Semiconductor Advances Driving Self-Powered Sensor Innovations

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Semiconductor Evolution and Energy Harvesting Goals

Semiconductor technology has undergone remarkable evolution since the invention of the first transistor in 1947. The trajectory from vacuum tubes to integrated circuits has been characterized by continuous miniaturization, following Moore's Law which predicted the doubling of transistor density approximately every two years. This exponential growth has enabled unprecedented computational power while simultaneously reducing energy consumption per operation, creating ideal conditions for the development of energy-efficient sensing technologies.

Recent semiconductor advances have been particularly significant in the ultra-low power domain. The development of sub-threshold operation techniques allows circuits to function at voltage levels below traditional thresholds, dramatically reducing power requirements. Complementary metal-oxide-semiconductor (CMOS) technology has evolved to include specialized processes optimized for analog and mixed-signal applications, critical for sensor interfaces that bridge the physical and digital worlds.

Wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) represent another frontier, offering superior performance in power conversion efficiency—a crucial factor for energy harvesting systems. These materials enable higher operating temperatures, faster switching frequencies, and lower losses compared to traditional silicon, making them ideal for compact energy harvesting circuits that must operate with minimal thermal management.

The primary goal of semiconductor evolution in the context of self-powered sensors is achieving what the industry terms "zero-power sensing"—devices that can perpetually operate without battery replacement or external power sources. This requires semiconductor technologies that can function at power levels measured in nanowatts or even picowatts, while still performing complex sensing and communication tasks.

Energy harvesting goals are equally ambitious, focusing on capturing ambient energy from multiple sources: vibration, temperature differentials, radio frequency signals, and light. The semiconductor industry aims to develop integrated solutions that can efficiently convert these diverse energy forms into usable electrical power with minimal conversion losses. Multi-source energy harvesting represents a particularly promising direction, allowing sensors to operate reliably across varying environmental conditions.

Another critical objective is the development of adaptive power management circuits that can dynamically adjust their operation based on available energy and application requirements. These systems must intelligently balance energy harvesting, storage, and consumption to ensure continuous operation even under unpredictable energy availability scenarios.

The convergence of advanced semiconductor manufacturing techniques with novel materials science is enabling unprecedented integration density for energy harvesting systems. The ultimate vision is to create complete systems-on-chip that incorporate sensing elements, energy harvesting, power management, processing capabilities, and wireless communication—all within a single semiconductor die or package measuring just a few square millimeters.

Recent semiconductor advances have been particularly significant in the ultra-low power domain. The development of sub-threshold operation techniques allows circuits to function at voltage levels below traditional thresholds, dramatically reducing power requirements. Complementary metal-oxide-semiconductor (CMOS) technology has evolved to include specialized processes optimized for analog and mixed-signal applications, critical for sensor interfaces that bridge the physical and digital worlds.

Wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) represent another frontier, offering superior performance in power conversion efficiency—a crucial factor for energy harvesting systems. These materials enable higher operating temperatures, faster switching frequencies, and lower losses compared to traditional silicon, making them ideal for compact energy harvesting circuits that must operate with minimal thermal management.

The primary goal of semiconductor evolution in the context of self-powered sensors is achieving what the industry terms "zero-power sensing"—devices that can perpetually operate without battery replacement or external power sources. This requires semiconductor technologies that can function at power levels measured in nanowatts or even picowatts, while still performing complex sensing and communication tasks.

Energy harvesting goals are equally ambitious, focusing on capturing ambient energy from multiple sources: vibration, temperature differentials, radio frequency signals, and light. The semiconductor industry aims to develop integrated solutions that can efficiently convert these diverse energy forms into usable electrical power with minimal conversion losses. Multi-source energy harvesting represents a particularly promising direction, allowing sensors to operate reliably across varying environmental conditions.

Another critical objective is the development of adaptive power management circuits that can dynamically adjust their operation based on available energy and application requirements. These systems must intelligently balance energy harvesting, storage, and consumption to ensure continuous operation even under unpredictable energy availability scenarios.

