Self-Powered Sensors in Supply Chain Monitoring: An Evaluation

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Powered Sensor Technology Background and Objectives

Self-powered sensor technology has evolved significantly over the past decade, transforming from experimental laboratory concepts to commercially viable solutions for industrial applications. The fundamental principle behind these sensors involves harvesting ambient energy from the surrounding environment—such as vibration, temperature differentials, light, or RF signals—to power sensing, processing, and communication functions without requiring batteries or wired power connections. This technological evolution has been driven by advancements in energy harvesting techniques, ultra-low-power electronics, and miniaturization of components.

The development trajectory of self-powered sensors can be traced back to early piezoelectric and thermoelectric generators, which have progressively improved in efficiency and applicability. Recent breakthroughs in materials science, particularly in the realm of nanomaterials and flexible electronics, have enabled more efficient energy conversion mechanisms and expanded the potential application scenarios for these devices.

In supply chain contexts, self-powered sensors represent a paradigm shift in monitoring capabilities. Traditional supply chain monitoring systems have been constrained by power limitations, requiring either frequent battery replacements or complex wiring infrastructures. These constraints have historically limited deployment scale and increased maintenance costs, particularly in remote or harsh environments where supply chains often operate.

The primary technical objectives for self-powered sensors in supply chain monitoring include achieving energy autonomy while maintaining reliable sensing performance, extending operational lifespans to match or exceed typical supply chain asset lifecycles, and ensuring robust operation across varying environmental conditions encountered throughout global supply networks.

Current research aims to optimize the energy balance equation—ensuring that harvested energy consistently meets or exceeds the power requirements for sensing, processing, and wireless communication. This involves developing more efficient energy harvesting mechanisms, implementing sophisticated power management algorithms, and reducing the energy consumption of sensor components through innovative circuit design and communication protocols.

Another critical objective is enhancing the versatility of these sensors to monitor multiple supply chain parameters simultaneously, including temperature, humidity, shock, vibration, location, and product-specific variables. This multi-parameter monitoring capability must be achieved while maintaining the energy self-sufficiency that makes these sensors valuable for supply chain applications.

The technology also aims to integrate seamlessly with existing supply chain management systems and emerging technologies such as blockchain and artificial intelligence, enabling not just data collection but actionable insights that can optimize logistics operations, reduce waste, and enhance transparency throughout the supply chain ecosystem.

The development trajectory of self-powered sensors can be traced back to early piezoelectric and thermoelectric generators, which have progressively improved in efficiency and applicability. Recent breakthroughs in materials science, particularly in the realm of nanomaterials and flexible electronics, have enabled more efficient energy conversion mechanisms and expanded the potential application scenarios for these devices.

In supply chain contexts, self-powered sensors represent a paradigm shift in monitoring capabilities. Traditional supply chain monitoring systems have been constrained by power limitations, requiring either frequent battery replacements or complex wiring infrastructures. These constraints have historically limited deployment scale and increased maintenance costs, particularly in remote or harsh environments where supply chains often operate.

The primary technical objectives for self-powered sensors in supply chain monitoring include achieving energy autonomy while maintaining reliable sensing performance, extending operational lifespans to match or exceed typical supply chain asset lifecycles, and ensuring robust operation across varying environmental conditions encountered throughout global supply networks.

Current research aims to optimize the energy balance equation—ensuring that harvested energy consistently meets or exceeds the power requirements for sensing, processing, and wireless communication. This involves developing more efficient energy harvesting mechanisms, implementing sophisticated power management algorithms, and reducing the energy consumption of sensor components through innovative circuit design and communication protocols.

Another critical objective is enhancing the versatility of these sensors to monitor multiple supply chain parameters simultaneously, including temperature, humidity, shock, vibration, location, and product-specific variables. This multi-parameter monitoring capability must be achieved while maintaining the energy self-sufficiency that makes these sensors valuable for supply chain applications.

