Analysis of Cross-Industry Applications for Self-Powered Sensors

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Powered Sensor Technology Background and Objectives

Self-powered sensor technology has evolved significantly over the past two decades, transforming from laboratory curiosities to practical solutions addressing real-world challenges. The fundamental concept behind these sensors lies in their ability to harvest ambient energy from their surroundings—whether mechanical vibrations, temperature gradients, light, or radio frequency signals—to power their sensing and communication functions without requiring external power sources or battery replacements.

The evolution of this technology can be traced back to early energy harvesting research in the 1990s, which primarily focused on piezoelectric materials that convert mechanical stress into electrical energy. By the early 2000s, researchers began exploring thermoelectric generators and photovoltaic cells as alternative energy sources for sensors. The 2010s witnessed significant breakthroughs in low-power electronics and energy storage technologies, enabling the development of more efficient and practical self-powered sensing systems.

Recent technological advancements have dramatically reduced the power consumption of sensors while simultaneously improving energy harvesting efficiencies. Modern self-powered sensors can operate with power budgets in the microwatt to milliwatt range, making them viable for numerous applications across industries. The miniaturization of components and integration of multiple energy harvesting mechanisms have further expanded their potential use cases.

The primary objective of self-powered sensor technology development is to create autonomous sensing systems that can operate indefinitely in diverse environments without maintenance or battery replacement. This goal addresses critical limitations of conventional battery-powered sensors, particularly in remote, hazardous, or inaccessible locations where regular maintenance is impractical or impossible.

Current research trends focus on enhancing energy conversion efficiencies, developing hybrid energy harvesting approaches, improving energy storage capabilities, and creating adaptive power management systems. These efforts aim to make self-powered sensors more reliable, versatile, and cost-effective across various applications.

Looking forward, the technology trajectory points toward increasingly integrated systems combining multiple energy harvesting mechanisms with advanced power management and wireless communication capabilities. The convergence with Internet of Things (IoT) architectures and edge computing paradigms is expected to accelerate adoption across industries, from manufacturing and healthcare to agriculture and smart infrastructure.

The ultimate technological goal is to develop "deploy and forget" sensing solutions that can seamlessly integrate into their environments, providing continuous data streams without human intervention for years or even decades, thereby enabling truly pervasive sensing capabilities across industrial, consumer, and environmental applications.

The evolution of this technology can be traced back to early energy harvesting research in the 1990s, which primarily focused on piezoelectric materials that convert mechanical stress into electrical energy. By the early 2000s, researchers began exploring thermoelectric generators and photovoltaic cells as alternative energy sources for sensors. The 2010s witnessed significant breakthroughs in low-power electronics and energy storage technologies, enabling the development of more efficient and practical self-powered sensing systems.

Recent technological advancements have dramatically reduced the power consumption of sensors while simultaneously improving energy harvesting efficiencies. Modern self-powered sensors can operate with power budgets in the microwatt to milliwatt range, making them viable for numerous applications across industries. The miniaturization of components and integration of multiple energy harvesting mechanisms have further expanded their potential use cases.

The primary objective of self-powered sensor technology development is to create autonomous sensing systems that can operate indefinitely in diverse environments without maintenance or battery replacement. This goal addresses critical limitations of conventional battery-powered sensors, particularly in remote, hazardous, or inaccessible locations where regular maintenance is impractical or impossible.

Current research trends focus on enhancing energy conversion efficiencies, developing hybrid energy harvesting approaches, improving energy storage capabilities, and creating adaptive power management systems. These efforts aim to make self-powered sensors more reliable, versatile, and cost-effective across various applications.

Looking forward, the technology trajectory points toward increasingly integrated systems combining multiple energy harvesting mechanisms with advanced power management and wireless communication capabilities. The convergence with Internet of Things (IoT) architectures and edge computing paradigms is expected to accelerate adoption across industries, from manufacturing and healthcare to agriculture and smart infrastructure.

The ultimate technological goal is to develop "deploy and forget" sensing solutions that can seamlessly integrate into their environments, providing continuous data streams without human intervention for years or even decades, thereby enabling truly pervasive sensing capabilities across industrial, consumer, and environmental applications.