The convergence of advanced semiconductor manufacturing techniques with novel materials science is enabling unprecedented integration density for energy harvesting systems. The ultimate vision is to create complete systems-on-chip that incorporate sensing elements, energy harvesting, power management, processing capabilities, and wireless communication—all within a single semiconductor die or package measuring just a few square millimeters.

Market Demand for Self-Powered Sensor Solutions

The global market for self-powered sensor solutions is experiencing unprecedented growth, driven by the convergence of IoT proliferation, energy efficiency demands, and sustainability initiatives. Current market research indicates that the self-powered sensor market is expanding at a compound annual growth rate exceeding 15%, with particularly strong adoption in industrial monitoring, smart infrastructure, and consumer electronics sectors.

Industrial applications represent the largest market segment, where self-powered sensors address critical needs for monitoring remote equipment, reducing maintenance costs, and enabling predictive maintenance strategies. Manufacturing facilities are increasingly deploying energy-harvesting sensors to monitor equipment performance, environmental conditions, and production processes without the limitations imposed by battery replacement schedules or wired power infrastructure.

Smart infrastructure and building automation constitute another rapidly growing segment, with self-powered sensors enabling more comprehensive monitoring of structural health, occupancy patterns, and environmental conditions. These solutions provide building managers with actionable insights while eliminating the need for complex wiring or regular battery maintenance, significantly reducing total ownership costs over traditional powered sensors.

Consumer electronics manufacturers are increasingly incorporating self-powered sensing capabilities into wearable devices, smart home products, and portable electronics. This trend is primarily driven by consumer demand for longer device operation between charges and reduced environmental impact. Market surveys indicate that consumers are willing to pay a premium of 8-12% for devices with extended operational lifetimes enabled by self-powered technologies.

Healthcare applications represent an emerging high-value market segment, with self-powered biosensors enabling continuous patient monitoring without the constraints of traditional power sources. These innovations are particularly valuable for implantable medical devices, remote patient monitoring systems, and point-of-care diagnostic tools in resource-limited settings.

The agricultural sector is also showing increased interest in self-powered sensor networks for precision farming applications, where remote deployment and minimal maintenance requirements are essential for economic viability. These systems enable more efficient resource utilization through continuous monitoring of soil conditions, crop health, and environmental factors.

Market analysis reveals significant regional variations in adoption patterns, with North America and Europe leading in industrial and healthcare applications, while Asia-Pacific shows stronger growth in consumer electronics and smart infrastructure implementations. Developing regions are increasingly exploring self-powered sensors for applications where traditional power infrastructure is unreliable or unavailable.

Customer requirements consistently emphasize reliability, operational longevity, and cost-effectiveness as the primary decision factors when evaluating self-powered sensor solutions. The market increasingly demands integrated systems that combine efficient energy harvesting, ultra-low-power semiconductor technologies, and robust wireless communication capabilities.

Industrial applications represent the largest market segment, where self-powered sensors address critical needs for monitoring remote equipment, reducing maintenance costs, and enabling predictive maintenance strategies. Manufacturing facilities are increasingly deploying energy-harvesting sensors to monitor equipment performance, environmental conditions, and production processes without the limitations imposed by battery replacement schedules or wired power infrastructure.

Smart infrastructure and building automation constitute another rapidly growing segment, with self-powered sensors enabling more comprehensive monitoring of structural health, occupancy patterns, and environmental conditions. These solutions provide building managers with actionable insights while eliminating the need for complex wiring or regular battery maintenance, significantly reducing total ownership costs over traditional powered sensors.

Consumer electronics manufacturers are increasingly incorporating self-powered sensing capabilities into wearable devices, smart home products, and portable electronics. This trend is primarily driven by consumer demand for longer device operation between charges and reduced environmental impact. Market surveys indicate that consumers are willing to pay a premium of 8-12% for devices with extended operational lifetimes enabled by self-powered technologies.