The technology also aims to integrate seamlessly with existing supply chain management systems and emerging technologies such as blockchain and artificial intelligence, enabling not just data collection but actionable insights that can optimize logistics operations, reduce waste, and enhance transparency throughout the supply chain ecosystem.

Supply Chain Monitoring Market Demand Analysis

The global supply chain monitoring market is experiencing significant growth driven by increasing complexity in logistics networks and the need for real-time visibility. Current market valuation stands at approximately $3.2 billion in 2023, with projections indicating a compound annual growth rate of 11.7% through 2028. This robust expansion reflects the urgent demand for more efficient monitoring solutions across diverse industries including manufacturing, retail, healthcare, and food distribution.

Self-powered sensor technology addresses a critical pain point in supply chain monitoring: the need for continuous, maintenance-free operation in remote or difficult-to-access locations. Traditional battery-powered sensors require regular replacement or recharging, creating logistical challenges and increasing operational costs. Market research indicates that companies spend between 15-20% of their sensor deployment budget on power management alone.

The demand for self-powered sensors is particularly strong in cold chain logistics, where temperature-sensitive goods require constant monitoring. The pharmaceutical cold chain segment alone is valued at $17.2 billion globally, with stringent regulatory requirements driving adoption of advanced monitoring solutions. Similarly, the food and beverage industry faces pressure to reduce waste, estimated at $750 billion annually worldwide, much of which occurs during transportation and storage due to inadequate monitoring.

Environmental sustainability concerns are further accelerating market demand. Organizations face increasing pressure to reduce electronic waste from disposable batteries while minimizing their carbon footprint. Self-powered sensors align with corporate sustainability goals, providing a compelling value proposition beyond operational efficiency.

Regional analysis reveals varying adoption patterns, with North America currently leading market share at 38%, followed by Europe at 29% and Asia-Pacific showing the fastest growth rate at 14.3% annually. Developing markets present significant opportunities as supply chain infrastructure modernizes and regulatory frameworks evolve.

Customer surveys indicate that key purchasing factors include reliability (cited by 87% of respondents), total cost of ownership (76%), ease of integration with existing systems (72%), and data accuracy (68%). Self-powered sensors score particularly well on reliability and total cost metrics when evaluated against traditional alternatives.

Industry-specific requirements are creating specialized market segments. For instance, hazardous materials transportation demands intrinsically safe monitoring solutions, while pharmaceutical supply chains require sensors with exceptional accuracy and compliance documentation. This segmentation is driving the development of customized self-powered sensing solutions tailored to specific vertical markets.

The COVID-19 pandemic has accelerated market growth by highlighting vulnerabilities in global supply chains and emphasizing the need for resilient, automated monitoring systems that can function with minimal human intervention. This structural shift in market demand is expected to persist beyond the immediate crisis, creating sustained opportunities for self-powered sensing technologies.

Self-powered sensor technology addresses a critical pain point in supply chain monitoring: the need for continuous, maintenance-free operation in remote or difficult-to-access locations. Traditional battery-powered sensors require regular replacement or recharging, creating logistical challenges and increasing operational costs. Market research indicates that companies spend between 15-20% of their sensor deployment budget on power management alone.

The demand for self-powered sensors is particularly strong in cold chain logistics, where temperature-sensitive goods require constant monitoring. The pharmaceutical cold chain segment alone is valued at $17.2 billion globally, with stringent regulatory requirements driving adoption of advanced monitoring solutions. Similarly, the food and beverage industry faces pressure to reduce waste, estimated at $750 billion annually worldwide, much of which occurs during transportation and storage due to inadequate monitoring.

Environmental sustainability concerns are further accelerating market demand. Organizations face increasing pressure to reduce electronic waste from disposable batteries while minimizing their carbon footprint. Self-powered sensors align with corporate sustainability goals, providing a compelling value proposition beyond operational efficiency.

