Research on Cold Climate Performance of Self-Powered Sensors

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cold Climate Sensor Technology Background and Objectives

Self-powered sensors have emerged as a transformative technology in remote monitoring systems, offering autonomous operation without external power sources. These devices harvest energy from their surroundings, converting ambient energy sources such as vibration, light, thermal gradients, or RF signals into electrical power. The evolution of this technology has progressed from simple mechanical self-winding mechanisms to sophisticated microelectromechanical systems (MEMS) capable of operating in challenging environments.

Cold climate environments present unique challenges for sensor technologies, with temperatures often dropping below -40°C in polar and sub-polar regions. The historical development of cold-resistant electronics dates back to military applications during the Cold War era, with significant advancements occurring in the early 2000s as wireless sensor networks gained prominence in environmental monitoring applications.

The primary objective of research in cold climate self-powered sensors is to develop robust sensing systems capable of reliable operation in extreme low-temperature environments while maintaining energy autonomy. This includes enhancing energy harvesting efficiency at low temperatures, improving energy storage capabilities, and optimizing power management systems to function effectively when thermal energy is scarce.

Current technological trends indicate a convergence of materials science, low-power electronics, and energy harvesting techniques. Particularly promising are developments in thermoelectric materials with enhanced low-temperature performance, piezoelectric systems optimized for cold-weather vibration patterns, and photovoltaic technologies designed for low-light polar conditions.

The market for these technologies spans critical infrastructure monitoring, environmental research, transportation systems in cold regions, and remote industrial applications where conventional power sources are impractical. The Internet of Things (IoT) revolution has further accelerated demand for autonomous sensing capabilities in previously inaccessible environments.

Technical evolution in this field shows a clear trajectory toward miniaturization, increased energy efficiency, and enhanced cold-temperature resilience. Recent breakthroughs in materials science, particularly in the development of flexible thermoelectric generators and cold-resistant energy storage solutions, have opened new possibilities for deployment in extreme environments.

The ultimate goal of this research is to achieve truly autonomous sensing systems capable of multi-year operation in temperatures as low as -60°C without maintenance or external power. Such technology would enable unprecedented data collection from remote arctic and alpine environments, supporting climate research, infrastructure monitoring, and early warning systems for natural disasters in cold regions.

Cold climate environments present unique challenges for sensor technologies, with temperatures often dropping below -40°C in polar and sub-polar regions. The historical development of cold-resistant electronics dates back to military applications during the Cold War era, with significant advancements occurring in the early 2000s as wireless sensor networks gained prominence in environmental monitoring applications.

The primary objective of research in cold climate self-powered sensors is to develop robust sensing systems capable of reliable operation in extreme low-temperature environments while maintaining energy autonomy. This includes enhancing energy harvesting efficiency at low temperatures, improving energy storage capabilities, and optimizing power management systems to function effectively when thermal energy is scarce.

Current technological trends indicate a convergence of materials science, low-power electronics, and energy harvesting techniques. Particularly promising are developments in thermoelectric materials with enhanced low-temperature performance, piezoelectric systems optimized for cold-weather vibration patterns, and photovoltaic technologies designed for low-light polar conditions.

The market for these technologies spans critical infrastructure monitoring, environmental research, transportation systems in cold regions, and remote industrial applications where conventional power sources are impractical. The Internet of Things (IoT) revolution has further accelerated demand for autonomous sensing capabilities in previously inaccessible environments.

Technical evolution in this field shows a clear trajectory toward miniaturization, increased energy efficiency, and enhanced cold-temperature resilience. Recent breakthroughs in materials science, particularly in the development of flexible thermoelectric generators and cold-resistant energy storage solutions, have opened new possibilities for deployment in extreme environments.

The ultimate goal of this research is to achieve truly autonomous sensing systems capable of multi-year operation in temperatures as low as -60°C without maintenance or external power. Such technology would enable unprecedented data collection from remote arctic and alpine environments, supporting climate research, infrastructure monitoring, and early warning systems for natural disasters in cold regions.

Market Analysis for Self-Powered Sensors in Cold Environments

The global market for self-powered sensors in cold environments is experiencing significant growth, driven by increasing demand across multiple industries including infrastructure monitoring, transportation, agriculture, and remote industrial applications. Current market valuations indicate that the self-powered sensor market reached approximately $2.5 billion in 2022, with cold-environment applications representing about 18% of this segment. This specialized market is projected to grow at a compound annual growth rate of 12.3% through 2028.

