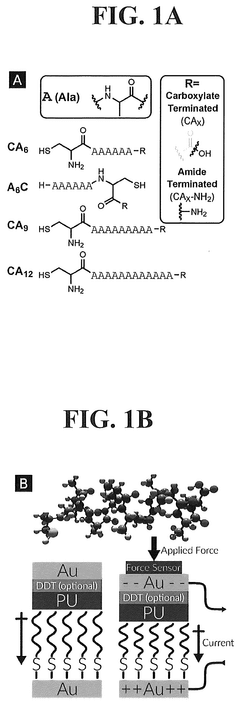

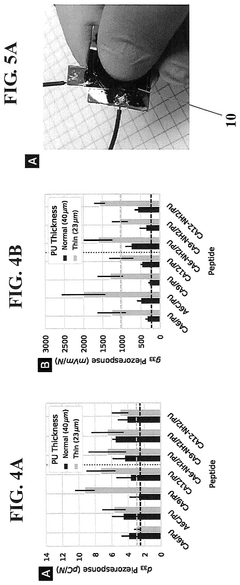

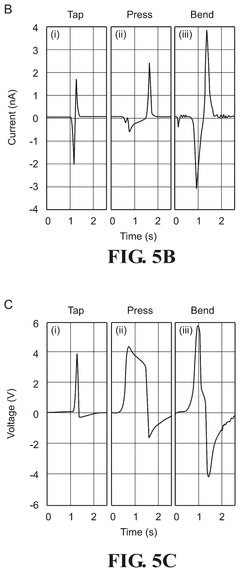

High voltage flexible molecular piezoelectric devices

PatentPendingUS20240324466A1

Innovation

- Development of self-assembled monolayers of oligopeptides that produce high piezoelectric voltage responses without the need for electrical poling, using a combination of oligopeptide self-assembled monolayers on electrodes with a dielectric layer, such as polyurethane, to create flexible, biocompatible piezoelectric sensors and devices.

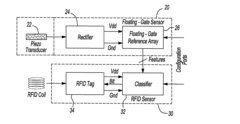

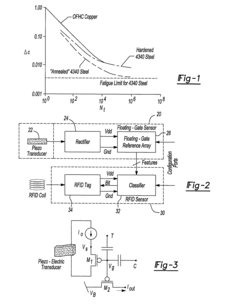

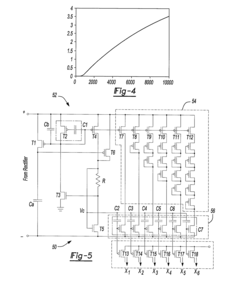

Self-powered sensor

PatentActiveUS8056420B2

Innovation

- A self-powered sensor system utilizing a piezoelectric transducer, a non-volatile memory with floating gate transistors, and a current reference circuit that operates in weak-inversion mode, allowing for energy harvesting and efficient storage and computation, while maintaining low power dissipation.

Sustainability Impact of Self-Powered Sensor Systems

The integration of self-powered sensor systems based on piezoelectric materials represents a significant advancement in sustainable technology development. These systems fundamentally reduce environmental impact by eliminating the need for conventional battery power sources, which typically contain toxic chemicals and heavy metals that pose disposal challenges. By harvesting ambient energy through piezoelectric mechanisms, these sensors substantially decrease electronic waste generation while extending operational lifespans.

Energy autonomy achieved through piezoelectric self-powered sensors contributes meaningfully to carbon footprint reduction. Traditional sensor networks often require regular battery replacements, involving manufacturing, transportation, and disposal processes that generate considerable greenhouse gas emissions. Self-powered alternatives minimize these emissions by reducing maintenance requirements and eliminating battery replacement cycles throughout their operational lifetime.

The material efficiency of piezoelectric sensor systems further enhances their sustainability profile. Modern piezoelectric materials increasingly incorporate environmentally benign components, moving away from lead-based compounds toward alternatives such as zinc oxide, aluminum nitride, and organic piezoelectric polymers. This transition addresses concerns regarding resource depletion and toxic material usage in electronic components.

From a lifecycle perspective, self-powered sensor technologies demonstrate superior sustainability metrics. Their extended operational lifetimes without maintenance interventions reduce raw material consumption and manufacturing energy requirements compared to conventional battery-powered alternatives. This advantage becomes particularly significant in large-scale deployments across smart infrastructure, environmental monitoring, and industrial applications.

The deployment of piezoelectric self-powered sensors enables more comprehensive environmental monitoring capabilities, contributing to broader sustainability goals. These systems can operate in remote or inaccessible locations without energy infrastructure, facilitating more effective natural resource management, pollution detection, and climate change monitoring. The resulting data supports evidence-based environmental policy development and conservation efforts.

Economic sustainability also improves through reduced total cost of ownership. While initial implementation costs may exceed conventional alternatives, the elimination of ongoing battery replacement expenses and maintenance requirements yields significant long-term economic benefits. This cost structure makes sustainable monitoring solutions more accessible to developing regions and resource-constrained applications.

Energy autonomy achieved through piezoelectric self-powered sensors contributes meaningfully to carbon footprint reduction. Traditional sensor networks often require regular battery replacements, involving manufacturing, transportation, and disposal processes that generate considerable greenhouse gas emissions. Self-powered alternatives minimize these emissions by reducing maintenance requirements and eliminating battery replacement cycles throughout their operational lifetime.