Regional analysis reveals varying adoption patterns, with North America currently leading market share at 38%, followed by Europe at 29% and Asia-Pacific showing the fastest growth rate at 14.3% annually. Developing markets present significant opportunities as supply chain infrastructure modernizes and regulatory frameworks evolve.

Customer surveys indicate that key purchasing factors include reliability (cited by 87% of respondents), total cost of ownership (76%), ease of integration with existing systems (72%), and data accuracy (68%). Self-powered sensors score particularly well on reliability and total cost metrics when evaluated against traditional alternatives.

Industry-specific requirements are creating specialized market segments. For instance, hazardous materials transportation demands intrinsically safe monitoring solutions, while pharmaceutical supply chains require sensors with exceptional accuracy and compliance documentation. This segmentation is driving the development of customized self-powered sensing solutions tailored to specific vertical markets.

The COVID-19 pandemic has accelerated market growth by highlighting vulnerabilities in global supply chains and emphasizing the need for resilient, automated monitoring systems that can function with minimal human intervention. This structural shift in market demand is expected to persist beyond the immediate crisis, creating sustained opportunities for self-powered sensing technologies.

Current State and Challenges of Self-Powered Sensing

Self-powered sensing technology has evolved significantly over the past decade, with current implementations primarily utilizing energy harvesting methods such as piezoelectric, thermoelectric, photovoltaic, and electromagnetic induction. These technologies have reached varying levels of maturity, with photovoltaic being the most established and widely deployed in supply chain monitoring applications. Recent advancements in low-power microelectronics have enabled sensors that can operate on sub-milliwatt power levels, making energy harvesting increasingly viable for practical applications.

Despite these advancements, self-powered sensors in supply chain monitoring face several critical challenges. Power generation consistency remains a significant obstacle, as environmental energy sources are inherently variable and unpredictable. For instance, solar-powered sensors become ineffective in low-light warehousing environments, while vibration-based energy harvesters may not generate sufficient power during stationary periods of transportation.

Energy storage limitations present another major challenge. Current battery technologies and supercapacitors still struggle with energy density constraints, limiting the operational duration of sensors during periods when energy harvesting is not possible. This is particularly problematic for cold chain monitoring, where temperature extremes can significantly reduce battery performance and lifespan.

Miniaturization efforts continue to face the fundamental physics challenge of reduced energy harvesting capacity as device size decreases. This creates a difficult balance between making sensors small enough for non-intrusive supply chain integration while ensuring they can generate sufficient power to operate effectively.

The reliability and durability of self-powered sensors in harsh supply chain environments remain concerning. Extreme temperatures, humidity, mechanical shocks, and vibration can all degrade energy harvesting components over time. Current encapsulation and protection technologies add bulk and cost while not fully addressing these environmental challenges.

From a geographical perspective, self-powered sensing technology development is concentrated primarily in North America, Europe, and East Asia. The United States leads in innovative energy harvesting research, while Japan and South Korea dominate in miniaturization and efficiency improvements. China has emerged as a manufacturing powerhouse for these technologies, though often implementing designs developed elsewhere.

Cost remains perhaps the most significant barrier to widespread adoption. Current self-powered sensors are typically 3-5 times more expensive than their battery-powered counterparts, making the return on investment calculations challenging for many supply chain applications. This cost premium is driven by specialized materials, complex manufacturing processes, and the need for redundant power systems to ensure reliability.

Despite these advancements, self-powered sensors in supply chain monitoring face several critical challenges. Power generation consistency remains a significant obstacle, as environmental energy sources are inherently variable and unpredictable. For instance, solar-powered sensors become ineffective in low-light warehousing environments, while vibration-based energy harvesters may not generate sufficient power during stationary periods of transportation.

Energy storage limitations present another major challenge. Current battery technologies and supercapacitors still struggle with energy density constraints, limiting the operational duration of sensors during periods when energy harvesting is not possible. This is particularly problematic for cold chain monitoring, where temperature extremes can significantly reduce battery performance and lifespan.