The primary market drivers include the expanding need for autonomous monitoring systems in remote locations where traditional power sources are unreliable or unavailable. Industries operating in cold regions face substantial challenges with conventional battery-powered sensors, which typically experience severe performance degradation at temperatures below -20°C. This creates a compelling value proposition for self-powered alternatives that can maintain operational reliability in extreme conditions.

Geographic distribution of market demand shows concentration in regions with extensive cold weather operations. North America leads with approximately 35% market share, followed by Europe at 28%, and Asia-Pacific at 22%. Within these regions, countries with significant arctic or sub-arctic territories such as Canada, Russia, and Nordic nations represent particularly strong growth markets.

Industry-specific demand analysis reveals that critical infrastructure monitoring constitutes the largest application segment at 31% of the market. This includes pipeline monitoring, structural health assessment of bridges and buildings in cold regions, and power grid monitoring systems. The transportation sector follows at 24%, with applications in railway monitoring, road condition sensing, and aviation systems.

Customer requirements in cold climate applications emphasize reliability under temperature extremes (-40°C to 0°C), extended maintenance-free operation periods (5+ years), and robust data transmission capabilities despite challenging environmental conditions. Energy harvesting efficiency in low-light and low-temperature conditions remains a critical performance metric that directly influences market adoption rates.

Market barriers include the higher initial cost of self-powered systems compared to conventional alternatives, with premium pricing averaging 30-45% above standard sensors. Technical limitations in energy harvesting efficiency at extremely low temperatures also restrict broader market penetration. Additionally, industry-specific certification requirements for critical applications in aerospace, defense, and infrastructure sectors create market entry challenges for new competitors.

Emerging market opportunities exist in the integration of self-powered cold-climate sensors with IoT platforms and edge computing capabilities, enabling more sophisticated remote monitoring solutions. The agricultural sector also presents growth potential, particularly for frost monitoring and soil condition sensing in cold climate farming operations.

The primary market drivers include the expanding need for autonomous monitoring systems in remote locations where traditional power sources are unreliable or unavailable. Industries operating in cold regions face substantial challenges with conventional battery-powered sensors, which typically experience severe performance degradation at temperatures below -20°C. This creates a compelling value proposition for self-powered alternatives that can maintain operational reliability in extreme conditions.

Geographic distribution of market demand shows concentration in regions with extensive cold weather operations. North America leads with approximately 35% market share, followed by Europe at 28%, and Asia-Pacific at 22%. Within these regions, countries with significant arctic or sub-arctic territories such as Canada, Russia, and Nordic nations represent particularly strong growth markets.

Industry-specific demand analysis reveals that critical infrastructure monitoring constitutes the largest application segment at 31% of the market. This includes pipeline monitoring, structural health assessment of bridges and buildings in cold regions, and power grid monitoring systems. The transportation sector follows at 24%, with applications in railway monitoring, road condition sensing, and aviation systems.

Customer requirements in cold climate applications emphasize reliability under temperature extremes (-40°C to 0°C), extended maintenance-free operation periods (5+ years), and robust data transmission capabilities despite challenging environmental conditions. Energy harvesting efficiency in low-light and low-temperature conditions remains a critical performance metric that directly influences market adoption rates.

Market barriers include the higher initial cost of self-powered systems compared to conventional alternatives, with premium pricing averaging 30-45% above standard sensors. Technical limitations in energy harvesting efficiency at extremely low temperatures also restrict broader market penetration. Additionally, industry-specific certification requirements for critical applications in aerospace, defense, and infrastructure sectors create market entry challenges for new competitors.

Emerging market opportunities exist in the integration of self-powered cold-climate sensors with IoT platforms and edge computing capabilities, enabling more sophisticated remote monitoring solutions. The agricultural sector also presents growth potential, particularly for frost monitoring and soil condition sensing in cold climate farming operations.

Technical Challenges and Limitations in Sub-Zero Conditions

Self-powered sensors face significant challenges when deployed in cold climate environments, particularly in sub-zero conditions. The primary limitation stems from the fundamental physics of energy harvesting mechanisms. Thermoelectric generators experience reduced efficiency as temperature differentials become less stable in extreme cold. Similarly, piezoelectric and triboelectric harvesters suffer from material stiffening at low temperatures, decreasing their mechanical responsiveness and energy conversion capabilities.

