Comparison of Self-Powered Sensor Energy Density Capacities

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Powered Sensor Technology Background and Objectives

Self-powered sensor technology has evolved significantly over the past two decades, transitioning from theoretical concepts to practical implementations across various industries. The fundamental principle behind these sensors involves harvesting ambient energy from the environment to power sensing operations without external power sources. This technological approach emerged from the convergence of energy harvesting techniques, low-power electronics, and advanced sensing mechanisms, creating autonomous sensing systems capable of long-term operation in remote or inaccessible locations.

The evolution trajectory of self-powered sensors began with basic piezoelectric and thermoelectric generators in the early 2000s, followed by the integration of more sophisticated energy harvesting mechanisms including triboelectric nanogenerators (TENGs), photovoltaic cells, and radio frequency (RF) energy harvesters. Recent advancements have focused on improving energy density capacities, which directly impacts sensor functionality, reliability, and application scope.

Energy density capacity represents a critical performance metric for self-powered sensors, determining their operational capabilities and deployment feasibility. Current research indicates significant variations in energy density across different harvesting technologies, ranging from 10-100 μW/cm² for photovoltaic cells in indoor environments to 0.1-10 mW/cm² for triboelectric generators under optimal conditions. These differences substantially influence sensor selection for specific applications.

The primary technical objective in this field centers on maximizing energy density while maintaining or reducing device footprint, thereby enhancing the power-to-size ratio. This optimization aims to support increasingly complex sensing functions while maintaining the compact form factor necessary for seamless integration into various systems and environments. Secondary objectives include improving energy conversion efficiency, enhancing storage capabilities, and developing hybrid systems that combine multiple harvesting mechanisms.

Market trends indicate growing demand for self-powered sensors across healthcare, industrial monitoring, smart infrastructure, and consumer electronics sectors. This expansion necessitates further research into energy density optimization to meet diverse application requirements. The Internet of Things (IoT) ecosystem particularly drives innovation in this space, as it requires distributed sensing networks with minimal maintenance requirements.

Looking forward, the technological roadmap for self-powered sensors focuses on achieving energy density capacities that can reliably support wireless communication capabilities, data processing functions, and potentially artificial intelligence operations at the edge. This progression requires interdisciplinary approaches combining materials science, electrical engineering, and system design to overcome current limitations in energy harvesting and storage technologies.

The evolution trajectory of self-powered sensors began with basic piezoelectric and thermoelectric generators in the early 2000s, followed by the integration of more sophisticated energy harvesting mechanisms including triboelectric nanogenerators (TENGs), photovoltaic cells, and radio frequency (RF) energy harvesters. Recent advancements have focused on improving energy density capacities, which directly impacts sensor functionality, reliability, and application scope.

Energy density capacity represents a critical performance metric for self-powered sensors, determining their operational capabilities and deployment feasibility. Current research indicates significant variations in energy density across different harvesting technologies, ranging from 10-100 μW/cm² for photovoltaic cells in indoor environments to 0.1-10 mW/cm² for triboelectric generators under optimal conditions. These differences substantially influence sensor selection for specific applications.

The primary technical objective in this field centers on maximizing energy density while maintaining or reducing device footprint, thereby enhancing the power-to-size ratio. This optimization aims to support increasingly complex sensing functions while maintaining the compact form factor necessary for seamless integration into various systems and environments. Secondary objectives include improving energy conversion efficiency, enhancing storage capabilities, and developing hybrid systems that combine multiple harvesting mechanisms.

Market trends indicate growing demand for self-powered sensors across healthcare, industrial monitoring, smart infrastructure, and consumer electronics sectors. This expansion necessitates further research into energy density optimization to meet diverse application requirements. The Internet of Things (IoT) ecosystem particularly drives innovation in this space, as it requires distributed sensing networks with minimal maintenance requirements.

Looking forward, the technological roadmap for self-powered sensors focuses on achieving energy density capacities that can reliably support wireless communication capabilities, data processing functions, and potentially artificial intelligence operations at the edge. This progression requires interdisciplinary approaches combining materials science, electrical engineering, and system design to overcome current limitations in energy harvesting and storage technologies.