Healthcare applications represent an emerging high-value market segment, with self-powered biosensors enabling continuous patient monitoring without the constraints of traditional power sources. These innovations are particularly valuable for implantable medical devices, remote patient monitoring systems, and point-of-care diagnostic tools in resource-limited settings.

The agricultural sector is also showing increased interest in self-powered sensor networks for precision farming applications, where remote deployment and minimal maintenance requirements are essential for economic viability. These systems enable more efficient resource utilization through continuous monitoring of soil conditions, crop health, and environmental factors.

Market analysis reveals significant regional variations in adoption patterns, with North America and Europe leading in industrial and healthcare applications, while Asia-Pacific shows stronger growth in consumer electronics and smart infrastructure implementations. Developing regions are increasingly exploring self-powered sensors for applications where traditional power infrastructure is unreliable or unavailable.

Customer requirements consistently emphasize reliability, operational longevity, and cost-effectiveness as the primary decision factors when evaluating self-powered sensor solutions. The market increasingly demands integrated systems that combine efficient energy harvesting, ultra-low-power semiconductor technologies, and robust wireless communication capabilities.

Current State and Challenges in Self-Powered Semiconductor Technology

The global landscape of self-powered semiconductor technology has witnessed significant advancements in recent years, yet continues to face substantial technical barriers. Currently, the field is characterized by a diverse ecosystem of energy harvesting mechanisms including piezoelectric, triboelectric, thermoelectric, and photovoltaic technologies, each with varying degrees of maturity and commercial readiness.

Leading research institutions across North America, Europe, and East Asia have established distinct technological approaches. North American research primarily focuses on silicon-based integration and MEMS compatibility, while European efforts emphasize sustainable materials and circular economy principles. East Asian development, particularly in Japan, South Korea, and China, has concentrated on miniaturization and mass production techniques.

Despite these advancements, several critical challenges persist in self-powered semiconductor technology. Power density limitations represent the most significant barrier, with current energy harvesting mechanisms typically generating only microwatts to milliwatts per square centimeter—insufficient for many practical applications beyond simple sensing functions.

Energy storage integration presents another major obstacle. The intermittent nature of harvested energy necessitates efficient storage solutions, yet existing thin-film batteries and supercapacitors suffer from limited capacity, high self-discharge rates, and poor cycling stability when miniaturized to the required dimensions for integrated sensor systems.

Material compatibility issues further complicate development efforts. Many promising energy harvesting materials contain rare earth elements or toxic compounds that pose environmental concerns and regulatory challenges. Additionally, these materials often require processing conditions incompatible with standard semiconductor fabrication techniques, creating significant manufacturing integration difficulties.

Reliability and environmental stability remain persistent concerns, particularly for outdoor or harsh environment applications. Current self-powered systems demonstrate significant performance degradation under temperature fluctuations, humidity variations, and mechanical stress, limiting their practical deployment scenarios.

From a manufacturing perspective, scalability challenges impede widespread adoption. The complex integration of multiple functional materials and components requires precise control over interfaces and interconnections, resulting in low yields and high production costs that currently restrict commercial viability to niche applications.

The geographical distribution of technical expertise shows notable concentration patterns, with specialized knowledge clusters forming around major semiconductor research hubs in California, Taiwan, Germany, and Japan. This distribution has created both collaborative opportunities and competitive tensions in the race to overcome these technical barriers.

Leading research institutions across North America, Europe, and East Asia have established distinct technological approaches. North American research primarily focuses on silicon-based integration and MEMS compatibility, while European efforts emphasize sustainable materials and circular economy principles. East Asian development, particularly in Japan, South Korea, and China, has concentrated on miniaturization and mass production techniques.

Despite these advancements, several critical challenges persist in self-powered semiconductor technology. Power density limitations represent the most significant barrier, with current energy harvesting mechanisms typically generating only microwatts to milliwatts per square centimeter—insufficient for many practical applications beyond simple sensing functions.

Energy storage integration presents another major obstacle. The intermittent nature of harvested energy necessitates efficient storage solutions, yet existing thin-film batteries and supercapacitors suffer from limited capacity, high self-discharge rates, and poor cycling stability when miniaturized to the required dimensions for integrated sensor systems.