Battery performance represents another critical challenge, with most conventional lithium-ion batteries experiencing dramatic capacity reduction below -20°C due to increased internal resistance and slowed electrochemical reactions. This often results in power delivery insufficient for sensor operation, particularly during startup phases which require peak current.

Material degradation accelerates in cold environments, with thermal cycling between day and night temperatures causing microcracking in circuit boards, solder joints, and energy harvesting components. Polymeric materials used in sensor casings and flexible substrates become brittle, leading to mechanical failures that compromise environmental sealing and overall reliability.

Sensor accuracy and calibration drift constitute significant technical hurdles. Temperature-dependent variations in semiconductor properties affect the precision of sensing elements, while thermal expansion mismatches between different materials can induce mechanical stress that alters calibration parameters. Many self-powered sensors lack the energy budget for continuous recalibration routines that could compensate for these effects.

Power management circuits face efficiency challenges in cold environments. CMOS-based circuits experience threshold voltage shifts and mobility changes at extreme temperatures, affecting the precision of power regulation. Low-power DC-DC converters typically show reduced efficiency below -30°C, wasting precious harvested energy during conversion processes.

Communication reliability deteriorates in cold conditions, with RF transceivers requiring higher power for equivalent transmission ranges due to increased internal losses. Antenna performance can shift with ice accumulation, altering impedance matching and radiation patterns. For sensors deployed in remote arctic regions, this often necessitates higher transmission power precisely when energy availability is most constrained.

Startup procedures become particularly problematic, creating a "cold-start paradox" where the system needs energy to begin harvesting energy. Without external intervention, self-powered sensors may remain dormant after complete power depletion in cold conditions, even when environmental energy becomes available again.

Battery performance represents another critical challenge, with most conventional lithium-ion batteries experiencing dramatic capacity reduction below -20°C due to increased internal resistance and slowed electrochemical reactions. This often results in power delivery insufficient for sensor operation, particularly during startup phases which require peak current.

Material degradation accelerates in cold environments, with thermal cycling between day and night temperatures causing microcracking in circuit boards, solder joints, and energy harvesting components. Polymeric materials used in sensor casings and flexible substrates become brittle, leading to mechanical failures that compromise environmental sealing and overall reliability.

Sensor accuracy and calibration drift constitute significant technical hurdles. Temperature-dependent variations in semiconductor properties affect the precision of sensing elements, while thermal expansion mismatches between different materials can induce mechanical stress that alters calibration parameters. Many self-powered sensors lack the energy budget for continuous recalibration routines that could compensate for these effects.

Power management circuits face efficiency challenges in cold environments. CMOS-based circuits experience threshold voltage shifts and mobility changes at extreme temperatures, affecting the precision of power regulation. Low-power DC-DC converters typically show reduced efficiency below -30°C, wasting precious harvested energy during conversion processes.

Communication reliability deteriorates in cold conditions, with RF transceivers requiring higher power for equivalent transmission ranges due to increased internal losses. Antenna performance can shift with ice accumulation, altering impedance matching and radiation patterns. For sensors deployed in remote arctic regions, this often necessitates higher transmission power precisely when energy availability is most constrained.

Startup procedures become particularly problematic, creating a "cold-start paradox" where the system needs energy to begin harvesting energy. Without external intervention, self-powered sensors may remain dormant after complete power depletion in cold conditions, even when environmental energy becomes available again.

Current Solutions for Low-Temperature Energy Harvesting

01 Energy harvesting mechanisms for cold environments

Various energy harvesting mechanisms can be employed to power sensors in cold climates. These include piezoelectric generators, thermoelectric generators that utilize temperature differentials, and mechanical energy harvesters that convert vibration or motion into electrical energy. These self-powering solutions are specifically designed to operate efficiently in low-temperature environments, ensuring continuous sensor operation without external power sources.- Energy harvesting mechanisms for cold environments: Various energy harvesting mechanisms are designed specifically for cold climate operations, enabling sensors to generate power from environmental sources. These include piezoelectric systems that convert mechanical vibrations into electrical energy, thermoelectric generators that utilize temperature differentials common in cold climates, and specialized photovoltaic cells optimized for low-light winter conditions. These technologies allow sensors to maintain functionality without external power sources even in harsh winter environments.