Cross-Industry Market Demand Analysis

The self-powered sensor market is experiencing robust growth across multiple industries, driven by the increasing need for autonomous monitoring solutions that eliminate battery replacement and maintenance costs. The global market for self-powered sensors was valued at approximately $47 billion in 2022 and is projected to reach $109 billion by 2028, representing a compound annual growth rate of 15.2% during the forecast period.

In the industrial manufacturing sector, demand for self-powered sensors is particularly strong, with applications in predictive maintenance, equipment monitoring, and process optimization. Manufacturing companies are increasingly adopting these sensors to reduce downtime, improve operational efficiency, and extend the lifespan of critical equipment. The industrial IoT segment alone accounts for nearly 35% of the total self-powered sensor market.

The healthcare industry represents another significant growth area, with applications ranging from wearable health monitors to implantable medical devices. The ability of self-powered sensors to operate continuously without battery replacement makes them ideal for long-term patient monitoring and chronic disease management. Market research indicates that healthcare applications for self-powered sensors are growing at 18.7% annually, outpacing the overall market growth rate.

Smart infrastructure and building automation systems are driving substantial demand for self-powered sensors in the construction and real estate sectors. These sensors enable energy-efficient building management, occupancy detection, and environmental monitoring without complex wiring or frequent maintenance. The smart building segment is expected to grow at 16.5% annually through 2028.

The automotive industry is rapidly adopting self-powered sensors for tire pressure monitoring, structural health monitoring, and various driver assistance systems. With the transition toward electric and autonomous vehicles, the demand for lightweight, maintenance-free sensing solutions continues to accelerate. Automotive applications currently represent approximately 22% of the total market value.

Consumer electronics manufacturers are increasingly incorporating self-powered sensors into wearable devices, smart home products, and portable electronics. The elimination of battery constraints enables new form factors and extended functionality that was previously impractical. This segment is projected to grow at 19.3% annually, representing the fastest-growing application area.

Agricultural applications for self-powered sensors are emerging rapidly, with solutions for soil moisture monitoring, crop health assessment, and livestock tracking. These technologies enable precision agriculture practices that optimize resource usage and increase yields while reducing environmental impact. Though currently a smaller segment at 8% of the market, agricultural applications are expected to grow significantly as farming operations increasingly digitize.

In the industrial manufacturing sector, demand for self-powered sensors is particularly strong, with applications in predictive maintenance, equipment monitoring, and process optimization. Manufacturing companies are increasingly adopting these sensors to reduce downtime, improve operational efficiency, and extend the lifespan of critical equipment. The industrial IoT segment alone accounts for nearly 35% of the total self-powered sensor market.

The healthcare industry represents another significant growth area, with applications ranging from wearable health monitors to implantable medical devices. The ability of self-powered sensors to operate continuously without battery replacement makes them ideal for long-term patient monitoring and chronic disease management. Market research indicates that healthcare applications for self-powered sensors are growing at 18.7% annually, outpacing the overall market growth rate.

Smart infrastructure and building automation systems are driving substantial demand for self-powered sensors in the construction and real estate sectors. These sensors enable energy-efficient building management, occupancy detection, and environmental monitoring without complex wiring or frequent maintenance. The smart building segment is expected to grow at 16.5% annually through 2028.

The automotive industry is rapidly adopting self-powered sensors for tire pressure monitoring, structural health monitoring, and various driver assistance systems. With the transition toward electric and autonomous vehicles, the demand for lightweight, maintenance-free sensing solutions continues to accelerate. Automotive applications currently represent approximately 22% of the total market value.

Consumer electronics manufacturers are increasingly incorporating self-powered sensors into wearable devices, smart home products, and portable electronics. The elimination of battery constraints enables new form factors and extended functionality that was previously impractical. This segment is projected to grow at 19.3% annually, representing the fastest-growing application area.

Agricultural applications for self-powered sensors are emerging rapidly, with solutions for soil moisture monitoring, crop health assessment, and livestock tracking. These technologies enable precision agriculture practices that optimize resource usage and increase yields while reducing environmental impact. Though currently a smaller segment at 8% of the market, agricultural applications are expected to grow significantly as farming operations increasingly digitize.

Current Technical Status and Challenges

Self-powered sensors have witnessed significant advancements globally, with research institutions and companies across North America, Europe, and Asia making substantial contributions. The United States leads in innovation with pioneering work from institutions like Georgia Tech and MIT, while European research centers in Germany and Switzerland focus on precision engineering applications. Asian countries, particularly China, Japan, and South Korea, have rapidly accelerated development with emphasis on manufacturing scalability and integration with IoT ecosystems.