Material compatibility issues further complicate development efforts. Many promising energy harvesting materials contain rare earth elements or toxic compounds that pose environmental concerns and regulatory challenges. Additionally, these materials often require processing conditions incompatible with standard semiconductor fabrication techniques, creating significant manufacturing integration difficulties.

Reliability and environmental stability remain persistent concerns, particularly for outdoor or harsh environment applications. Current self-powered systems demonstrate significant performance degradation under temperature fluctuations, humidity variations, and mechanical stress, limiting their practical deployment scenarios.

From a manufacturing perspective, scalability challenges impede widespread adoption. The complex integration of multiple functional materials and components requires precise control over interfaces and interconnections, resulting in low yields and high production costs that currently restrict commercial viability to niche applications.

The geographical distribution of technical expertise shows notable concentration patterns, with specialized knowledge clusters forming around major semiconductor research hubs in California, Taiwan, Germany, and Japan. This distribution has created both collaborative opportunities and competitive tensions in the race to overcome these technical barriers.

Current Self-Powered Sensor Architectures and Solutions

01 Energy harvesting for semiconductor devices

Semiconductor devices can be designed to harvest energy from their environment, enabling self-powered operation. These systems convert ambient energy sources such as light, heat, vibration, or RF signals into electrical power. The harvested energy can be used to power the semiconductor device directly or stored in capacitors or batteries for later use, eliminating the need for external power sources and enabling autonomous operation in remote or inaccessible locations.- Energy harvesting for semiconductor devices: Semiconductor devices can be designed to harvest energy from their environment, enabling self-powered operation. These systems convert ambient energy sources such as light, heat, vibration, or RF signals into electrical power. The harvested energy can be used to power the semiconductor device directly or stored in capacitors or batteries for later use, eliminating the need for external power sources and enabling autonomous operation in remote or inaccessible locations.

- Triboelectric nanogenerators for self-powered semiconductors: Triboelectric nanogenerators (TENGs) provide a novel approach for self-powered semiconductor systems. These devices generate electrical energy through contact electrification and electrostatic induction when two materials with different electron affinities come into contact and separate. The generated power can be used to drive semiconductor devices without external power sources. TENGs offer advantages including simple structure, high efficiency, low cost, and compatibility with flexible electronics applications.

- Photovoltaic integration with semiconductor devices: Integrating photovoltaic cells directly with semiconductor devices enables self-powered operation using ambient light. These integrated systems convert light energy into electrical power that can be used to operate the semiconductor components. The photovoltaic elements can be fabricated on the same substrate as the semiconductor device or bonded as separate components. This approach is particularly useful for low-power applications such as sensors, IoT devices, and portable electronics where continuous external power is impractical.

- Power management circuits for self-powered semiconductors: Specialized power management circuits are essential for effective self-powered semiconductor operation. These circuits optimize the use of harvested energy through techniques such as maximum power point tracking, efficient voltage regulation, and intelligent power distribution. They manage the flow of energy between harvesting components, storage elements, and the semiconductor device, ensuring stable operation despite fluctuating energy inputs. Advanced designs include ultra-low power sleep modes, adaptive duty cycling, and prioritized power allocation to critical functions.

- Energy storage integration for self-powered semiconductors: Self-powered semiconductor systems often incorporate energy storage elements to maintain operation during periods when energy harvesting is insufficient. These storage components include supercapacitors, thin-film batteries, or other compact energy storage technologies integrated with the semiconductor device. The storage elements are charged during periods of excess energy availability and discharge when needed. Advanced designs feature hybrid storage systems that combine different technologies to optimize for both power density and energy density requirements.