- Cold-resistant battery and power storage solutions: Advanced battery technologies and power storage solutions designed for low-temperature operation ensure continuous sensor functionality in cold climates. These include specialized lithium-ion formulations with modified electrolytes, thermal insulation systems for energy storage components, and phase-change materials that release heat during temperature drops. These solutions address the common problem of battery performance degradation in cold environments, enabling reliable sensor operation during winter conditions.

- Thermal management systems for cold climate sensors: Innovative thermal management systems protect sensitive sensor components and power generation mechanisms in extreme cold. These include self-heating circuits that activate at critical temperature thresholds, passive thermal insulation designs that preserve generated heat, and microheating elements powered by harvested energy. These systems ensure that both the sensing elements and power generation components maintain optimal operating temperatures even in sub-zero conditions.

- Smart power management for cold climate operation: Advanced power management algorithms and circuitry optimize energy usage in cold environments where power generation may be limited. These systems include adaptive duty cycling that adjusts sensor activity based on available power, hibernation modes triggered by temperature thresholds, and prioritization frameworks for critical sensor functions. By intelligently managing power consumption, these technologies extend operational lifetimes of self-powered sensors in challenging winter conditions.

- Cold-optimized sensor materials and designs: Specialized materials and structural designs enable sensors to maintain accuracy and reliability in cold climates. These include low-temperature flexible substrates that resist cracking, cold-resistant semiconductor materials with optimized bandgaps for low-temperature operation, and encapsulation techniques that prevent moisture condensation and ice formation. These material innovations ensure that self-powered sensors maintain measurement accuracy and structural integrity despite thermal cycling and extreme cold exposure.

02 Cold-resistant battery and power storage technologies

Specialized battery technologies and power storage systems are developed to maintain performance in cold climates. These include low-temperature electrolytes, insulated battery compartments, and thermal management systems that prevent power loss in freezing conditions. Advanced energy storage solutions ensure that self-powered sensors can operate reliably even when energy harvesting is temporarily limited due to extreme cold conditions.Expand Specific Solutions03 Thermal management systems for sensor operation

Thermal management systems are integrated into self-powered sensors to maintain optimal operating temperatures in cold environments. These systems include insulation materials, heat-generating components, and passive heating mechanisms that utilize harvested energy to maintain sensor functionality. By regulating internal temperatures, these systems prevent sensor failure and ensure accurate data collection in sub-zero conditions.Expand Specific Solutions04 Cold-optimized sensor materials and designs

Specialized materials and design approaches are employed to create sensors that can withstand and operate efficiently in cold climates. These include low-temperature resistant semiconductors, flexible substrates that resist cracking in freezing conditions, and ruggedized housings that protect sensitive components. The designs often incorporate redundant systems and cold-specific calibration to maintain measurement accuracy despite temperature fluctuations.Expand Specific Solutions05 Smart power management for cold climate operation

Advanced power management algorithms and systems are implemented to optimize energy usage in cold environments. These include adaptive duty cycling, conditional sensing protocols, and intelligent sleep modes that conserve power during extreme cold periods. By dynamically adjusting power consumption based on environmental conditions and available energy, these systems maximize sensor uptime and reliability in challenging cold climate applications.Expand Specific Solutions

Industry Leaders in Cold-Resistant Self-Powered Sensor Development

The self-powered sensor market for cold climate applications is currently in its growth phase, with increasing demand driven by smart grid development and IoT expansion. The market is projected to reach significant scale as energy harvesting technologies mature and sustainability concerns grow. Technologically, the field shows varying maturity levels across players. State Grid Corp. of China and Samsung Electronics lead with substantial R&D investments, while specialized companies like Rosemount Aerospace offer industry-specific expertise in extreme environment sensing. Academic institutions including Chongqing University and China University of Mining & Technology contribute fundamental research. Haier and Gree are leveraging their appliance expertise to integrate cold-resistant self-powered sensors, while automotive players like BYD are exploring applications for electric vehicles operating in harsh conditions.