Despite these advancements, self-powered sensor technology faces several critical challenges. Energy harvesting efficiency remains a primary limitation, with most current solutions capturing only a fraction of available ambient energy. This efficiency gap restricts continuous operation in low-energy environments and limits application scope. Miniaturization presents another significant hurdle, as reducing sensor dimensions while maintaining energy harvesting capabilities involves complex trade-offs between size, functionality, and power generation capacity.

Material durability and longevity constitute persistent challenges, particularly in harsh industrial environments where sensors must withstand extreme temperatures, chemical exposure, and mechanical stress. Current materials often degrade over time, reducing energy harvesting efficiency and sensor reliability. Additionally, standardization across the industry remains fragmented, with various proprietary technologies and protocols hindering widespread adoption and interoperability.

Cost factors present substantial barriers to mass-market penetration. Manufacturing processes for specialized energy harvesting components remain expensive compared to traditional battery-powered alternatives, creating adoption resistance in price-sensitive markets. The integration complexity with existing systems further complicates implementation, as many industrial infrastructures were not designed to accommodate self-powered sensing technologies.

Cross-industry applications face unique technical challenges in different sectors. In healthcare, biocompatibility and ultra-low power requirements present significant hurdles. Industrial environments demand robust designs capable of withstanding electromagnetic interference and vibration. Automotive applications require sensors that can function reliably across extreme temperature ranges while meeting stringent safety standards.

Recent technological breakthroughs show promise in addressing these limitations. Advanced piezoelectric materials with higher conversion efficiencies have emerged, alongside hybrid energy harvesting approaches that combine multiple sources such as vibration, thermal, and RF energy. Machine learning algorithms are increasingly being deployed to optimize power management, allowing sensors to adapt their operation based on available energy and application priorities.

Despite these advancements, self-powered sensor technology faces several critical challenges. Energy harvesting efficiency remains a primary limitation, with most current solutions capturing only a fraction of available ambient energy. This efficiency gap restricts continuous operation in low-energy environments and limits application scope. Miniaturization presents another significant hurdle, as reducing sensor dimensions while maintaining energy harvesting capabilities involves complex trade-offs between size, functionality, and power generation capacity.

Material durability and longevity constitute persistent challenges, particularly in harsh industrial environments where sensors must withstand extreme temperatures, chemical exposure, and mechanical stress. Current materials often degrade over time, reducing energy harvesting efficiency and sensor reliability. Additionally, standardization across the industry remains fragmented, with various proprietary technologies and protocols hindering widespread adoption and interoperability.

Cost factors present substantial barriers to mass-market penetration. Manufacturing processes for specialized energy harvesting components remain expensive compared to traditional battery-powered alternatives, creating adoption resistance in price-sensitive markets. The integration complexity with existing systems further complicates implementation, as many industrial infrastructures were not designed to accommodate self-powered sensing technologies.

Cross-industry applications face unique technical challenges in different sectors. In healthcare, biocompatibility and ultra-low power requirements present significant hurdles. Industrial environments demand robust designs capable of withstanding electromagnetic interference and vibration. Automotive applications require sensors that can function reliably across extreme temperature ranges while meeting stringent safety standards.

Recent technological breakthroughs show promise in addressing these limitations. Advanced piezoelectric materials with higher conversion efficiencies have emerged, alongside hybrid energy harvesting approaches that combine multiple sources such as vibration, thermal, and RF energy. Machine learning algorithms are increasingly being deployed to optimize power management, allowing sensors to adapt their operation based on available energy and application priorities.

Current Self-Powered Sensor Solutions

01 Energy harvesting mechanisms for self-powered sensors

Various energy harvesting mechanisms can be employed to power sensors without external power sources. These include piezoelectric generators that convert mechanical vibrations into electrical energy, thermoelectric generators that utilize temperature differences, and photovoltaic cells that convert light into electricity. These energy harvesting technologies enable sensors to operate autonomously in remote or inaccessible locations by generating power from ambient environmental conditions.- Energy harvesting mechanisms for self-powered sensors: Various energy harvesting mechanisms can be employed to power sensors autonomously. These include piezoelectric elements that convert mechanical vibrations into electrical energy, thermoelectric generators that utilize temperature differentials, and photovoltaic cells that convert light into electricity. These mechanisms eliminate the need for external power sources or battery replacements, making sensors self-sufficient and suitable for long-term deployment in remote or inaccessible locations.