02 Triboelectric nanogenerators for self-powered semiconductors

Triboelectric nanogenerators (TENGs) provide a novel approach for self-powered semiconductor devices by converting mechanical energy into electricity through contact electrification and electrostatic induction. These nanogenerators can be integrated with semiconductor systems to create self-sufficient power sources. The technology enables semiconductors to operate autonomously by harvesting energy from everyday mechanical movements, vibrations, or fluid flows, making them suitable for applications in wearable electronics, IoT devices, and environmental monitoring systems.Expand Specific Solutions03 Photovoltaic integration with semiconductor devices

Integrating photovoltaic cells directly with semiconductor devices enables self-powered operation through solar energy harvesting. These integrated systems can convert light energy into electrical power to operate semiconductor circuits without external power sources. The photovoltaic elements can be designed as part of the semiconductor fabrication process, allowing for compact, efficient designs. This approach is particularly valuable for outdoor applications, remote sensors, and portable electronics where continuous access to conventional power sources is limited.Expand Specific Solutions04 Power management circuits for self-powered semiconductors

Specialized power management circuits are essential for enabling self-powered semiconductor operation. These circuits efficiently regulate, store, and distribute harvested energy to ensure stable operation despite fluctuating energy inputs. They typically include low-power voltage regulators, energy storage management systems, and intelligent power distribution networks. Advanced designs incorporate adaptive power modes that adjust semiconductor operation based on available energy, ensuring critical functions remain operational during energy shortages while maximizing performance when energy is abundant.Expand Specific Solutions05 Self-powered semiconductor sensors and IoT applications

Self-powered semiconductor sensors represent a significant advancement in IoT and environmental monitoring applications. These devices integrate sensing capabilities with energy harvesting technologies to create autonomous monitoring systems that can operate indefinitely without battery replacement. The semiconductor sensors can detect various parameters such as temperature, pressure, humidity, or chemical composition while generating their own operating power. This technology enables deployment in hard-to-reach locations, industrial environments, or large-scale distributed sensing networks where regular maintenance would be impractical.Expand Specific Solutions

Key Players in Self-Powered Sensor Semiconductor Industry

The semiconductor industry for self-powered sensors is transitioning from early development to growth phase, with market projections reaching $3.5-4 billion by 2028. The competitive landscape features established semiconductor giants like TSMC, Texas Instruments, and Intel driving innovation in energy harvesting and ultra-low-power ICs, alongside specialized players such as Renesas and Infineon focusing on sensor-specific solutions. Academic institutions including Chongqing University and UESTC are contributing fundamental research, while companies like Samsung and GlobalFoundries are advancing manufacturing processes for miniaturized, energy-efficient designs. The technology is approaching commercial maturity with early applications in industrial IoT, automotive systems, and environmental monitoring, though challenges in power density and integration complexity remain.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has pioneered ultra-low power semiconductor manufacturing processes specifically designed for self-powered sensor applications. Their 22nm ultra-low leakage (22ULL) process technology reduces static power consumption by up to 50% compared to previous generations while maintaining performance, making it ideal for energy harvesting applications. TSMC has also developed specialized RF-CMOS processes that enable single-chip integration of sensing elements, energy harvesting circuits, and wireless communication capabilities. Their advanced packaging technologies, including InFO (Integrated Fan-Out) and CoWoS (Chip on Wafer on Substrate), allow for the integration of different functional components such as MEMS sensors, energy harvesting modules, and power management circuits in a compact form factor with minimal interconnect losses[2]. TSMC's N12e process technology specifically targets IoT applications with ultra-low standby power requirements as low as 1nW, enabling sensors to operate for years on harvested energy. Additionally, their specialized back-end processes support the integration of piezoelectric, thermoelectric, and photovoltaic materials directly onto silicon substrates.