State Grid Corp. of China

Technical Solution: State Grid has developed innovative self-powered sensor systems specifically designed for power transmission infrastructure in extreme cold environments. Their technology utilizes thermoelectric generators that leverage temperature differentials between equipment and ambient air to harvest energy even in sub-zero conditions. These sensors incorporate proprietary cold-resistant materials and specialized low-temperature electronics that maintain functionality down to -40°C. State Grid's solution includes adaptive power management systems that dynamically adjust power consumption based on available energy and environmental conditions, ensuring continuous operation during harsh winters. The company has implemented these sensors across thousands of kilometers of transmission lines in northern China, where they provide real-time monitoring of ice accumulation, structural integrity, and electrical parameters without requiring external power sources or frequent maintenance.

Strengths: Extensive field deployment experience in real-world extreme cold environments; robust integration with existing grid infrastructure; proven reliability in remote locations. Weaknesses: Higher initial implementation costs compared to conventional sensors; limited energy harvesting capacity during periods of minimal temperature differential.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed innovative self-powered sensor technology for cold climate applications focusing on IoT and consumer electronics. Their approach utilizes advanced thin-film battery technology combined with multi-source energy harvesting, including indoor photovoltaics optimized for low-light conditions and RF energy harvesting from ambient signals. Samsung's cold-climate sensors incorporate ultra-low-power processing units that implement sophisticated power management algorithms, activating different components only when necessary. The company has developed specialized cold-resistant semiconductor materials that maintain electrical properties at temperatures down to -25°C without requiring additional heating. Samsung's sensors feature adaptive data transmission protocols that adjust sampling rates and transmission frequency based on available energy and environmental conditions. These technologies have been implemented in smart home systems, agricultural monitoring solutions, and outdoor consumer electronics designed for operation in cold regions of North America, Europe, and Asia.

Strengths: Leverages Samsung's expertise in semiconductor manufacturing and miniaturization; excellent integration with consumer electronics ecosystems; sophisticated power management. Weaknesses: Less robust than industrial-grade solutions; limited energy harvesting capacity in extended darkness; moderate cold temperature threshold compared to specialized industrial solutions.

Key Innovations in Cold-Resistant Materials and Power Management

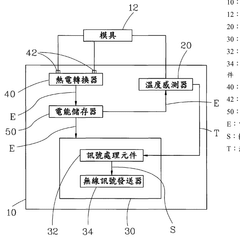

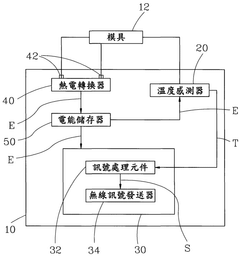

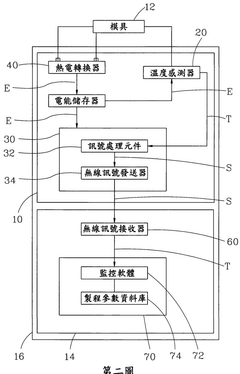

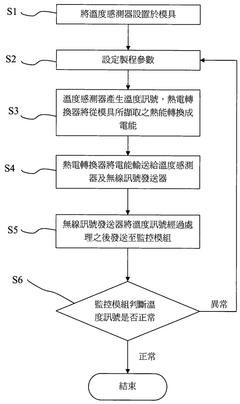

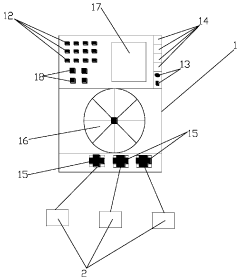

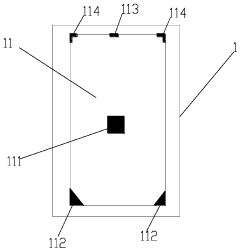

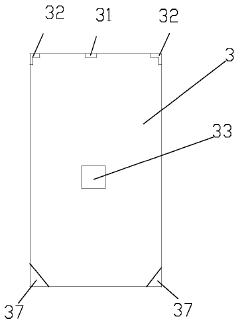

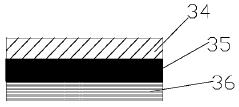

Self-power generation sensing module for thermal processing equipment, monitoring system having the same, and operating method of monitoring system

PatentInactiveTW201412488A

Innovation

- A self-generating sensing module that utilizes a thermoelectric converter to convert thermal energy into electricity, powering a temperature sensor and wireless signal transmitter without batteries, integrated with an energy storage system for efficient energy management.