- Wireless self-powered sensor networks: Self-powered sensors can be integrated into wireless sensor networks for various applications. These networks consist of multiple sensor nodes that can communicate with each other and transmit data to central processing units without requiring wired connections. The self-powering capability ensures continuous operation without maintenance for battery replacement, making them ideal for environmental monitoring, structural health monitoring, and industrial automation applications.

- Triboelectric self-powered sensing systems: Triboelectric nanogenerators (TENGs) can be used to develop self-powered sensors by harvesting energy from friction between different materials. When two dissimilar materials come into contact and then separate, they generate electrical charges that can be collected and used to power sensing elements. These systems are particularly effective for motion detection, touch sensing, and pressure monitoring applications, offering high sensitivity and energy efficiency.

- Integrated power management for self-powered sensors: Advanced power management circuits are essential components of self-powered sensor systems. These circuits regulate the harvested energy, store excess energy in capacitors or small rechargeable batteries, and distribute power efficiently to sensing and communication components. Intelligent power management strategies include duty cycling, adaptive sampling rates, and sleep modes to optimize energy usage and ensure continuous operation even under variable energy harvesting conditions.

- Applications of self-powered sensors in IoT and wearable technology: Self-powered sensors are increasingly being integrated into Internet of Things (IoT) devices and wearable technology. These applications include health monitoring wearables that track vital signs, smart building sensors that monitor environmental conditions, and industrial IoT sensors that detect equipment performance parameters. The self-powering capability enables these devices to operate autonomously for extended periods, reducing maintenance costs and expanding deployment possibilities in various fields including healthcare, agriculture, and smart infrastructure.

02 Wireless self-powered sensor networks

Self-powered sensors can be integrated into wireless sensor networks for various applications. These networks utilize energy-efficient communication protocols to transmit data while minimizing power consumption. The sensors in these networks can harvest energy from their surroundings and operate without battery replacement, making them suitable for long-term deployment in hard-to-reach areas. This technology enables continuous monitoring systems with minimal maintenance requirements.Expand Specific Solutions03 Triboelectric nanogenerators for self-powered sensing

Triboelectric nanogenerators (TENGs) represent an emerging technology for self-powered sensors. These devices generate electricity through contact electrification and electrostatic induction when two different materials come into contact and separate. TENGs can be designed in various configurations to harvest energy from human motion, vibration, or fluid flow, making them ideal for wearable sensors and IoT applications. Their high energy conversion efficiency and simple structure enable truly self-powered sensing systems.Expand Specific Solutions04 Power management circuits for self-powered sensors

Specialized power management circuits are essential for optimizing the performance of self-powered sensors. These circuits regulate the harvested energy, store excess power in capacitors or small batteries, and ensure stable operation of the sensor under varying energy availability conditions. Advanced power management techniques include maximum power point tracking, ultra-low power sleep modes, and adaptive duty cycling to match energy consumption with harvesting capabilities. These systems enable sensors to function reliably even with intermittent energy sources.Expand Specific Solutions05 Applications of self-powered sensor technologies

Self-powered sensors find applications across numerous fields including structural health monitoring, environmental sensing, medical devices, and industrial automation. In structural monitoring, these sensors can detect and report damage or stress without requiring power infrastructure. In healthcare, wearable self-powered sensors can continuously monitor vital signs without battery replacement. Environmental applications include remote monitoring of pollution, weather conditions, or wildlife. The ability to operate without external power makes these sensors particularly valuable in harsh environments or for long-term deployments.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The self-powered sensors market is currently in a growth phase, characterized by increasing cross-industry applications and expanding market potential. The global market is projected to reach significant scale as industries seek energy-efficient and autonomous sensing solutions. From a technological maturity perspective, the landscape shows varied development levels across players. Academic institutions like Zhejiang University, Chongqing University, and Case Western Reserve University are driving fundamental research, while established corporations including Eaton Corp., Samsung Electronics, and Siemens Corp. are commercializing applications. Energy-focused companies such as Gentle Energy Corp. and State Grid Corp. of China are developing specialized implementations. The competitive dynamics reveal a collaborative ecosystem where industrial giants partner with research institutions to bridge the gap between theoretical advances and practical deployments.