Miniaturization efforts continue to face the fundamental physics challenge of reduced energy harvesting capacity as device size decreases. This creates a difficult balance between making sensors small enough for non-intrusive supply chain integration while ensuring they can generate sufficient power to operate effectively.

The reliability and durability of self-powered sensors in harsh supply chain environments remain concerning. Extreme temperatures, humidity, mechanical shocks, and vibration can all degrade energy harvesting components over time. Current encapsulation and protection technologies add bulk and cost while not fully addressing these environmental challenges.

From a geographical perspective, self-powered sensing technology development is concentrated primarily in North America, Europe, and East Asia. The United States leads in innovative energy harvesting research, while Japan and South Korea dominate in miniaturization and efficiency improvements. China has emerged as a manufacturing powerhouse for these technologies, though often implementing designs developed elsewhere.

Cost remains perhaps the most significant barrier to widespread adoption. Current self-powered sensors are typically 3-5 times more expensive than their battery-powered counterparts, making the return on investment calculations challenging for many supply chain applications. This cost premium is driven by specialized materials, complex manufacturing processes, and the need for redundant power systems to ensure reliability.

Current Self-Powered Sensor Implementation Approaches

01 Energy harvesting mechanisms for self-powered sensors

Various energy harvesting mechanisms can be employed to power sensors without external power sources. These include piezoelectric generators that convert mechanical vibrations into electrical energy, thermoelectric generators that utilize temperature differentials, and electromagnetic induction systems that generate power from motion. These self-sustaining power sources enable sensors to operate autonomously in remote or inaccessible locations, eliminating the need for battery replacement or external power connections.- Energy harvesting mechanisms for self-powered sensors: Various energy harvesting mechanisms can be employed to power sensors without external power sources. These include piezoelectric generators that convert mechanical vibrations into electrical energy, thermoelectric generators that utilize temperature differences, and photovoltaic cells that convert light into electricity. These energy harvesting technologies enable sensors to operate autonomously in remote or inaccessible locations by generating power from ambient environmental conditions.

- Wireless self-powered sensor networks: Self-powered sensors can be integrated into wireless sensor networks for various applications. These networks utilize energy-efficient communication protocols to transmit data while minimizing power consumption. The sensors in these networks can harvest energy from their surroundings, store it in energy storage devices, and use it for sensing and communication functions. This approach eliminates the need for battery replacement and enables long-term deployment in hard-to-reach areas.

- Motion and vibration-based energy harvesting for sensors: Motion and vibration can be harnessed to power sensors in dynamic environments. Technologies such as electromagnetic induction, triboelectric generators, and kinetic energy harvesters convert mechanical movement into electrical energy. These systems are particularly useful in applications involving transportation, industrial machinery, or human movement, where vibrations are abundant. The harvested energy can be used directly or stored for later use by the sensor system.

- Self-powered sensors with integrated energy storage: Self-powered sensor systems often incorporate energy storage components such as supercapacitors or thin-film batteries to manage intermittent energy harvesting. These storage elements accumulate energy during periods of abundant environmental energy and provide stable power during energy-scarce periods. Advanced power management circuits optimize energy usage by implementing sleep modes, adaptive sampling rates, and efficient power conversion to extend the operational lifetime of the sensor system.

- Applications of self-powered sensors in IoT and environmental monitoring: Self-powered sensors find extensive applications in Internet of Things (IoT) deployments and environmental monitoring systems. These sensors can measure parameters such as temperature, humidity, air quality, structural health, and water conditions without requiring connection to the power grid. By eliminating wiring and battery replacement requirements, self-powered sensors enable cost-effective, large-scale deployment for smart cities, agriculture, infrastructure monitoring, and remote environmental sensing applications.