Self-generating monitoring device

PatentActiveCN111541399A

Innovation

- A power generation board composed of a hot end face, a cold end face and a heat insulation layer is used to generate electricity automatically by using the Seebeck effect to generate potential differences. The temperature difference is maintained through a fan, which provides power for the operation of the monitoring device. At the same time, a sensor interface is set up to obtain detection data, achieving no need for Environmental monitoring of external strong power supplies.

Environmental Impact Assessment of Cold Climate Sensor Deployment

The deployment of self-powered sensors in cold climate regions necessitates a thorough environmental impact assessment to ensure sustainable implementation. These autonomous sensing systems, while offering significant advantages in remote monitoring capabilities, introduce various environmental considerations that must be carefully evaluated.

The physical footprint of sensor networks represents a primary concern, particularly in pristine arctic and subarctic ecosystems. Installation activities may disrupt fragile vegetation patterns and permafrost stability, potentially triggering longer-term ecological changes. Research indicates that even minimal surface disturbance in these environments can require decades for complete recovery, emphasizing the importance of low-impact installation methodologies.

Material composition of sensors deployed in extreme cold environments presents additional environmental challenges. Conventional battery technologies contain potentially harmful chemicals that pose contamination risks if structural integrity is compromised during freeze-thaw cycles. Self-powered alternatives utilizing energy harvesting mechanisms generally offer reduced environmental risk profiles, though comprehensive lifecycle analysis remains essential for accurate impact assessment.

Wildlife interaction represents another critical dimension requiring evaluation. Studies have documented behavioral modifications in certain species responding to electromagnetic emissions from sensing equipment. Particularly in protected wilderness areas, sensor deployment strategies must incorporate sufficient setback distances from known wildlife corridors and sensitive habitat zones to minimize potential disruption to natural movement patterns.

End-of-life considerations for cold climate sensor networks demand particular attention. Retrieval logistics in remote polar regions often present significant challenges, increasing the likelihood of permanent environmental presence. This necessitates the development of biodegradable component designs and predetermined decommissioning protocols to prevent long-term environmental persistence of technological waste.

Energy harvesting mechanisms employed by self-powered sensors generally demonstrate favorable environmental profiles compared to traditional power sources. Solar, thermal gradient, and vibration-based energy collection systems operate with minimal ecological disruption. However, certain piezoelectric materials and specialized semiconductors utilized in these systems may contain rare earth elements with environmentally problematic extraction processes, requiring careful sourcing and disposal considerations.

Regulatory compliance frameworks for environmental impact vary significantly across cold climate regions, with arctic territories generally maintaining more stringent protection standards. Comprehensive environmental impact assessments must therefore incorporate jurisdiction-specific requirements while maintaining best practices for ecological protection across the entire deployment footprint.

The physical footprint of sensor networks represents a primary concern, particularly in pristine arctic and subarctic ecosystems. Installation activities may disrupt fragile vegetation patterns and permafrost stability, potentially triggering longer-term ecological changes. Research indicates that even minimal surface disturbance in these environments can require decades for complete recovery, emphasizing the importance of low-impact installation methodologies.

Material composition of sensors deployed in extreme cold environments presents additional environmental challenges. Conventional battery technologies contain potentially harmful chemicals that pose contamination risks if structural integrity is compromised during freeze-thaw cycles. Self-powered alternatives utilizing energy harvesting mechanisms generally offer reduced environmental risk profiles, though comprehensive lifecycle analysis remains essential for accurate impact assessment.

Wildlife interaction represents another critical dimension requiring evaluation. Studies have documented behavioral modifications in certain species responding to electromagnetic emissions from sensing equipment. Particularly in protected wilderness areas, sensor deployment strategies must incorporate sufficient setback distances from known wildlife corridors and sensitive habitat zones to minimize potential disruption to natural movement patterns.

End-of-life considerations for cold climate sensor networks demand particular attention. Retrieval logistics in remote polar regions often present significant challenges, increasing the likelihood of permanent environmental presence. This necessitates the development of biodegradable component designs and predetermined decommissioning protocols to prevent long-term environmental persistence of technological waste.

Energy harvesting mechanisms employed by self-powered sensors generally demonstrate favorable environmental profiles compared to traditional power sources. Solar, thermal gradient, and vibration-based energy collection systems operate with minimal ecological disruption. However, certain piezoelectric materials and specialized semiconductors utilized in these systems may contain rare earth elements with environmentally problematic extraction processes, requiring careful sourcing and disposal considerations.