Eaton Corp.

Technical Solution: Eaton Corporation has developed self-powered sensor technology primarily focused on power management and electrical distribution applications. Their approach integrates current transformers and voltage sensors directly into power distribution equipment, harvesting energy from the monitored electrical systems themselves. Eaton's self-powered sensors utilize proprietary power management circuits that can operate from induced currents as low as 5-10 mA, sufficient to power microcontrollers and wireless communication modules. These sensors incorporate flash memory for data logging during communication outages and feature adaptive sampling rates based on available harvested energy. The technology has been deployed across commercial buildings, data centers, and industrial facilities, where it monitors electrical parameters including current, voltage, power factor, and harmonics without requiring external power sources or battery replacements. Implementation has demonstrated up to 25% reduction in energy consumption through improved power quality monitoring and load management.

Strengths: Direct integration with electrical infrastructure, elimination of separate power sources, and comprehensive power quality monitoring capabilities. Weaknesses: Limited application outside electrical systems and dependence on minimum current flow for operation.

Pepperl+Fuchs, Inc.

Technical Solution: Pepperl+Fuchs has developed specialized self-powered sensor solutions for hazardous industrial environments where conventional power sources present safety risks. Their technology utilizes intrinsically safe energy harvesting methods, primarily focused on electromagnetic induction from rotating machinery and thermal gradients in process equipment. Their self-powered sensors incorporate proprietary explosion-proof enclosures that meet ATEX and IECEx standards while housing the energy harvesting components. The company's approach includes ultra-efficient signal conditioning circuits that can operate with harvested power levels as low as 50-200 μW, sufficient for periodic wireless transmission of critical process parameters. These sensors have been successfully deployed in oil and gas facilities, chemical plants, and mining operations, where they monitor equipment parameters without requiring potentially hazardous electrical connections or battery replacements in explosive atmospheres.

Strengths: Specialized design for hazardous environments, intrinsically safe certification, and elimination of battery replacement requirements in difficult-to-access locations. Weaknesses: Limited functionality in low-energy environments and higher cost compared to conventional sensors for non-hazardous applications.

Core Patents and Technical Innovations

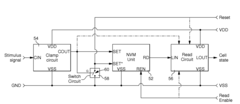

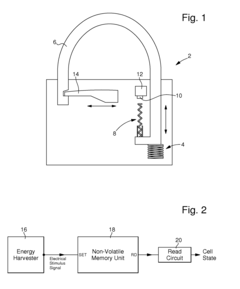

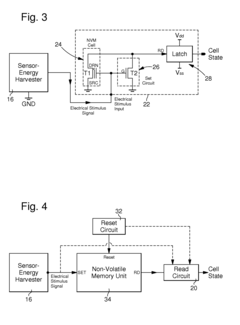

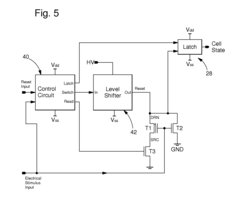

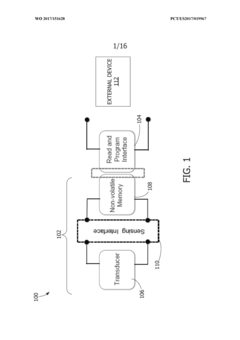

Self-powered detection device with a non-volatile memory

PatentActiveUS8411505B2

Innovation

- A self-powered detection device comprising a non-volatile memory unit and a sensor that uses a clamp circuit to harness energy from physical or chemical events, allowing efficient storage and protection of data without external power, while preventing unauthorized resets through a clamp circuit that blocks inappropriate voltage signals.

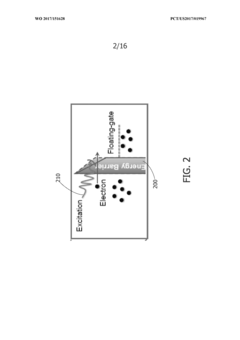

Self-powered sensors for long-term monitoring

PatentWO2017151628A1

Innovation

- The development of a self-powered sensor system utilizing a floating-gate transistor with a sensing interface that leaks electrons at a predetermined rate through Fowler-Nordheim tunneling, allowing for continuous data storage and timestamping of events by modulating the energy barrier geometry in response to sensor signals, and varying electron leakage rates with ambient temperature.