02 Wireless self-powered sensor networks

Self-powered sensors can be integrated into wireless sensor networks for distributed monitoring applications. These networks utilize energy-efficient communication protocols to transmit data while minimizing power consumption. The sensors harvest ambient energy from their environment, enabling long-term deployment without maintenance. Applications include environmental monitoring, structural health monitoring, and industrial process control where traditional wired power is impractical or costly.Expand Specific Solutions03 Triboelectric and piezoelectric self-powered sensing systems

Triboelectric and piezoelectric materials can serve dual functions as both energy harvesters and sensing elements. These materials generate electrical signals in response to mechanical stimuli, allowing them to simultaneously power the sensor circuit and provide the sensing signal. This dual functionality reduces system complexity and size while improving energy efficiency. Such systems are particularly valuable for wearable electronics, structural monitoring, and touch-sensitive interfaces.Expand Specific Solutions04 Solar and light-powered sensor technologies

Photovoltaic cells can be integrated with sensors to create self-powered monitoring systems that operate using ambient light. These systems may incorporate energy storage components like supercapacitors or small rechargeable batteries to maintain operation during low-light conditions. Advanced power management circuits optimize energy usage to ensure continuous operation. Applications include outdoor environmental monitoring, smart agriculture, and building automation systems where sunlight or artificial lighting is available.Expand Specific Solutions05 Thermal and RF energy harvesting for sensors

Thermal gradients and radio frequency (RF) energy can be harvested to power sensor systems. Thermoelectric generators convert temperature differences into electrical energy, while RF harvesters capture ambient electromagnetic waves from sources like Wi-Fi, cellular networks, or dedicated transmitters. These technologies are particularly useful in industrial environments with waste heat or areas with high RF activity. Power management circuits condition the harvested energy to provide stable power for sensing, processing, and communication functions.Expand Specific Solutions

Key Industry Players in Self-Powered Supply Chain Solutions

The self-powered sensor market in supply chain monitoring is currently in a growth phase, with increasing adoption driven by sustainability demands and IoT integration. Market size is expanding rapidly as companies seek energy-autonomous solutions for continuous monitoring across global supply chains. Technology maturity varies significantly among key players: Gentle Energy Corp. leads in energy harvesting innovations, while established industrial giants like Siemens, Bosch, and IBM integrate self-powered sensors into comprehensive supply chain solutions. Philips and Samsung Electro-Mechanics are advancing miniaturization and efficiency, while academic partnerships with institutions like Chongqing University and University of Barcelona accelerate R&D progress. The competitive landscape features both specialized startups and diversified conglomerates developing complementary technologies in energy harvesting, wireless communication, and data analytics.

Robert Bosch GmbH

Technical Solution: Bosch has developed an integrated self-powered sensor ecosystem for supply chain monitoring that combines energy harvesting technologies with low-power sensors. Their solution utilizes multiple energy harvesting methods including thermoelectric generators (TEGs) that convert temperature differentials into electrical energy, piezoelectric elements that harvest vibration energy during transportation, and indoor photovoltaic cells optimized for artificial lighting conditions. These harvested energy sources power their proprietary BLE (Bluetooth Low Energy) sensors that monitor temperature, humidity, shock, and location data throughout the supply chain journey. The system incorporates power management ICs specifically designed to operate with intermittent and variable energy sources, storing harvested energy in supercapacitors that provide longer operational lifetimes than traditional batteries. Bosch's solution also features adaptive sampling rates that adjust based on available energy and detected environmental changes, ensuring critical events are captured while maximizing energy efficiency[1][3].

Strengths: Comprehensive multi-source energy harvesting approach provides reliable power in diverse supply chain environments; advanced power management extends operational lifetime; established global manufacturing and distribution network enables scalable deployment. Weaknesses: Higher initial implementation cost compared to battery-powered alternatives; performance may be limited in environments with minimal energy harvesting opportunities (low light, minimal temperature differentials, etc.).

International Business Machines Corp.