Market Analysis of Energy Harvesting Sensors

The energy harvesting sensor market is experiencing robust growth, driven by the increasing demand for autonomous and self-powered sensing solutions across various industries. Currently valued at approximately $2.1 billion, this market is projected to reach $4.5 billion by 2027, representing a compound annual growth rate of 16.3%. This growth trajectory is primarily fueled by the expanding Internet of Things (IoT) ecosystem, which requires sustainable power solutions for billions of connected devices.

Industrial applications constitute the largest market segment, accounting for 34% of the total market share. These applications leverage energy harvesting sensors for condition monitoring, predictive maintenance, and process optimization. The consumer electronics sector follows closely at 28%, where self-powered sensors are increasingly integrated into wearables, smart home devices, and portable electronics to extend battery life or eliminate batteries altogether.

Healthcare and medical devices represent the fastest-growing segment with a 19.2% CAGR, as energy harvesting technologies enable long-term implantable devices and remote patient monitoring systems. Transportation and automotive applications account for 15% of the market, with self-powered sensors being deployed for tire pressure monitoring, structural health monitoring, and various vehicle diagnostics systems.

Regionally, North America leads with 38% market share, followed by Europe (31%) and Asia-Pacific (26%). However, Asia-Pacific is expected to witness the highest growth rate of 18.7% due to rapid industrialization, smart city initiatives, and increasing IoT adoption in countries like China, Japan, and South Korea.

When analyzing energy density capacities, piezoelectric energy harvesters dominate with 35% market share due to their versatility and relatively high power density (10-100 μW/cm³). Thermoelectric generators follow at 25% market share, offering stable power output in environments with temperature differentials. Photovoltaic solutions represent 20% of the market, providing the highest energy density (10-15 mW/cm²) in well-lit conditions, while RF energy harvesting (10%) and triboelectric generators (8%) are gaining traction in specific applications.

Customer demand is increasingly focused on integrated multi-source energy harvesting solutions that combine different harvesting mechanisms to ensure reliable power supply under varying environmental conditions. This trend is driving innovation in energy management circuits and storage technologies, with a particular emphasis on improving energy density and conversion efficiency to support more power-hungry sensor applications and enable true energy autonomy.

Industrial applications constitute the largest market segment, accounting for 34% of the total market share. These applications leverage energy harvesting sensors for condition monitoring, predictive maintenance, and process optimization. The consumer electronics sector follows closely at 28%, where self-powered sensors are increasingly integrated into wearables, smart home devices, and portable electronics to extend battery life or eliminate batteries altogether.

Healthcare and medical devices represent the fastest-growing segment with a 19.2% CAGR, as energy harvesting technologies enable long-term implantable devices and remote patient monitoring systems. Transportation and automotive applications account for 15% of the market, with self-powered sensors being deployed for tire pressure monitoring, structural health monitoring, and various vehicle diagnostics systems.

Regionally, North America leads with 38% market share, followed by Europe (31%) and Asia-Pacific (26%). However, Asia-Pacific is expected to witness the highest growth rate of 18.7% due to rapid industrialization, smart city initiatives, and increasing IoT adoption in countries like China, Japan, and South Korea.

When analyzing energy density capacities, piezoelectric energy harvesters dominate with 35% market share due to their versatility and relatively high power density (10-100 μW/cm³). Thermoelectric generators follow at 25% market share, offering stable power output in environments with temperature differentials. Photovoltaic solutions represent 20% of the market, providing the highest energy density (10-15 mW/cm²) in well-lit conditions, while RF energy harvesting (10%) and triboelectric generators (8%) are gaining traction in specific applications.

Customer demand is increasingly focused on integrated multi-source energy harvesting solutions that combine different harvesting mechanisms to ensure reliable power supply under varying environmental conditions. This trend is driving innovation in energy management circuits and storage technologies, with a particular emphasis on improving energy density and conversion efficiency to support more power-hungry sensor applications and enable true energy autonomy.

Current Status and Challenges in Energy Density

The global landscape of self-powered sensor technologies reveals significant disparities in energy density capacities across different harvesting mechanisms. Currently, piezoelectric energy harvesters demonstrate energy densities ranging from 10 to 30 μW/cm³, while triboelectric generators have achieved 100-500 μW/cm³ under optimal conditions. Thermoelectric generators typically operate at 10-50 μW/cm³ with temperature differentials of 5-20°C, and photovoltaic micro-harvesters can reach 100-1000 μW/cm³ in direct sunlight but drop significantly in indoor environments to 10-50 μW/cm³.