Energy Harvesting Mechanisms for Different Industries

Energy harvesting technologies have evolved significantly across various industries, each adapting specific mechanisms to suit their operational environments and requirements. In manufacturing sectors, vibration-based energy harvesting has gained substantial traction, utilizing piezoelectric materials that convert machine vibrations into usable electrical energy. These systems are particularly effective in factory settings where continuous mechanical motion from production equipment provides a consistent energy source for powering condition monitoring sensors and wireless transmitters.

The transportation industry leverages multiple harvesting mechanisms, with thermoelectric generators capturing temperature differentials in automotive exhaust systems and regenerative shock absorbers converting suspension movement into electrical energy. Additionally, photovoltaic films integrated into vehicle surfaces harvest solar energy, creating a hybrid approach that maximizes power generation in varying conditions. These combined systems enable self-powered sensors for tire pressure monitoring, structural health assessment, and environmental monitoring without requiring battery replacements.

In smart building applications, energy harvesting mechanisms focus primarily on indoor light harvesting through specialized low-light photovoltaic cells, capable of generating sufficient power even under artificial lighting conditions. Complementing this approach, thermal gradient harvesters capture energy from HVAC systems and building envelope temperature differentials. Motion energy from door operations and human movement is captured through electromagnetic induction and triboelectric nanogenerators, powering occupancy sensors and environmental monitoring systems.

Healthcare applications employ unique bio-mechanical energy harvesting techniques, including piezoelectric implants that harvest energy from natural body movements and heartbeats. These mechanisms power implantable sensors for continuous health monitoring without requiring surgical battery replacement. External wearable devices utilize thermoelectric generators that convert body heat into electrical energy, while motion-based harvesters capture energy from limb movements during regular activities.

Agricultural implementations focus on environmental energy sources, with solar-powered sensors being the predominant solution for field monitoring. These are increasingly supplemented by wind micro-turbines in open areas and hydro-kinetic harvesters in irrigation systems. A notable innovation in this sector is microbial fuel cell technology, which generates electricity from soil bacterial activity, enabling truly autonomous soil quality monitoring systems that operate indefinitely without maintenance.

Each industry's energy harvesting approach is tailored to maximize available ambient energy sources while meeting specific operational constraints such as size limitations, environmental exposure, and power requirements of the associated sensing technologies. Cross-industry knowledge transfer has accelerated development, with innovations from one sector frequently finding applications in others through adaptive engineering.

The transportation industry leverages multiple harvesting mechanisms, with thermoelectric generators capturing temperature differentials in automotive exhaust systems and regenerative shock absorbers converting suspension movement into electrical energy. Additionally, photovoltaic films integrated into vehicle surfaces harvest solar energy, creating a hybrid approach that maximizes power generation in varying conditions. These combined systems enable self-powered sensors for tire pressure monitoring, structural health assessment, and environmental monitoring without requiring battery replacements.

In smart building applications, energy harvesting mechanisms focus primarily on indoor light harvesting through specialized low-light photovoltaic cells, capable of generating sufficient power even under artificial lighting conditions. Complementing this approach, thermal gradient harvesters capture energy from HVAC systems and building envelope temperature differentials. Motion energy from door operations and human movement is captured through electromagnetic induction and triboelectric nanogenerators, powering occupancy sensors and environmental monitoring systems.

Healthcare applications employ unique bio-mechanical energy harvesting techniques, including piezoelectric implants that harvest energy from natural body movements and heartbeats. These mechanisms power implantable sensors for continuous health monitoring without requiring surgical battery replacement. External wearable devices utilize thermoelectric generators that convert body heat into electrical energy, while motion-based harvesters capture energy from limb movements during regular activities.

Agricultural implementations focus on environmental energy sources, with solar-powered sensors being the predominant solution for field monitoring. These are increasingly supplemented by wind micro-turbines in open areas and hydro-kinetic harvesters in irrigation systems. A notable innovation in this sector is microbial fuel cell technology, which generates electricity from soil bacterial activity, enabling truly autonomous soil quality monitoring systems that operate indefinitely without maintenance.