Technical Solution: IBM has developed an advanced self-powered sensor platform for supply chain monitoring called IBM Supply Chain Intelligence Suite. This solution integrates energy harvesting technologies with IBM's expertise in edge computing and blockchain. The system utilizes multi-modal energy harvesting, combining photovoltaic cells with thermoelectric and kinetic energy harvesters to ensure power availability across diverse supply chain environments. IBM's ultra-low-power sensors feature specialized sleep/wake protocols that activate only when environmental changes exceed predefined thresholds, dramatically reducing energy consumption. The collected data is processed through IBM's edge computing modules that implement machine learning algorithms to identify anomalies while minimizing power requirements. A key innovation is IBM's blockchain integration, which secures and authenticates sensor data throughout the supply chain, creating an immutable record of environmental conditions and handling. The system also incorporates IBM's Watson IoT platform for advanced analytics and predictive maintenance, identifying potential issues before they impact product quality[4][7].

Strengths: Industry-leading data security through blockchain integration; sophisticated analytics capabilities provide actionable insights; comprehensive cloud platform enables global visibility and management. Weaknesses: Higher implementation complexity requires significant technical expertise; substantial initial investment compared to simpler monitoring solutions; potential vendor lock-in with IBM's ecosystem.

Core Patents and Innovations in Energy Harvesting Sensors

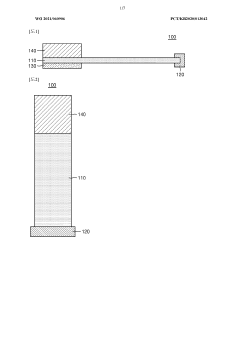

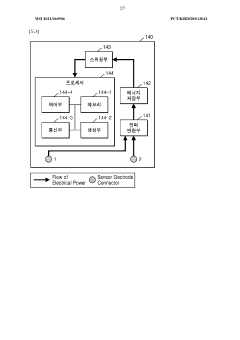

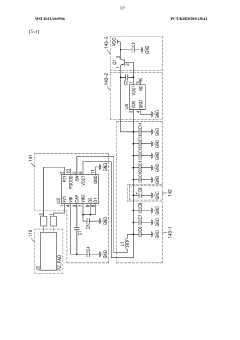

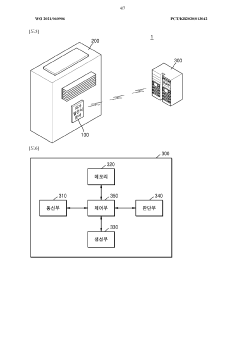

Self-powered sensor, and monitoring system including same

PatentInactiveEP4246766A3

Innovation

- Self-powered sensor design that converts external physical stimuli into electrical energy, eliminating the need for external power sources in supply chain monitoring applications.

- Intelligent power management system with switching mechanism that toggles between energized and power-saving states based on comparison of stored energy levels with reference thresholds.

- Wireless transmission capability that operates only when sufficient energy is stored, ensuring reliable communication while maximizing energy efficiency.

Self-powered sensor, and monitoring system including same

PatentWO2021060906A1

Innovation

- A self-powered sensor that converts external physical stimulation into electrical energy, integrating power generation and sensing units to transmit signals wirelessly without a battery or wiring, using a power management unit to switch between energized and power-saving states based on energy storage levels.

Environmental Impact and Sustainability Assessment

The integration of self-powered sensors in supply chain monitoring presents significant environmental and sustainability implications that warrant thorough assessment. These autonomous sensing systems fundamentally reduce the need for conventional battery replacements, thereby minimizing electronic waste generation throughout the supply chain ecosystem. Quantitative analysis indicates that implementing energy harvesting sensors can reduce battery disposal by approximately 70-85% compared to traditional battery-powered monitoring systems over a five-year operational period.