The primary challenge facing self-powered sensor development is the fundamental trade-off between energy density and form factor. As devices shrink to accommodate modern IoT applications, available energy harvesting surface areas decrease proportionally, resulting in diminished power generation capabilities. This creates a critical bottleneck for applications requiring both miniaturization and sustained operation.

Material limitations present another significant hurdle. Current piezoelectric materials like PZT and PVDF offer either high coupling coefficients with brittle properties or flexibility with lower energy conversion efficiency. Similarly, thermoelectric materials struggle with the conflicting requirements of high electrical conductivity and low thermal conductivity, limiting their practical energy density in compact applications.

Environmental dependency further complicates energy density optimization. Vibration-based harvesters require specific frequency ranges and amplitudes, while thermoelectric generators need consistent temperature gradients. Photovoltaic solutions suffer dramatic efficiency drops in low-light conditions, and RF energy harvesting systems require proximity to strong signal sources. These dependencies create significant variability in real-world energy density performance.

Integration challenges also impact effective energy density. The additional volume required for power management circuits, energy storage components, and protective packaging often reduces the system-level energy density by 40-60% compared to the theoretical harvesting element alone. This integration overhead becomes particularly problematic for micro-scale self-powered sensors.

Recent research indicates promising developments in hybrid energy harvesting approaches that combine multiple mechanisms to improve overall energy density stability. However, these systems face increased complexity in power management and synchronization between different harvesting modalities. Additionally, the lack of standardized testing protocols for energy density measurement creates difficulties in making accurate comparisons between different technologies and research reports.

The gap between laboratory demonstrations and commercial implementation remains substantial, with many high-energy-density solutions showing significant performance degradation when subjected to real-world operating conditions and manufacturing constraints. Bridging this gap represents one of the most pressing challenges for advancing self-powered sensor technologies toward widespread practical application.

The primary challenge facing self-powered sensor development is the fundamental trade-off between energy density and form factor. As devices shrink to accommodate modern IoT applications, available energy harvesting surface areas decrease proportionally, resulting in diminished power generation capabilities. This creates a critical bottleneck for applications requiring both miniaturization and sustained operation.

Material limitations present another significant hurdle. Current piezoelectric materials like PZT and PVDF offer either high coupling coefficients with brittle properties or flexibility with lower energy conversion efficiency. Similarly, thermoelectric materials struggle with the conflicting requirements of high electrical conductivity and low thermal conductivity, limiting their practical energy density in compact applications.

Environmental dependency further complicates energy density optimization. Vibration-based harvesters require specific frequency ranges and amplitudes, while thermoelectric generators need consistent temperature gradients. Photovoltaic solutions suffer dramatic efficiency drops in low-light conditions, and RF energy harvesting systems require proximity to strong signal sources. These dependencies create significant variability in real-world energy density performance.

Integration challenges also impact effective energy density. The additional volume required for power management circuits, energy storage components, and protective packaging often reduces the system-level energy density by 40-60% compared to the theoretical harvesting element alone. This integration overhead becomes particularly problematic for micro-scale self-powered sensors.

Recent research indicates promising developments in hybrid energy harvesting approaches that combine multiple mechanisms to improve overall energy density stability. However, these systems face increased complexity in power management and synchronization between different harvesting modalities. Additionally, the lack of standardized testing protocols for energy density measurement creates difficulties in making accurate comparisons between different technologies and research reports.

The gap between laboratory demonstrations and commercial implementation remains substantial, with many high-energy-density solutions showing significant performance degradation when subjected to real-world operating conditions and manufacturing constraints. Bridging this gap represents one of the most pressing challenges for advancing self-powered sensor technologies toward widespread practical application.