Regulatory compliance frameworks for environmental impact vary significantly across cold climate regions, with arctic territories generally maintaining more stringent protection standards. Comprehensive environmental impact assessments must therefore incorporate jurisdiction-specific requirements while maintaining best practices for ecological protection across the entire deployment footprint.

Reliability Testing Methodologies for Extreme Temperature Applications

Reliability testing for self-powered sensors in extreme cold environments requires specialized methodologies that accurately simulate real-world conditions while providing reproducible results. Temperature cycling tests represent the cornerstone of cold climate reliability assessment, typically involving repeated exposure to temperature ranges from -40°C to +85°C, with extended dwell times at the temperature extremes to evaluate material fatigue and component degradation. For arctic applications, testing may extend to -60°C or lower to ensure functionality in the most extreme environments.

Accelerated life testing protocols have been developed specifically for cold climate applications, compressing years of operational stress into weeks or months of laboratory testing. These protocols typically incorporate rapid temperature transitions, humidity variations, and mechanical vibrations that mimic the harsh conditions experienced in cold regions. Statistical analysis of failure rates under these accelerated conditions allows for accurate prediction of long-term reliability and mean time between failures (MTBF).

Power generation capability testing is particularly critical for self-powered sensors, as energy harvesting efficiency often decreases dramatically at low temperatures. Standardized methodologies measure power output across temperature gradients, with particular attention to performance during temperature transitions. These tests typically monitor voltage stability, current output, and energy storage capacity at various temperature points to identify potential failure thresholds.

Material degradation analysis forms another essential component of reliability testing. Cold temperatures can cause embrittlement of polymers, thermal expansion mismatches between different materials, and changes in electrical properties of semiconductors. Specialized testing protocols evaluate these effects through repeated freeze-thaw cycles combined with UV exposure and moisture ingress tests to simulate real-world aging processes in cold environments.

Sensor calibration drift assessment is crucial as extreme temperatures can significantly affect measurement accuracy. Testing methodologies include reference measurements at various temperature points, stability evaluations during temperature transitions, and long-term drift analysis under constant cold conditions. Advanced testing facilities employ precision reference standards that maintain their accuracy across the entire temperature range to ensure valid calibration verification.

Field validation complements laboratory testing by deploying prototype sensors in actual cold climate environments. These real-world tests provide valuable data on unexpected failure modes and performance limitations that may not be apparent in controlled laboratory conditions. Successful reliability testing programs typically combine accelerated laboratory testing with extended field trials to develop comprehensive reliability models for self-powered sensor systems operating in extreme cold environments.

Accelerated life testing protocols have been developed specifically for cold climate applications, compressing years of operational stress into weeks or months of laboratory testing. These protocols typically incorporate rapid temperature transitions, humidity variations, and mechanical vibrations that mimic the harsh conditions experienced in cold regions. Statistical analysis of failure rates under these accelerated conditions allows for accurate prediction of long-term reliability and mean time between failures (MTBF).

Power generation capability testing is particularly critical for self-powered sensors, as energy harvesting efficiency often decreases dramatically at low temperatures. Standardized methodologies measure power output across temperature gradients, with particular attention to performance during temperature transitions. These tests typically monitor voltage stability, current output, and energy storage capacity at various temperature points to identify potential failure thresholds.

Material degradation analysis forms another essential component of reliability testing. Cold temperatures can cause embrittlement of polymers, thermal expansion mismatches between different materials, and changes in electrical properties of semiconductors. Specialized testing protocols evaluate these effects through repeated freeze-thaw cycles combined with UV exposure and moisture ingress tests to simulate real-world aging processes in cold environments.

Sensor calibration drift assessment is crucial as extreme temperatures can significantly affect measurement accuracy. Testing methodologies include reference measurements at various temperature points, stability evaluations during temperature transitions, and long-term drift analysis under constant cold conditions. Advanced testing facilities employ precision reference standards that maintain their accuracy across the entire temperature range to ensure valid calibration verification.

Field validation complements laboratory testing by deploying prototype sensors in actual cold climate environments. These real-world tests provide valuable data on unexpected failure modes and performance limitations that may not be apparent in controlled laboratory conditions. Successful reliability testing programs typically combine accelerated laboratory testing with extended field trials to develop comprehensive reliability models for self-powered sensor systems operating in extreme cold environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!