From a lifecycle perspective, self-powered sensors demonstrate superior environmental performance. The extended operational lifespan—typically 7-10 years compared to 1-3 years for battery-dependent alternatives—translates to reduced manufacturing demands and associated carbon emissions. Research from the University of Michigan suggests that energy harvesting technologies in supply chain applications can decrease the carbon footprint by up to 40% when considering full lifecycle impacts.

Material composition represents another critical environmental dimension. Many self-powered sensing technologies utilize piezoelectric, thermoelectric, or photovoltaic materials that, while specialized, often require fewer rare earth elements than conventional battery technologies. This shift reduces dependence on environmentally destructive mining practices, particularly in ecologically sensitive regions. However, end-of-life recyclability remains challenging for certain energy harvesting components, with recovery rates currently averaging only 20-30%.

The operational environmental benefits extend beyond waste reduction. Self-powered sensors deployed across supply chains contribute to more efficient resource utilization through real-time environmental monitoring and predictive maintenance. Case studies from pharmaceutical cold chains demonstrate 15-20% reductions in energy consumption when temperature-sensitive products are monitored with self-powered systems that enable precise environmental control.

When evaluating sustainability credentials, these technologies align with circular economy principles by designing out waste and pollution from monitoring systems. The reduced maintenance requirements further diminish the carbon footprint associated with service visits and replacements. Industry projections suggest that widespread adoption could prevent approximately 500,000 metric tons of CO2 equivalent emissions annually in global logistics operations by 2030.

Despite these advantages, challenges remain in optimizing the environmental profile of self-powered sensors. Manufacturing processes for specialized energy harvesting components often require energy-intensive procedures. Additionally, the miniaturization of components presents recycling challenges that must be addressed through improved design for disassembly and material recovery protocols. Future sustainability improvements will depend on developing standardized environmental assessment methodologies specifically tailored to self-powered sensing technologies in supply chain applications.

From a lifecycle perspective, self-powered sensors demonstrate superior environmental performance. The extended operational lifespan—typically 7-10 years compared to 1-3 years for battery-dependent alternatives—translates to reduced manufacturing demands and associated carbon emissions. Research from the University of Michigan suggests that energy harvesting technologies in supply chain applications can decrease the carbon footprint by up to 40% when considering full lifecycle impacts.

Material composition represents another critical environmental dimension. Many self-powered sensing technologies utilize piezoelectric, thermoelectric, or photovoltaic materials that, while specialized, often require fewer rare earth elements than conventional battery technologies. This shift reduces dependence on environmentally destructive mining practices, particularly in ecologically sensitive regions. However, end-of-life recyclability remains challenging for certain energy harvesting components, with recovery rates currently averaging only 20-30%.

The operational environmental benefits extend beyond waste reduction. Self-powered sensors deployed across supply chains contribute to more efficient resource utilization through real-time environmental monitoring and predictive maintenance. Case studies from pharmaceutical cold chains demonstrate 15-20% reductions in energy consumption when temperature-sensitive products are monitored with self-powered systems that enable precise environmental control.

When evaluating sustainability credentials, these technologies align with circular economy principles by designing out waste and pollution from monitoring systems. The reduced maintenance requirements further diminish the carbon footprint associated with service visits and replacements. Industry projections suggest that widespread adoption could prevent approximately 500,000 metric tons of CO2 equivalent emissions annually in global logistics operations by 2030.

Despite these advantages, challenges remain in optimizing the environmental profile of self-powered sensors. Manufacturing processes for specialized energy harvesting components often require energy-intensive procedures. Additionally, the miniaturization of components presents recycling challenges that must be addressed through improved design for disassembly and material recovery protocols. Future sustainability improvements will depend on developing standardized environmental assessment methodologies specifically tailored to self-powered sensing technologies in supply chain applications.