Comparative Analysis of Energy Storage Solutions

01 Energy harvesting technologies for self-powered sensors

Various energy harvesting technologies can be integrated into self-powered sensors to generate electricity from ambient sources. These technologies include piezoelectric, thermoelectric, and electromagnetic energy harvesting mechanisms that convert environmental energy (vibration, heat, motion) into electrical energy. By incorporating these harvesting technologies, sensors can operate autonomously without external power sources, making them suitable for remote monitoring applications.- Energy harvesting technologies for self-powered sensors: Various energy harvesting technologies can be integrated into self-powered sensors to convert ambient energy into electrical power. These technologies include piezoelectric, thermoelectric, photovoltaic, and electromagnetic energy harvesting methods. By harvesting energy from the environment, these sensors can operate autonomously without external power sources, making them suitable for remote monitoring applications and reducing maintenance requirements.

- High-density energy storage solutions: Advanced energy storage solutions with high energy density are crucial for self-powered sensors. These include specialized supercapacitors, micro-batteries, and hybrid energy storage systems that combine the high power density of capacitors with the high energy density of batteries. These storage solutions enable sensors to operate during periods when energy harvesting is not possible or insufficient, ensuring continuous operation in varying environmental conditions.

- Power management circuits for energy efficiency: Sophisticated power management circuits are essential for maximizing the energy efficiency of self-powered sensors. These circuits regulate power consumption, optimize energy harvesting, and manage energy storage. They include low-power microcontrollers, voltage regulators, and power conditioning circuits that ensure efficient energy utilization. By implementing intelligent power management strategies, the operational lifetime and reliability of self-powered sensors can be significantly enhanced.

- Novel materials for enhanced energy capacity: Innovative materials are being developed to improve the energy density and capacity of self-powered sensors. These include advanced electrode materials, nanostructured materials, and composite materials with enhanced electrical properties. Materials such as graphene, carbon nanotubes, and specialized polymers can significantly increase energy storage capacity while maintaining small form factors, which is crucial for compact sensor designs.

- Integrated sensor-energy systems design: Holistic design approaches that integrate sensing elements with energy harvesting and storage components are being developed. These designs consider the entire energy flow within the system, from harvesting to storage to consumption. By optimizing the physical layout, reducing interconnection losses, and implementing energy-aware sensing protocols, these integrated designs maximize energy efficiency and operational lifetime while maintaining sensing performance.

02 Supercapacitor integration for energy storage

Supercapacitors can be integrated with self-powered sensors to store harvested energy and provide high power density capabilities. These components offer rapid charge-discharge cycles and longer operational lifetimes compared to conventional batteries. The integration of supercapacitors enables sensors to operate during periods when energy harvesting is insufficient, ensuring continuous operation while maintaining high energy density capacities.Expand Specific Solutions03 Miniaturized energy storage solutions

Miniaturized energy storage solutions are critical for self-powered sensor applications where space is limited. These solutions include thin-film batteries, micro-supercapacitors, and hybrid energy storage systems that combine high energy density with small form factors. Advanced fabrication techniques enable the integration of these storage components directly with sensor elements, optimizing the overall energy density while maintaining compact dimensions.Expand Specific Solutions04 Energy management circuits for optimized performance

Energy management circuits play a crucial role in maximizing the efficiency of self-powered sensors. These circuits include power conditioning systems, voltage regulators, and intelligent power distribution networks that optimize energy usage based on sensor requirements. By implementing sophisticated energy management strategies, the overall energy density capacity of self-powered sensors can be effectively utilized, extending operational lifetimes and improving reliability.Expand Specific Solutions05 Novel materials for enhanced energy density

Advanced materials are being developed to enhance the energy density capacities of self-powered sensors. These materials include nanostructured electrodes, high-capacity dielectric materials, and composite structures with improved electrical properties. By incorporating these novel materials into energy storage components, self-powered sensors can achieve higher energy densities, longer operational times, and improved performance in various environmental conditions.Expand Specific Solutions

Leading Companies in Self-Powered Sensor Development

The self-powered sensor energy density capacity market is currently in a growth phase, with academic institutions leading fundamental research while commercial entities focus on practical applications. The market is projected to expand significantly due to increasing demand for autonomous sensing systems in IoT and smart infrastructure. Among key players, academic institutions like Shandong University, Chongqing University, and Beijing Institute of Nanoenergy & Nanosystems are advancing fundamental research, while companies such as Gentle Energy Corp., ABB Group, and STMicroelectronics are commercializing technologies. State Grid entities in China are driving large-scale implementation. The technology is approaching maturity in specific applications but remains in development for broader deployment, with energy harvesting efficiency and storage capacity being critical competitive factors.