The material efficiency of piezoelectric sensor systems further enhances their sustainability profile. Modern piezoelectric materials increasingly incorporate environmentally benign components, moving away from lead-based compounds toward alternatives such as zinc oxide, aluminum nitride, and organic piezoelectric polymers. This transition addresses concerns regarding resource depletion and toxic material usage in electronic components.

From a lifecycle perspective, self-powered sensor technologies demonstrate superior sustainability metrics. Their extended operational lifetimes without maintenance interventions reduce raw material consumption and manufacturing energy requirements compared to conventional battery-powered alternatives. This advantage becomes particularly significant in large-scale deployments across smart infrastructure, environmental monitoring, and industrial applications.

The deployment of piezoelectric self-powered sensors enables more comprehensive environmental monitoring capabilities, contributing to broader sustainability goals. These systems can operate in remote or inaccessible locations without energy infrastructure, facilitating more effective natural resource management, pollution detection, and climate change monitoring. The resulting data supports evidence-based environmental policy development and conservation efforts.

Economic sustainability also improves through reduced total cost of ownership. While initial implementation costs may exceed conventional alternatives, the elimination of ongoing battery replacement expenses and maintenance requirements yields significant long-term economic benefits. This cost structure makes sustainable monitoring solutions more accessible to developing regions and resource-constrained applications.

Standardization Challenges for Emerging Piezoelectric Technologies

The standardization landscape for piezoelectric materials in self-powered sensor technologies presents significant challenges that impede widespread commercial adoption and technological advancement. Current standardization efforts remain fragmented across different regions and industries, creating barriers to interoperability and market growth. The International Electrotechnical Commission (IEC) has established some standards for piezoelectric devices, but these primarily focus on traditional applications rather than emerging self-powered sensor technologies.

A critical standardization gap exists in measurement protocols for energy harvesting efficiency. Without unified testing methodologies, comparing performance across different piezoelectric materials and devices becomes problematic, hindering investment decisions and technology selection. The variability in testing conditions—including mechanical input parameters, electrical load conditions, and environmental factors—leads to inconsistent performance reporting in scientific literature and commercial specifications.

Material characterization standards also present challenges, particularly for novel piezoelectric nanomaterials and composites. Traditional characterization methods developed for bulk ceramic materials often prove inadequate for nanoscale piezoelectric structures, resulting in unreliable performance metrics. This deficiency creates uncertainty in material selection processes for manufacturers developing self-powered sensor systems.

Reliability and durability testing frameworks remain underdeveloped, despite being crucial for commercial applications. The absence of standardized accelerated aging tests and failure mode analyses specific to piezoelectric energy harvesters leaves significant questions about long-term performance in real-world environments. This uncertainty increases perceived risk for potential adopters and investors.

Safety standards represent another critical area requiring attention, especially as piezoelectric materials find applications in wearable technologies and biomedical devices. Current regulatory frameworks inadequately address the unique characteristics of self-powered piezoelectric sensors, creating potential barriers to market entry in sensitive application domains like healthcare and consumer electronics.

Cross-compatibility standards between piezoelectric energy harvesters and power management circuits remain underdeveloped. The lack of standardized electrical interfaces and communication protocols limits the integration potential of these technologies into broader IoT ecosystems and sensor networks. This standardization gap particularly affects system designers attempting to incorporate piezoelectric energy harvesting into complex multi-sensor platforms.

Industry consortia and standards organizations have begun recognizing these challenges, with initiatives emerging from IEEE, ASTM International, and regional standardization bodies. However, coordination between these efforts remains limited, highlighting the need for a more cohesive international approach to standardization in this rapidly evolving technological domain.

A critical standardization gap exists in measurement protocols for energy harvesting efficiency. Without unified testing methodologies, comparing performance across different piezoelectric materials and devices becomes problematic, hindering investment decisions and technology selection. The variability in testing conditions—including mechanical input parameters, electrical load conditions, and environmental factors—leads to inconsistent performance reporting in scientific literature and commercial specifications.

Material characterization standards also present challenges, particularly for novel piezoelectric nanomaterials and composites. Traditional characterization methods developed for bulk ceramic materials often prove inadequate for nanoscale piezoelectric structures, resulting in unreliable performance metrics. This deficiency creates uncertainty in material selection processes for manufacturers developing self-powered sensor systems.

Reliability and durability testing frameworks remain underdeveloped, despite being crucial for commercial applications. The absence of standardized accelerated aging tests and failure mode analyses specific to piezoelectric energy harvesters leaves significant questions about long-term performance in real-world environments. This uncertainty increases perceived risk for potential adopters and investors.

Safety standards represent another critical area requiring attention, especially as piezoelectric materials find applications in wearable technologies and biomedical devices. Current regulatory frameworks inadequately address the unique characteristics of self-powered piezoelectric sensors, creating potential barriers to market entry in sensitive application domains like healthcare and consumer electronics.

Cross-compatibility standards between piezoelectric energy harvesters and power management circuits remain underdeveloped. The lack of standardized electrical interfaces and communication protocols limits the integration potential of these technologies into broader IoT ecosystems and sensor networks. This standardization gap particularly affects system designers attempting to incorporate piezoelectric energy harvesting into complex multi-sensor platforms.

Industry consortia and standards organizations have begun recognizing these challenges, with initiatives emerging from IEEE, ASTM International, and regional standardization bodies. However, coordination between these efforts remains limited, highlighting the need for a more cohesive international approach to standardization in this rapidly evolving technological domain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!