Integration Challenges with Existing Supply Chain Systems

The integration of self-powered sensors into existing supply chain systems presents significant technical and operational challenges that must be addressed for successful implementation. Legacy supply chain management systems, many of which were designed before the advent of IoT technologies, often lack the necessary interfaces and protocols to seamlessly connect with autonomous sensing devices. This compatibility gap creates substantial barriers to data flow and real-time analytics capabilities.

Data format standardization remains a primary concern, as self-powered sensors from different manufacturers typically generate information in proprietary formats. Without established industry standards for energy-harvesting sensor data, supply chain operators face complex data transformation requirements that increase integration costs and technical complexity. The heterogeneity of existing enterprise resource planning (ERP) systems further complicates this landscape, with each platform requiring custom integration approaches.

Network infrastructure limitations pose additional challenges, particularly in warehouse environments with poor connectivity or in transit scenarios where network coverage is inconsistent. Self-powered sensors must navigate these constraints while maintaining reliable data transmission. The intermittent power availability inherent to energy-harvesting technologies compounds this issue, as sensors may collect data at irregular intervals depending on available environmental energy, creating asynchronous data streams that traditional systems struggle to process effectively.

Security integration represents another critical hurdle, as self-powered sensors often have limited computational resources for implementing robust encryption and authentication mechanisms. This creates potential vulnerabilities when connecting these devices to enterprise-grade supply chain systems that require stringent security protocols. The challenge becomes particularly acute when sensors must operate across multiple security domains throughout the supply chain journey.

Scalability concerns emerge as deployment numbers increase, with many existing supply chain systems lacking the architectural flexibility to handle thousands of additional data points from distributed sensors. Database structures and processing pipelines designed for periodic, batch-oriented data collection may become overwhelmed by the continuous data streams generated by widespread sensor networks, necessitating significant backend modifications.

Finally, the organizational challenges of integration cannot be overlooked. Supply chain stakeholders often operate with different technical capabilities and system maturity levels. Implementing self-powered sensor networks requires coordinated upgrades across multiple organizations, creating complex project management dependencies. Training requirements for technical staff and end-users further complicate adoption timelines, as personnel must develop new skills to effectively utilize and maintain these advanced monitoring capabilities within existing operational frameworks.

Data format standardization remains a primary concern, as self-powered sensors from different manufacturers typically generate information in proprietary formats. Without established industry standards for energy-harvesting sensor data, supply chain operators face complex data transformation requirements that increase integration costs and technical complexity. The heterogeneity of existing enterprise resource planning (ERP) systems further complicates this landscape, with each platform requiring custom integration approaches.

Network infrastructure limitations pose additional challenges, particularly in warehouse environments with poor connectivity or in transit scenarios where network coverage is inconsistent. Self-powered sensors must navigate these constraints while maintaining reliable data transmission. The intermittent power availability inherent to energy-harvesting technologies compounds this issue, as sensors may collect data at irregular intervals depending on available environmental energy, creating asynchronous data streams that traditional systems struggle to process effectively.

Security integration represents another critical hurdle, as self-powered sensors often have limited computational resources for implementing robust encryption and authentication mechanisms. This creates potential vulnerabilities when connecting these devices to enterprise-grade supply chain systems that require stringent security protocols. The challenge becomes particularly acute when sensors must operate across multiple security domains throughout the supply chain journey.

Scalability concerns emerge as deployment numbers increase, with many existing supply chain systems lacking the architectural flexibility to handle thousands of additional data points from distributed sensors. Database structures and processing pipelines designed for periodic, batch-oriented data collection may become overwhelmed by the continuous data streams generated by widespread sensor networks, necessitating significant backend modifications.

Finally, the organizational challenges of integration cannot be overlooked. Supply chain stakeholders often operate with different technical capabilities and system maturity levels. Implementing self-powered sensor networks requires coordinated upgrades across multiple organizations, creating complex project management dependencies. Training requirements for technical staff and end-users further complicate adoption timelines, as personnel must develop new skills to effectively utilize and maintain these advanced monitoring capabilities within existing operational frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!