Strengths: Industry-leading semiconductor manufacturing processes optimized for ultra-low power applications; advanced packaging technologies enabling highly integrated sensor systems with minimal power losses. Weaknesses: As a foundry, TSMC depends on customers' designs rather than developing complete solutions; higher manufacturing costs for specialized processes compared to standard nodes.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed comprehensive semiconductor solutions for self-powered sensors through their MSP430 ultra-low-power microcontroller platform and specialized power management ICs. Their BQ25570 energy harvesting chip can start operation with input voltages as low as 100mV and achieves up to 90% efficiency in converting harvested energy. TI's MSP430FR series incorporates FRAM (Ferroelectric Random Access Memory) technology that requires significantly less power than traditional flash memory while providing faster write speeds and virtually unlimited endurance. Their CC2650 wireless MCU integrates Bluetooth Low Energy, ZigBee, and 6LoWPAN protocols with ultra-low power consumption, enabling self-powered sensors to transmit data wirelessly[3]. TI has also pioneered advanced power management techniques such as their ULP Advisor software tools that help developers optimize code for minimal energy consumption. Their latest generation of analog front-ends can operate at sub-microamp levels while maintaining high precision for sensor measurements, and their TPS62840 DC-DC converter maintains high efficiency even at the extremely low load currents typical of self-powered sensor applications.

Strengths: Comprehensive ecosystem spanning ultra-low-power microcontrollers, specialized power management ICs, and wireless connectivity solutions; extensive software support for power optimization. Weaknesses: Some solutions require multiple chips rather than fully integrated single-chip designs; higher power consumption in wireless communication compared to some competitors.

Core Innovations in Low-Power Semiconductor Design

Sensor

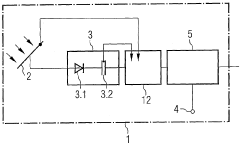

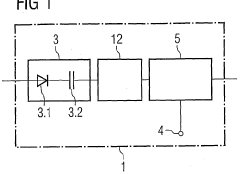

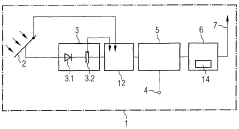

PatentWO2004065908A2

Innovation

- A self-sufficient sensor system utilizing a photovoltaic element to generate electrical voltage from ambient light, coupled with a storage element and timer circuit to manage energy use, allowing intermittent operation and wireless transmission of data, eliminating the need for batteries and reducing energy consumption.

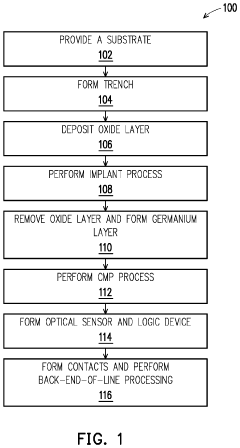

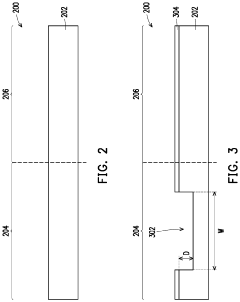

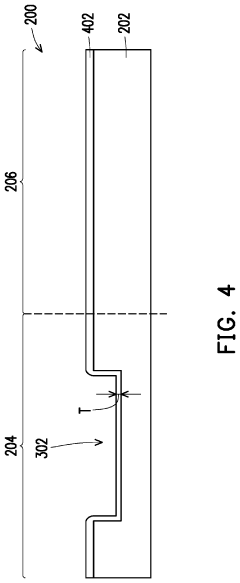

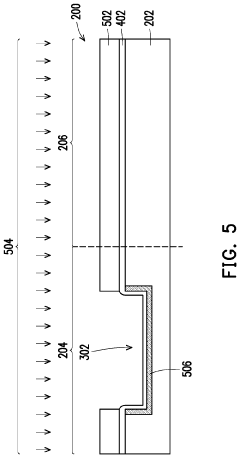

Semiconductor sensor and methods thereof

PatentActiveUS12015099B2

Innovation

- The introduction of dopant species such as P-type materials (e.g., boron, aluminum) or Group VIIA materials (e.g., fluorine, chlorine) at the Ge-Si interface through ion implantation or diffusion to passivate the interface, optimizing the Ge-Si interface and reducing leakage current.

Environmental Impact and Sustainability of Self-Powered Sensors

The environmental impact of self-powered sensors represents a critical dimension in evaluating their overall value proposition. As semiconductor technologies advance to enable more efficient energy harvesting mechanisms, these innovations are simultaneously reducing the ecological footprint of sensing systems across various applications. Self-powered sensors eliminate the need for battery replacements, significantly decreasing electronic waste that traditionally ends up in landfills. This waste reduction is particularly impactful considering the toxic materials present in conventional batteries, including heavy metals and corrosive electrolytes.