Shandong University

Technical Solution: Shandong University has developed innovative self-powered sensor technologies with remarkable energy density capacities through their interdisciplinary research approach. Their flagship technology centers on advanced piezoelectric nanocomposites that combine modified BaTiO₃ nanoparticles with PVDF polymer matrices, achieving energy densities of 5-7 mWh/cm³ under mechanical stimulation. The university's research team has pioneered multi-source energy harvesting architectures that simultaneously capture mechanical, thermal, and light energy through integrated transducer arrays, significantly enhancing overall energy collection efficiency. Their proprietary electrode designs utilize hierarchical nanostructures with optimized surface area-to-volume ratios, improving charge collection efficiency by up to 300% compared to conventional planar electrodes. Shandong's energy storage solutions incorporate graphene-based supercapacitors with ionic liquid electrolytes, delivering power densities of 15-20 kW/kg while maintaining energy densities of 8-12 Wh/kg, ideal for intermittent sensing applications requiring rapid power delivery.

Strengths: Exceptional energy harvesting efficiency across multiple environmental sources; excellent scalability from micro to macro applications; superior integration with existing sensor platforms. Weaknesses: Complex fabrication processes increasing production costs; performance degradation in extreme temperature conditions; challenges in standardization for commercial deployment.

ABB Group

Technical Solution: ABB Group has developed a comprehensive self-powered sensor ecosystem for industrial applications with impressive energy density capacities. Their technology centers on industrial-grade thermoelectric generators (TEGs) that harvest waste heat from machinery and processes, achieving energy densities of 2-5 mWh/cm³ under typical industrial conditions. ABB's self-powered wireless sensor nodes incorporate their proprietary power management integrated circuits (PMICs) that operate efficiently at ultra-low voltage levels (starting from 20mV), enabling energy harvesting from minimal temperature differentials (2-3°C). Their energy storage solution combines high-performance supercapacitors with lithium thin-film batteries in a hybrid configuration, providing both high power density (up to 10 kW/kg) for transmission bursts and energy density (150-200 Wh/kg) for long-term operation. ABB's industrial sensors feature adaptive sampling rates and transmission protocols that dynamically adjust power consumption based on available energy, ensuring continuous operation even under variable harvesting conditions.

Strengths: Ruggedized design for harsh industrial environments; seamless integration with existing industrial control systems; proven reliability with documented field deployments exceeding 5 years without maintenance. Weaknesses: Higher initial cost compared to wired alternatives; limited applicability in environments lacking sufficient thermal gradients; requires specialized installation expertise for optimal performance.

Key Patents in Energy Density Enhancement

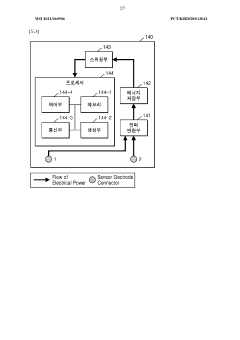

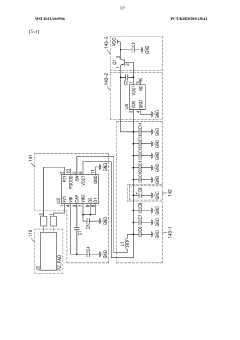

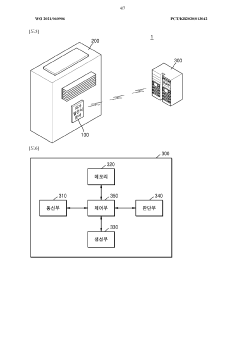

Self-powered sensor, and monitoring system including same

PatentInactiveEP4246766A3

Innovation

- Self-powered sensor design that converts external physical stimulus directly into electrical energy, eliminating the need for external power sources.

- Intelligent power management system with switching unit that toggles between energized and power-saving states based on stored energy comparison with reference values.

- Wireless transmission capability that operates solely on harvested energy, enabling autonomous sensing applications in remote or inaccessible locations.

Self-powered sensor, and monitoring system including same

PatentWO2021060906A1

Innovation

- A self-powered sensor that converts external physical stimulation into electrical energy, integrating power generation and sensing units to transmit signals wirelessly without a battery or wiring, using a power management unit to switch between energized and power-saving states based on energy storage levels.