Each industry's energy harvesting approach is tailored to maximize available ambient energy sources while meeting specific operational constraints such as size limitations, environmental exposure, and power requirements of the associated sensing technologies. Cross-industry knowledge transfer has accelerated development, with innovations from one sector frequently finding applications in others through adaptive engineering.

Sustainability Impact and Environmental Benefits

Self-powered sensors represent a significant advancement in sustainable technology, offering substantial environmental benefits across multiple industries. These autonomous sensing devices harvest energy from their surroundings, eliminating the need for traditional battery power sources and their associated environmental impacts. The sustainability advantages of self-powered sensors extend far beyond mere energy conservation, creating cascading positive effects throughout product lifecycles and industrial operations.

The primary environmental benefit comes from the dramatic reduction in battery waste. Conventional sensor networks often require thousands of disposable batteries, which contain toxic chemicals and heavy metals that pose serious environmental hazards when improperly disposed of. Self-powered sensors effectively eliminate this waste stream, reducing landfill contamination and the environmental costs of battery production and disposal.

Energy harvesting mechanisms employed in these sensors—whether piezoelectric, thermoelectric, photovoltaic, or RF-based—utilize renewable energy sources that would otherwise go untapped. This represents a shift toward truly sustainable sensing infrastructure with minimal carbon footprint. In large-scale industrial deployments, the cumulative energy savings can be substantial, contributing to overall greenhouse gas emission reductions.

The extended operational lifespan of self-powered sensors further enhances their sustainability profile. Without battery limitations, these sensors can function for years or even decades with minimal maintenance, reducing the resource-intensive manufacturing and replacement cycles typical of conventional sensor networks. This longevity translates directly into reduced material consumption and manufacturing emissions over time.

In remote environmental monitoring applications, self-powered sensors enable non-invasive, continuous data collection without human intervention. This capability supports more effective conservation efforts, pollution detection, and natural resource management while minimizing ecosystem disruption. The resulting data helps inform evidence-based environmental policies and remediation strategies.

The miniaturization potential of self-powered sensors also contributes to material efficiency. As these technologies advance, sensors require fewer raw materials while delivering equal or superior functionality. This resource optimization aligns with circular economy principles and reduces the environmental footprint of sensing technologies across their lifecycle.

When integrated into smart building systems and industrial processes, self-powered sensors enable unprecedented energy optimization. The continuous monitoring and automated adjustments they facilitate can reduce energy consumption by 15-30% in typical applications, representing a significant indirect environmental benefit beyond the sensors' own sustainability advantages.

The primary environmental benefit comes from the dramatic reduction in battery waste. Conventional sensor networks often require thousands of disposable batteries, which contain toxic chemicals and heavy metals that pose serious environmental hazards when improperly disposed of. Self-powered sensors effectively eliminate this waste stream, reducing landfill contamination and the environmental costs of battery production and disposal.

Energy harvesting mechanisms employed in these sensors—whether piezoelectric, thermoelectric, photovoltaic, or RF-based—utilize renewable energy sources that would otherwise go untapped. This represents a shift toward truly sustainable sensing infrastructure with minimal carbon footprint. In large-scale industrial deployments, the cumulative energy savings can be substantial, contributing to overall greenhouse gas emission reductions.

The extended operational lifespan of self-powered sensors further enhances their sustainability profile. Without battery limitations, these sensors can function for years or even decades with minimal maintenance, reducing the resource-intensive manufacturing and replacement cycles typical of conventional sensor networks. This longevity translates directly into reduced material consumption and manufacturing emissions over time.

In remote environmental monitoring applications, self-powered sensors enable non-invasive, continuous data collection without human intervention. This capability supports more effective conservation efforts, pollution detection, and natural resource management while minimizing ecosystem disruption. The resulting data helps inform evidence-based environmental policies and remediation strategies.

The miniaturization potential of self-powered sensors also contributes to material efficiency. As these technologies advance, sensors require fewer raw materials while delivering equal or superior functionality. This resource optimization aligns with circular economy principles and reduces the environmental footprint of sensing technologies across their lifecycle.

When integrated into smart building systems and industrial processes, self-powered sensors enable unprecedented energy optimization. The continuous monitoring and automated adjustments they facilitate can reduce energy consumption by 15-30% in typical applications, representing a significant indirect environmental benefit beyond the sensors' own sustainability advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!