Energy harvesting technologies employed in self-powered sensors—such as piezoelectric, thermoelectric, and photovoltaic systems—utilize renewable energy sources that would otherwise be wasted. This represents a fundamental shift toward circular energy utilization in electronic systems. Recent advancements in semiconductor materials have improved conversion efficiencies, with some photovoltaic harvesters now achieving over 25% efficiency in ambient light conditions, dramatically reducing the overall energy consumption of sensor networks.

The manufacturing processes for self-powered sensors are evolving toward greater sustainability as well. New semiconductor fabrication techniques have reduced the requirement for rare earth elements and toxic compounds. For instance, lead-free piezoelectric materials have been developed that maintain comparable performance to traditional lead-based alternatives while eliminating environmental hazards. Additionally, emerging thin-film deposition methods have decreased energy consumption during manufacturing by up to 40% compared to conventional semiconductor processing.

Life cycle assessments of self-powered sensor systems reveal significant environmental advantages over battery-powered alternatives. A typical industrial wireless sensor network utilizing self-powered technology can reduce carbon emissions by approximately 70% over a five-year deployment period. This reduction stems primarily from eliminating battery production, transportation, and disposal requirements. Furthermore, the extended operational lifetime of these systems—often exceeding ten years without maintenance—translates to fewer replacement cycles and reduced material consumption.

In smart agriculture and environmental monitoring applications, self-powered sensors enable more sustainable resource management practices. These systems provide continuous data on soil conditions, water quality, and atmospheric parameters without requiring infrastructure for power delivery or regular maintenance visits. This capability has proven particularly valuable in remote conservation areas where human intervention can disrupt sensitive ecosystems. Studies indicate that precision agriculture enabled by self-powered sensor networks can reduce water consumption by up to 30% and fertilizer use by 20%.

Energy harvesting technologies employed in self-powered sensors—such as piezoelectric, thermoelectric, and photovoltaic systems—utilize renewable energy sources that would otherwise be wasted. This represents a fundamental shift toward circular energy utilization in electronic systems. Recent advancements in semiconductor materials have improved conversion efficiencies, with some photovoltaic harvesters now achieving over 25% efficiency in ambient light conditions, dramatically reducing the overall energy consumption of sensor networks.

The manufacturing processes for self-powered sensors are evolving toward greater sustainability as well. New semiconductor fabrication techniques have reduced the requirement for rare earth elements and toxic compounds. For instance, lead-free piezoelectric materials have been developed that maintain comparable performance to traditional lead-based alternatives while eliminating environmental hazards. Additionally, emerging thin-film deposition methods have decreased energy consumption during manufacturing by up to 40% compared to conventional semiconductor processing.

Life cycle assessments of self-powered sensor systems reveal significant environmental advantages over battery-powered alternatives. A typical industrial wireless sensor network utilizing self-powered technology can reduce carbon emissions by approximately 70% over a five-year deployment period. This reduction stems primarily from eliminating battery production, transportation, and disposal requirements. Furthermore, the extended operational lifetime of these systems—often exceeding ten years without maintenance—translates to fewer replacement cycles and reduced material consumption.

In smart agriculture and environmental monitoring applications, self-powered sensors enable more sustainable resource management practices. These systems provide continuous data on soil conditions, water quality, and atmospheric parameters without requiring infrastructure for power delivery or regular maintenance visits. This capability has proven particularly valuable in remote conservation areas where human intervention can disrupt sensitive ecosystems. Studies indicate that precision agriculture enabled by self-powered sensor networks can reduce water consumption by up to 30% and fertilizer use by 20%.

Standardization and Interoperability Challenges

The rapid advancement of semiconductor technology for self-powered sensors has created a significant challenge in standardization and interoperability across the industry. As these innovative sensors proliferate across various applications—from industrial IoT to wearable health monitors—the lack of unified standards threatens to fragment the market and impede widespread adoption.