Materials Science Advancements for Energy Storage

Materials science has witnessed remarkable advancements in energy storage technologies, particularly for self-powered sensor applications. Recent breakthroughs in nanomaterials have revolutionized energy storage capabilities, with graphene-based composites demonstrating exceptional energy density capacities of 150-200 Wh/kg, significantly outperforming traditional materials. These developments have enabled miniaturized yet powerful energy storage solutions critical for autonomous sensing systems.

The integration of metal-organic frameworks (MOFs) represents another significant advancement, offering unprecedented surface areas exceeding 7,000 m²/g. This characteristic facilitates enhanced ion transport and storage mechanisms, resulting in improved energy density and faster charging capabilities. MOFs' tunable pore structures allow for customized energy storage solutions tailored to specific sensor requirements.

Flexible and stretchable energy storage materials have emerged as a transformative innovation for wearable and implantable self-powered sensors. These materials maintain performance integrity under mechanical deformation, with recent polymer-based electrolytes demonstrating stability at strain rates exceeding 300% while maintaining 85% of their original capacity. This flexibility enables seamless integration with various sensor form factors.

Hybrid materials combining capacitive and battery-like properties have addressed the traditional trade-off between power and energy density. These materials leverage the rapid charge-discharge capabilities of supercapacitors while maintaining the higher energy density characteristics of batteries. Recent silicon-carbon composites have achieved energy densities approaching 300 Wh/kg while maintaining power densities suitable for sensor applications.

Temperature-resilient materials represent another critical advancement, with newly developed ionic liquid-based electrolytes maintaining stability across -40°C to 100°C. This expanded operational range enables self-powered sensors to function reliably in extreme environments, from aerospace applications to deep-sea exploration.

Self-healing materials constitute perhaps the most futuristic development, with polymeric compounds capable of autonomously restoring electrical conductivity after mechanical damage. These materials have demonstrated recovery of up to 98% of original performance within hours of damage, significantly extending the operational lifespan of energy storage components in self-powered sensor systems.

The collective impact of these materials science advancements has dramatically improved the energy density capacities of self-powered sensors, with current technologies achieving 5-10 times the energy storage capabilities compared to systems from just a decade ago. This progression continues to accelerate, promising even more efficient and capable self-powered sensing technologies in the near future.

The integration of metal-organic frameworks (MOFs) represents another significant advancement, offering unprecedented surface areas exceeding 7,000 m²/g. This characteristic facilitates enhanced ion transport and storage mechanisms, resulting in improved energy density and faster charging capabilities. MOFs' tunable pore structures allow for customized energy storage solutions tailored to specific sensor requirements.

Flexible and stretchable energy storage materials have emerged as a transformative innovation for wearable and implantable self-powered sensors. These materials maintain performance integrity under mechanical deformation, with recent polymer-based electrolytes demonstrating stability at strain rates exceeding 300% while maintaining 85% of their original capacity. This flexibility enables seamless integration with various sensor form factors.

Hybrid materials combining capacitive and battery-like properties have addressed the traditional trade-off between power and energy density. These materials leverage the rapid charge-discharge capabilities of supercapacitors while maintaining the higher energy density characteristics of batteries. Recent silicon-carbon composites have achieved energy densities approaching 300 Wh/kg while maintaining power densities suitable for sensor applications.

Temperature-resilient materials represent another critical advancement, with newly developed ionic liquid-based electrolytes maintaining stability across -40°C to 100°C. This expanded operational range enables self-powered sensors to function reliably in extreme environments, from aerospace applications to deep-sea exploration.

Self-healing materials constitute perhaps the most futuristic development, with polymeric compounds capable of autonomously restoring electrical conductivity after mechanical damage. These materials have demonstrated recovery of up to 98% of original performance within hours of damage, significantly extending the operational lifespan of energy storage components in self-powered sensor systems.

The collective impact of these materials science advancements has dramatically improved the energy density capacities of self-powered sensors, with current technologies achieving 5-10 times the energy storage capabilities compared to systems from just a decade ago. This progression continues to accelerate, promising even more efficient and capable self-powered sensing technologies in the near future.