Currently, multiple proprietary protocols and communication interfaces exist among different manufacturers, creating compatibility issues when integrating self-powered sensors into larger systems. This fragmentation forces developers to create custom interfaces for each sensor type, significantly increasing development costs and time-to-market for end products.

Energy harvesting mechanisms, a critical component of self-powered sensors, face particular standardization challenges. The diverse methods employed—including piezoelectric, thermoelectric, and photovoltaic technologies—each operate under different parameters and output characteristics. Without standardized power management interfaces, system designers must develop custom power conditioning circuits for each energy harvesting method.

Data format standardization represents another critical challenge. Self-powered sensors generate data in various formats, resolutions, and sampling rates, making data aggregation and analysis across different sensor types extremely difficult. This inconsistency hampers the development of unified analytics platforms that could extract maximum value from sensor networks.

Industry consortia such as the IEEE, IEC, and ISO have begun addressing these challenges through working groups focused on self-powered sensor standardization. The IEEE P2851 working group, for example, is developing standards for interoperable energy harvesting interfaces, while the IEC Technical Committee 47 is addressing semiconductor device standards relevant to self-powered applications.

Interoperability testing and certification programs remain underdeveloped, creating uncertainty for manufacturers and end-users alike. Without reliable certification mechanisms, organizations hesitate to invest heavily in self-powered sensor deployments, fearing future compatibility issues or technological obsolescence.

Cross-industry collaboration will be essential to overcome these challenges. Semiconductor manufacturers, sensor developers, system integrators, and end-users must collectively establish open standards that address power management, data formats, communication protocols, and physical interfaces. The development of reference designs and open-source implementations could accelerate standardization efforts and foster a more cohesive ecosystem.

Regulatory considerations further complicate standardization efforts, particularly for sensors deployed in sensitive applications like healthcare or critical infrastructure. Ensuring that standards meet regulatory requirements across different regions will be crucial for global adoption of self-powered sensor technologies.

Currently, multiple proprietary protocols and communication interfaces exist among different manufacturers, creating compatibility issues when integrating self-powered sensors into larger systems. This fragmentation forces developers to create custom interfaces for each sensor type, significantly increasing development costs and time-to-market for end products.

Energy harvesting mechanisms, a critical component of self-powered sensors, face particular standardization challenges. The diverse methods employed—including piezoelectric, thermoelectric, and photovoltaic technologies—each operate under different parameters and output characteristics. Without standardized power management interfaces, system designers must develop custom power conditioning circuits for each energy harvesting method.

Data format standardization represents another critical challenge. Self-powered sensors generate data in various formats, resolutions, and sampling rates, making data aggregation and analysis across different sensor types extremely difficult. This inconsistency hampers the development of unified analytics platforms that could extract maximum value from sensor networks.

Industry consortia such as the IEEE, IEC, and ISO have begun addressing these challenges through working groups focused on self-powered sensor standardization. The IEEE P2851 working group, for example, is developing standards for interoperable energy harvesting interfaces, while the IEC Technical Committee 47 is addressing semiconductor device standards relevant to self-powered applications.

Interoperability testing and certification programs remain underdeveloped, creating uncertainty for manufacturers and end-users alike. Without reliable certification mechanisms, organizations hesitate to invest heavily in self-powered sensor deployments, fearing future compatibility issues or technological obsolescence.

Cross-industry collaboration will be essential to overcome these challenges. Semiconductor manufacturers, sensor developers, system integrators, and end-users must collectively establish open standards that address power management, data formats, communication protocols, and physical interfaces. The development of reference designs and open-source implementations could accelerate standardization efforts and foster a more cohesive ecosystem.

Regulatory considerations further complicate standardization efforts, particularly for sensors deployed in sensitive applications like healthcare or critical infrastructure. Ensuring that standards meet regulatory requirements across different regions will be crucial for global adoption of self-powered sensor technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!