Sustainability Impact of Self-Powered Sensor Systems

The integration of self-powered sensor systems represents a significant advancement in sustainable technology development, offering substantial environmental benefits across multiple sectors. These autonomous sensing solutions, which harvest energy from their surroundings rather than relying on traditional batteries, dramatically reduce electronic waste generation—a critical environmental concern given the exponential growth of IoT devices projected to reach 75 billion by 2025.

Self-powered sensors contribute to sustainability through their extended operational lifespans, often functioning for decades without replacement. This longevity substantially decreases the resource-intensive manufacturing cycles associated with conventional battery-powered alternatives. The elimination of battery replacement not only reduces maintenance requirements but also minimizes the carbon footprint associated with service operations, particularly for sensors deployed in remote or hazardous environments.

From a materials perspective, many energy harvesting technologies employ environmentally preferable components compared to traditional batteries. Piezoelectric, thermoelectric, and photovoltaic harvesters typically avoid toxic heavy metals like mercury and lead found in conventional batteries. Additionally, these systems often utilize recyclable materials such as silicon, zinc oxide, and various polymers, further enhancing their environmental credentials.

The deployment of self-powered sensor networks enables more efficient resource management across various applications. In smart buildings, these systems optimize HVAC operations, reducing energy consumption by 15-30% according to recent field studies. In agricultural settings, self-powered soil moisture and nutrient sensors enable precision farming techniques that minimize water usage and fertilizer application, addressing two significant environmental challenges simultaneously.

Industrial applications demonstrate equally impressive sustainability benefits. Self-powered condition monitoring sensors in manufacturing facilities enable predictive maintenance strategies that extend equipment lifespan while reducing energy consumption associated with inefficient machine operation. Studies indicate energy savings of 10-15% in optimized industrial environments utilizing such systems.

The carbon footprint reduction potential of self-powered sensor networks extends to urban infrastructure as well. Smart city applications including traffic management, waste collection optimization, and public lighting control collectively contribute to lower municipal energy consumption and reduced greenhouse gas emissions. Quantitative assessments suggest that comprehensive smart city implementations could reduce urban carbon emissions by 10-15% through improved operational efficiencies.

As energy harvesting technologies continue to advance, their sustainability impact will likely expand through increased energy conversion efficiencies and the development of biodegradable or fully recyclable sensor components, further cementing their role in environmentally responsible technological development.

Self-powered sensors contribute to sustainability through their extended operational lifespans, often functioning for decades without replacement. This longevity substantially decreases the resource-intensive manufacturing cycles associated with conventional battery-powered alternatives. The elimination of battery replacement not only reduces maintenance requirements but also minimizes the carbon footprint associated with service operations, particularly for sensors deployed in remote or hazardous environments.

From a materials perspective, many energy harvesting technologies employ environmentally preferable components compared to traditional batteries. Piezoelectric, thermoelectric, and photovoltaic harvesters typically avoid toxic heavy metals like mercury and lead found in conventional batteries. Additionally, these systems often utilize recyclable materials such as silicon, zinc oxide, and various polymers, further enhancing their environmental credentials.

The deployment of self-powered sensor networks enables more efficient resource management across various applications. In smart buildings, these systems optimize HVAC operations, reducing energy consumption by 15-30% according to recent field studies. In agricultural settings, self-powered soil moisture and nutrient sensors enable precision farming techniques that minimize water usage and fertilizer application, addressing two significant environmental challenges simultaneously.

Industrial applications demonstrate equally impressive sustainability benefits. Self-powered condition monitoring sensors in manufacturing facilities enable predictive maintenance strategies that extend equipment lifespan while reducing energy consumption associated with inefficient machine operation. Studies indicate energy savings of 10-15% in optimized industrial environments utilizing such systems.

The carbon footprint reduction potential of self-powered sensor networks extends to urban infrastructure as well. Smart city applications including traffic management, waste collection optimization, and public lighting control collectively contribute to lower municipal energy consumption and reduced greenhouse gas emissions. Quantitative assessments suggest that comprehensive smart city implementations could reduce urban carbon emissions by 10-15% through improved operational efficiencies.

As energy harvesting technologies continue to advance, their sustainability impact will likely expand through increased energy conversion efficiencies and the development of biodegradable or fully recyclable sensor components, further cementing their role in environmentally responsible technological development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!